OSAM-1 (On-orbit Servicing, Assembly, and Manufacturing-1)

Non-EO

NASA

Quick facts

Overview

| Mission type | Non-EO |

| Agency | NASA |

OSAM-1 (On-orbit Servicing, Assembly, and Manufacturing-1), formerly Restore-L mission

Spacecraft Development Status Launch Experiment complement References

Up until April 2020, OSAM-1 was called Restore-L (Robotic Servicing Demonstration Mission) to highlight how servicing capabilities can return a satellite to its original capability. With the addition of the SPIDER (Space Infrastructure Dexterous Robot) payload, NASA decided to change the mission's name in order to fully encapsulate the expanded scope of the world's first ever servicing, assembly, and manufacturing mission. 1)

OSAM-1 will be the first of multiple planned missions to bring key OSAM technologies to operational status. This foundational mission will demonstrate various world's firsts from the refueling of a satellite not designed to be serviced, to In-space robotic precision assembly. OSAM-2 (formerly known as Archinaut) will be the second installment in the series of demonstrations.

On May 27, the On-Orbit Servicing, Assembly & Manufacturing mission 1 (OSAM-1), formerly known as Restore-L, successfully passed Key Decision Point-C (KDP-C), an important NASA milestone. 2)

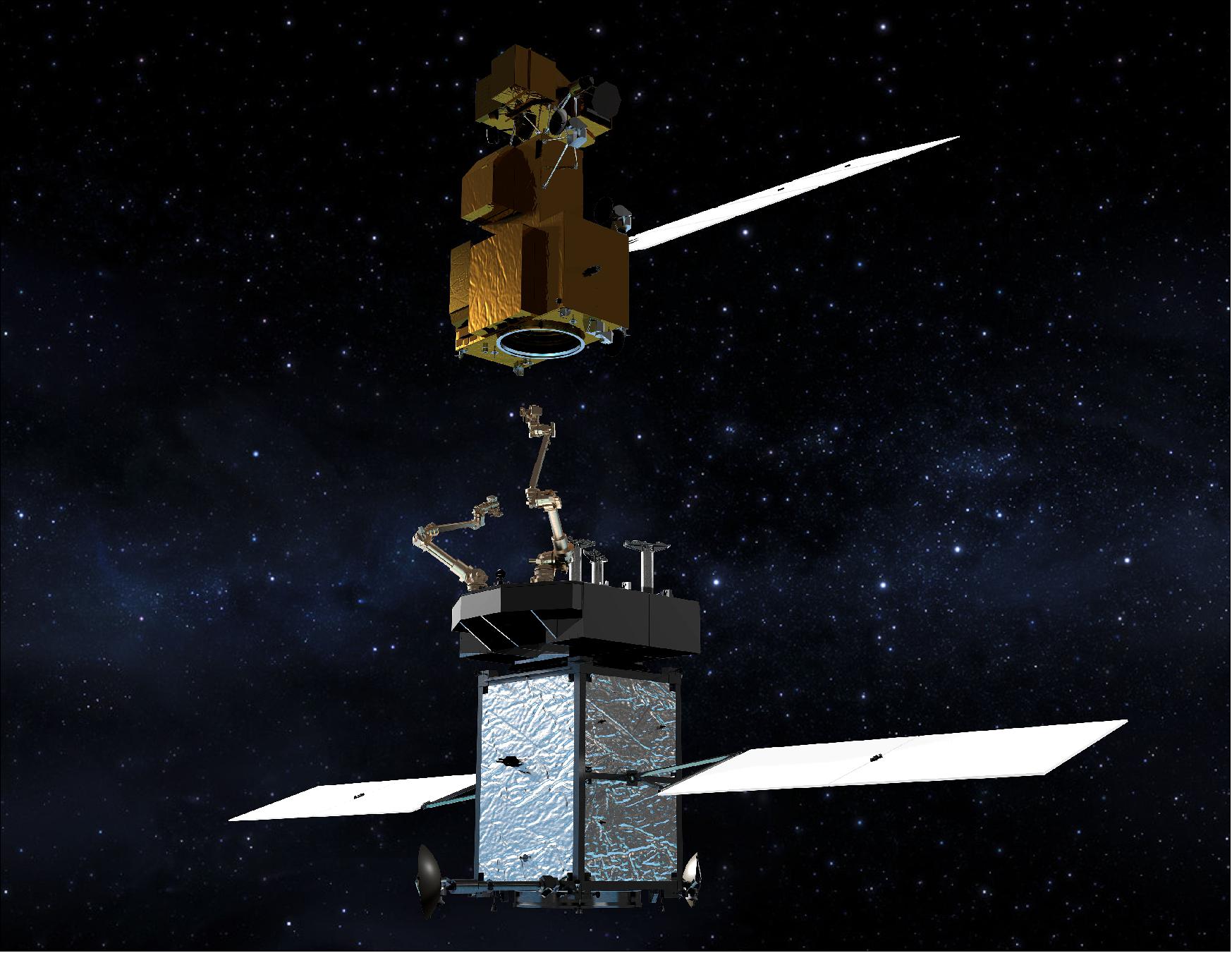

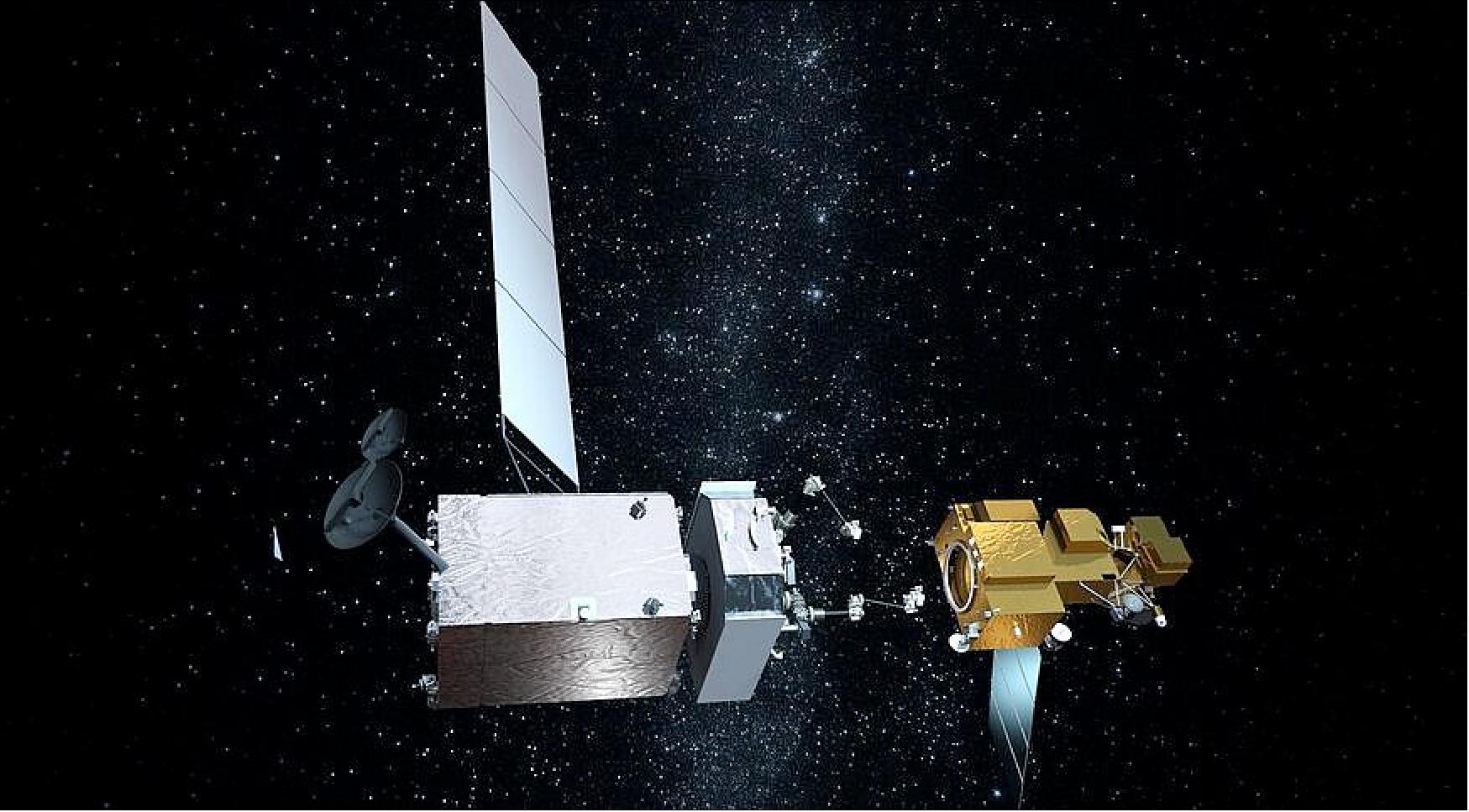

OSAM-1 is NASA's Exploration & In-space Services Projects Division (NExIS)' flagship mission, and is being executed in collaboration with Maxar Technologies. The OSAM-1 space vehicle and its attached SPace Infrastructure DExterous Robot (SPIDER) payload will refuel a satellite in space, assemble a communications antenna, and manufacture a beam. The expanded scope of the mission beyond servicing was the impetus for its name change from Restore-L to OSAM-1. By demonstrating these capabilities, the mission is developing never-before tested technologies for use in future NASA missions.

Servicing Technologies of OSAM-1

1) AutonomousReal-time Relative Navigation System: Sensors, algorithms and a processor join forces, allowing OSAM-1 to rendezvous safely with its client.

2) Servicing Avionics: In addition to ingesting and crunching sensor data, these elements control OSAM-1's rendezvous and robotic tasks.

3) Dexterous Robotc Arms: Two nimble, maneuverable arms precisely execute servicing assignments. Software comes included.

4) Advanced Tool Drive and Tools: Sophisticated, multifunction tools are manufactured to execute each servicing task.

5) Propellant Transfer System: This system delivers measured amounts of fuel to the client at the right temperature, pressure and rate.

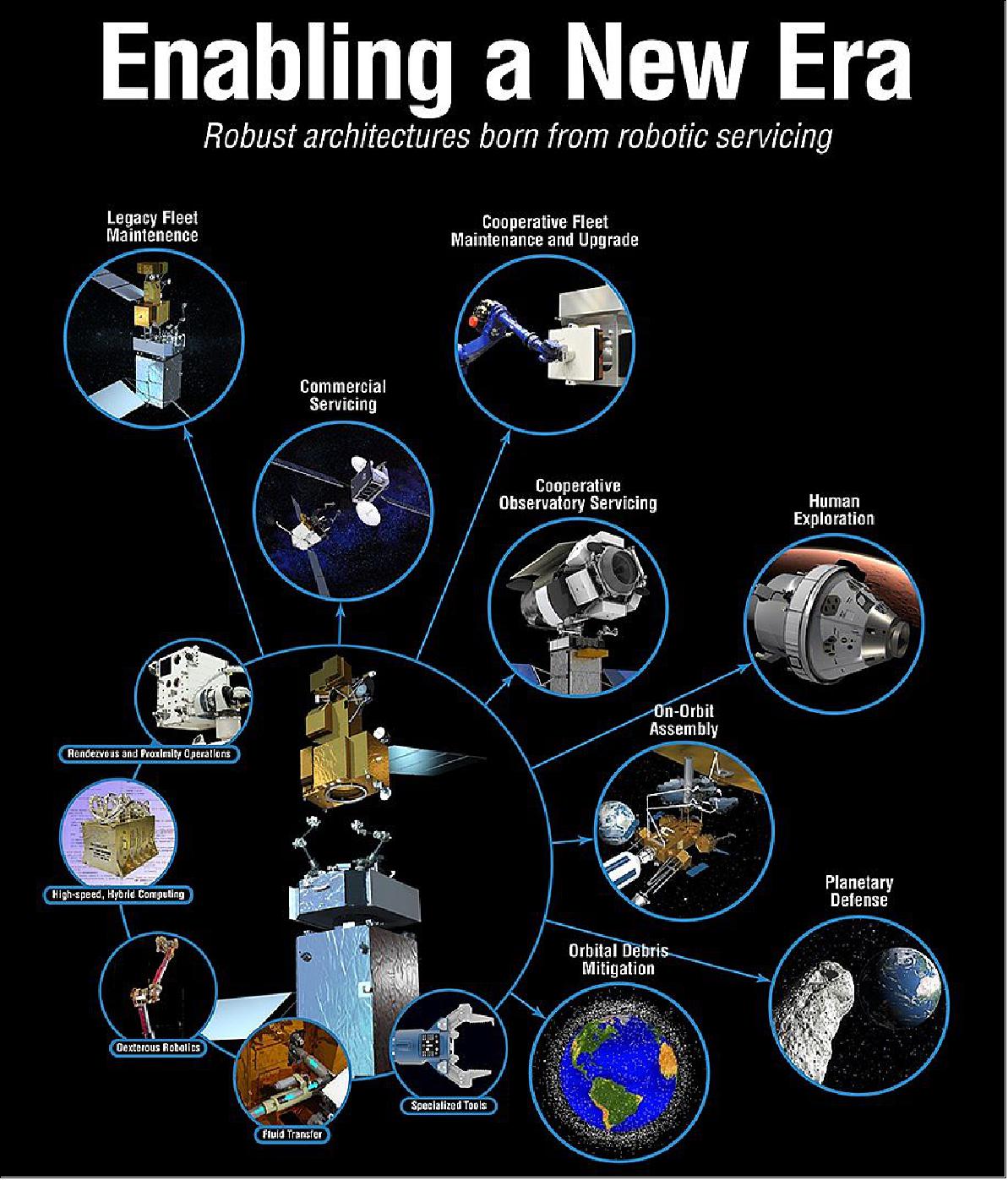

Disruptive technologies often have changed the course of history, breaking the status quo and unlocking possibilities yet to be imagined. Building on a history of upgrading and maintaining assets in space, NASA's new Restore-L project is developing an unprecedented capability crucial to a robust, cost-effective space infrastructure: robotic satellite servicing. 3)

NASA's Restore-L mission is an ambitious, technology-rich endeavor to launch a robotic spacecraft in 2020 to refuel a live satellite. The mission — the first of its kind in LEO (LowEarth Orbit) — will demonstrate a carefully curated suite of satellite-servicing technologies. These on-orbit solutions for autonomous, on-orbit satellite rendezvous and grasping, with telerobotics-enabled refueling and satellite repositioning, could dramatically reduce or eliminate the need for crewed servicing flights from Earth.

The Restore-L mission is led by NASA/GSFC in Greenbelt, Maryland, and funded by NASA's Space Technology Mission Directorate. Restore-L, named to highlight how proper servicing capabilities can return a satellite to its original proficiency, is a robotic spacecraft equipped with the tools, technologies and techniques needed to extend satellites' lifespans — even those not originally designed to be serviced on orbit.

In May 2016, NASA officially moved forward with plans to execute the ambitious, technology-rich Restore-L mission, an endeavor to launch a robotic spacecraft in 2020 to refuel a live satellite. The mission will demonstrate that a carefully curated suite of satellite-servicing technologies are fully operational. The current candidate client for this venture is Landsat-7, a government-owned satellite in LEO. 4) 5) 6)

The Restore-L technologies include an autonomous relative navigation system with supporting avionics, and dexterous robotic arms and software. The suite is completed by a tool drive that supports a collection of sophisticated robotic tools for robotic spacecraft refueling, and a propellant transfer system that delivers measured amounts of fuel at the proper temperature, rate, and pressure.

Future candidate applications for individual Restore-L technologies include on-orbit manufacturing and assembly, propellant depots, observatory servicing, and orbital debris management. NASA is also directly applying several Restore-L technologies to the Asteroid Redirect Mission.

The robotic vehicle of NASA's Asteroid Redirect Mission directly leverages Restore-L's autonomous rendezvous system, avionics, dexterous robotics and software, and tool drive and other systems. This mission, along with the WFIRST (Wide-Field Infrared Survey Telescope) observatory, is being designed to be refuelable.

NASA's second, equally important objective for Restore-L is to infuse its technologies to domestic commercial entities to help jumpstart a new, competitive industry in robotic satellite servicing, an area ripe with possibility.

Background

Of the more than 1,000 operational satellites in space today, only two—the Hubble Telescope and the International Space Station—were designed to be serviced. Despite decades of spacecraft design and development, servicing satellites is a challenging prospect for any spacecraft. Satellites typically travel thousands of miles per hour, are not designed to be serviced and, until now, none of the most in-demand satellite-servicing technologies, like a robotic arm and camera, was available on free-flying spacecraft. 7) 8)

Draper of Cambridge MA, in support of NASA's Restore-L Project and in collaboration with SSL (Space Systems Loral), is addressing this challenge by developing a suite of technologies for servicing government-owned satellites. For the mission Draper is supporting SSL in utilizing a robotic servicing platform equipped with a camera, robotic arm, fuel reserve and capabilities in GN&C rendezvous and proximity operations. NASA awarded the contract to SSL in 2016.

Until now, being able to rendezvous with, grasp, refuel and reposition a satellite hasn't been available to commercial markets. Adding to the frustration, ground controllers have had no way to examine satellites closely once they are launched, open them up for service, or refuel them.

During the proposed flight mission, ground controllers will closely track Restore-L as it marches through its tasks step-by-step, first to autonomously catch the satellite in orbit more than 600 km above Earth, then lock on to it, manipulate its fill and drain valve to gain access to its propellant tank, and refuel the satellite, and do almost all of it by itself.

With robotic servicing, satellite owners can extend the lifespan of satellites that are running low on fuel, reaping additional years of service from their initial investment. If a solar array or a communications antenna fails to deploy, a servicer with inspection cameras and repair tools could help recover the asset that otherwise would have been lost, along with the satellites' anticipated revenue stream.

Spacecraft

A new contract from NASA to build the agency's Restore-L satellite servicing spacecraft could bring SSL (Space Systems Loral) that much closer to launching its own satellite servicing business. NASA awarded the contract to SSL on Dec. 5, 2016 tasking the company with supplying a chassis, hardware and services for the mission. The Palo Alto, California-based satellite builder is responsible for supporting integration, test, launch and operations. 9)

SSL, with parent company MDA (MacDonald Dettwiler and Associates Ltd.) of Richmond, Canada, has been actively entertaining the notion of launching a commercial in-orbit servicing business, one that would combine MDA's past experience from the almost-launched Space Infrastructure Services system in the early 2010s with SSL's knowledge of satellite manufacturing. Steve Oldham, the former president of MDA's Space Infrastructure Services division who currently leads strategic business development at SSL, said the company has interest from prospective customers in using an SSL-built servicer, and that the MDA board of directors expects to make a decision on relaunching such a business through SSL in the very near future.

SSL has been steadily accruing space robotics experience through other government programs with NASA and DARPA (Defense Advanced Research Projects Agency). The Restore-L contract adds to that base, especially given NASA's intentions of transferring technology from the program to commercial entities.

Development Status of the OSAM-1 (former Restore-L) Project

• March 3, 2022: NASA's OSAM-1 (On-orbit Servicing, Assembly, and Manufacturing-1), a mission that will be the first to robotically refuel a satellite not designed to be serviced, and will also demonstrate assembly and manufacturing technologies and capabilities, has passed its mission critical design review (CDR). This is an important milestone that paves the way for the construction of the spacecraft, payloads, and ground system. 10)

- NASA and Maxar Technologies successfully completed the mission CDR in February 2022, less than a year after the same milestone was reached for the mission's spacecraft bus, which focused on the portion of the spacecraft responsible for communications, power, and maneuvering.

- The mission review included all elements that will act together as an integrated system:

a) Spacecraft bus

b) Servicing payload with 16 subsystems including tools, visions systems, and two robotic arms

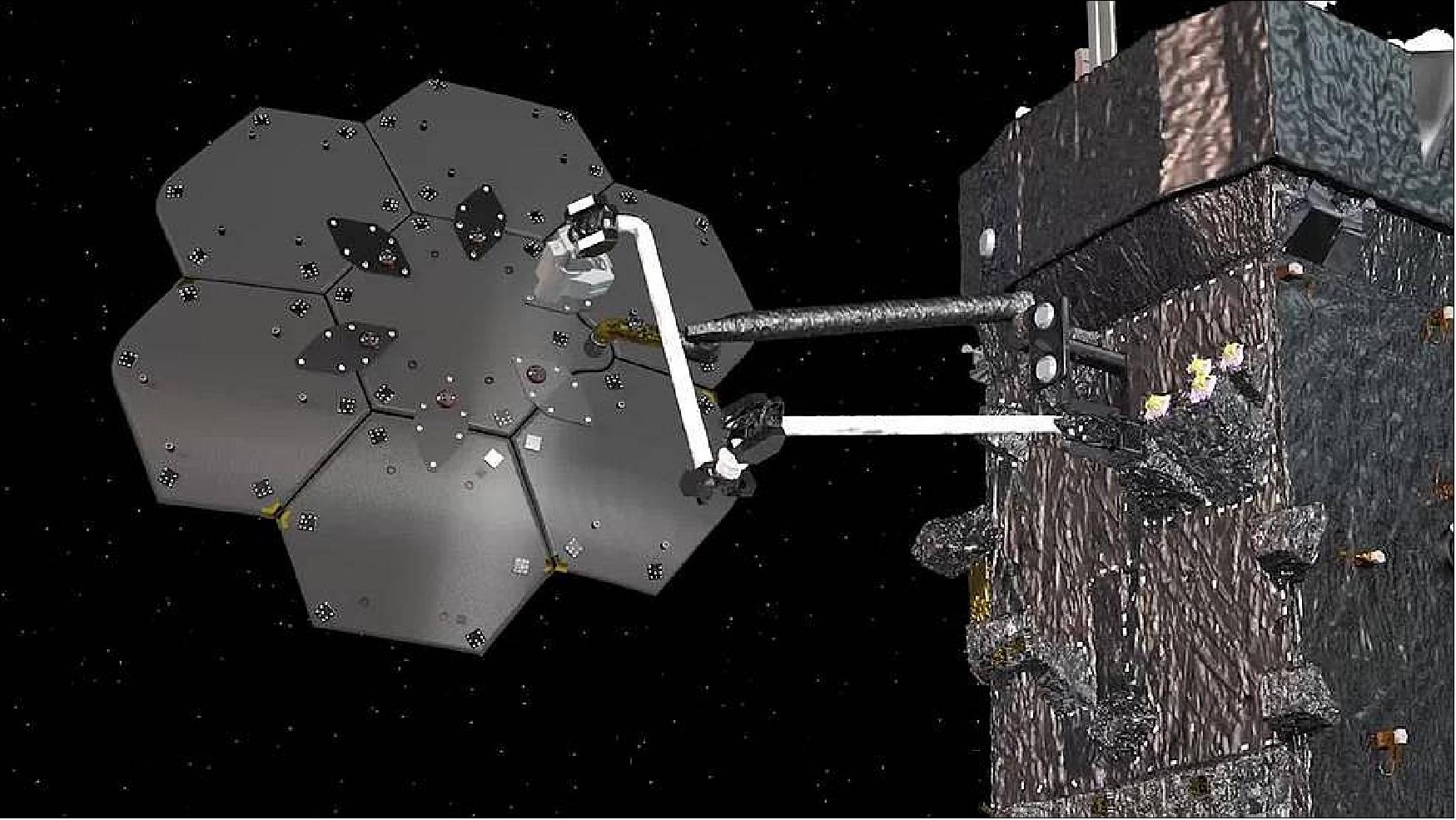

c) Space Infrastructure Dexterous Robot (SPIDER) payload that will manufacture a beam and assemble a communications antenna using a third robotic arm

d) Ground system

- During the review, NASA engineers and leadership confirmed that the OSAM-1 design is complete and meets specified requirements. NASA can now proceed with flight manufacturing, assembly, and integration of the three-armed robotic spacecraft.

- Later this year, Maxar Technologies will deliver the spacecraft bus to NASA's Goddard Space Flight Center in Greenbelt, Maryland, where engineers will complete the integration and testing of all the OSAM-1 components in preparation for launch no earlier than 2025.

- OSAM-1 will use a robotic arm and tools to grapple Landsat 7 and provide the Earth-observing satellite launched in 1999 with more fuel, a first-of-its-kind refueling demonstration by NASA. Following the servicing, the space vehicle's SPIDER payload will demonstrate in-space assembly by constructing a functional communications antenna from stowed parts, as well as in-space manufacturing by producing a spacecraft beam through a process called pultrusion.

- In combination, on-orbit servicing, assembly, and manufacturing technologies and capabilities could help create a more sustainable future for exploration of our solar system and beyond, from servicing spacecraft so that they can journey farther, to constructing and maintaining structures to support a continued human presence in space.

- OSAM-1 is funded by NASA's Space Technology Mission Directorate through its Technology Demonstration Missions program.

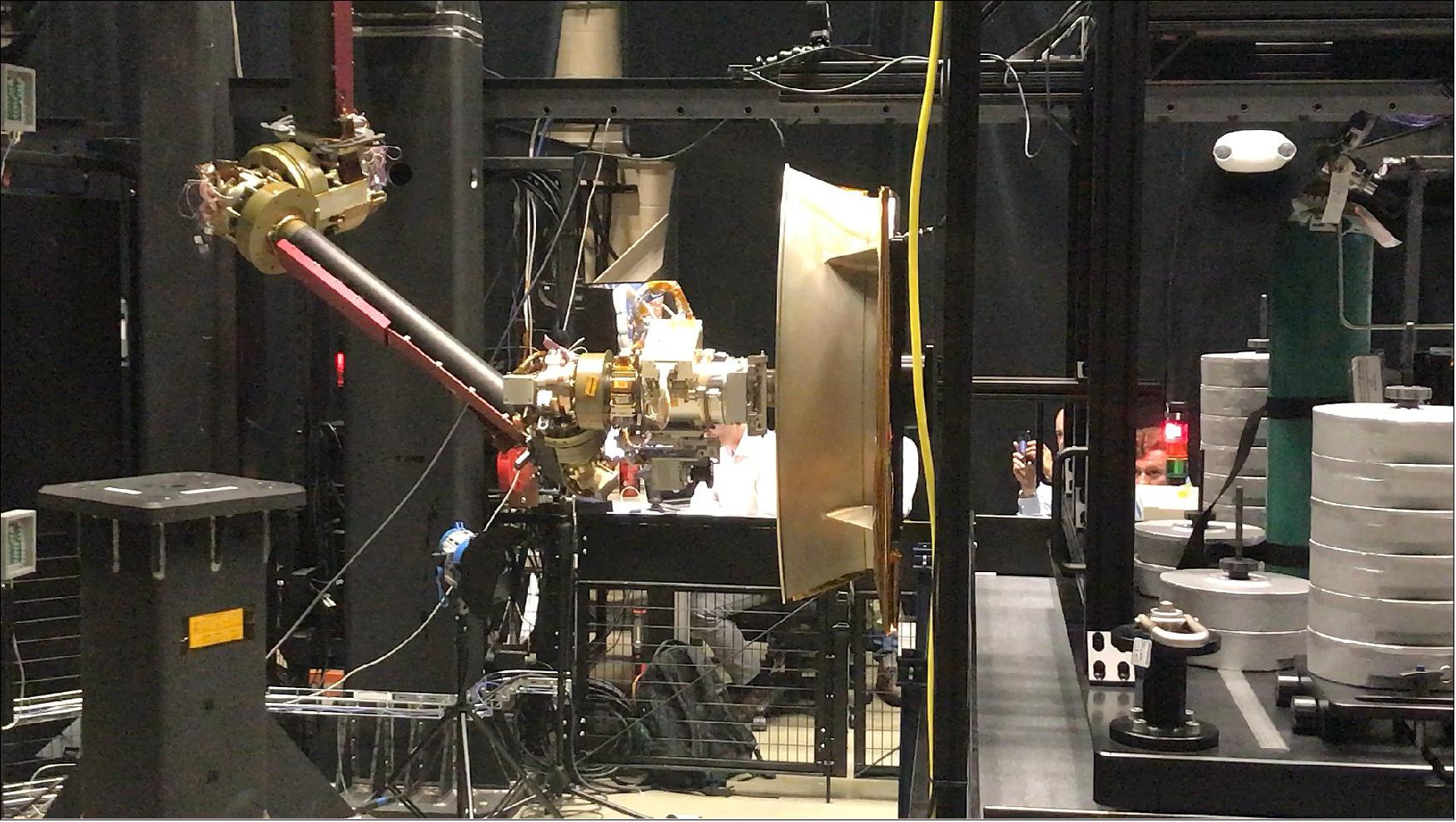

• October 5, 2021: In August 2021, new testing equipment arrived at NASA's Goddard Space Flight Center in Greenbelt, Maryland, in the form of a gravity offset table. NASA engineers will use the table to test robotic satellite servicing technologies that will one day operate in space. 11)

- A gravity offset table is a large piece of granite used for testing space payloads in simulated zero-gravity conditions. Measuring 8 feet by 10 feet and weighing 8.5 tons, the slab is polished precisely then leveled. A sled on top holds the test hardware. Three air bearings under the sled output a thin layer of air from a pressurized source allowing items to "float", which simulates how a payload moves in space.

- "It's basically like an air hockey table in reverse," said Joe Easley, robot operator group lead at NASA's Exploration and In-Space Services Division at NASA Goddard. "For air hockey, a table perforated with jets of air floats a puck. In our system, it's more like the puck, with the mass of a satellite, floats itself."

- To reach true zero-gravity, the table would need to simulate six degrees of freedom or directions in which objects can move. The gravity offset table has three degrees of freedom. It comes very close to zero-gravity – so close that you could push the payload with your finger, and it would glide away from you, just as it would in space.

- NASA Goddard has been using this gravity offset technique for developing satellite servicing technologies since receiving its first gravity offset table in early 2017. It was and continues to be used for testing elements of the On-orbit Servicing, Assembly, and Manufacturing 1 (OSAM-1) mission, which will robotically refuel a satellite in space. This technique helps ensure that our complex simulations are accurate and realistic.

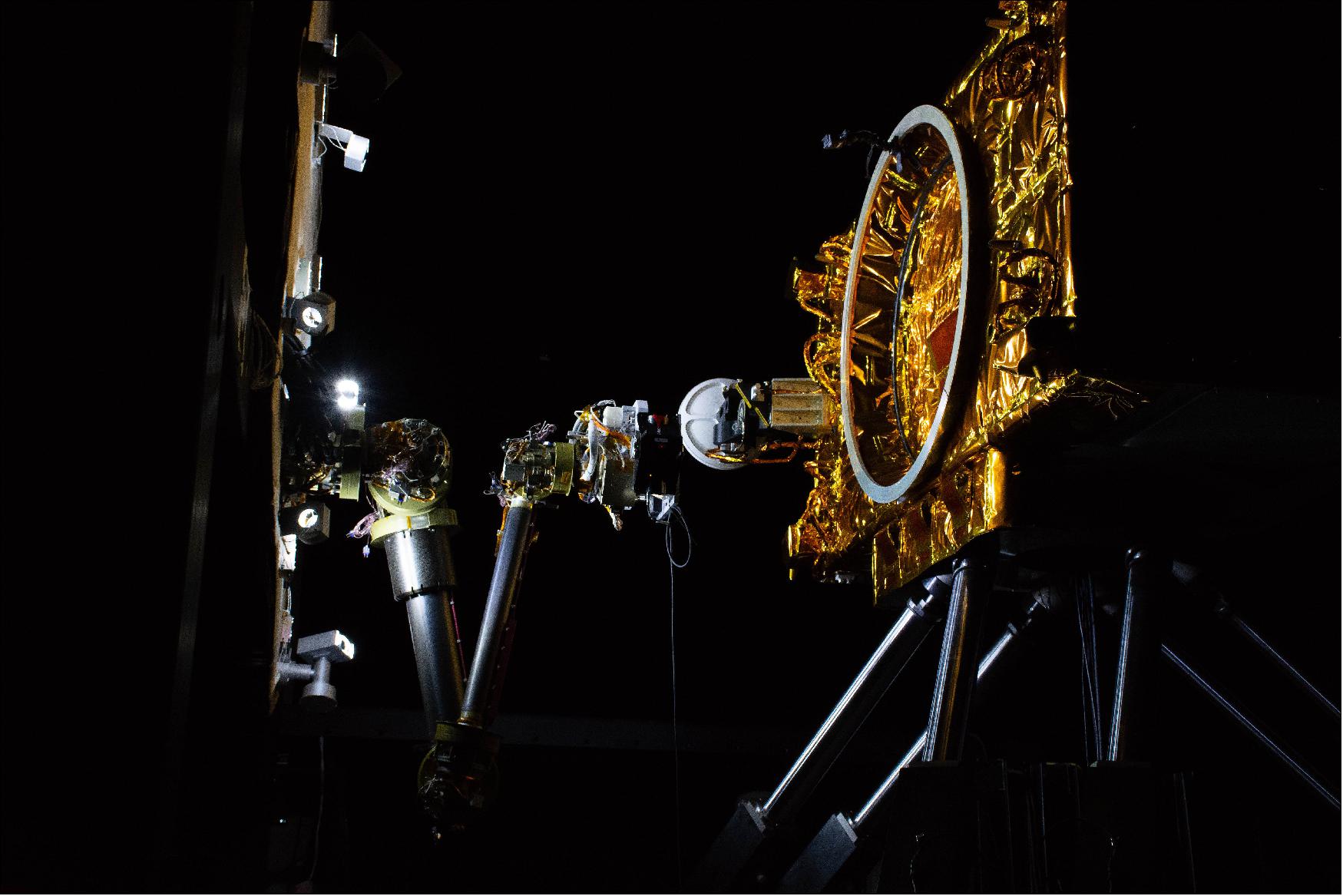

- Simulating a space-like environment is critical to OSAM-1 testing. The technology demonstration mission will utilize a servicing spacecraft with two robotic arms that must match speed with and grapple a client satellite to refuel it. This is no easy feat since the client satellite was not designed to be grappled, and this operation must be fully autonomous. Reach too far and the servicer could push the satellite away; don't reach far enough, and the servicer could miss the satellite. A gravity offset table allows NASA to test how a robot arm would interact with a satellite in space, which is mimicked by the payload on top of the sled.

- "It represents physics pretty well," Easley said. "If I were to push on a satellite in space with my hand, it would probably move a lot like how the gravity offset table would move it here on Earth, with a few more directional constraints on Earth, of course."

- Goddard's two gravity offset tables have essentially the same design and capabilities. The new gravity offset table will allow engineers to test various satellite servicing applications at once. Engineers plan to use the new gravity offset table to test hardware called grapple fixtures that could make satellites easier to grapple and, therefore, service when incorporated in the design.

- "Simulating space-like conditions on Earth with gravity offset tables expands NASA's ability to test groundbreaking technologies and maximize the chance of success in first-of-their-kind missions," Easley said.

- OSAM-1 is managed by NASA Goddard and funded by NASA's Space Technology Mission Directorate through its Technology Demonstration Missions program.

• June 27, 2021: NASA has established a working group to examine what new roles the agency can take to mitigate the growth of orbital debris and promote space sustainability. 12)

- In a talk at the Secure World Foundation's Summit for Space Sustainability June 23, Bhavya Lal, senior adviser to the NASA administrator for budget and finance, said she is leading a recently established team that will examine how the agency could take a larger role in efforts to mitigate and remediate orbital debris.

- "We've assembled an orbital debris review team in-house to evaluate how NASA can be a more effective leader in the area of space sustainability," she said. "Our goal is to examine how NASA could be a better leader in space sustainability."

- NASA's efforts in orbital debris research, she said, have focused primarily on protecting the agency's own missions, from the International Space Station to robotic spacecraft. "We are looking in this review team on things that NASA could be doing beyond what we do in protecting our own assets, being leaders in the broader community," she said.

- Lal didn't elaborate on the team's work beyond that it is an internal NASA effort rather than an interagency one. "We hope to be sharing our thoughts with you in the coming months," she said.

- She described tackling the orbital debris problem with a three-prong approach: reducing the creation of new debris, improving tracking of debris and developing ways to remove debris. That's similar, she argued, to ways of dealing with climate change, with ongoing efforts to reduce emissions, track progress and study ways to sequester greenhouse gases.

- It's also the model outlined in a National Orbital Debris Research and Development Plan, published in January by the White House Office of Science and Technology Policy in the final days of the Trump administration. It identified as three elements of the plan ways to limit the creation of debris, track and characterize debris, and remediate or repurpose debris.

- That report recommended that agencies work together to address the research areas identified in the report but did not make any formal assignments. The report listed NASA as having a role in 13 of 14 research areas, the exception being work to improve processing of data for space object catalogs.

- Lal endorsed that report. "It is important that we begin to implement this plan," she said.

- One potential area of activity would be active debris removal. NASA is already developing technologies for satellite servicing that could also be used to remove debris. That includes the On-orbit Servicing, Assembly, and Manufacturing (OSAM-1) mission, formerly known as Restore-L, currently in development.

- That's attracted the attention of some in Congress. "You read in the paper quite a bit — and it seems like more and more — that space debris is becoming a problem," Sen. Shelley Moore Capito (R-W.V.) said at a June 15 hearing of a Senate appropriations subcommittee on NASA's budget proposal. "With OSAM-1, since you can repair in-space and elongate the life of a satellite, it could help address that issue."

- Asked about NASA's interest in active debris removal technology, Lal said the agency was focused more on early-stage technology development efforts rather than operational systems. An example she mentioned was NASA funding of several studies through the NASA Innovative Advanced Concepts program for very early stage technologies.

- NASA has not, unlike some other space agencies, funded demonstrations of debris removal technology. During another panel discussion at the conference June 22, one expert warned the United States was in danger of falling behind other nations in this field.

- "I do think the U.S. is losing an opportunity" in active debris removal technologies, said Asha Balakrishnan, a research staff member at the Science and Technology Policy Institute. "In order to do it, we need direction, at least in the U.S., on which agency is going to take the lead on doing it and who is going to be funded to do it."

- Removing orbital debris brings with it both technical and policy challenges, but Lal also mentioned the high costs of debris remediation. Pilot projects funded by the European Space Agency and Japan Aerospace Exploration Agency to remove objects have a cost of more than $1 million per kilogram, she noted. Given current estimates of more than 8,000 metric tons — 8 million kilograms — of debris in orbit, "we're talking about trillions of dollars of debris removal," she said.

- "This is a challenge, but, of course, it's also an opportunity," she said. "Space is a big, diverse and innovative sector, and together we can come up with amazing approaches that don't just involve technology but also regulatory, policy and other kinds of innovations."

• May 05, 2021: NASA is one step closer to robotically refueling a satellite and demonstrating in-space assembly and manufacturing thanks to the completion of an important milestone. 13)

- In April 2021, NASA and Maxar Technologies successfully completed the On-orbit Servicing, Assembly, and Manufacturing 1 (OSAM-1) mission spacecraft accommodation Critical Design Review (CDR). This milestone demonstrates that the maturity of the design for the OSAM-1 spacecraft bus is appropriate to support proceeding with fabrication, assembly, integration, and testing.

- OSAM-1 will, for the first time ever, robotically refuel a U.S. government satellite not designed to be serviced. The spacecraft will consist of a servicing payload, provided by NASA's Goddard Space Flight Center in Greenbelt, Maryland, with two robotic arms that will be attached to the spacecraft bus. The bus will also incorporate a payload called Space Infrastructure Dexterous Robot (SPIDER) that will demonstrate in-space assembly and manufacturing. SPIDER will use a third robotic arm to assemble a communications antenna and an element called MakerSat built by Tethers Unlimited to manufacture a beam. The spacecraft bus and SPIDER are being built by Maxar Technologies.

• March 25, 2021: Redwire, a firm that has acquired several space technology companies in the last year, announced March 25 that it will go public by merging with a special-purpose acquisition corporation (SPAC). 14)

- Redwire said it will merge with Genesis Park Acquisition Corp., a SPAC that went public in November 2020. The merger will provide Redwire with $170 million in capital, valuing the company at $615 million. The companies expect the deal to close by the end of the second quarter of this year, at which point Redwire will be publicly traded on the New York Stock Exchange.

- AE Industrial Partners, a private equity firm, created Redwire in June 2020 by combining two space technology companies, Adcole Space and Deep Space Systems, it had acquired. Redwire has since gone on to acquire several more companies, including in-space manufacturing company Made In Space, structures companies LoadPath and Roccor, engineering firm Oakman Aerospace and, most recently, Deployable Space Systems, a developer of spacecraft structures and solar arrays.

- Those acquisitions have turned Redwire into a major supplier for the space industry, fueling its growth. "Many people believe that the next decade of space is a new gold rush. In that context, Redwire is providing the highly specialized picks and shovels required for the space industry," Peter Cannito, chairman and chief executive of Redwire, said in a March 25 call with investors about the deal.

- That business has made Redwire unique among space companies going public through SPACs in that it has both revenues and profits. The company reported $119 million in revenue in 2020, with adjusted earnings before interest, taxes, depreciation, and amortization (EBITDA) of $13 million. The company projects revenue to grow to $163 million in 2021, with adjusted EBITDA of $20 million. By 2025, the company expects to grow to $1.4 billion in revenue with an adjusted EBITDA of $250 million.

- "Redwire has the unique combination of profitability and breakout organic growth, which sets us apart from SPAC peers in space and additive manufacturing," said Jonathan Baliff, president and chief financial officer of Genesis Park Acquisition Corporation, on the call.

- Andrew Rush, president and chief operating officer of Redwire, noted in the call the company has won more than $70 million in new business in recent months, such as a solar sail for a NASA heliophysics mission, a robotic arm for the Vigoride tug being developed by Momentus and avionics for Firefly Aerospace's lunar lander. "These wins underscore the confidence that we have in our financial projections," he said.

- Redwire said in an investor presentation that the cash it raises from the deal will be "dry powder for strategic investments and continued pursuit of Redwire's proprietary M&A [merger and acquisition] pipeline."

- "We also believe there is significant opportunity to accelerate growth through strategic combinations in the fragmented space landscape," Paul Hobby, chief executive of Genesis Park, said in the statement announcing the deal. "Redwire has established itself as a first-mover consolidator and an acquirer of choice, and we believe its position will be further improved as a public company."

- Redwire will also pursue business opportunities in five "strategic focus areas," including on-orbit servicing and assembly, low Earth orbit commercialization, digital engineering of spacecraft, space domain awareness and advanced sensors and components. Those areas leverage capabilities from the companies it has acquired, such as Made In Space for on-orbit assembly and Oakman Aerospace for digital spacecraft engineering.

- "We are well on our way to achieving our five-year projection of $1.4 billion in revenue by 2025 by organic means alone," Cannito said. "For additional upside, this transaction is with the opportunity to significantly enhance this growth by continuing our proven track record of strategic acquisitions as well as accelerated research and development and additional capex."

- Redwire joins a wave of companies in the space sector that have announced plans to go public through SPACs. Those have included in the last six months in-space transportation company Momentus, space communications company AST SpaceMobile, small launch vehicle companies Astra and Rocket Lab, imaging company Black Sky and satellite services company Spire. None of those deals have yet closed, but shareholders in New Providence Acquisition Corp., the SPAC that announced in December an agreement with AST SpaceMobile, are scheduled to vote to approve the merger April 1.

• March 15, 2021: NASA's Goddard Space Flight Center in Greenbelt, Maryland, has chosen three companies to participate in a new partnership to test and evaluate satellite servicing technologies. 15)

Altius Space Machines of Broomfield, Colorado, Honeybee Robotics of Brooklyn, New York, and Orbit Fab of San Francisco will provide cooperative robotic grapple fixtures and data to be studied by NASA's Exploration and In-Space Services projects division (NExIS, formerly known as the Satellite Servicing Projects Division) engineers. The engineers will utilize robotics facilities at Goddard via Space Act Agreements to collect data on the performance of the companies' fixtures.

NASA will document the test results and make the information available to other federal agencies for incorporation in future projects. NASA is planning to begin testing in the spring and summer of 2021 and to release the report by the end of the year.

Goddard also leads NASA's On-orbit Servicing, Assembly, and Manufacturing 1 (OSAM-1) mission of Redwire. In order to refuel another satellite, the spacecraft's robotic arms will have to capture it. Like most other satellites, OSAM-1's client was not designed to be grappled. OSAM-1 will also demonstrate assembly of a communications antenna and manufacturing of a beam with its Space Infrastructure Dexterous Robot (SPIDER) payload, developed by Maxar Technologies.

OSAM-1 is a robotic spacecraft equipped with the tools, technologies and techniques needed to extend satellites' lifespans - even if they were not designed to be serviced on orbit.

During its mission, the OSAM-1 servicer will rendezvous with, grasp, refuel and relocate a government-owned satellite to extend its life. But OSAM-1's effect will not end there.

The benefits are many. OSAM-1's capabilities can give satellite operators new ways to manage their fleets more efficiently, and derive more value from their initial investment. These capabilities could even help mitigate the looming problem of orbital debris.

Successfully completing this mission will demonstrate that servicing technologies are ready for incorporation into other NASA missions, including exploration and science ventures. NASA is also transferring OSAM-1 technologies to commercial entities to help jumpstart a new domestic servicing industry.

• April 8, 2019: Maxar Technologies, a U.S.-based global technology innovator powering the new space economy, today announced that the spacecraft bus it is building for NASA's Restore-L project to refuel a satellite in LEO (Low Earth Orbit) has completed an important review process called the CDR (Critical Design Review). With the CDR complete, the spacecraft bus is on track to ship to NASA in 2020 for integration with the robotic payload and a forecasted launch in 2022. Maxar is also building both nimble robotic arms for the Restore-L spacecraft, which will capture, manipulate and refuel the Landsat-7 satellite. 16)

- As previously announced, Maxar is working with NASA Goddard Space Flight Center's Satellite Servicing Projects Division (SSPD) to build a spacecraft that will rendezvous with, refuel, and safely release the U.S. Geological Survey's Landsat-7 remote sensing satellite in LEO. Restore-L is funded by NASA's Space Technology Mission Directorate. In addition to demonstrating the ability to refuel a satellite that was not designed to be serviced, Restore-L aims to validate the use of tools, technologies and techniques developed to enable future exploration missions and jumpstart a new satellite servicing industry for government and commercial customers.

- The CDR took place over a five-day period at Maxar's Silicon Valley manufacturing facility and demonstrated that the company's spacecraft bus design meets mission requirements. NASA missions undergo multiple rigorous technical and programmatic reviews as they proceed through the phases of development prior to launch. The CDR is the third of six major NASA mission milestones, culminating with the spacecraft's launch.

- The Maxar-built Restore-L spacecraft bus will provide the structural support, propulsion, attitude control, data and communications interface and power to support the Restore-L robotic payload for the on-orbit demonstration. The spacecraft design is based on Maxar's decades-proven 1300-class platform, which has the flexibility and power to enable a broad range of missions and technology advances.

- "The technologies proven on Restore-L are of great value to future exploration and science missions, and will play a crucial role in enabling our exploration of the Moon and beyond," said Mike Edwards, Maxar's Senior Vice President of Strategic Growth. "Satellite servicing is one of many disruptive technologies that Maxar is pioneering to provide our customers with expanded options for more resilient and cost-effective operations in space."

![Figure 13: Restore-L's central structure in Maxar's Silicon Valley manufacturing facility [image credit: Maxar (CNW Group/Maxar Technologies Ltd.)]](https://eoportal.org/ftp/satellite-missions/o/OSAM-1_040322/OSAM-1_Auto1.jpeg)

• October 22, 2018: Orbit Logic reports NASA has selected the company's STK Scheduler software for the Restore-L technology demonstration mission. During its mission, the Restore-L spacecraft will demonstrate the technologies required to rendezvous with, grasp, refuel and relocate a government-owned satellite. 17)

- Restore-L chose an Orbit Logic solution because STK Scheduler's timing and event constraint checking, along with its auto-sequencing features, will provide NASA with an adaptable, invaluable tool to perform Restore-L's highly complex mission timeline and sequencing.

- Given that Restore-L is both complex in its rendezvous and servicing tasks, and is being executed in low-Earth orbit, schedule visibility for radio frequency (RF) communications is critical to mission success.

- Strict rulesets and mission constraints, coupled with RF communications, must be cross-referenced for specific servicing tasks and approach sequences.

- The STK Scheduler supports the configuration and implementation of all Restore-L scheduling constraints out-of-the-box, allowing for quick initial deployment, testing, and use in pre-launch planning, simulations, and on-orbit mission execution at a fraction of the cost of custom software development.

• December 20, 2017: SSL, a business unit of Maxar Technologies (formerly MacDonald, Dettwiler and Associates Ltd.) has announced that the Restore-L mission to provide satellite servicing in LEO has completed an extensive NASA review called the Mission Preliminary Design Review (PDR) and is on track to meet the next development milestone, which is called Key Decision Point C (KDP-C). 18)

• April 10, 2017: SSL (Space Systems Loral (SSL) has successfully completed the SRR (Systems Requirements Review) for the Restore-L project to demonstrate satellite servicing in LEO (Low Earth Orbit). 19)

- As announced on December 9, 2016, SSL is working with NASA/GSFC ( Goddard Space Flight Center) to build a spacecraft that will use robotics to grasp, refuel, and relocate an existing US government satellite already in LEO orbit with the goal of demonstrating tools, technologies, and techniques that can be implemented on future government and commercial missions.

- The SRR, which occurred over a two-day period at the SSL satellite manufacturing facility in Palo Alto, California, enabled the SSL and NASA teams to work together to review and verify the functional and performance requirements defined for the Restore-L spacecraft. The requirements that the teams agreed upon will drive modifications to the SSL 1300 platform, which is commonly used for commercial missions in geostationary orbit. The spacecraft will provide the structural support, propulsion, attitude control, data and communications interface, and power to support the Restore-L robotic payload for the on-orbit demonstration.

Launch

A launch of the OSMA-1 mission (former Restore-L) is scheduled for 2025, using a commercial satellite bus provided by Maxar. OSAM-1 will rendezvous with the Landsat-7 spacecraft and refuel it, and then conduct a series of demonstrations of in-space robotic assembly of an antenna and a boom. 20)

Experiment Complement (Kodiak, SPIDER)

Kodiak

One test changed the fortunes of an advanced 3-D imaging lidar system now baselined for NASA's Restore-L project that will demonstrate an autonomous satellite-servicing capability. 21) 22)

Officials with NASA's Satellite Servicing Projects Division, have officially baselined the Kodiak system — formerly known as the GRSSLi (Goddard Reconfigurable Solid-state Scanning Lidar) — to provide real-time images and distance-ranging information during Restore-L. This project will demonstrate how a specially equipped robotic servicer spacecraft can extend a satellite's lifespan — even one not originally designed for on-orbit servicing.

During the demonstration, the Restore-L servicer will use its relative navigation technologies — of which the Kodiak system now is a part — to essentially drive itself to its destination, much like a self-driving car here on terra firma. Once it locates Landsat-7, it will use its dexterous robotic arms and software to autonomously grasp, refuel, and relocate Landsat-7. Launched in 1999, this Earth-observing satellite was not designed for servicing or on-orbit repairs.

Principal Investigator Nat Gill, who, along with other technologists, began developing the Kodak advanced scanning lidar system five years ago in part with Goddard Internal Research and Development program funding. Less than a year ago, only a portion of Kodiak was being considered for use, primarily as a back-up to another system, Gill said.

This partial capability would have provided ranging measurements to guide the Restore-L robotic servicer as it approached the satellite from 1.5 miles down to five feet. To carry out this orbital dance, the system would have flashed its low-power laser light at Landsat-7 every 25 microseconds. Its onboard telescopes and detectors would have collected the returning light as it bounced off the satellite and another Goddard-developed technology — a hybrid computing platform called SpaceCube 2.0 — then would have calculated the light's time of flight to determine distance.

Real-Time Imaging Added: Restore-L will use a second piece of the Kodiak system: its ability to provide real-time, high-resolution images as the robotic servicer approaches the target, which, itself, is moving at thousands of miles per hour.

This capability includes a micro-electro-mechanical scanner and a photodetector. With these components, the system "paints" a scene with the scanning laser and its detector senses the reflected light to create a 3D image, with millimeter-level resolution, over a range of distances, from meters to kilometers.

A Test Made the Difference: A test changed Kodiak's fortunes, Gill explained. During a demonstration involving the imaging portion of Kodiak and a mockup of Landsat-7, Gill and his team showed that the system's 3D imaging capabilities, coupled with specially developed algorithms, "could do the job the Restore-L project requires," Gill said. "Now, we have the whole job for Restore-L, including the 3-D imaging."

As a result, mission controllers will be able to see Landsat-7 in high resolution as the robotic servicer approaches as well as automatically determine its location and relative orientation with one small, lightweight system, Gill said. "Because of our team's work ethic, technical skill, and belief in a crazy idea, we've succeeded in raising the cutting edge of spaceflight technology."

SPIDER (Space Infrastructure Dexterous Robot)

NASA has awarded a $142 million contract to Maxar Technologies of Westminster, Colorado, to robotically assemble a communications antenna and manufacture a spacecraft beam in orbit. The technology demonstration is slated to take place on NASA's former Restore-L spacecraft (now OSAM-1), designed to service and refuel a satellite in low-Earth orbit. 23)

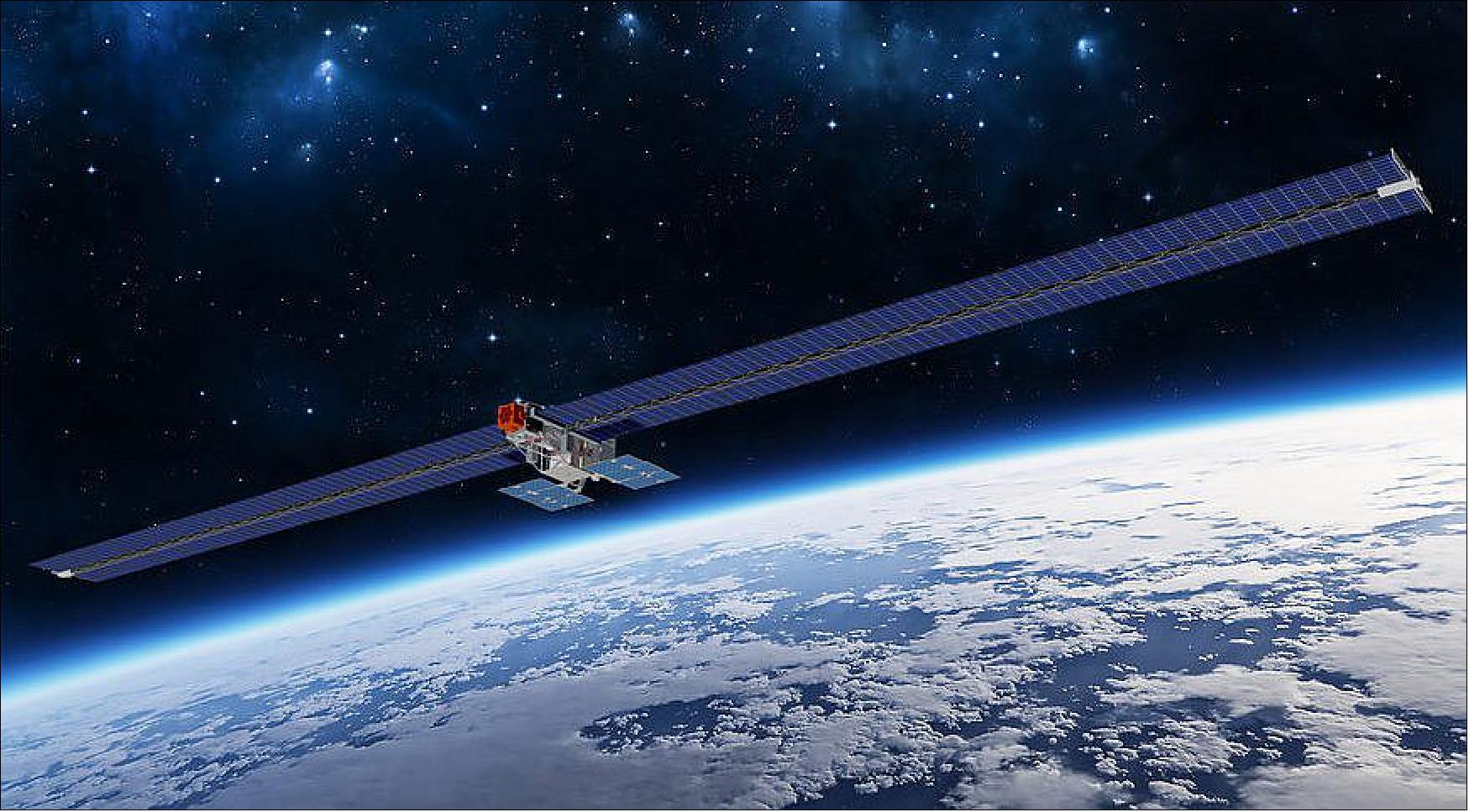

The OSAM-1 (Restore-L) spacecraft will be modified to accommodate a payload called Space Infrastructure Dexterous Robot (SPIDER). The payload includes a lightweight 16-foot (5-meter) robotic arm. Previously known as Dragonfly during the ground demonstration phase of the NASA Tipping Point partnership, SPIDER will assemble seven elements to form a functional 9-foot (3-meter) communications antenna. The robotically assembled antenna will demonstrate Ka-band transmission with a ground station.

The payload also will manufacture a 32-foot (10 m) lightweight composite beam using technology developed by Tethers Unlimited of Bothell, Washington. The manufacturing element of the demonstration will verify the capability to construct large spacecraft structures in orbit.

Maxar, in partnership with NASA and the West Virginia Robotic Technology Center, is developing advanced robotic arms that will semi-automatically assemble and reconfigure spacecraft components while on orbit. This revolutionary process allows satellites, telescopes and other systems to use larger and more powerful components that might not fit into a standard rocket fairing when fully assembled. 24)

References

1) "NExIS (NASA's Exploration In-space Services)," NASA, URL: https://nexis.gsfc.nasa.gov/OSAM-1.html

2) "Mission Update: OSAM-1 Successfully Passes Key Decision Point-C," NASA NExIS, 29 May 2020, URL: https://nexis.gsfc.nasa.gov/05292020_osam1_update.html

3) Benjamin B. Reed, "STMD: Tech Demo Missions — Restore-L," NASA, URL: https://www.nasa.gov/mission_pages/tdm/restore-l/index.html

4) Adrienne Alessandro, "Restore-L Mission to Demonstrate Technology by Refueling Landsat-7," NASA, June 23, 2016, URL: http://landsat.gsfc.nasa.gov/nasas-restore-l-mission-to-demonstrate-crosscutting-technologies-by-refueling-landsat-7/

5) "Restore-L Robotic Servicing Mission," NASA, URL: https://sspd.gsfc.nasa.gov/restore-l.html

6) Bringing Restore-L to Life," NASARestore-L factsheet, URL: https://www.nasa.gov/sites/default/files/atoms/files/restore_l_factsheet_062816_01.pdf

7) "Draper Heads to Space to Make Service Calls to Satellites, Company builds on space heritage in partnership with SSL" Draper, Feb. 17, 2017, URL: http://www.draper.com/news/draper-heads-space-make-service-calls-satellites

8) "Restore-L Mission Information," NASA, URL: https://www.nasa.gov/sites/default/files/atoms/files/restore-l-info_nnh15heomd001_r7.pdf

9) Caleb Henry, "NASA's Restore-L contract nudges SSL closer to in-orbit servicing ," Space News, Dec. 6, 2016, URL: http://spacenews.com/nasas-restore-l-contract-nudges-ssl-closer-to-in-orbit-servicing/

10) "NASA's Robotic OSAM-1 Mission Completes its Critical Design Review," NASA Feature, 3 March 2022, URL: https://www.nasa.gov/feature/goddard/2022/nasa-s-robotic-osam-1-mission-completes-its-critical-design-review

11) Bryana Quintana, "Simulating Space on Earth: NASA Receives Hardware for Testing Satellite Servicing Tech," NASA Feature, 05 October 2021, URL: https://www.nasa.gov/feature/goddard/2021/simulating-space-on-earth-nasa-receives-hardware-for-testing-satellite-servicing-tech

12) Jeff Foust, "NASA team to study new roles for the agency in addressing orbital debris," SpaceNews, 27 June 2021, URL: https://spacenews.com/nasa-team-to-study-new-roles-for-the-agency-in-addressing-orbital-debris/

13) "NASA's On-orbit Servicing, Assembly, and Manufacturing 1 Mission Ready for Spacecraft Build," NASA, 5 May 2021, URL: https://www.nasa.gov/image-feature/goddard/2021/nasa-s-on-orbit-servicing-assembly-and-manufacturing-1-mission-ready-for-spacecraft

14) Jeff Foust, "Redwire to go public through a SPAC merger," SpaceNews, 25 March 2021, URL: https://spacenews.com/redwire-to-go-public-through-a-spac-merger/

15) "NASA Partners with Companies to Test Satellite Fixtures for Robotic Grappling," NASA Feature, 15 March 2021, URL: https://www.nasa.gov/feature/goddard/2021/nasa-partners-to-test-satellite-fixtures-for-robotic-grappling

16) "Innovative spacecraft on track to make history as first-ever to refuel satellite in Low Earth Orbit," PR Newswire, 8 April 2019, URL: https://www.prnewswire.com/news-releases/maxar-and-nasa-successfully-complete-design-review-for-restore-l-on-orbit-servicing-spacecraft-bus-300825835.html

17) "Orbit Logic's scheduling software selected for NASA satellite servicing mission," Space Daily, 22 October 2018, URL: http://www.spacedaily.com/reports/Orbit_Logics_Scheduling_Software_Selected_for_NASA_Satellite_Servicing_Technology_Demonstration_Mission_999.html

18) "Restore-L On-Orbit Servicing Mission Enabled by SSL-Built Spacecraft Passes Critical NASA Design Review," SSL, 20 Dec. 2017, URL: https://sslmda.com/html/pressreleases/2017-12-20-Restore-L-On-Orbit-Servicing-Mission-Enabled-by-SSL-Built-Spacecraft-Passes-Critical-NASA-Design-Review.php

19) "SSL's Serious Satellite Servicing Demo Success for the Restore-L Project," Satnews Daily, April 10, 2017, URL: http://www.satnews.com/story.php?number=869458979

20) Jeff Foust, "New initiative to promote satellite servicing and in-space assembly technologies," SpaceNews, 3 Novemver 2020, URL: https://spacenews.com/new-initiative-to-promote-satellite-servicing-and-in-space-assembly-technologies/

21) "The Self-Driving Servicer, Full-Up Kodiak System Now Baselined for NASA's Restore-L Satellite-Servicing Demonstration" Cutting edge, Volume 14, Issue 2, Winter 2018, pp: 14-15, URL: https://www.nasa.gov/sites/default/files/atoms/files/winter_2018_final_lowrez.pdf

22) Lori Keesey, "Self-Driving Servicer Now Baselined for NASA's Restore-L Satellite-Servicing Demonstration," NASA Technology, 13 Feb. 2018, URL: https://www.nasa.gov/feature/goddard/2018/self-driving-servicer-now-baselined-for-nasa-s-restore-l-satellite-servicing-demonstration

23) "NASA Funds Demonstration of Assembly and Manufacturing in Space," NASA Press Release 20-009, 31 January 2020, URL: https://www.nasa.gov/press-release/nasa-funds-demonstration-of-assembly-and-manufacturing-in-space

24) "NASA and Maxar's Space Infrastructure Dexterous Robot (SPIDER) program for on-orbit satellite assembly and servicing," Maxar, URL: https://is.gd/3LUEf2

The information compiled and edited in this article was provided by Herbert J. Kramer from his documentation of: "Observation of the Earth and Its Environment: Survey of Missions and Sensors" (Springer Verlag) as well as many other sources after the publication of the 4th edition in 2002. - Comments and corrections to this article are always welcome for further updates (herb.kramer@gmx.net).

Spacecraft Development Status Launch Experiment complement References Back to top