SABRE (Synergetic Air-Breathing Rocket Engine)

Launchers and Propulsion

SABRE (Synergetic Air-Breathing Rocket Engine)

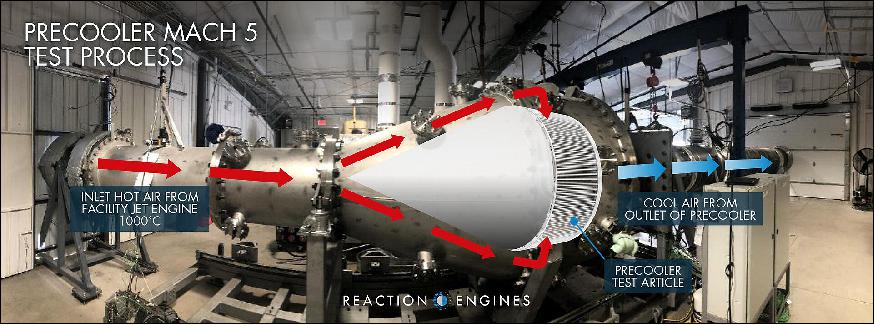

The UK company Reaction Engines has tested its innovative precooler at airflow temperature conditions equivalent to Mach 5, or five times the speed of sound. This achievement marks a significant milestone in its ESA-supported development of the air-breathing SABRE engine, paving the way for a revolution in space access and hypersonic flight. 1)

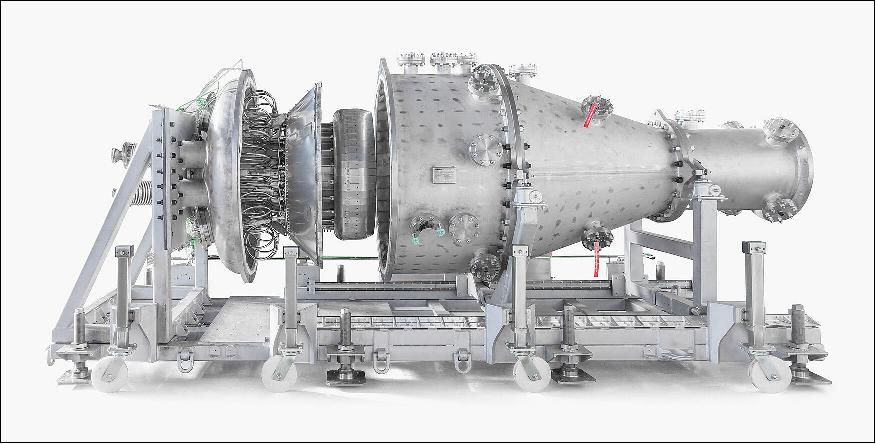

The precooler heat exchanger is an essential SABRE element that cools the hot airstream generated by air entering the engine intake at hypersonic speed.

“This is not only an excellent achievement in its own right but one important step closer to demonstrating the feasibility of the entire SABRE engine concept,” said Mark Ford, heading ESA’s Propulsion Engineering section.

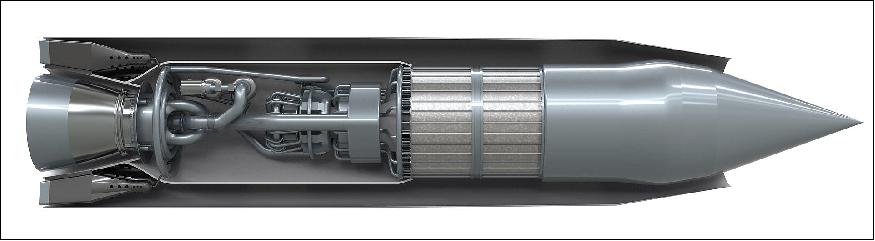

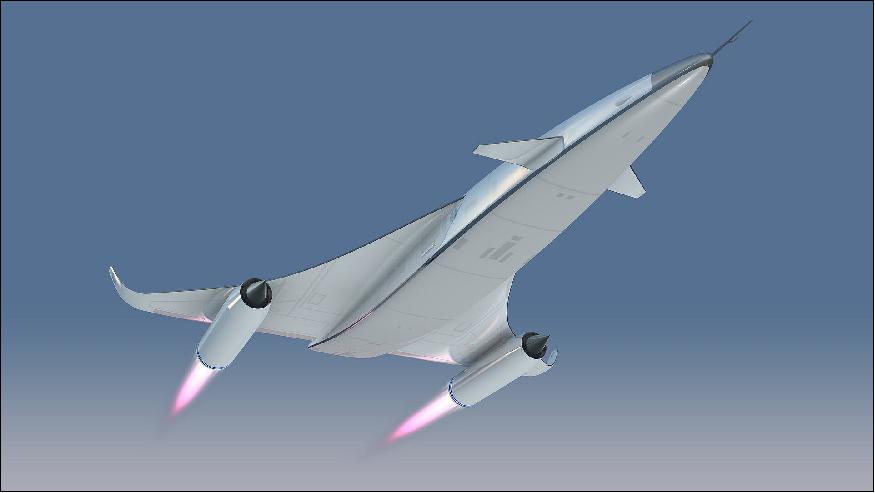

SABRE is uniquely designed to scoop up atmospheric air during the initial part of its ascent to space at up to five times the speed of sound. At about 25 km it would then switch to pure rocket mode for its final climb to orbit.

In the future, SABRE could serve as the basis of a reusable launch vehicle that operates like an aircraft. Because the initial flight to Mach 5 uses the atmospheric air as one propellant it would carry much less heavy liquid oxygen on board. Such a system could deliver the same payload to orbit with a vehicle half the mass of current launchers, potentially offering a large reduction in cost and a higher launch rate.

Reaction Engines constructed the precooler test item in the UK, then shipped it to its specially constructed facility at the Colorado Air and Space Port in the US for its test campaign.

In 2017, the US DARPA (Defense Advanced Research Projects Agency) contracted with Reaction Engines to build a high-temperature airflow test facility at Front Range Airport near Watkins, Colorado. The objective was to test the SABRE engine's precooler heat exchanger (HTX).

This ground-based test achieved the highest temperature objective of the company’s ‘HTX’ hot heat exchanger test program: it successfully quenched airflow temperatures in excess of 1000ºC in less than 1/20th of a second.

The tests demonstrated the precooler’s ability to cool airflow at speeds significantly in excess of the operational limit of any jet-engine powered aircraft in history. Mach 5 is more than twice as fast as the cruising speed of Concorde and over 50% faster than the SR-71 Blackbird aircraft – the world’s fastest jet-engine powered aircraft.

This most recent test builds upon the success of previous HTX hot tests undertaken in April 2019 which saw the precooler successfully operate at temperatures of 420ºC – matching the thermal conditions corresponding to Mach 3.3 flight.

ESA, via the UKSA (UK Space Agency), has invested €10 million in the SABRE development, together with £50 million (€58 million) from UKSA. ESA also performs a technical oversight role on behalf of UKSA. In March, the two agencies reviewed and validated the preliminary design of the demonstrator engine core of SABRE, which Reaction Engines will use to undertake ground-based testing at its under-construction TF1 test facility at Westcott, Buckinghamshire, UK.

Background

Reaction Engines is a UK-based company formed in 1989 by three propulsion engineers from Rolls Royce, Alan Bond, Richard Varvill and John Scott Scott. Their goal was to design and develop the technologies needed for a new class of innovative hypersonic propulsion system – the Synergetic Air-Breathing Rocket Engine (SABRE). 2)

The company achieved a breakthrough in aerospace engine technology by developing ultra-lightweight heat exchangers. Developed for our high speed SABRE engines, the heat exchangers stop engine components from overheating at high flight speeds.

SABRE class engines will enable aircraft to fly over five times the speed of sound in the atmosphere and allow space launch vehicles to be built that will radically improve the affordability and responsiveness of access to space.

Reaction Engines heat exchanger technology has the potential to revolutionize what can be achieved with thermal management across a range of industries, from aerospace to motorsport, industrial processes, and the energy industry.

In addition to the SABRE development program, Reaction Engines offers a unique and extensive range of capabilities, from propulsion systems and advanced heat exchanger design and development, through to advanced manufacturing and precision machining.

Reaction Engines' patented heat exchanger technologies present the opportunity to create a step change of industries, including aerospace, automotive, energy and industrial processes. 3)

Developed for high speed flight, the high performance and lightweight heat exchangers are capable of rapid heat transfer within an exceptionally compact package. The combination of the proprietary design methodology and revolutionary architecture enables class leading performance, while maintaining a competitive price point. the result is an application specific solution focused upon key requirements, allowing for industry-specific optimization.

References

1) ”Air-breathing engine precooler achieves record-breaking Mach 5 performance,” ESA, 23 October 2019, URL: http://www.esa.int/Enabling_Support/Space_Engineering_Technology

/Air-breathing_engine_precooler_achieves_record-breaking_Mach_5_performance

2) ”Unlocking the future of space access and hypersonic flight,” Reaction Engines, URL: https://www.reactionengines.co.uk/about

3) ”The potential to revolutionize multiple industries,” Reaction Engines, URL: https://www.reactionengines.co.uk/technology

The information compiled and edited in this article was provided by Herbert J. Kramer from his documentation of: ”Observation of the Earth and Its Environment: Survey of Missions and Sensors” (Springer Verlag) as well as many other sources after the publication of the 4th edition in 2002. - Comments and corrections to this article are always welcome for further updates (eoportal@symbios.space).