MetOp-SG (MetOp-Second Generation Program)

EO

ESA

Atmosphere

Ocean

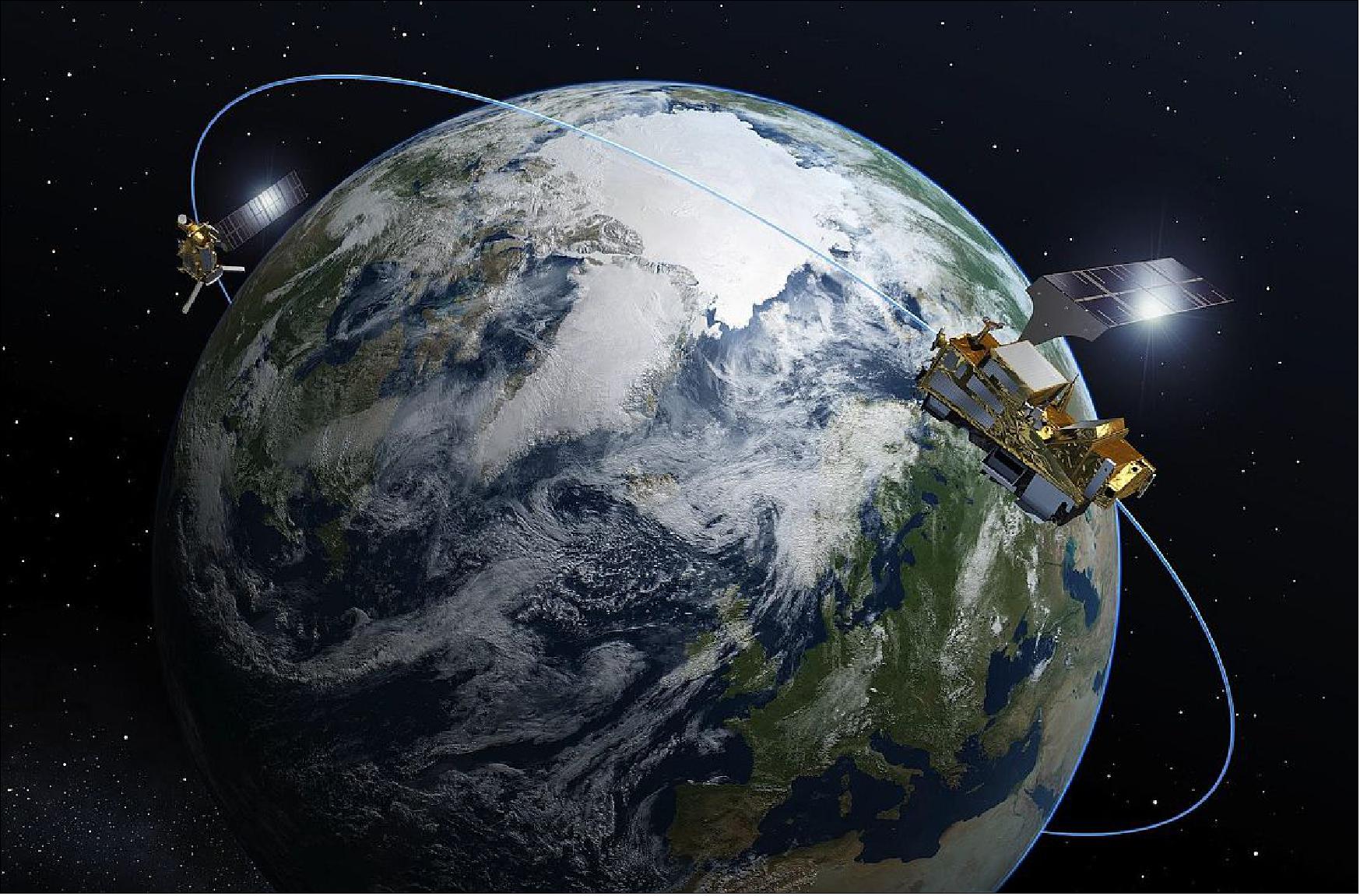

MetOp-SG (Meteorological Operational satellite- Second Generation) is a series of 6 meteorological satellites, which will act as the successor to the MetOp series. The mission is developed by ESA (European Space Agency) and EUMETSAT (European Organisation for the Exploitation of Meteorological Satellites), and divided into two different series, MetOp-SG-A and -B, with complementary sensor payloads that will orbit in pairs.

Quick facts

Overview

| Mission type | EO |

| Agency | ESA, CNES, DLR, EUMETSAT, COM |

| Mission status | Approved |

| Measurement domain | Atmosphere, Ocean, Land, Snow & Ice |

| Measurement category | Cloud type, amount and cloud top temperature, Liquid water and precipitation rate, Atmospheric Temperature Fields, Cloud particle properties and profile, Aerosols, Radiation budget, Multi-purpose imagery (land), Surface temperature (land), Vegetation, Albedo and reflectance, Surface temperature (ocean), Atmospheric Humidity Fields, Ozone, Trace gases (excluding ozone), Sea ice cover, edge and thickness, Soil moisture, Snow cover, edge and depth, Ocean surface winds, Atmospheric Winds |

| Measurement detailed | Cloud top height, Precipitation Profile (liquid or solid), Cloud cover, Cloud optical depth, Precipitation intensity at the surface (liquid or solid), Aerosol optical depth (column/profile), Cloud ice (column/profile), Cloud imagery, Cloud liquid water (column/profile), Land surface imagery, Cloud drop effective radius, Cloud ice effective radius (column/profile), Fire fractional cover, Earth surface albedo, Atmospheric specific humidity (column/profile), O3 Mole Fraction, Atmospheric temperature (column/profile), Land surface temperature, Sea surface temperature, CH4 Mole Fraction, HNO3 (column/profile), Wind vector over sea surface (horizontal), NO2 Mole Fraction, Sea-ice cover, Snow cover, Soil moisture at the surface, Wind speed over sea surface (horizontal), Cloud top temperature, Normalized Differential Vegetation Index (NDVI), BrO (column/profile), Wind profile (horizontal), Atmospheric stability index, Volcanic ash, Fraction of Absorbed PAR (FAPAR), CO2 Mole Fraction, OClO (column/profile), CO Mole Fraction, Sea-ice type, SO2 Mole Fraction, Wind profile (vertical), Downward short-wave irradiance at Earth surface, Sea-ice surface temperature, Cloud mask, Sea-ice Concentration, Aerosol Layer Height, HCHO Mole Fraction, Water vapour imagery, CHOCHO (column/profile), Cloud top pressure, Upwelling (Outgoing) spectral radiance at TOA, SO2 Total Column, Sea-ice motion |

| Instruments | A-DCS4, SCA, METimage, MWS, IASI-NG, RO, ICI, MWI, 3MI, UVNS (Sentinel-5) |

| Instrument type | Imaging multi-spectral radiometers (vis/IR), Scatterometers, Atmospheric chemistry, Imaging multi-spectral radiometers (passive microwave), Data collection, Atmospheric temperature and humidity sounders |

| CEOS EO Handbook | See MetOp-SG (MetOp-Second Generation Program) summary |

Summary

Mission Capabilities

The MetOp-SG series contains 9 sensor instruments in all, these being: METImage (Meteorological Imager), IASI-NG (Infrared Atmospheric Sounding Interferometer–New Generation), MWS (Microwave Sounder), SCA (Scatterometer), RO (Radio Occultation sounder), UVNS/S5 (Ultraviolet /Visible/Near Infrared/Shortwave Infrared spectrometer -Sentinel-5), MWI (Microwave Imager), ICI (Ice and Cloud Imager) and 3MI (Multi-viewing, Multi-channel, Multi-polarization Imager). The MetOp-SG-A series satellites will carry the 3MI, IASI-NG, MWS, METImage, RO, and UVNS/S5 instruments, while MetOp-SG-B series craft will carry the ICI, MWI, RO and SCA instruments.

The instruments utilised by the MetOp-SG series cover applications of aerosol and cloud microphysical observations (METImage, 3MI), temperature/humidity sounding (IASI-NG, MWS, RO), ozone column and total profile observations (IASI-NG), wind speed and vector observations (SCA), cloud ice observations (ICI), atmospheric density observations (RO) and supplementary climate and atmospheric imaging (MWI), as well as atmospheric chemistry observations (UVNS/S5).

Performance Specifications

Across all instruments, MetOp-SG has spatial resolutions of 0.5km (METImage) to 25km (SCA). It has swath widths of 2715km (UVNS/S5)- 500km (RO). The MetOp-SG satellites will be in a sun-synchronous orbit with a planned mean altitude of approximately 835km and a planned LTDN (Local Time at Descending Node) at 0930 hours.

Space and Hardware Components

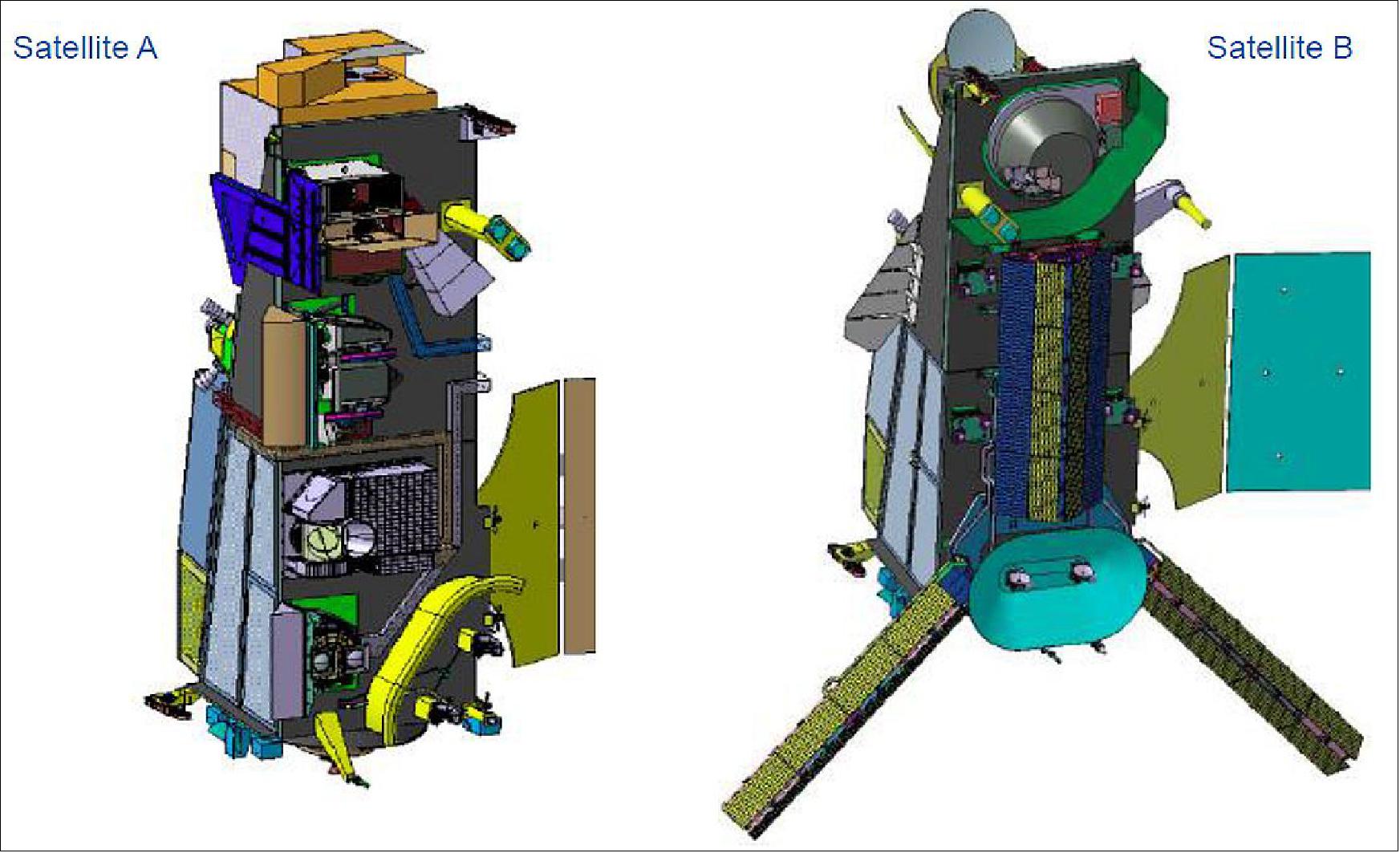

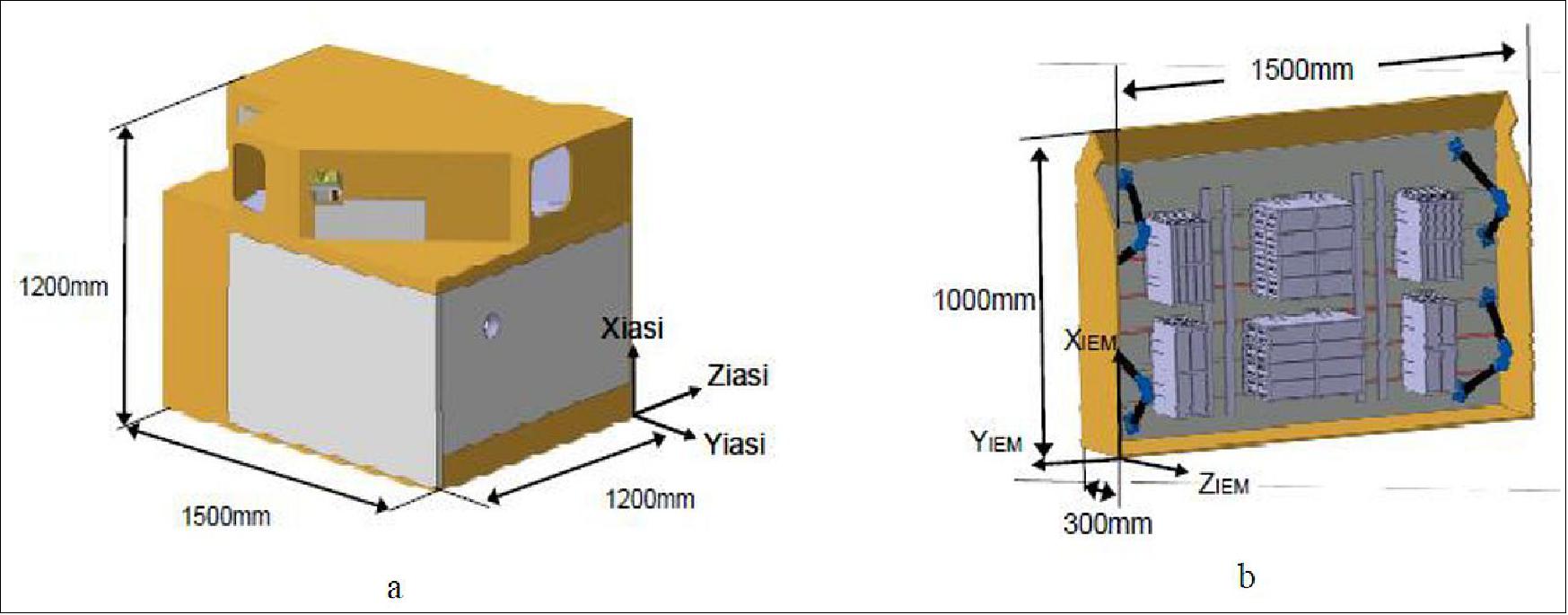

The MetOp-SG program utilises a two-satellite architecture of craft equipped with different but complementary sensors, operating within an identical sun-synchronous orbit. The two series of MetOp-SG satellites will use slightly different buses, designed and manufactured by Airbus Defence and Space, with dimensions of 6.5 m x 2.97 m x 3.46 m for the A series satellites, and 6.1 m x 2.91 m x 3.43 m for B series units. The MetOp-SG-B satellites are all equipped with an ADCS (Advanced Data Collection System) module, which collects and transmits observations and data from collection platforms.

MetOp-SG (MetOp-Second Generation Program)

Spacecraft Development Status Launch Sensor Complement References

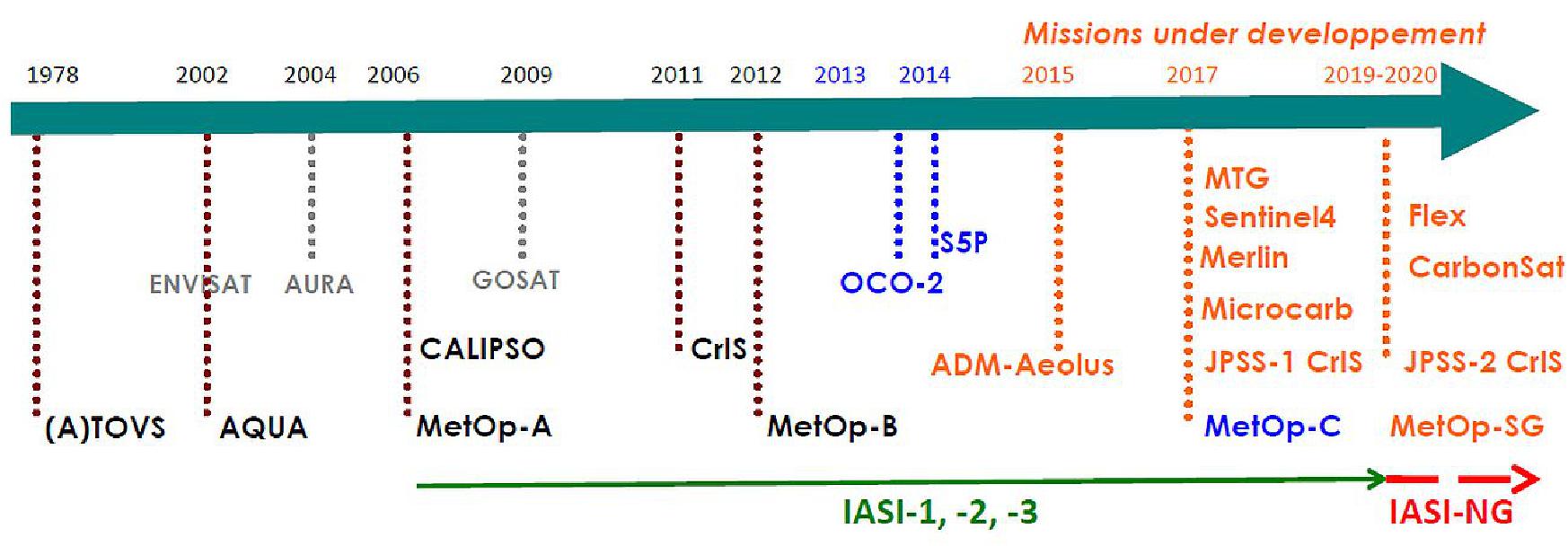

The current MetOp series of EUMETSAT has three identical satellites. Launched in 2006, MetOp-A is Europe's first polar-orbiting mission dedicated to operational meteorology, and will be followed by MetOp-B in 2012 and MetOp-C in 2016. - These first three MetOp satellites guarantee the continuous delivery of high-quality data for medium- and long-term weather forecasting and for climate monitoring until at least 2020.

The EPS-SG (EUMETSAT Polar System-Second Generation) Phase System baseline has been agreed by Council in June 2010 and is based on a Two-Satellite In-orbit Configuration. 1)

In 2011, ESA, in partnership with EUMETSAT, embarked upon the initial steps (industrial studies, Phase A) towards developing concepts for the next generation of MetOp -SG satellites. While the three satellites in the first series are identical, the current concept for MetOp-SG, also known as 'Post-EPS', will comprise two different satellites orbiting as a pair. It is envisaged that each satellite will carry a different, but complementary, instrument package. 2) 3)

In November 2012, the EUMETSAT Council successfully concluded the approval process for the EPS-SG (EUMETSAT Polar System Second Generation) Preparatory Program with all 26 Member States having now firmly committed themselves. 4)

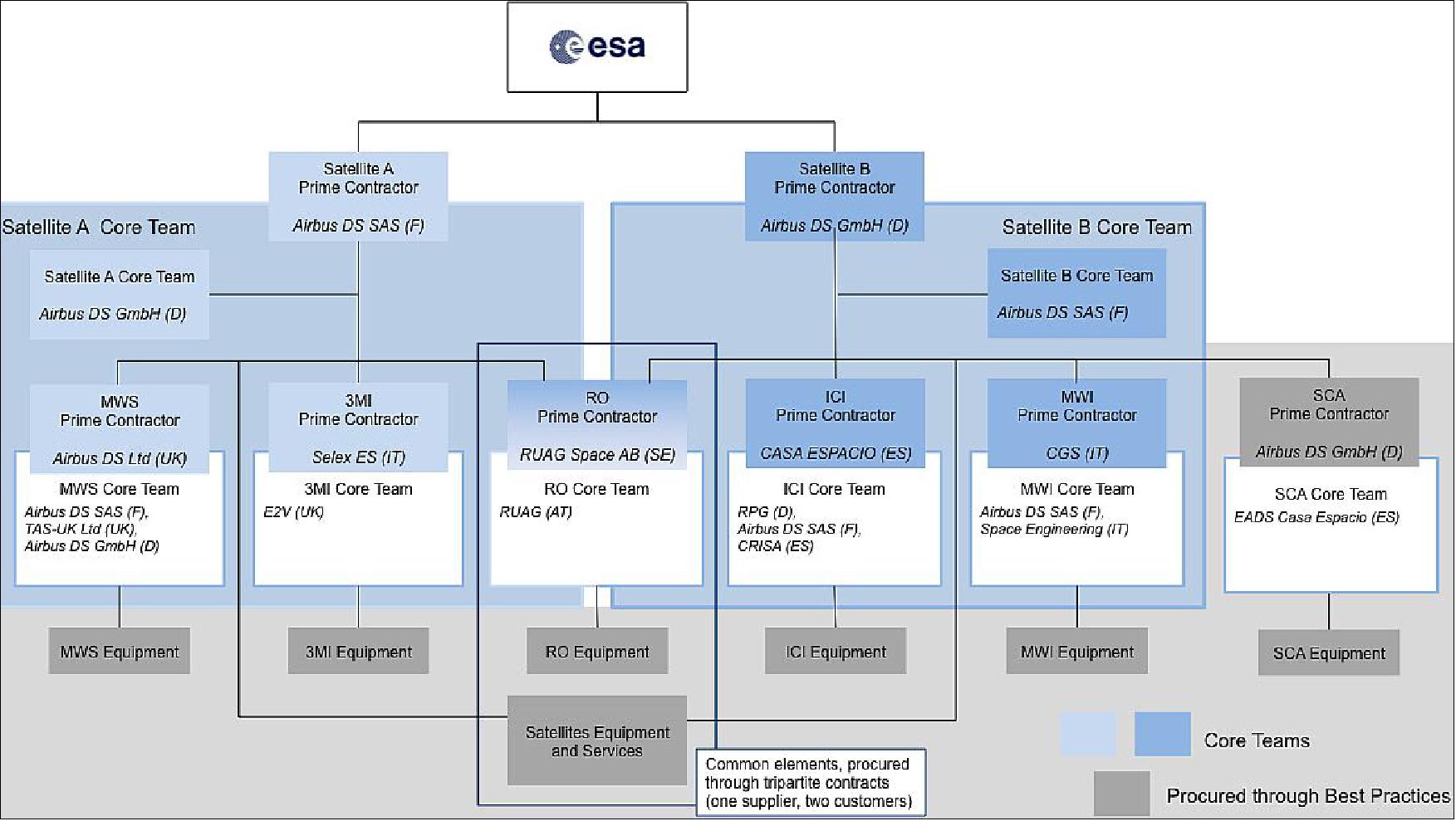

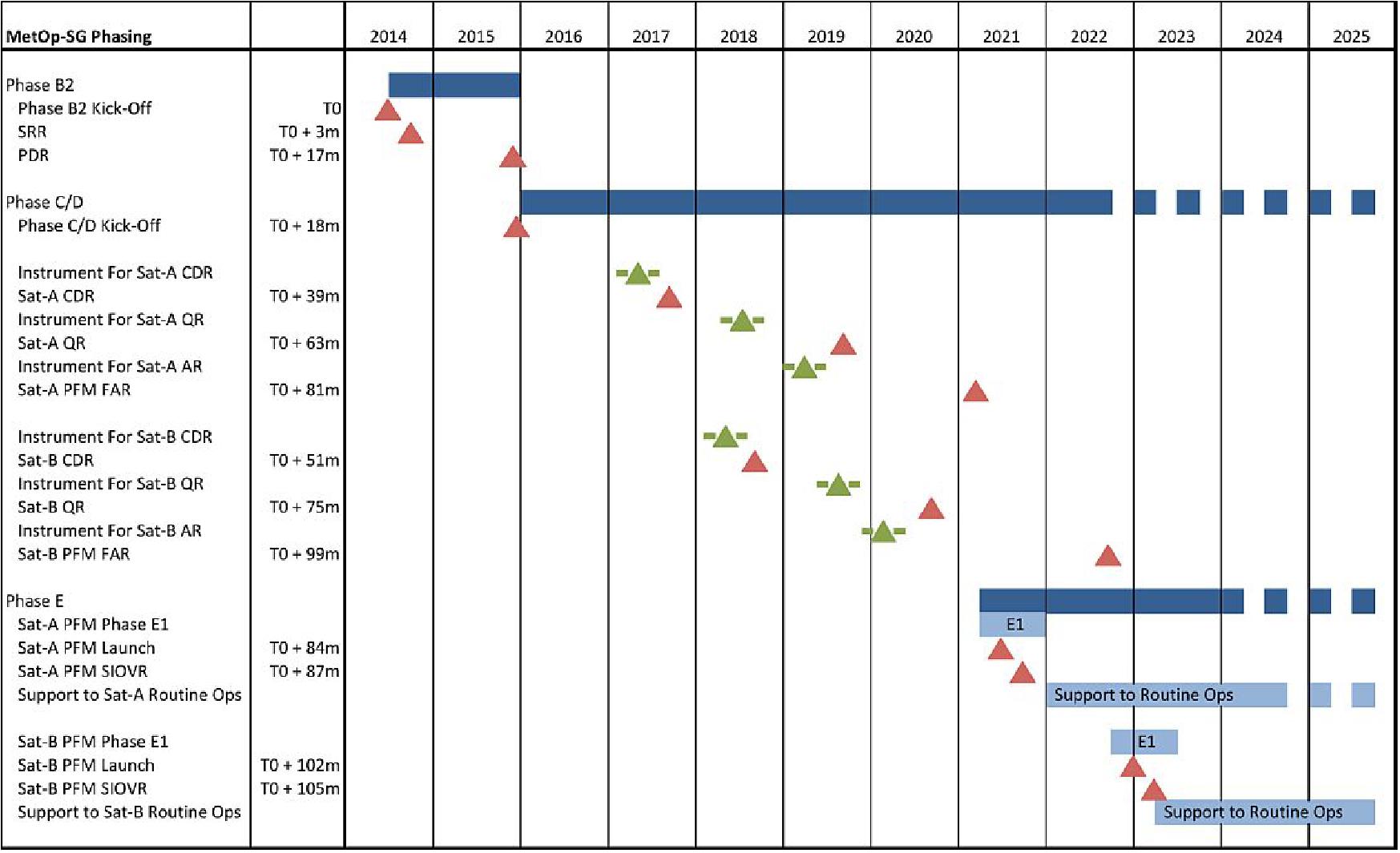

On May 20, 2014, the first documents signalling the go-ahead for Europe’s fleet of MetOp Second Generation weather satellites were signed by Volker Liebig, ESA Director of Earth Observation Programs, and Michael Menking, Head of Airbus Defence & Space’s Earth Observation, Navigation and Science Programs in the presence of the German Chancellor Angela Merkel at the Berlin Air Show. - With the first contractual documents now signed, the ‘A’ satellites will be developed and built by Airbus Defence and Space in Toulouse, France, while the ‘B’ satellites will be developed and built at the company’s facilities in Friedrichshafen, Germany. However, under the leadership of Airbus Defence and Space, a large industrial consortium of many different companies around Europe will be involved. 5) 6)

MetOp-SG encompasses the objective of obtaining consistent, long-term collection of remotely sensed data of uniform quality for operational services for meteorology and climate monitoring state analysis, forecasting and operational service provision, in the context of the EUMETSAT’s EPS-SG system.

| MetOp-SG-A | MetOp-SG-B |

|

| |

Orbit, altitude | SSO, 830 km | SSO, 830 km |

S/C mass | ~4.017 (+135 adaptor) kg | ~3.818 (+135 adaptor) kg |

Lifetime | 8.5 years | 8.5 years |

|

|

|

Sensor complement | 8 instruments | 7 instruments |

| METimage (DLR) | MWI (Microwave Imaging Radiometer), (ESA) |

| MWS (Microwave Sounder), (ESA) | ICI (Ice Cloud Imager), (ESA) |

| IASI-NG (Infrared Atmospheric Sounder Interferometer-Next Generation), (CNES) | SCA (Scatterometer), (ESA) |

| RO (Radio Occultation), (ESA) | RO (Radio Occultation), (ESA) |

| 3MI (Multi-view Multi-channel Multi-polarization Imager), (ESA) | Argos-4 (Data Collection Service) (NOAA/CNES) |

| Radiation Energy Radiometer (NOAA) | Search and Rescue (COSPAS-SARSAT) |

| Sentinel-5/UVNS (ESA/Copernicus) | Space Environment Monitor (NOAA) |

| Low Light Imager (NOAA) |

|

The MetOp-SG program is being implemented in collaboration with EUMETSAT. ESA develops the prototype MetOp-SG satellites (including associated instruments) and procures, on behalf of EUMETSAT, the recurrent satellites (and associated instruments). EUMETSAT is responsible for the overall mission, funds the recurrent satellites, develops the ground segment, procures the launch and LEOP services and performs the satellites operations. The corresponding EUMETSAT Program is termed EPS-SG (EUMETSAT Polar System – Second Generation).

On October 16, 2014, contracts were signed to build three pairs of MetOp Second Generation satellites, ensuring the continuity of essential information for global weather forecasting and climate monitoring for decades to come. Airbus Defence and Space of France now takes up the role as prime contractor for the A satellites and Airbus Defence and Space of Germany for the B series. Although the different satellites will be developed and built in Toulouse, France and Friedrichshafen, Germany, respectively, a large industrial consortium of many European companies will be involved under the leadership of Airbus Defence and Space. 9)

New instruments observing extended spectral and frequency ranges will allow new environmental measurements to be collected. In addition, the A series will carry the Copernicus Sentinel-5 instrument on behalf of the European Commission. Sentinel-5 includes five ‘spectrometers’ from the ultraviolet to the shortwave infrared, to monitor atmospheric composition and support the forecasting of air quality.

• On 15 December 2016, Europe and the US achieved another milestone in the cooperation on meteorological satellite systems when Marc Cohen, EUMETSAT Associate Director for LEO Programs and Harry A. Cikanek III, NOAA Director, Joint Polar Satellite System, signed the plan that will implement the JPS (Joint Polar System). 10)

- The PIP (Polar System Program Implementation Plan) encompasses the space and ground segments associated with EUMETSAT’s EPS-SG (Polar System Second Generation) and the Joint Polar Satellite System of NOAA (National Oceanic and Atmospheric Administration). It also regulates the use of assets and operations as well as access to third party mission products such as the Copernicus Earth Observation Program of the EU and the NOAA COSMIC (Constellation Observing System for Meteorology Ionosphere and Climate) and follow-on partnerships.

- The JPS extends to a new generation of polar-orbiting satellites the cooperation established since 1998 on the IJPS (Initial Joint Polar System) which builds on EUMETSAT’s MetOp and NOAA’s POES and Suomi-NPP satellites. — The agreement on the JPS was signed on 2 December 2015, between the EUMETSAT Director-General Alain Ratier and Stephen Volz, NOAA Assistant Administrator for Satellite and Information Services.

- JPS can be considered as a ‘system of systems’, with each party responsible for designing, sizing, and operating their own space and ground assets to meet their mission needs. At the same time, the partners have agreed to exploit those assets in a way that optimizes cross-support to the other party. Data and products generated by each party will be distributed to their own user community and will be available for access by the other party. Each party will fulfill its responsibilities on a best effort basis, taking into account schedule and funding constraints.

- Marc Cohen, Associate Director EUMETSAT said, “JPS is designed to provide observations from two complementary polar orbits in the period from 2020 to 2040. The Implementation Plan we have now signed will translate our designs into action.”

MetOp-SG Program Overview 11) 12)

• MetOp-Second Generation is a follow-on system to the first generation series of MetOp (Meteorological Operational) satellites, which currently provide operational meteorological observations from polar orbit.

• MetOp-SG is a collaborative program between ESA and EUMETSAT, similar to the previous successful cooperations between the two organizations.

• ESA is responsible for the development of the prototype satellites and, on behalf of EUMETSAT, for the procurement of the recurrent satellites.

• EUMETSAT is responsible for overall user requirements, procurement of the launchers and LEOP services, development of the ground segment and also performs the operations.

• ESA funding comes from the ESA MetOp-SG Program, which was approved at the ESA Council at Ministerial Level in November 2012.

• EUMETSAT funding will come from the EUMETSAT Polar System Second Generation (EPS-SG) Program, which is currently in the final stages of approval (Poland has already approved the Program).

Overall MetOp-SG Objectives

• To provide operational observations and measurements from polar orbit for numerical weather prediction and climate monitoring in the 2020 to mid-2040’s timeframe.

• In addition, to provide services to atmospheric chemistry, operational oceanography and hydrology.

• With respect to the first generation of MetOp satellites:

- to ensure continuity of essential operational meteorological observations from polar orbit, without a gap

- to improve the accuracy / resolution / dynamic range of the measurements (e.g. MWS, RO, SCA as well as METimage, IASI-NG, Sentinel-5)

- to add new measurements / missions (e.g. 3MI, MWI, ICI as well as Sentinel-5).

• MetOp-SG consists of two series of satellites (termed Satellite A and Satellite B), with three satellites in each series (3+3 configuration).

• A total of ten different instruments will be flown across the two satellites.

• Six instruments are developed as part of the MetOp-SG Program (Contractor Provided Item or CPI instruments):

- MWS (MicroWave Sounder)

- MWI (MicroWave Imager)

- ICI (Ice Cloud Imager)

- SCA (SCAtterometer)

- 3MI (Multi-viewing, Multi-channel, Multi-polarization Imager)

- RO (Radio Occultation sounder)

• Four instruments are Customer Furnished Items or CFIs (Sentinel-5 from ESA / EU Copernicus Program, METimage from DLR, and IASI-NG and Argos-4 from CNES) and are NOT the subject of this briefing.

• The ground segment development is the responsibility of EUMETSAT and is also NOT the subject of this briefing (Ref. 11).

Spacecraft

A two-satellite architecture has been selected for MetOp-SG by ESA and EUMETSAT, namely MetOp-SG- A and -B, flying in the same sun-synchronous orbit. Unlike the current MetOp system of identical satellites operating in a relay, the MetOp-SG system envisages a pair of different satellites, each carrying a different but complementary suite of instruments. This will comprise a mix of instruments offering data continuity with improved performance and new instruments to meet the evolving demands of the meteorological community.

The overall system lifetime is 21 years, with each satellite designed to exceed an eight and a half year lifetime.

On October 17, 2014, Airbus Defence and Space signed formal contracts with ESA to design and manufacture of six MetOp-SG satellites. 13)

Satellites key parameters | Satellite A | Satellite B |

Payload complement | METimage, IASI-NG, MWS, Sentinel-5, 3MI, RO | SCA, MWI, ICI, RO, Argos-4 |

Spacecraft mass | 4,400 kg | 4,180 kg |

Fuel | 684 kg | 659 kg |

Total ΔV | 325.8 m/s (of which 68% is for controlled reentry) | |

Stowed dimensions (m) | 6.5 (+0.55) x 2.97 x 3.46 | 6.1 (+0.55) x 2.91 x 3.43 |

Power consumption | 3.29 kW | 2.40 kW |

Nominal mode | Yaw steering – gyroless | |

Reaction wheels | 5 | 6 |

Safe mode | Earth pointing – 3 axes stabilized | |

Data storage | 745 Gbit (sized for 1.5 orbits of Satellite A) | |

Average data rate (Mbit/s) | 65 (day) & 27 (night) | 19 (day & night) |

Ka-band downlink (Mbit/s) | 781 (2 channels) | 390.5 (1 channel) |

X-band downlink (Mbit/s) | 80 | |

Design life | Nominal = 7.5 years, Extended = 9.5 years | |

EPS-SG Direct Broadcast: 14)

• Roughly 20-fold increase of sensing data rates from EPS to EPS-SG, with a corresponding increase in global and direct broadcast data rates

• Direct broadcast data rates will be 80 Mbit/s, making it impossible to remain in L-band as per EPS. The X-band has been chosen instead; The L-band will not be supported on the MetOp-SG satellites

• Satellite A has a much higher peak data rate than Satellite B, but both satellites will have exactly the same direct broadcast data rates (filler data to be inserted on Satellite B)

• In routine operations, Satellite B will be flying about 90° / 25 minutes ahead of Satellite A. MetOp satellites will also be flying in the same orbit, with MetOp-C nominally at 90° after MetOp-SG A1 until its deorbiting.

Characteristic | NPP/JPSS-1 | EPS-SG |

Reception station performance requirement, G/T | 22.7 dB/K | 22.7 dB/K |

Typical resulting antenna size | 2.4 m | 2.4 m |

Data rate (instrument data) | 16 Mbit/s | 80 Mbit/s |

Radio frequency | 7.8 GHz | 7.8 GHz |

Modulation scheme | QPSK | Offset QPSK |

Polarization | RHCP | RHCP |

• The parameter G/T is the main driver for the Reception Station Performance Requirements. For EPS-SG, the plan is to match the NPP requirement

• The G/T depends on the full chain of equipment including antenna dish quality and size, antenna tracking performance, feed, LNA, cabling, etc

• With good quality equipment, the required G/T can be achieved with a 2.4m antenna dish. To add additional margins for severe weather conditions and to mitigate potential local RF interference, a larger dish size may be chosen.

Figure 3: MetOp-SG industrial consortia (image credit: ESA, Ref. 6)

Development Status

• March 8, 2023: Test data have been released to users in BUFR format for the following instruments: MWS L1B, IASI-NG L1C, IASI-NG L1D, MWI L1B, ICI L1B, SCA L1B SZF, SCA L1B SZR, VII L2 (AMV, CLD, CTP, OCA, WVI, WVV), IASI-NG L2 (CLD, CO, GHG, NAC, O3, SFC, SO2, TWV). 65)

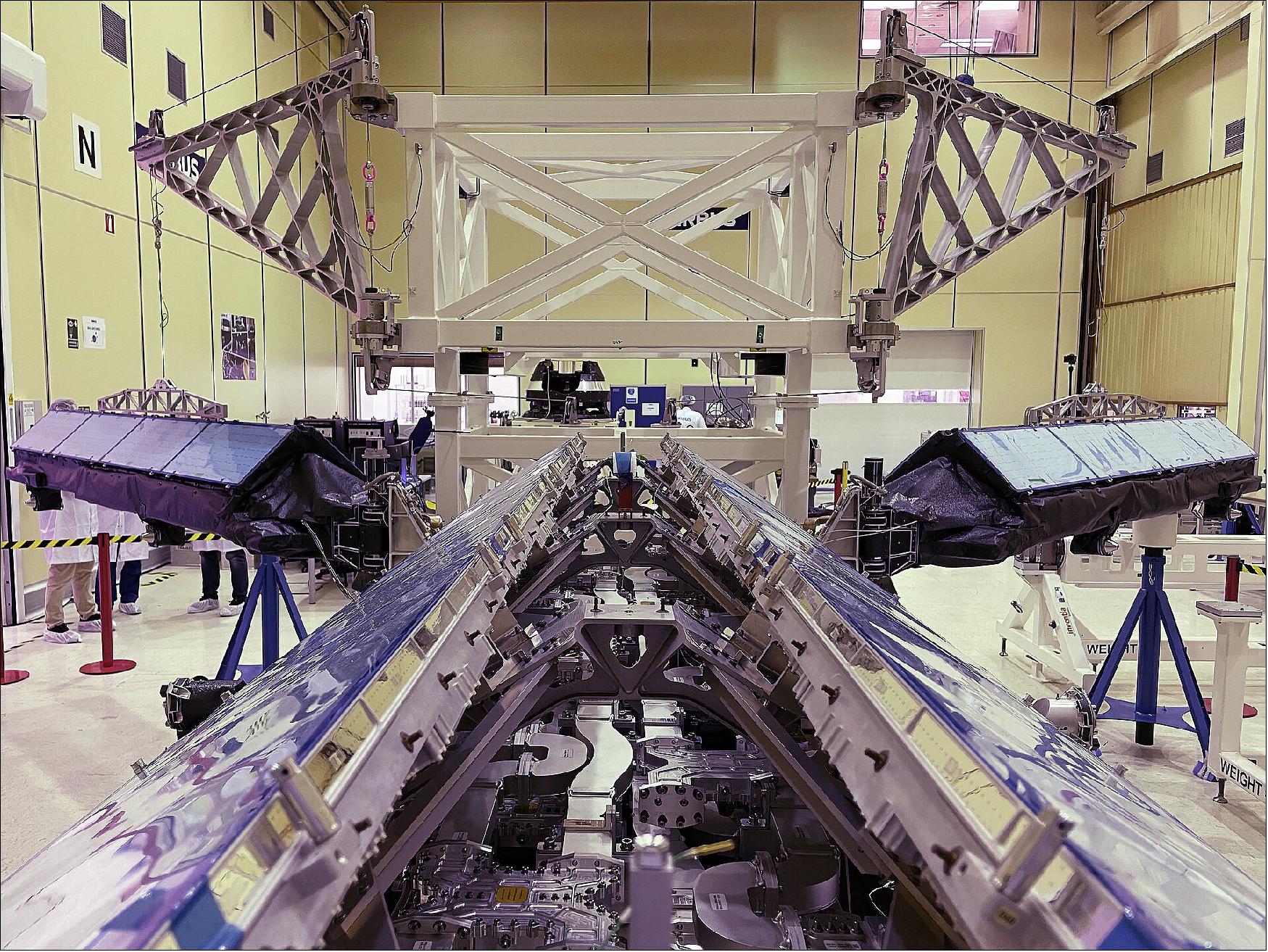

• April 4, 2022: The scatterometer antenna of MetOp Second Generation has successfully undergone extensive testing at Airbus' facilities in Madrid, Spain. The four-month testing campaign included trials replicating the extreme conditions of launch and space, covering aspects such as antenna deployment, thermal cycling, mechanical vibrations, and acoustic exposure. As one of the five instruments on the new MetOp-SG-B satellites, the scatterometer will play a crucial role in monitoring ocean winds, continental ice sheets, and land-surface soil moisture. This instrument is designed to provide comprehensive coverage of 99% of Earth's surface within a two-day period, offering a resolution of 25 km. 15)

Figure 4: MetOp-SG B antenna deployment test (image credit: Airbus)

• October 7, 2021: The first MetOp-SG "B" model, part of the next-generation polar-orbiting weather satellite series, has undergone a precise integration with its propulsion system at Airbus' satellite integration center in Friedrichshafen, Germany. The propulsion system, constructed in Stevenage, UK, accommodates 760 kg of hydrazine fuel for maintaining the satellite's orbit and attitude throughout its mission, with controlled re-entry planned over the South Pacific at the mission's end. 16)

• May 6, 2021: RUAG Space in Zürich, Switzerland, is providing the second of six flight models for the MetOp-SG (Meteorological Operational Satellite-Second Generation), contributing to the enhancement of weather forecasting accuracy and the prediction of extreme weather events. The six-meter-high and 1000 kg basic structure, designed to endure the rigors of launch, extreme temperatures, and vacuum conditions in space, was developed by RUAG Space and assembled from over 24,000 parts. Constructed as a lightweight "sandwich" with an aluminum honeycomb core and carbon fiber-reinforced plastic cover layers, the structure aims to optimize fuel efficiency.17)

• November 25, 2019: ESA/ESTEC in the Netherlands has successfully completed the initial test campaign for MetOp Second Generation (MetOp-SG), the follow-on system to the MetOp satellites. The test item, a prototype version known as the 'structural and thermal model' (STM), underwent rigorous testing, including vibration testing, thermal testing in a vacuum chamber, acoustic testing simulating the noise of a launch, a separation test, and alignment testing. The MetOp-SG system comprises two different satellites, each with different instrument suites. The testing of the STM provides essential qualification data, confirming the analysis performed during the design stage. 18)

• May 30, 2019: The SENER Group has delivered the Engineering Qualification Models (EQM) of the Ice Cloud Imager (ICI) Back End Receivers for MetOp SG, the second generation of weather satellites. These satellites, consisting of six units, are set to be deployed by the European Space Agency (ESA) and the European Organization for the Exploitation of Meteorological Satellites (EUMETSAT) starting in 2021 until mid-2040. The Back End Receivers play a crucial role in measuring the power detected within the received signal across different channels, involving complex conditioning and amplification stages. After delivering the EQMs, SENER will proceed with manufacturing the Flight Models. Additionally, SENER is responsible for various components, including hold-down and release mechanisms, deployment and latching mechanisms, and reception equipment for radiometers and telemetry/telecommand antennas for MetOp-SG. 19)

• November 18, 2016: Airbus Defence and Space has awarded the Communications & Medical Products Division of Communications & Power Industries (CPI) an 8.7 million euro contract to support a new generation of satellites set to provide global advanced meteorological data from 2021 until after 2040. Under the contract, CPI will develop engineering and flight models of 5.355 GHz Extended Interaction Klystrons (EIKs). These EIKs are essential for the Scatterometer (SCA) radar instrument, generating high-power microwaves crucial for measuring surface winds over the ocean. The work will be carried out at CPI’s facilities in Georgetown, Ontario, Canada, with the delivery of flight models beginning in 2019. 20)

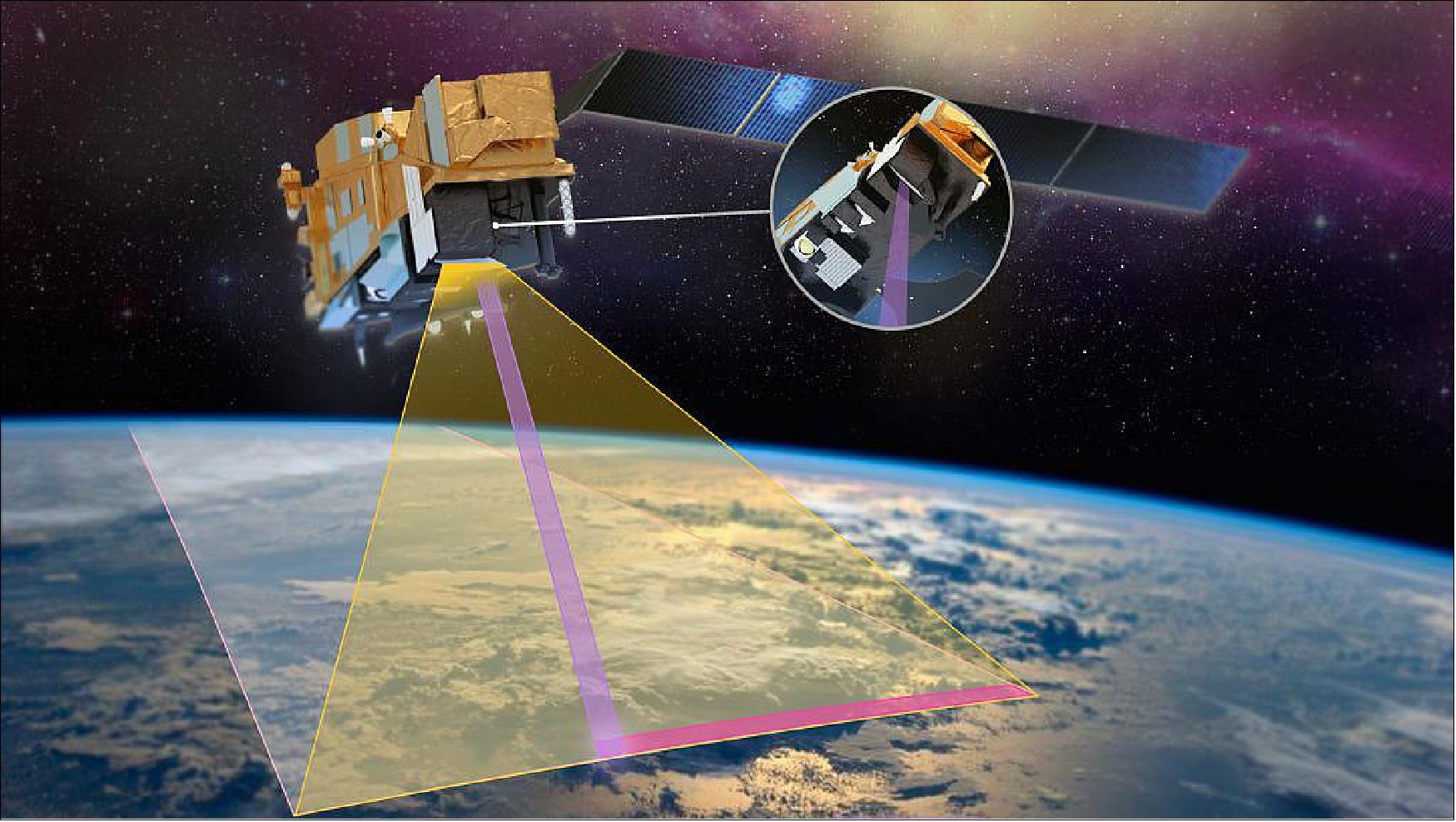

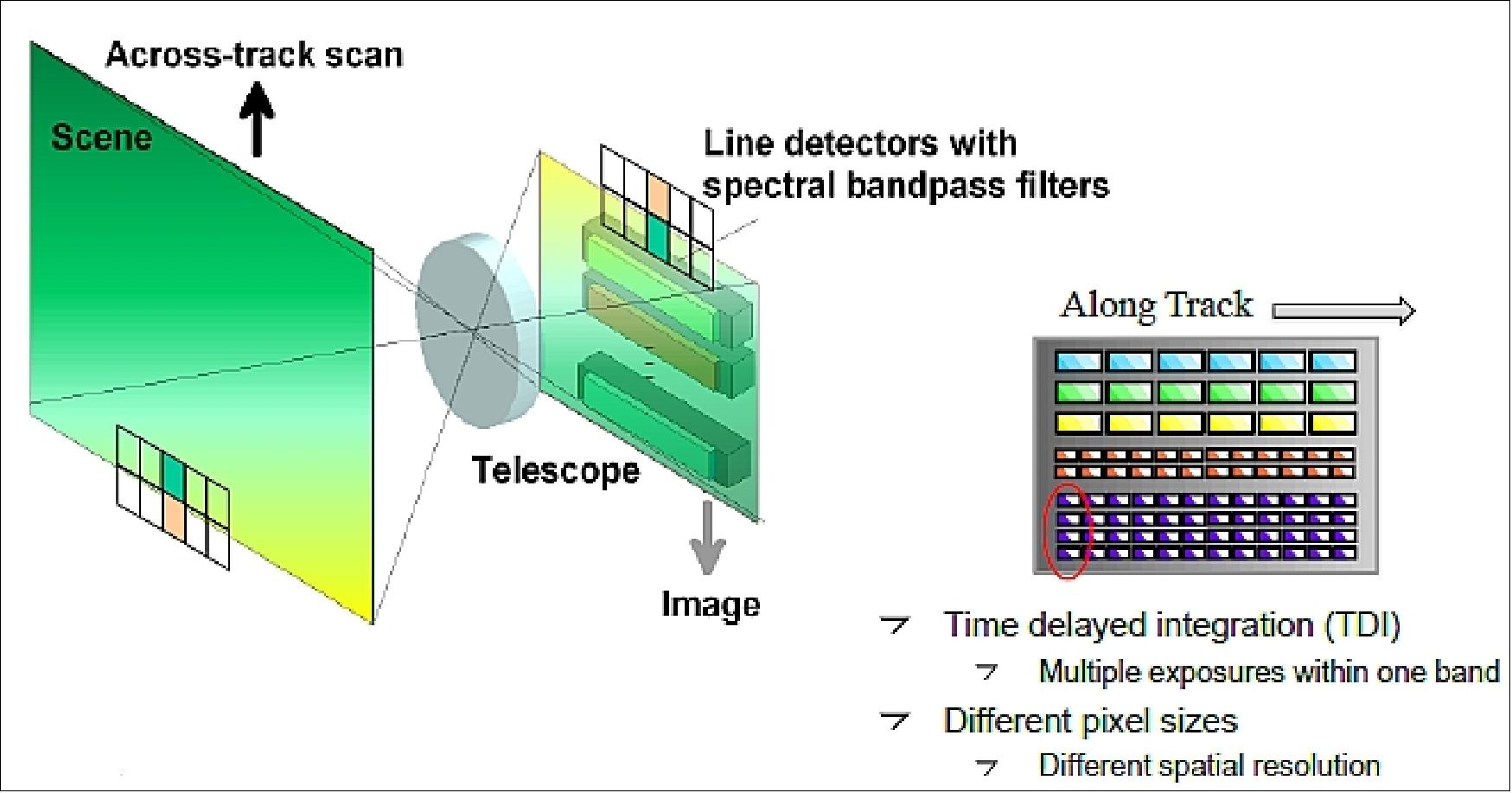

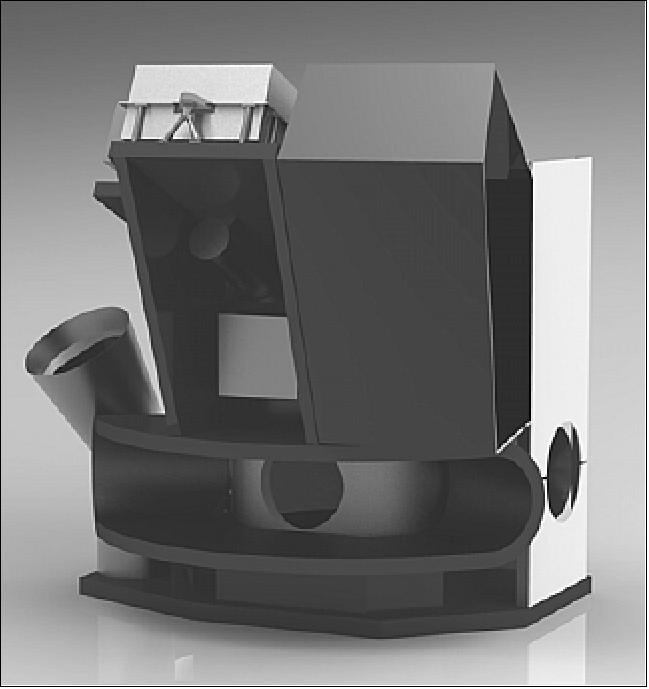

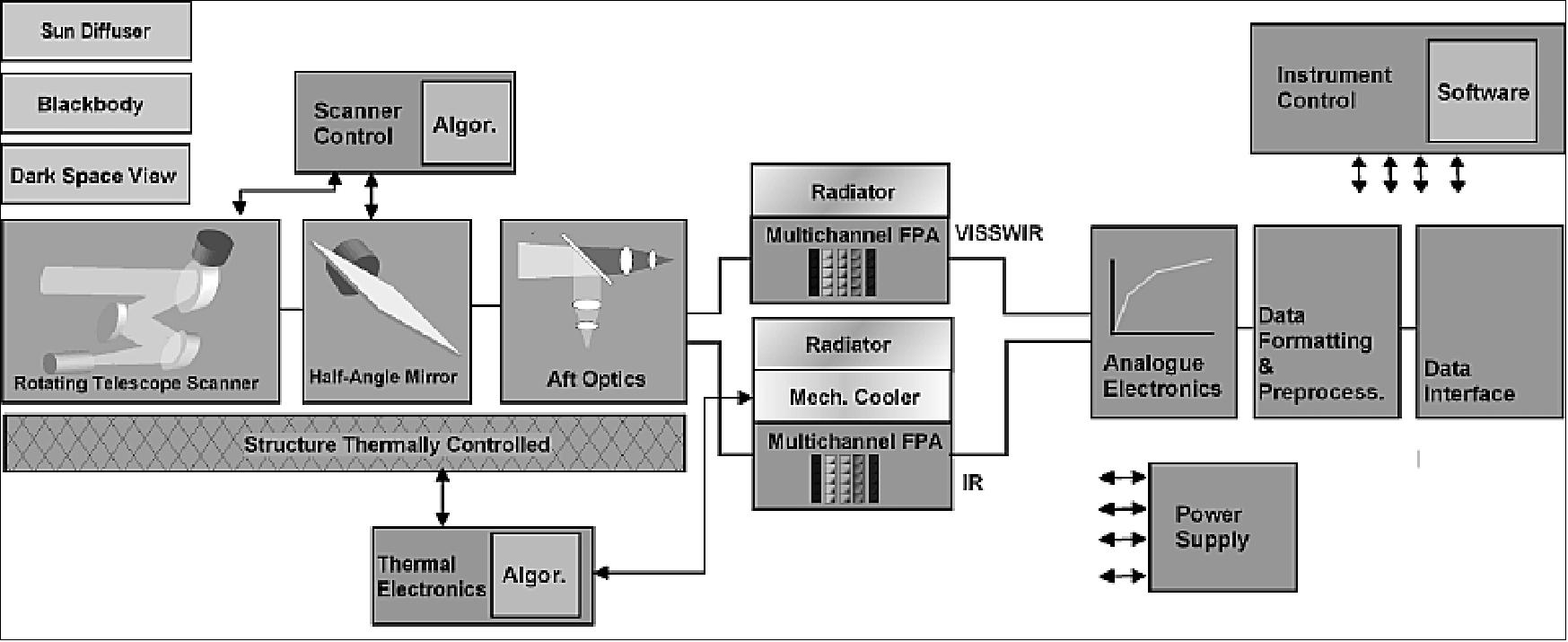

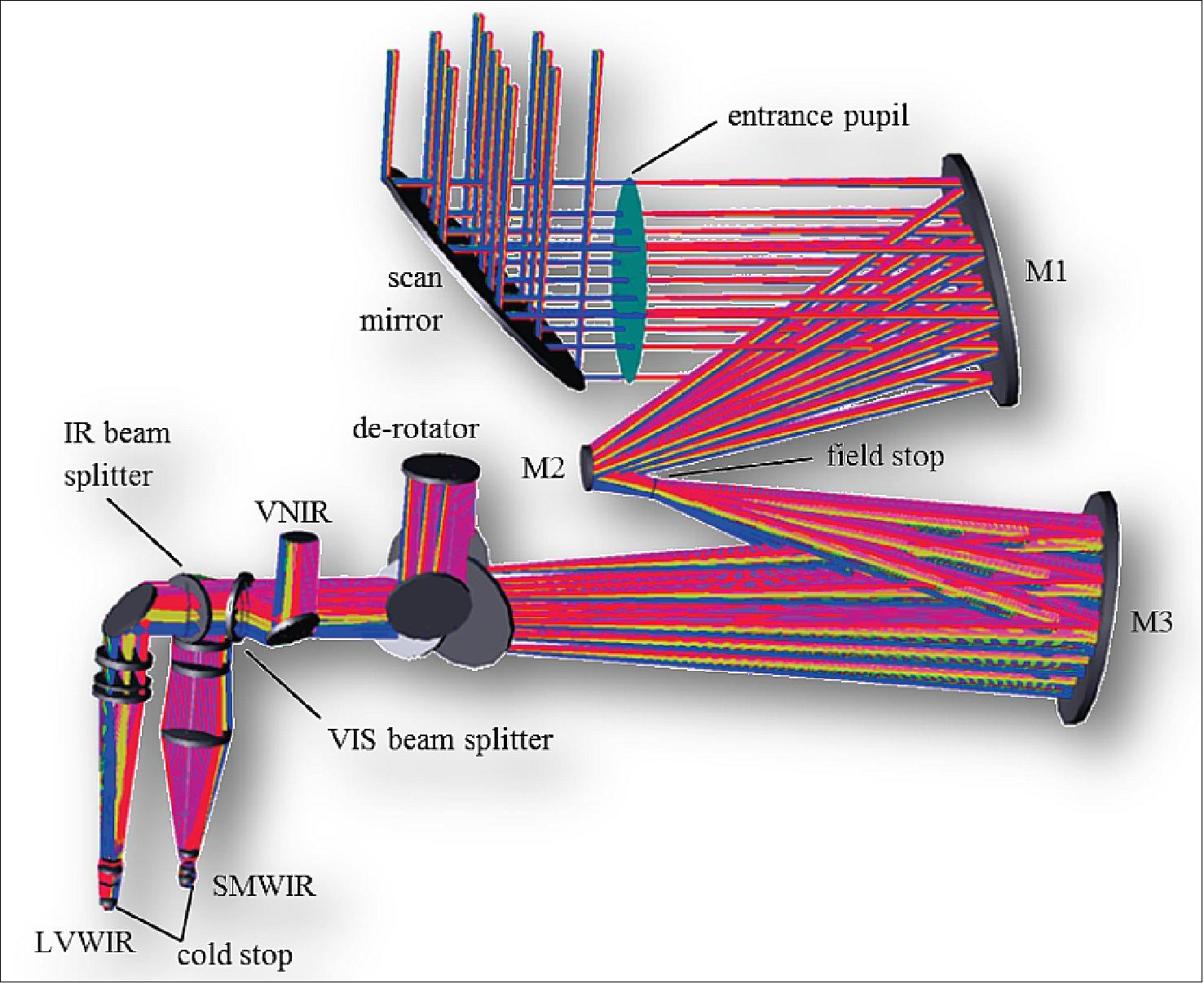

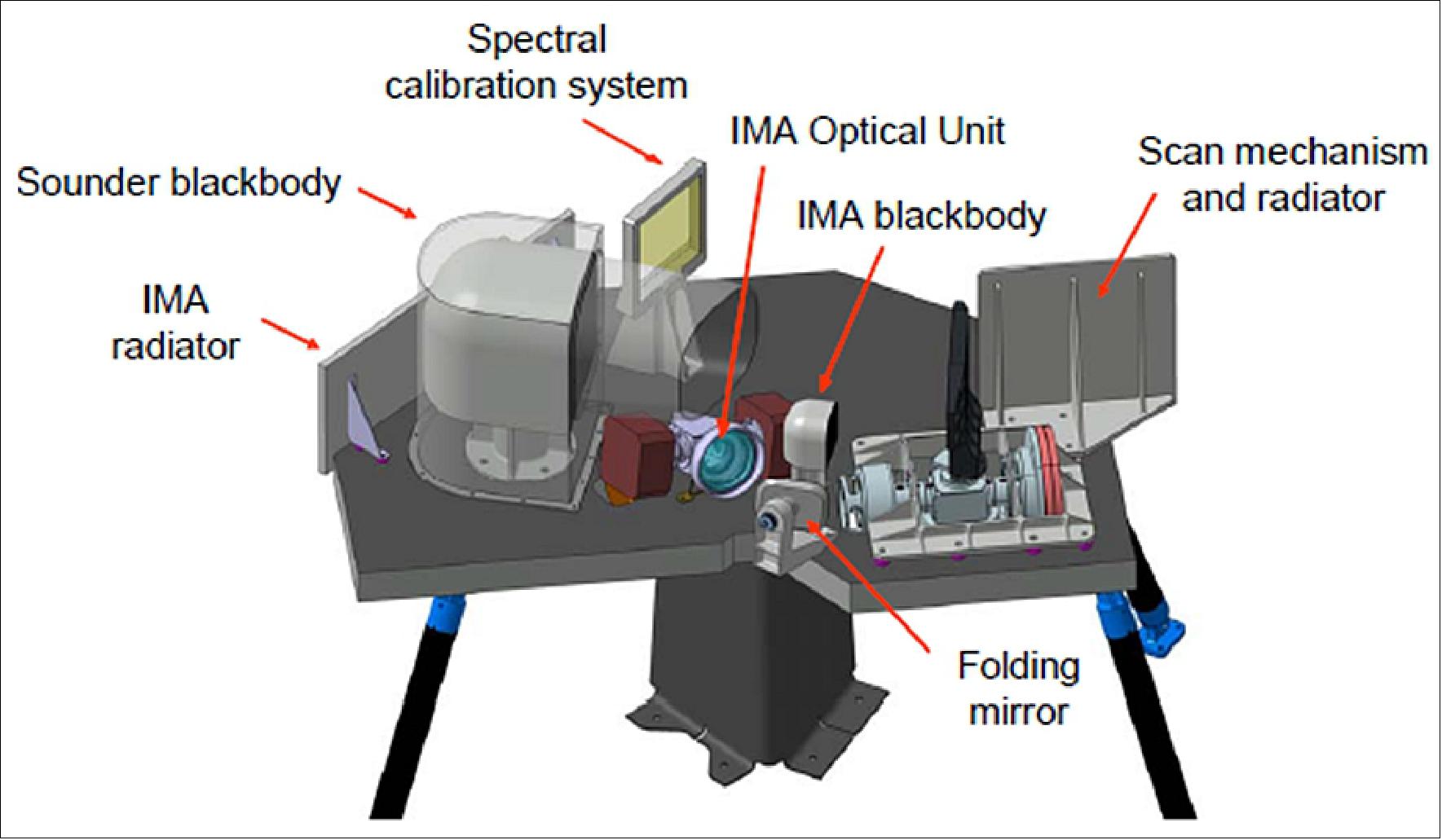

• September 20, 2016: DLR has awarded a contract to Airbus DS for the design, construction, and testing of the METimage radiometer (Figure 9). This complex instrument, comprising three sensors, two of which are infrared sensors operating at cryogenic temperatures below -210°C, observes a 12 km wide and 2,670 km long swath of the Earth's surface within 1.7 seconds using a scan mirror oriented perpendicular to the flight direction. METimage delivers data through 20 channels, making it one of the most intricate instruments Airbus Defence and Space is currently developing. 21) 22)

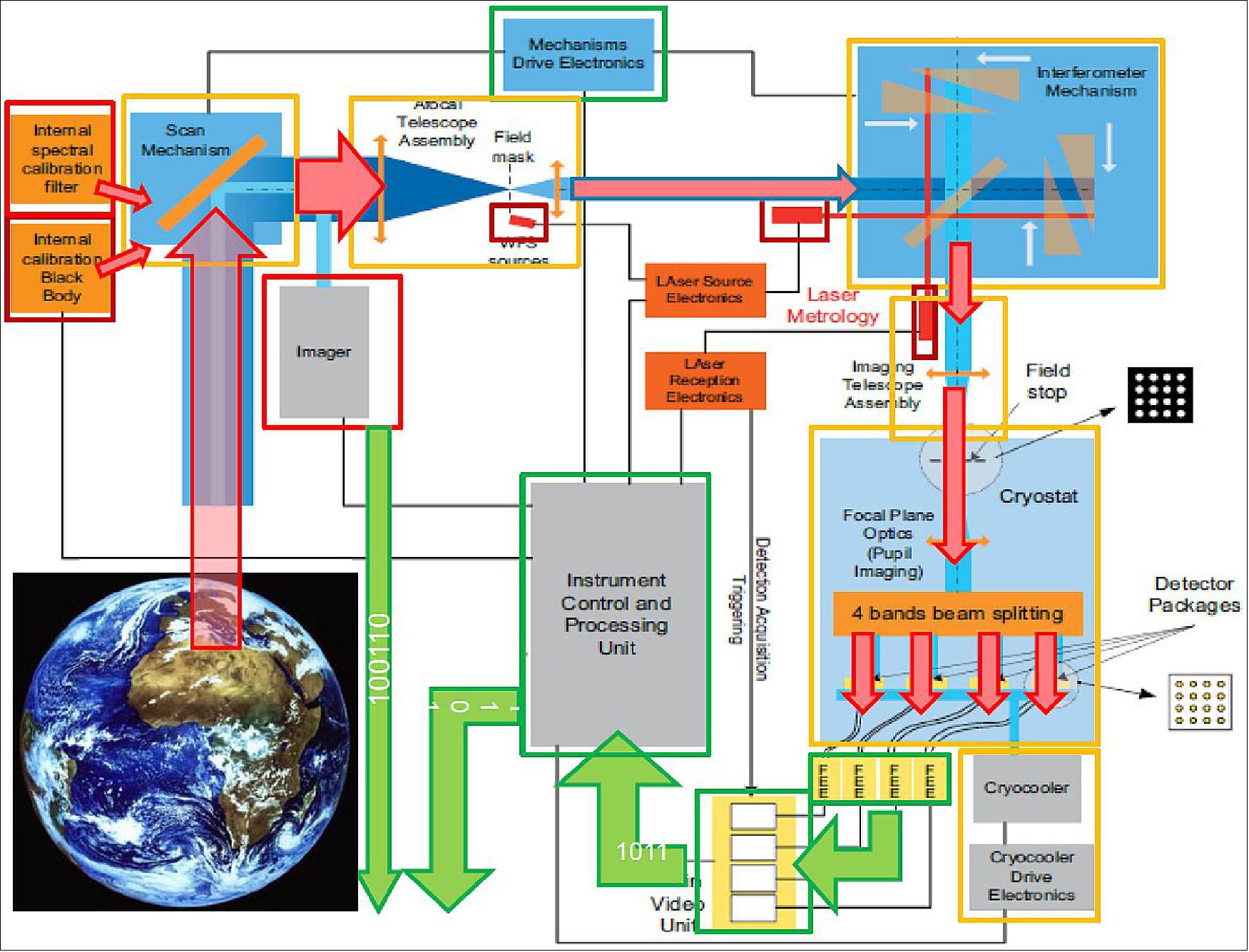

• December 8, 2015: EUMETSAT and CNES have entered a cooperation agreement for the development of a new generation of IASI-NG (Infrared Atmospheric Sounding Interferometers). Under this agreement, CNES will be responsible for developing the complete IASI-NG system, including the instrument and the data processing chain. CNES will also procure recurrent instruments on behalf of EUMETSAT and provide operational support. EUMETSAT will fund 30% of the development costs for the first instrument and all recurrent instruments. Furthermore, EUMETSAT will integrate the IASI-NG data processing chain into its operational ground systems and utilize the instrument chain throughout the EPS-SG system's lifetime. 23)

• October 5, 2015: EUMETSAT and ESA signed a cooperation agreement that secures the development of the MetOp Second Generation satellites which form the space segment of the EUMETSAT Polar System of Second Generation. 24)

MetOp-SG Status as of May 2015

• Phase B2 Kick-off: 28 May 2014

• Industry Days Event: 25 – 26 June 2014

• System Requirements Review: September – October 2014

• Contract Signature: 16 October 2014

• SCA Kick-off: 11 December 2014

• Preliminary Design Review: September – November 2015

• MWS, 3MI, RO, MWI and ICI instruments kicked-off together with the Satellites in May 2014.

• SCA instrument selected through Best Practices and kicked-off in December 2014.

• Currently, the main industrial activities are the build-up of the industrial consortia through the Best Practices procurements and preparation for the PDR.

Launch

Orbit: The MetOp-SG satellites will orbit Earth in a sun-synchronous orbit at a mean altitude of ~835 km to provide global coverage, LTDN (Local Time on Descending Node) = 09:30 hours. Identical orbit as for EPS ⇒ shared orbit between MetOp and MetOp-SG satellites.

Sensor Complement

Since 2006, the European contribution to operational meteorological observations from polar orbit has been provided by the first generation of Meteorological Operational (MetOp) satellites. The MetOp-SG (MetOp Second Generation) series of satellites will provide continuity and enhancement of these observations in the timeframe of 2020 to 2040.

The payload of the MetOp-SG satellites consists of the following 10 instruments: 25) 26) 27)

• METimage (Meteorological Imager), to provide information on clouds, cloud cover, land surface properties, sea, ice and land surface temperatures, etc. The METimage instrument is provided by DLR via EUMETSAT.

• IASI-NG (Infrared Atmospheric Sounding Interferometer–New Generation), to provide atmospheric temperature and humidity profiles, as well as monitor ozone and various trace gases. IASI-NG is provided by CNES via EUMETSAT.

• MWS (MicroWave Sounder), to provide atmospheric temperature and humidity profiles. MWS is provided by ESA

• SCA (Scatterometer), to provide ocean surface wind vectors and land surface soil moisture. SCA is provided by ESA.

• RO (Radio Occultation sounder), to provide atmospheric temperature and humidity profiles, as well as information about the ionosphere. RO is provided by ESA.

• UVNS/S5 (Ultra-Violet /Visible/Near Infrared/Short Wave Infrared spectrometer -Sentinel-5) instrument, to monitor various trace gases, air quality and support climate monitoring. Sentinel-5 is provided by ESA.

Note: The Sentinel-5/UVNS instrument is described in a separate file on the eoPortal.

• MWI (MicroWave Imager), to provide precipitation monitoring as well as sea ice extent information. MWI is provided by ESA.

• ICI (Ice and Cloud Imager), to measure cloud ice water path, properties and altitude. ICI is provided by ESA.

• 3MI (Multi-viewing, Multi-channel, Multi-polarization Imager), to provide information on atmospheric aerosols

• ADCS (Advanced Data Collection System) Argos-4, for the collection and transmission of observations and data from surface, buoy, ship, balloon or airborne data collection platforms. ADCS-4 is provided by CNES via EUMETSAT.

ESA is responsible for design/development of the following 6 instruments within the MetOp-SG program: MWS, SCA, RO, MWI, ICI and 3MI. The Sentinel-5 instrument (UVNS/S5) is developed by ESA under the Copernicus Program, formerly GSC (GMES Space Component) program. The other instruments are provided through EUMETSAT under cooperation agreements with its partners DLR, CNES and NOAA and will be provided as Customer Furnished Items to the MetOp-SG contractor.

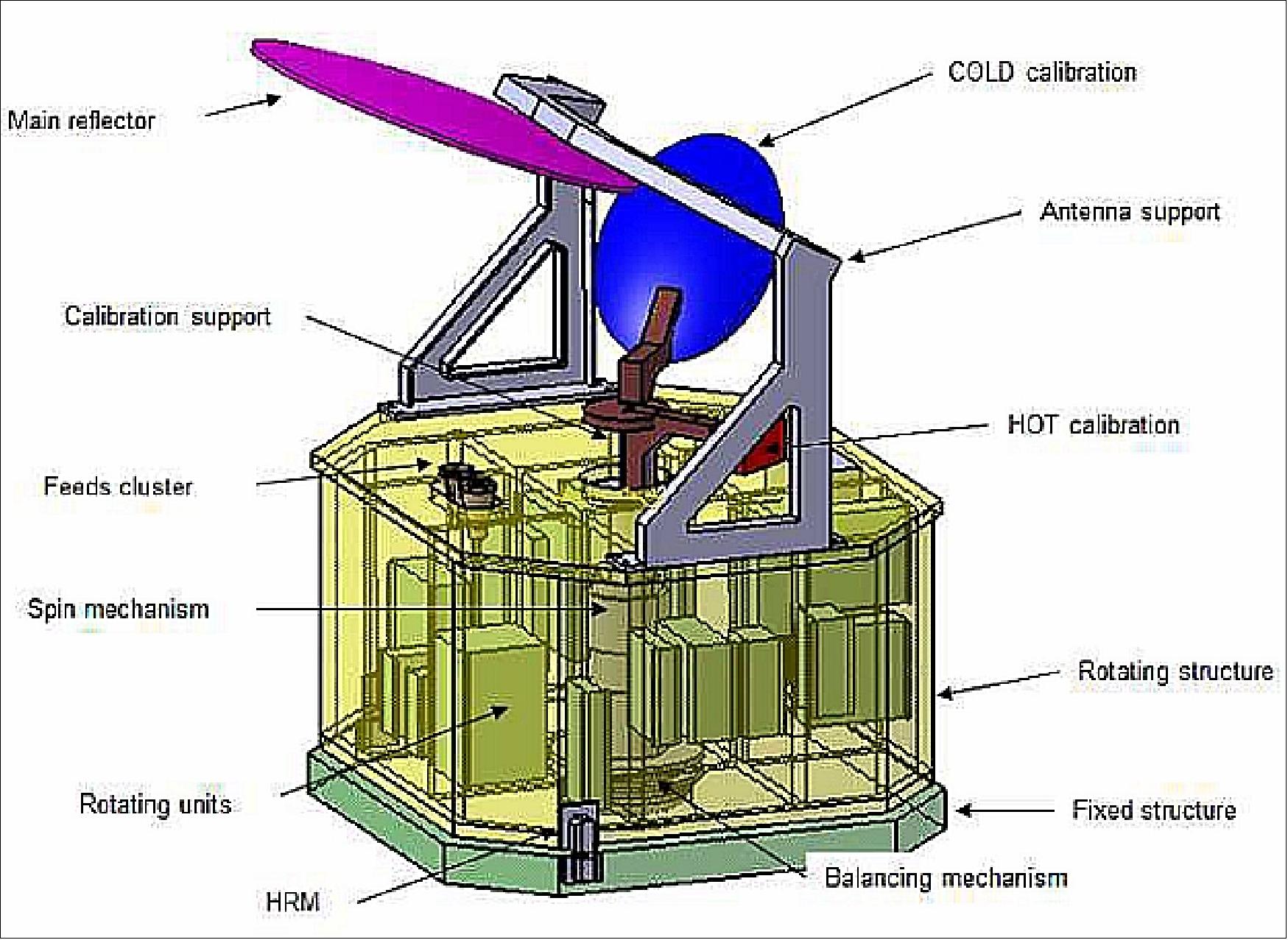

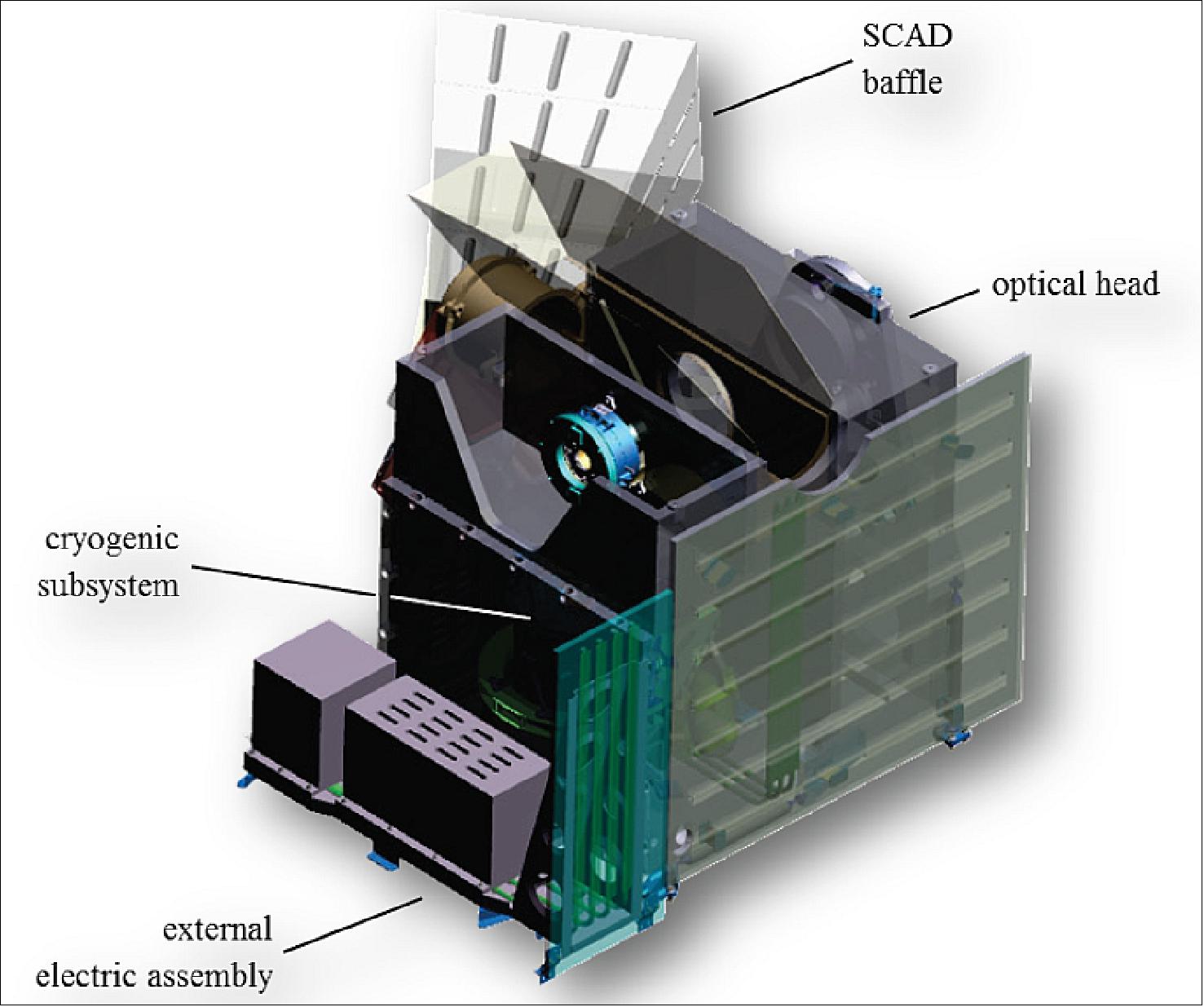

ICI (Ice Cloud Imager)

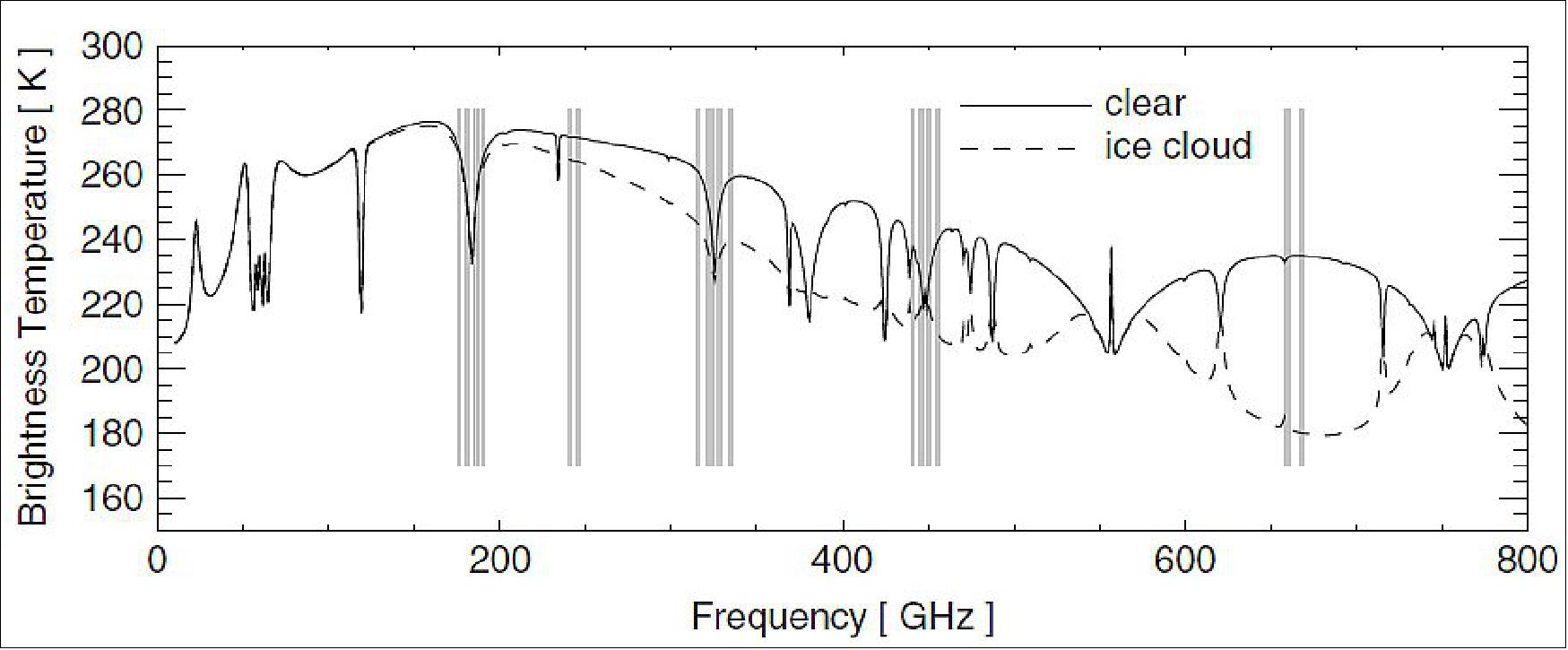

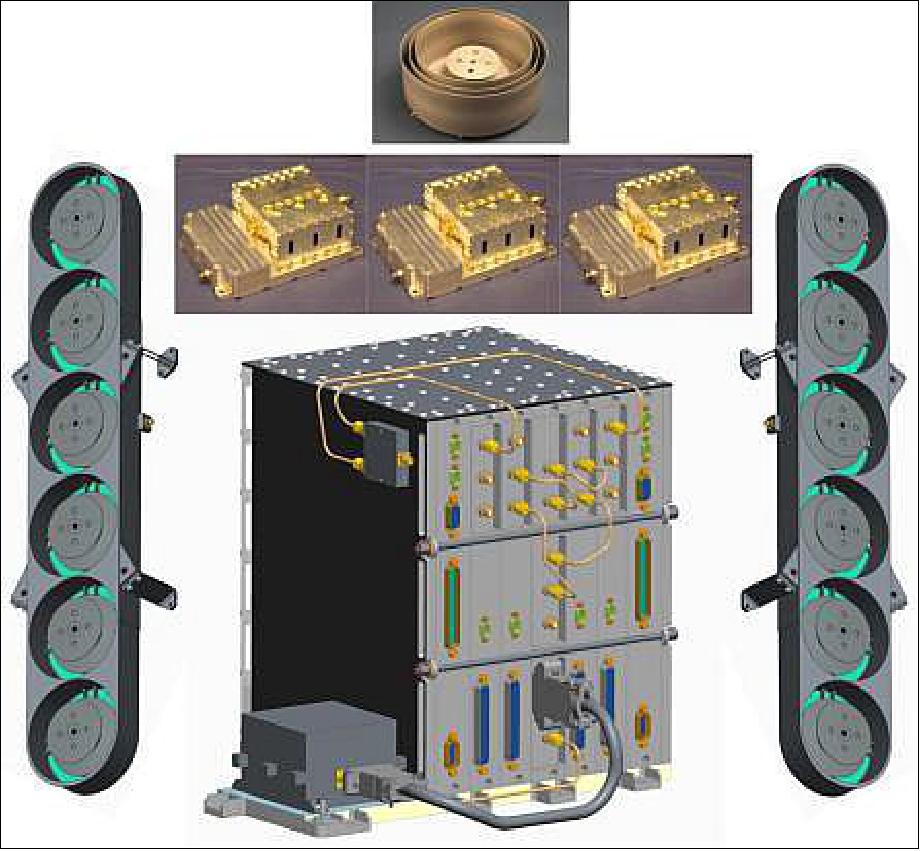

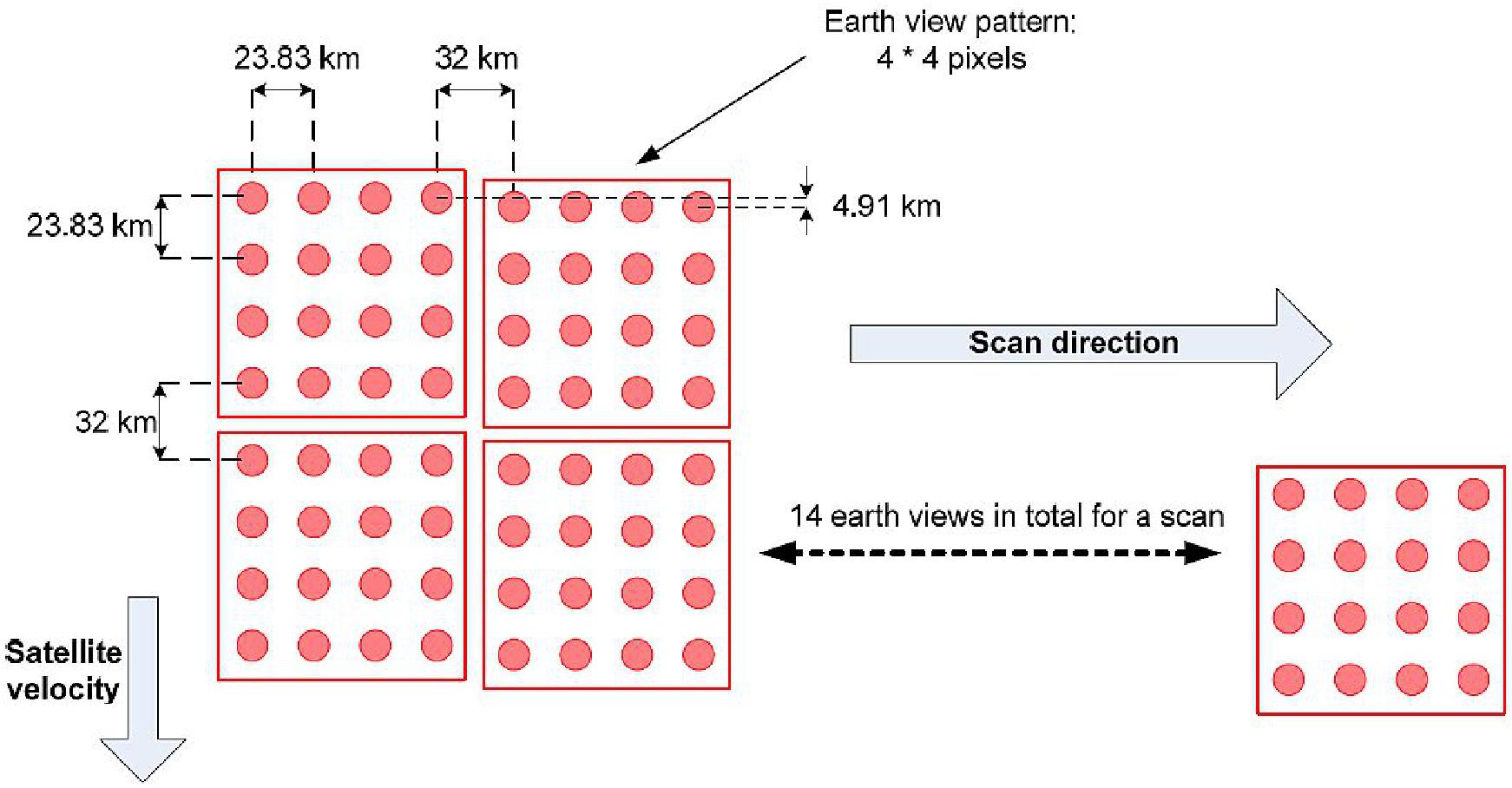

The ICI instrument is a total power millimeter and sub-millimeter wave conically scanning radiometer, providing brightness temperature measurements in 11 channels, two of them dual-pol, ranging from 183 GHz up to 664 GHz. ICI is designed to monitor the exchange mechanisms in Earth's upper troposphere and lower stratosphere, and focusing in particular on the remote sensing of high altitude ice clouds using several heterodyne receiver channels centered at 183 GHz, 243 GHz, 325 GHz, 448 GHz and 664 GHz, with two window channels (243 GHz and 664 GHz) measured at both V and H polarization. In recent years, several ESA funded activities have been aimed at further advancing the maturity of sub-millimeter wave Schottky technology in Europe in order to fulfil the ICI stringent requirements (Ref. 39). 28) 29) 30) 31)

Airbus DS-CASA Espacio, Spain (former EADS CASA Espacio) was selected by ESA (European Space Agency) as the prime contractor of the ICI instrument. Airbus DS SAS (France), RPG and CRISA are part of the industrial core team as well. Even if the technique to measure ice clouds was already proposed in 1995, this sub-millimeterwave imager will be the first radiometer of its kind ever developed for Earth observation from space.

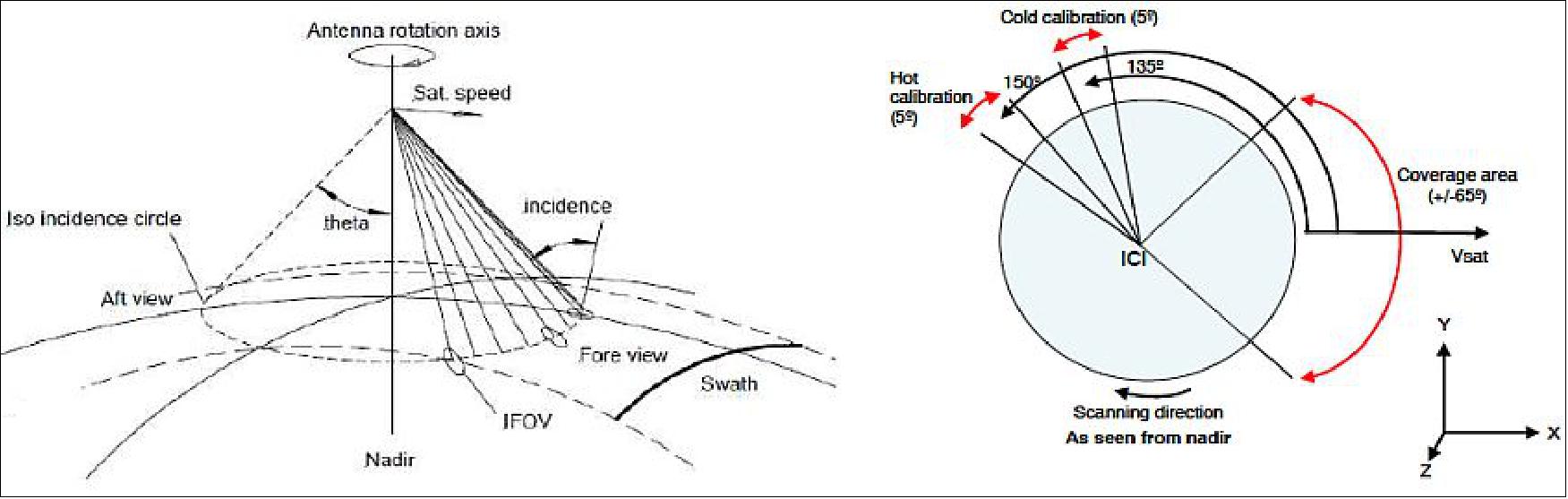

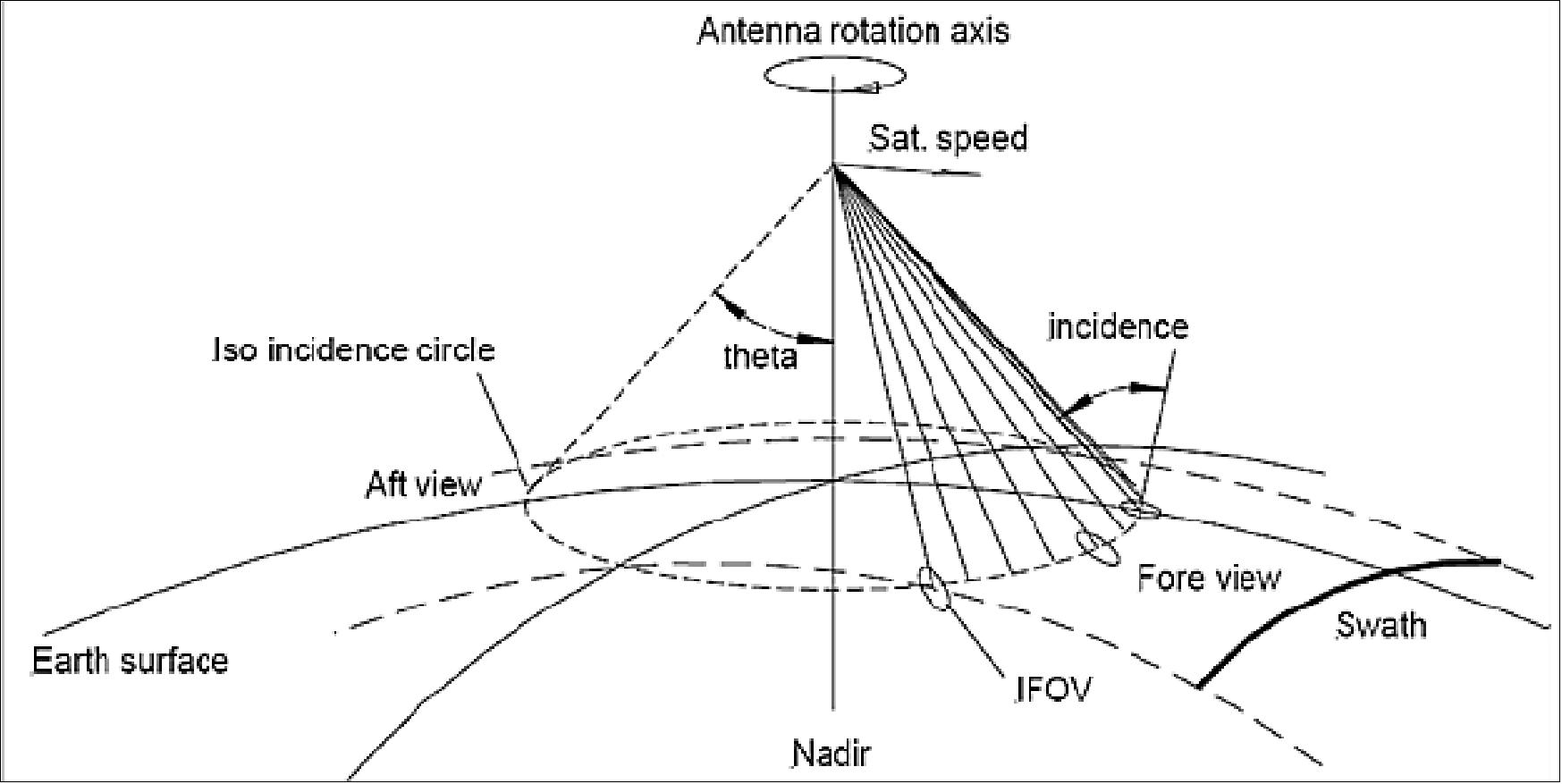

The ICI radiometer rotates at a constant speed of 45 rpm, providing Earth scene measurements to over an azimuth range of ±65º, with an incidence angle of around 53º and a projected footprint of 15 km for all channels. All footprints are sampled at Nyquist, providing a good image quality capability. The channels at 243 GHz and 664 GHz are measured at V and H polarizations, while all other channels are measured in V polarization. Hot and Cold calibrations are performed periodically at each rotation.

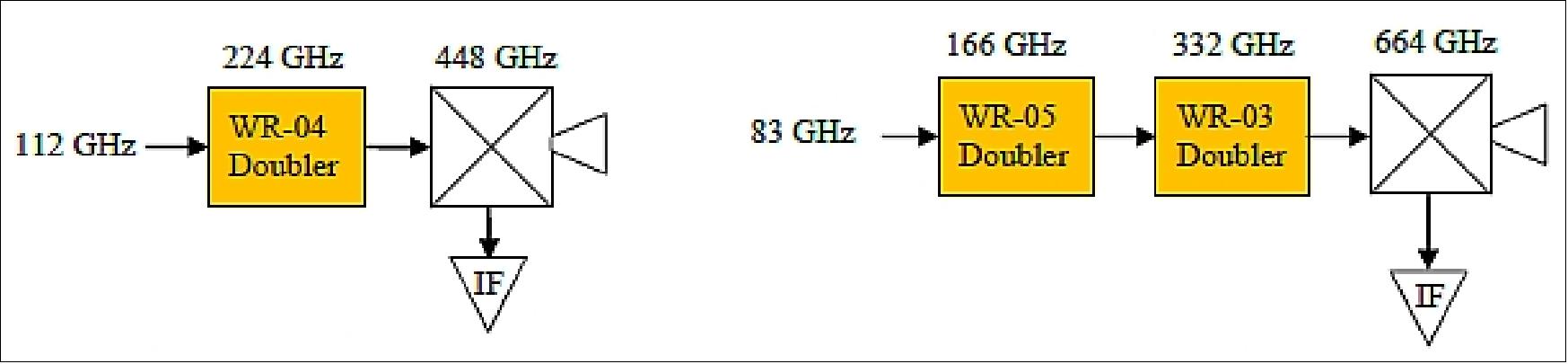

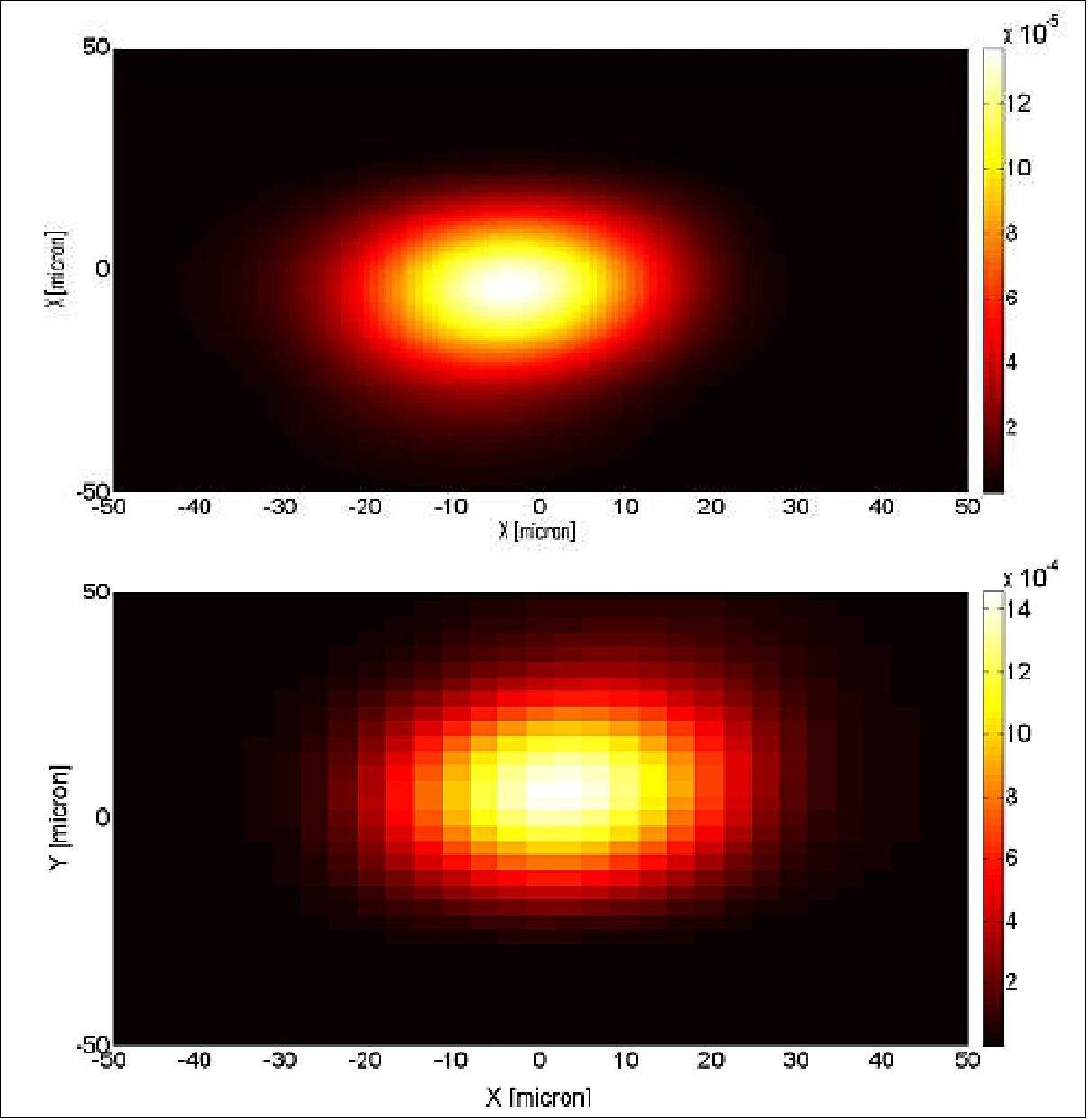

The ICI instrument onboard the MetOp-SG-B series will include several receiver channels that cover part of the millimeter and part of the sub-millimeter wave range, at center frequencies of 183 GHz, 243 GHz, 325 GHz, 448 GHz and 664 GHz. A lot of results have already been obtained up to 325 GHz, as discrete devices can be used in this frequency range without major limitation or performance degradation compared to integrated MMIC devices. At 448 GHz, it is expected that both discrete and integrated mixer devices will give a similar performance. The decision factor might come from repeatability issues during mounting and eventually stress tests. A schematic of a 448 GHz receiver frontend is shown in Figure 13 on the left hand side. It includes a medium power 224 GHz doubler, a 448 GHz sub-harmonic mixer and an IF Low Noise Amplifier (LNA).

Channel No | Frequency (GHz) | Bandwidth (GHz) | Polarization | Utilization | NEΔT (K) |

ICI-1 | 183.31±8.4 | 6 | V |

| 0.6 |

ICI-2 | 183.31±3.4 | 3 | V | 0.7 | |

ICI-3 | 183.31±2.0 | 3 | V | 0.7 | |

ICI-4 | 243.2±2.5 | 6 | V, H | Quasi-window, cloud ice retrieval, cirrus clouds | 0.6 |

ICI-5 | 325.15±9.5 | 6 | V |

| 1.1 |

ICI-6 | 325.15±3.5 | 4.8 | V | 1.2 | |

ICI-7 | 325.15±1.5 | 3.2 | V | 1.4 | |

ICI-8 | 448±7.2 | 6 | V |

| 1.3 |

ICI-9 | 448±3.0 | 4 | V | 1.5 | |

ICI-10 | 448±1.4 | 2.4 | V | 1.9 | |

ICI-11 | 664±4.2 | 10 | V, H | Quasi-window, cirrus clouds, cloud ice water path | 1.5 |

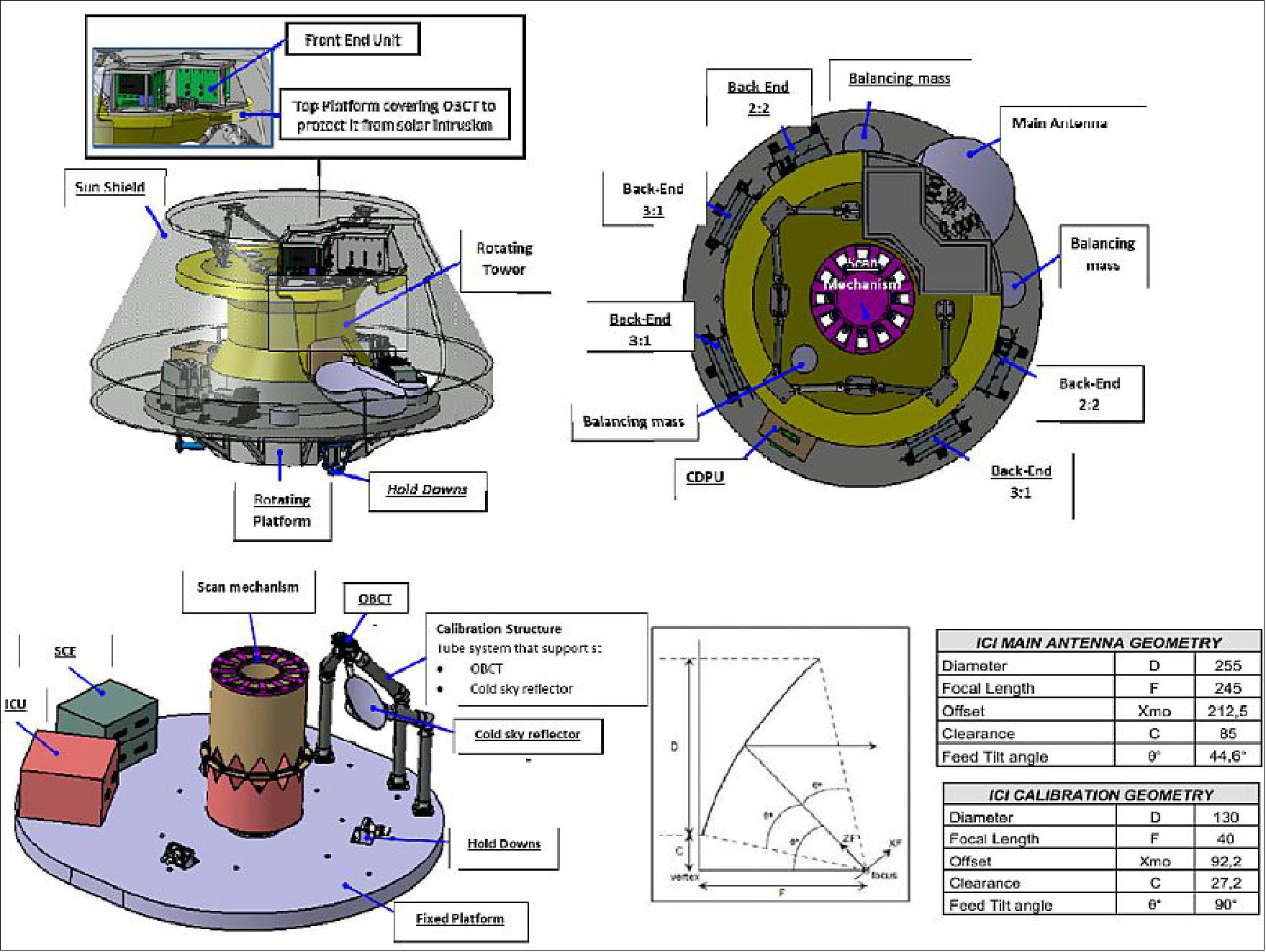

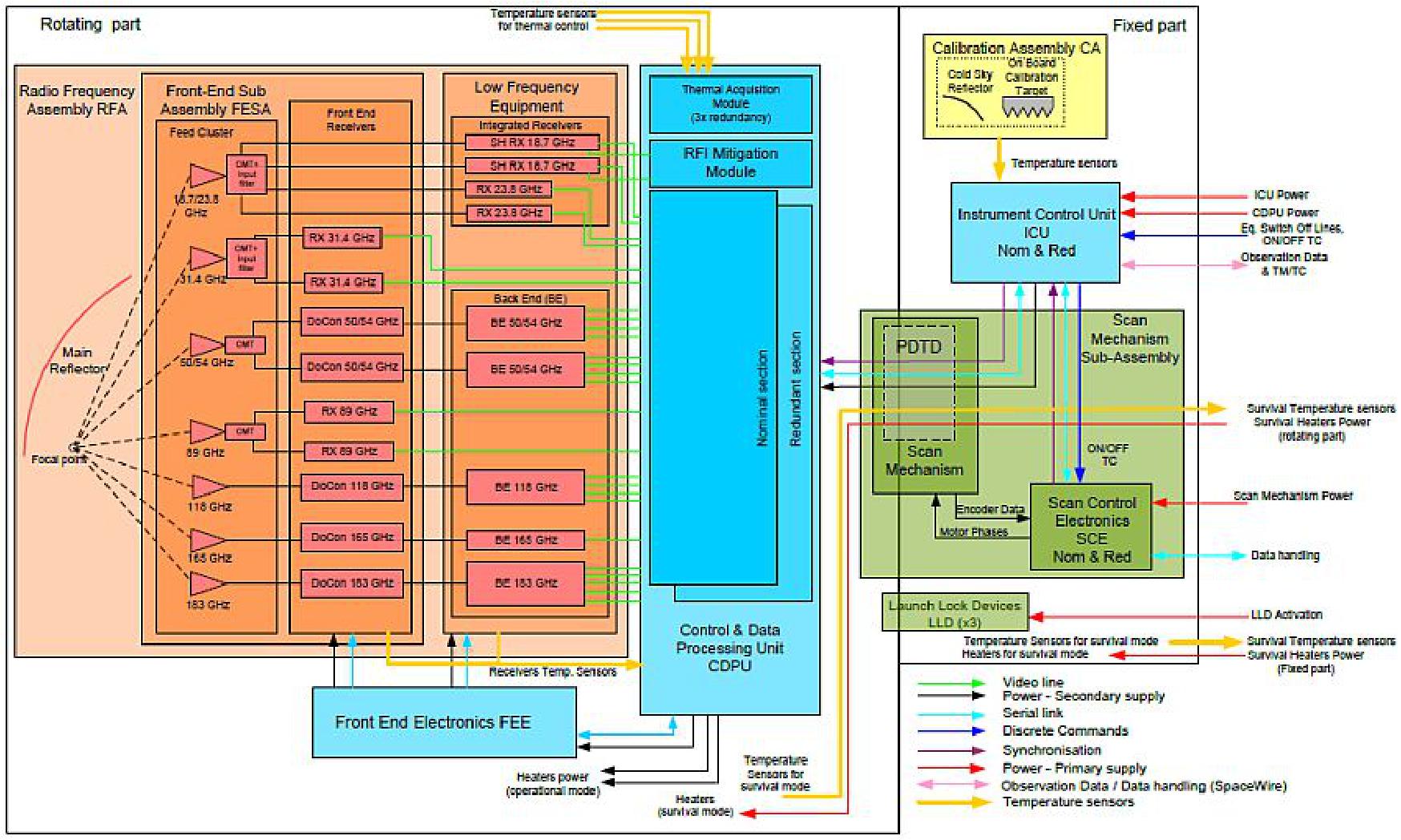

While the rotating part has to be external to the platform, the fixed part can be accommodated either internally or externally to the platform. The advantage of having the fixed part placed inside the platform is the reduction of instrument envelope that makes it easier to manage the ICI payload accommodation.

The moving part is rotated about the axis of the instrument by a coaxially mounted motor and it includes the reflector and feed horns that are mounted on a "drum" which contains the receivers, a digital processing unit and a power supply unit.

Contrary to traditional conical scanners, ICI will be mounted on the nadir side of the spacecraft. The 183 GHz channel selection overlaps with the one of MWI, allowing a cross-calibration between the two instruments.

Scanning technique | Conical: 53.1º zenith angle, swath width of 1700 km; Scan rate: ~ 27 scan/min = ~ 15 km/scan |

Spatial resolution | Consistent with an antenna diameter of ~ 0.5 m, brought to same (15 km) for all channels |

Coverage / Cycle | Global coverage once/day |

Instrument mass, power, data rate | 70 kg, 80 W, 60 kbit/s |

The new (Sub)millimeter-wave Scanner Test Facility at ESA/ESTEC in Noordwijk, the Netherlands, was used for the first time for early testing of prototype feed horns designed for the highest frequency channel of a ‘radiometer’ to scan Earth’s atmosphere for icy cirrus clouds. 34)

These high-altitude clouds play a crucial role in global climate. They reflect radiation from the Sun back into space as well as trapping upwelling radiation from below in a natural greenhouse effect. Which of these two competing mechanisms dominates depends on the altitude, the composition of the clouds and the size and shape of the ice crystals making up the clouds. - As part of the MetOp-SG payload, ICI (Ice Cloud Imager) will continuously observe Earth’s atmosphere in 11 mm and sub-mm channels.

“With our new (Sub)mm-wave Scanner we can easily work with frequencies up to 750 GHz,” explains ESA antenna engineer Elena Saenz. “This test bench, equipped to build up a detailed signal picture in all directions, is the functional equivalent of the full-scale Hertz Hybrid European RF and Antenna Test Zone chamber, big enough to encapsulate entire satellites or large antennas, which operates up to 50 GHz. But there are big challenges associated with extending our operating frequencies upwards in this way. First of all, the extreme electronics performance needed to generate the radio signals, and then to ensure the highly precise alignment of the test, using laser measurement systems. The scanner itself rests on a granite block to isolate it from external vibration.”

MWI (MicroWave Imager)

MWI is a conically scanning total power microwave radiometer (antenna size of ~ 75 cm), an imager which rotates continuously about an axis parallel to the local spacecraft vertical with an active portion of the scan of > ±65º centered on the fore (or afterward) direction of the spacecraft. The antenna system will view an Earth scene with a nearly constant incidence angle ,or OZA (Observation Zenith Angle), of ~53º±2º. 35) 36)

The instrument is providing a total number of 26 channels (including dual polarization channels). The MWI frequency coverage is from 18 GHz up to 183 GHz. Table 6 shows the MWI channels, utilization purpose and NEΔT. All MWI channels up to 89 GHz are measured with both V- and H polarizations. Channels above 89 GHz are measured at V polarization only (Ref. 39).

The main goal of the MWI is to serve operational meteorology, oceanography, sea-ice/snow/land surface observation and climate applications. The MWI will provide continuity of other key microwave imager channels (e.g., SSM/I, TRMM TMI, SSMIS, AMSRE, AMSR-2, GMI) in support of long-term climate records.

Channel No | Frequency (GHz) | Bandwidth MHz) | Utilization | NEΔT (K) | Footprint (km) |

MWI-1 | 18.7 | 200 | Precipitation over sea | 0.7 | 50 |

MWI-2 | 23.8 | 400 | Total column water vapor over sea | 0.6 | |

MWI-3 | 31.4 | 200 | Precipitation over sea and (marginally) land | 0.8 |

|

MWI-4 | 50.3 | 400 |

|

| |

MWI-5 | 52.61 | 400 | |||

MWI-6 | 53.24 | 400 | |||

MWI-7 | 53.75 | 400 | |||

MWI-8 | 89 | 4000 | Precipitation (sea & land) & snowfall | 0.8 |

|

MWI-9 | 118.7503±3.2 | 2 x 500 |

|

| |

MWI-10 | 118.7503±2.1 | 2 x 400 | |||

MWI-11 | 118.7503±1.4 | 2 x 400 | |||

MWI-12 | 118.7503±1.2 | 2 x 400 | |||

MWI-13 | 165.5±0.725 | 2 x 1350 | Quasi-window, water-vapor profile, precipitation over land, snowfall | 1.1 | |

MWI-14 | 183.31±8.4 | 2 x 2000 |

| 1.0 | |

MWI-15 | 183.31±6.1 | 2 x 1500 | 1.1 | ||

MWI-16 | 183.31±4.9 | 2 x 1500 | 1.1 | ||

MWI-17 | 183.31±3.4 | 2 x 1500 | 1.1 | ||

MWI-18 | 183.31±2.0 | 2 x 1500 | 1.2 |

The main objective of the MWI is to measure precipitation. In addition, MWI provides measurements of cloud products, water vapor and temperature profiles and surface imagery. MWI supports NWP (Numerical Weather Prediction) at regional and global scales. MWI has a moderate antenna size providing on-ground footprints ranging from 50 km down to 10 km, depending on frequency. The smallest antenna footprint defines the minimum rotation cycle, and footprint overlap is present also for highest frequencies due to the high rotation rate (45 rpm). This guarantees a good image quality and even Nyquist spatial sampling at the lowest frequency channels.

The relatively small antenna of MWI does not require deployment mechanism and enables a complete sun shield around the instrument to protect from sun-intrusions.

Additional features of MWI include RFI (Radio Frequency Interference) mitigation at the lowest frequency channel and internal calibration targets to complement traditional external targets. RFI mitigation is done by dividing the measured signal spatially, spectrally and temporally and detecting non-Gaussian (man-made) signals and removing them from the data. Internal calibration targets will be implemented at the lowest frequency channels, providing improvement of orbital stability of the instrument.

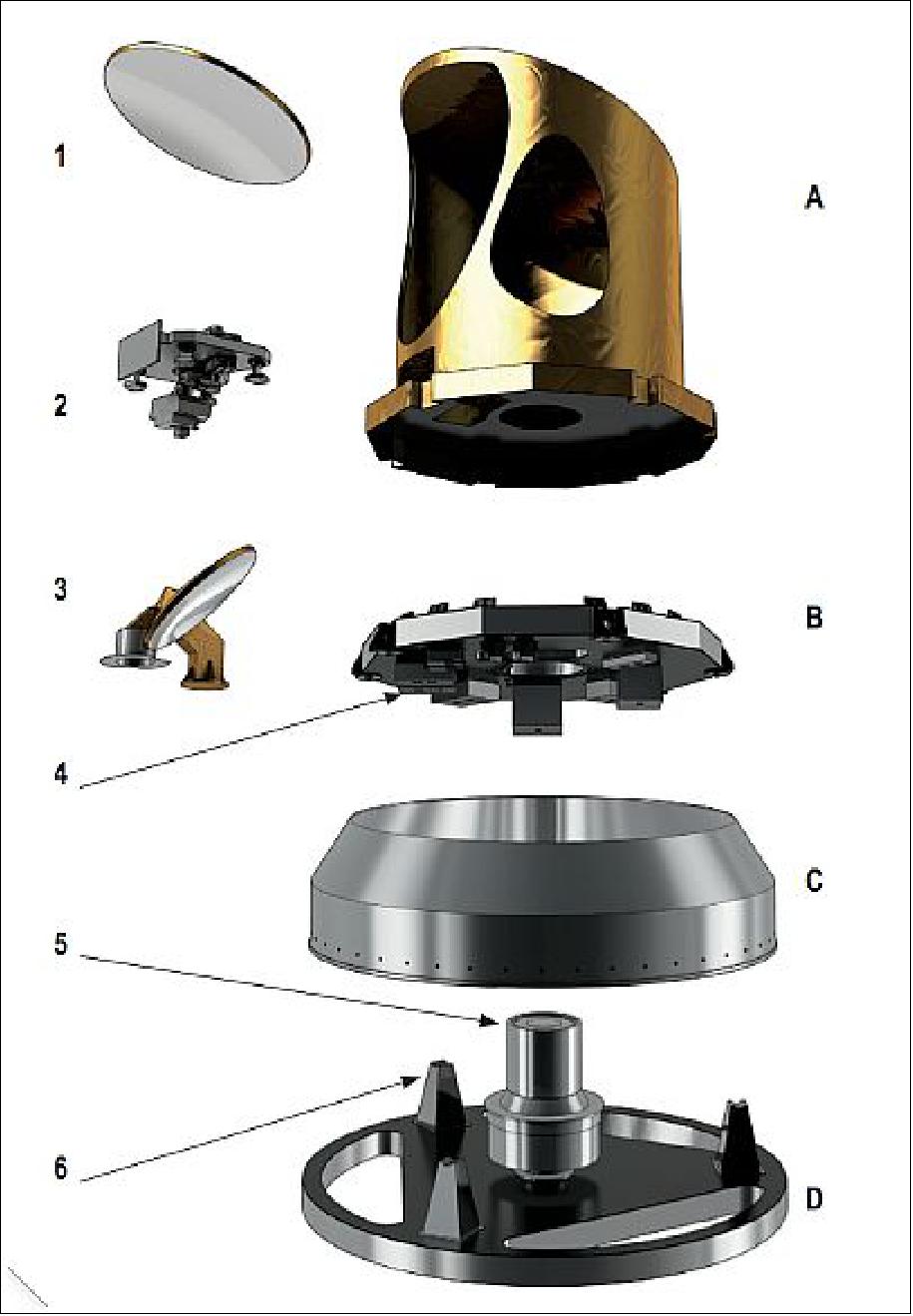

Instrument: The MWI instrument consists of a fixed part and a rotating part. The moving part is rotated about the axis of the instrument by a coaxially mounted motor and it includes the reflector and feed horns that are mounted on a "drum" which contains the receivers, a digital processing unit and a power supply unit.

The scan mechanism assembly provides the rotation of the instrument and acts as mechanical and electrical interface between the fixed and rotating part. All data, commands, timing and telemetry signals, and power, pass through the rotating part to the fixed part via the PSTD (Power and Signal Transfer Device). A DSCE (Dedicated Scan Control Electronics) device is included for the control of the scan mechanism.

The fixed part of the instrument comprises the assembly of scan mechanism (which locates the scan motor, an angular position encoder, mechanical unbalance sensors, various electronics including the control of scan and balance functions), and allocates the units interfacing with the platform (power supply connected to the platform power bus and a control/processing unit which links respectively with the platform command & telemetry bus and the platform science data bus).

A fixed rod through the scan assembly, emerging above the rotating drum upper plane, is providing off axis mechanical support in a fixed position for the two calibration targets that consist of a small reflector and a hot blackbody load, which once per rotation illuminates the feed horns obscuring them from the view of the main reflector.

Legend: A) Tube Structure, B) Rotating Deck, C) Baseplate Cover, D) Baseplate, 1) Main Reflector, 2) Frontend Subassembly, 3) Calibration Assembly, 4) Receiver Backends, Electronics and CDPU, 5) Scan Mechanism, 6) Launch Lock Devices.

To achieve very good radiometric accuracy and stability, the MWI is designed with a sun-shield (tube structure) to minimize sun-intrusion on the instrument units. MWI is calibrated using an internal hot target and a cold sky, which is viewed through a dedicated antenna reflector. The calibration targets, a CCR (Cold sky Calibration Reflector) and the on-board HL (Hot Load),are accommodated in such a way that the CCR is constantly pointing to the deep space on the opposite side of the sun direction. The CCR and the HL calibration devices are viewed once every rotation cycle. A specific baffle is included around the OBCT (On-Board Calibration Target) to eliminate sun intrusion into the target. In addition, 4-point calibration is used for the lowest frequency channels by means of noise diodes.

MWI includes a mixture of direct detection and heterodyne receiver architectures. Low noise amplifiers are foreseen to be used as first element of the receiver. For highest frequency channels (166 GHz and 183 GHz), Schottky-based mixers and multipliers are foreseen. For lower frequencies, several technologies are still possible from discrete components to fully integrated MMIC receiver. For all heterodyne receivers, frontends and backends are separated to optimize the accommodation and thermal dissipation.

MWI provides a robust design as required for an operational instrument. The MWI includes stringent input filtering before the receiver at the lowest channels up to 31 GHz to provide protection against RFI (Radio Frequency Interference). An RFI processor at 18.7 GHz is also included to detect and mitigate interference on-board.

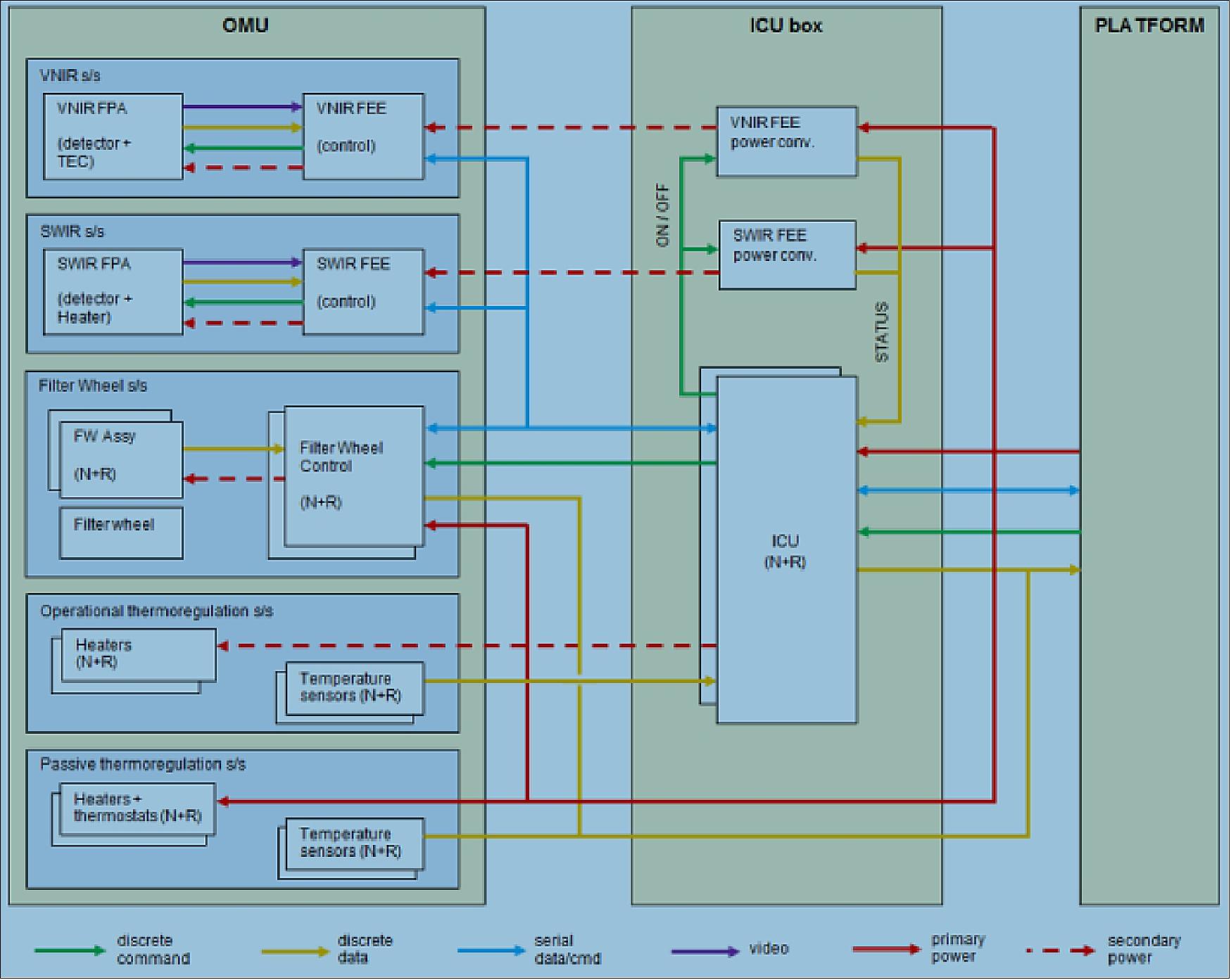

The MWI instrument has high failure detection and recovery autonomy. The ICU will automatically switch ON/OFF subsystems in case of SEEs (Single Event Effects). In case of hardware failures, MWI will have a capability to shut down each channel individually and keep the other channels still operational. The MWI instrument is designed to guarantee very good reliability and availability for the whole lifetime of 7.5 years. For key electronics on both the rotating and fixed part, full redundancy is included.

The structural design and the adopted materials of the rotating assembly shall be such to optimize the stiffness to mass ratio and minimize the in orbit mechanical and thermal distortions.

Technology challenges: To guarantee the performance and reliability of the mission, many technological challenges exist. One of the most critical elements of the MWI instrument is the scan mechanism assembly. The criticality of this element is mainly due to the very high number of revolutions to be performed within the instrument lifetime, which are in the order of 180 million cycles. Other critical functions of this subsystem are the power transfer (in the order of 200 W), the pointing accuracy and the repeatability of the release after launch. Breadboard developments of this critical subsystem are currently ongoing.

On the other hand, the required performances obviously need improvements in semiconductor technologies, which have recently been finished successfully. In addition to performance, the reliability of components is a key factor for the MWI instrument and for the in-orbit nominal lifetime of 7.5 years for the MetOp-SG mission, combined with a maximum of 19 years of in -storage period; these requirements were not seen before. For critical semiconductor technologies (receiver front-ends), reliability testing is already on-going to make sure that the components will be able to withstand the environment. Temperature + DC & RF step stress tests, storage + DC & RF life tests, humidity and environmental tests are being performed to all non-hermetic components.

In the timeframe 2021-2042, the MWI instrument is required to support NWP activities at regional and global scales, by providing high quality operational cloud and precipitation observations, snow and sea-ice coverage as well as gross profiles of water vapor and temperature.

Development Status

• In November 2014, Airbus DS GmbH awarded a contract to CGS (Carlo Gavazzi Space) S.p.A, Milan, Italy for the realization of the MWI instrument of the MetOp Second Generation satellites. CGS is a unit of OHB AG. The MWI is a sophisticated instrument that will be installed on board the MetOp-SG-B satellite series and provide Europe’s National Meteorological Services and, by extension, the international users and Science Community, with unprecedented and high-value data for meteorological and climate monitoring. By signing this contract, which has a total volume of € 134 million, CGS will assume responsibility for the design and the development of the MWI instrument, from Phase B2 to the final in-orbit verification of three flight models, to be supplied to Airbus DS GmbH, the prime contractor of the MetOp-SG-B satellite series. 37)

MWS (Microwave Sounding Mission)

MWS is a total power radiometer with the goal to measure the brightness temperature, at various altitudes, and delivering calibrated and geo-located atmospheric temperature and water-vapor sounding data, in all weather and illumination conditions, this instrument will be a key element in the provision of operational meteorological data over the next two decades. By offering significant improvements in measurement performance over the MetOp First Generation instruments and indeed all microwave sounders currently operating on meteorological satellites, MWS offers a significant upgrade to input data for the operational NWP (Numerical Weather Prediction) service. 38)

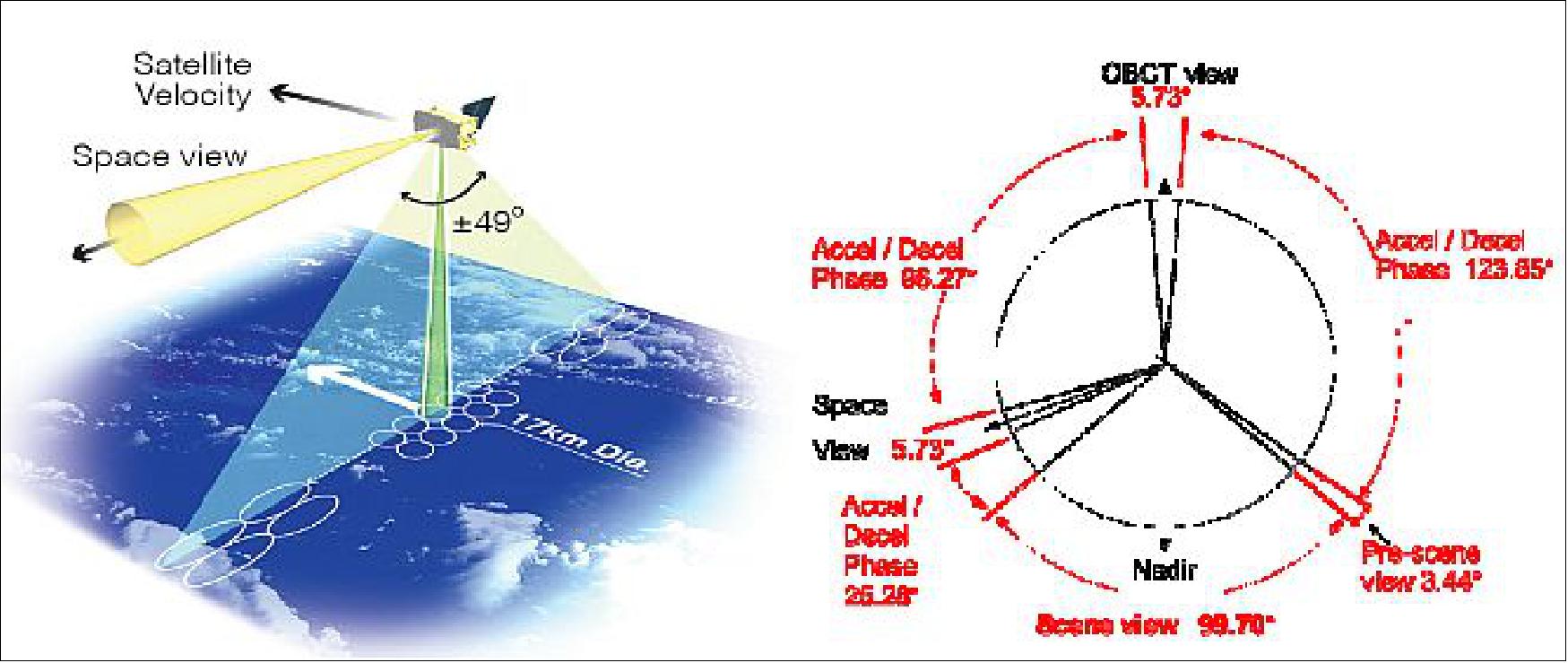

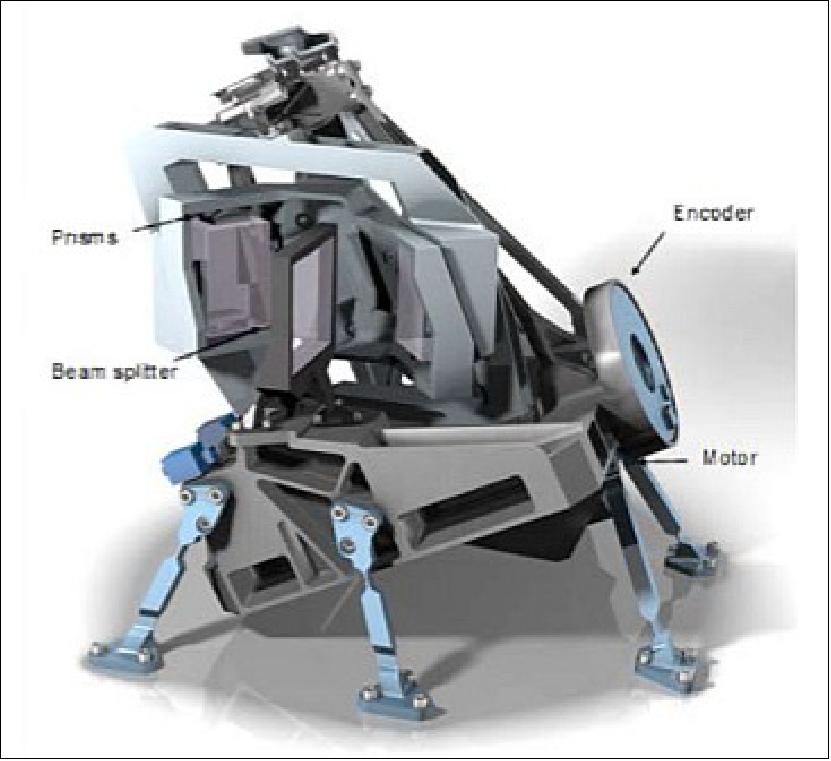

The MWS is an cross-track scanning microwave radiometer, measuring the total power, atmospheric brightness temperature in 24 channels over the frequency range from 23.8 GHz up to 229 GHz. In recognition of the significance of the temperature sounding data, the channels (50 GHz – 58 GHz) are fully redundant. The instrument provides measurements of temperature and humidity (water vapor) profiles and total liquid water columns. These are key parameters for Numerical Weather Microwave soundings, which greatly enhance the ability of the various NMS (National Meteorological Services) to initialize global and regional NWP models with realistic information on temperature and moisture. The frequent availability of detailed temperature and moisture soundings would also contribute to fulfil other key requirements common to NWC (Now Casting) and very short range weather forecasting at regional scales. 39)

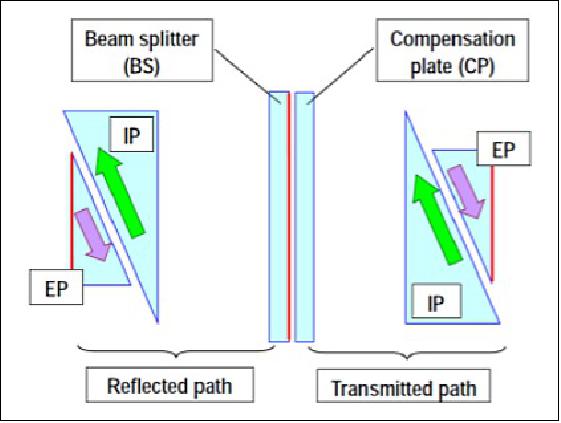

The MWS measurement principle is essentially similar to that of predecessor instruments (e.g. MHS, AMSU), the main difference being the inclusion of the complete range of radiometric frequency channels within a single instrument with a single main antenna. One particular difference is that the two lowest frequency channels (MWS-1 and MWS-2) will be over-sampled with respect to the footprint in the scanning direction, in order to allow the possibility of filtering out RFI (Radio Frequency Interference). The principle mode of operation, as before, uses a scanning antenna. This rotates every 2½ seconds, sampling the atmosphere below (to 49° each side). Each rotation also views a warm OBCT (On-Board Calibration Target) and the cold sky. The antenna rotates at non-uniform speed as shown in Figure 20 in order to maximize the scene and calibration targets integration times.

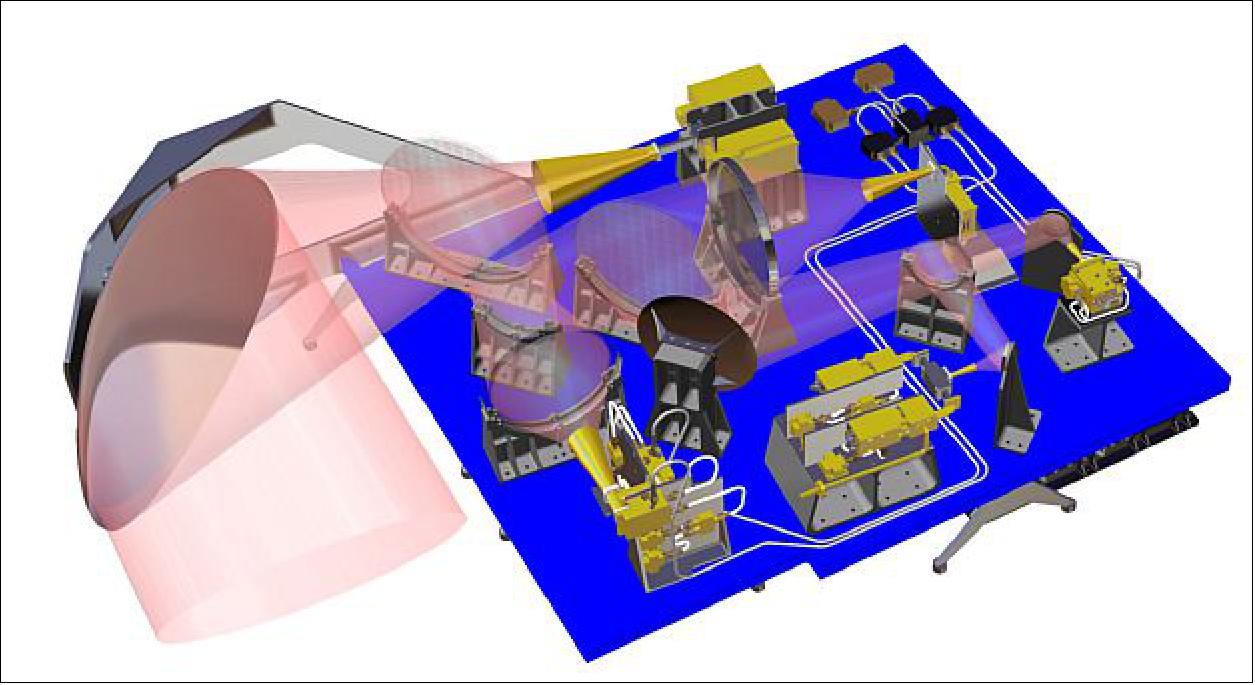

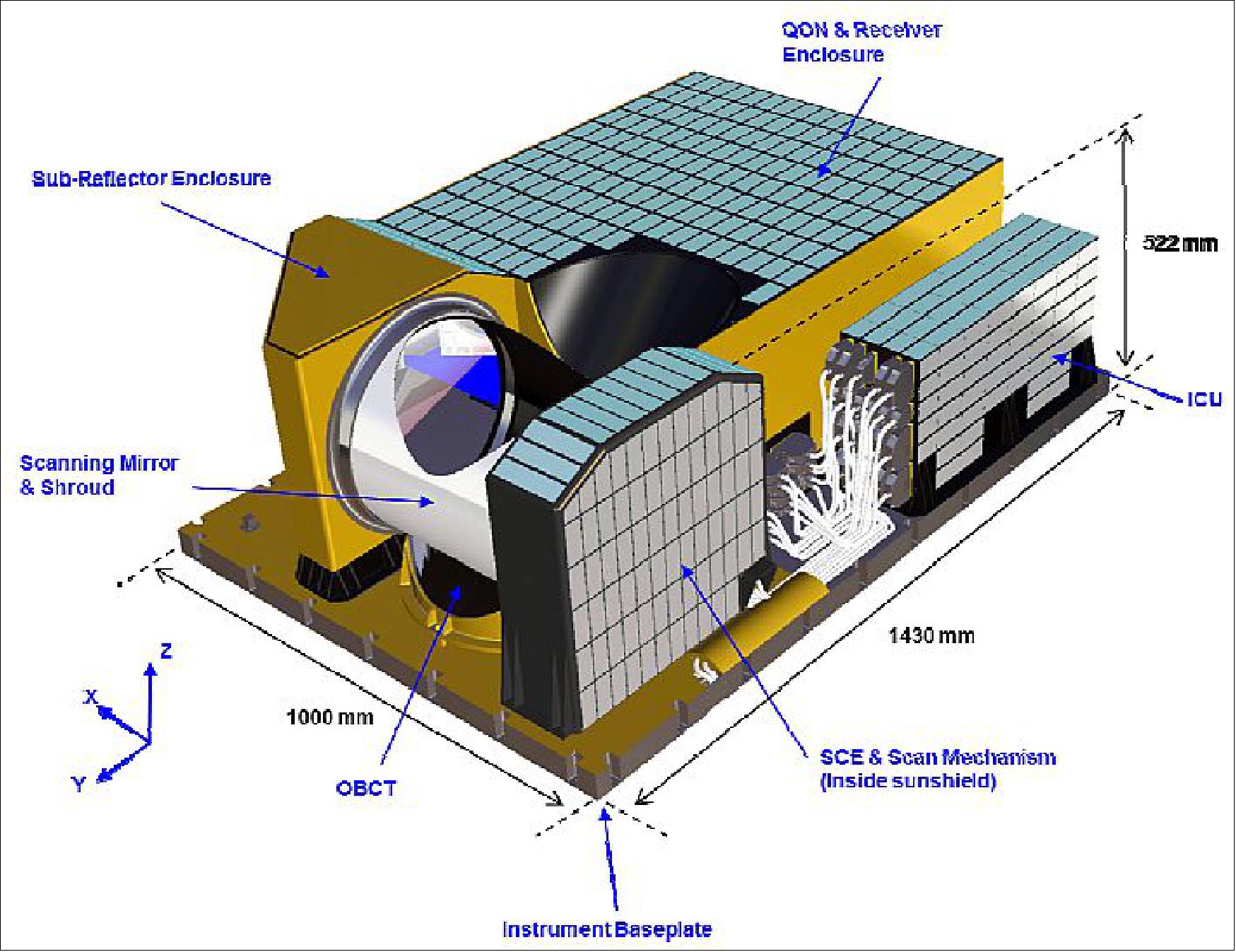

The single antenna concept allows the MWS instrument to remain compact but requires a complex QON (Quasi-Optical Network) capable of splitting the different channels in the instrument. A fixed, parabolic sub-reflector is used to fold the signal into the QON.

All MWS measurements are performed with a single polarization (QV or QH). The instrument will have a 40 km footprint at the lowest frequencies leading to an antenna size of ~35 cm. The footprint at highest frequency channels will be 17 km. The sampling distance on the ground is defined by the highest frequency channels.

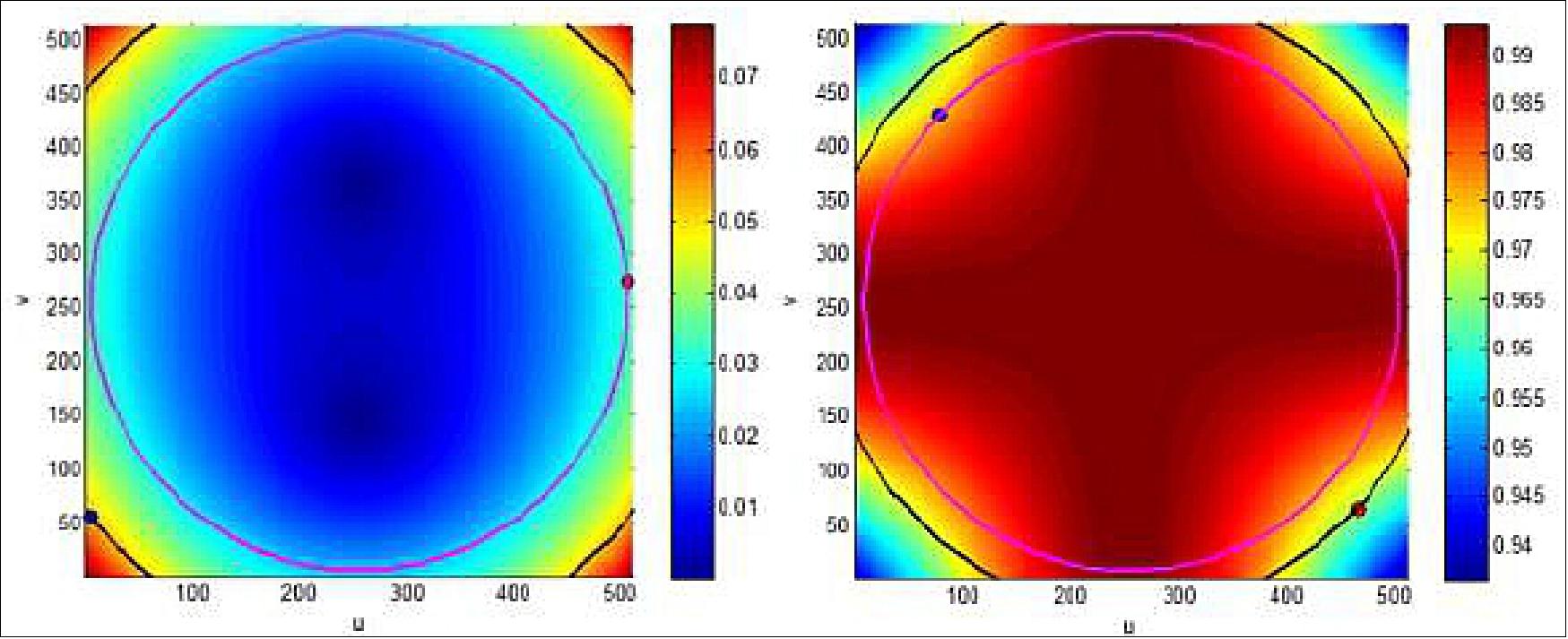

The instrument design is a single unit, single antenna concept. The large frequency range required infers a stringent requirement to the MWS quasi-optical network, which must be able to handle this frequency range. The first electrical demonstrator of the QON has been built and measured losses are typically below 0.3 dB for all channels. Table 7 shows the predicted NEΔT values for each channel in nominal conditions at BOL (Beginning of Life). The predicted radiometric accuracy (RSS) is below 1 K for all channels, the inter-channel accuracy is better than 0.5 K and the inter-pixel accuracy <0.3 K (at 280 K reference scene). An orbital stability of better than 0.2 K is targeted. The beam efficiency is between 95% and 99%, depending on channel.

Channel No | Frequency (GHz) | Utilization | NEΔT (K) |

MWS-1 | 23.8 | Water-vapor column |

|

MWS-2 | 31.4 | Window, water-vapor column | |

MWS-3 | 50.3 | Quasi-window, surface emissivity | |

MWS-4 | 52.8 |

| |

MWS-5 | 53.246±0.08 | ||

MWS-6 | 53.596±0.115 | ||

MWS-7 | 53.948±0.081 | ||

MWS-8 | 54.4 | ||

MWS-9 | 54.94 | ||

MWS-10 | 55.5 | ||

MWS-11 | 57.290344 | 0.35 | |

MWS-12 | 57.290344±0.217 | 0.5 | |

MWS-13 | 57.290344±0.3222±0.048 | 0.5 | |

MWS-14 | 57.290344±0.3222±0.022 | 0.8 | |

MWS-15 | 57.290344±0.3222±0.010 | 1.1 | |

MWS-16 | 57.290344±0.3222±0.0045 | 1.8 | |

MWS-17 | 89 | Window | 0.2 |

MWS-18 | 165.5±0.725 | Quasi-window, water-vapor profile | 0.4 |

MWS-19 | 183.311±7.0 | Water-vapor profile, precipitation | 0.35 |

MWS-20 | 183.311±4.5 |

| 0.35 |

MWS-21 | 183.311±3.0 | 0.5 | |

MWS-22 | 183.311±1.8 | 0.5 | |

MWS-23 | 183.311±1.0 | 0.7 | |

MWS-24 | 229 | Quasi-window, water-vapor profile | 0.5 |

Channel (GHz) | AMSU/MHS | ATMS | MWS |

23.8 | 50 km | 77 km | 40 km |

31.4 | 50 km | 77 km | 40 km |

50-58 | 50 km | 33 km | 20 km |

89 | 50 km/16 km | 33 km | 17 km |

165.5±0.725 | 16 km | 16 km | 17 km |

183 | 16 km | 16 km | 17 km |

229 | Not included | Not included | 17 km |

The QON separates the incoming radiation from the antenna system into 6 separate frequency bands. The signal is split out through the use of dichroics or splitters and transfers the separated frequencies to the RF feed horns coupled to the receiver front ends, specific for the different channels. This is illustrated in Figure 21.

MWS includes a mixture of direct detection and heterodyne receivers, which comprise the front end receiver elements. Those channels not employing direct detection down-convert and amplify the signals, sending them to the backend electronics for further down-conversion and filtering. Finally the analog data is passed to the ICU (Instrument Control Unit) for digitization and downlink.

Key design features of MWS. The instrument has been divided into the following functional blocks:

- RSA (Reflector and Shroud Assembly): The reflector is a scanning flat mirror which collects the microwave energy from the Earth scene and calibration targets and directs it into the QON (Quasi-Optics Network). The shroud limits stray radiation entering the QON.

- SM (Scan Mechanism) and SCE (Scan Control Electronics): The SM rotates the reflector across the scenes and targets at a uniform velocity. The reflector rapidly accelerates and decelerates between the scenes and targets in order to maximize the time spent looking at them. The SCE provides the power and electronics control necessary to achieve the required scan profile.

The SM and the SCE form a single functional block which drives the reflector in the required scan profile under closed loop control, with only a simple start and stop command required from the ICU and its software. This has the advantage that the scan control function can be designed, developed and tested independently of the ICU and its software. On MHS, scan control could not be tested until the Scan Mechanism, ICU and its software were integrated.

- QON (Quasi Optics Network): This consists of a parabolic sub-reflector, a set of dichroic and polarizing mirrors and lenses to direct the radiation from the reflector into 5 separate feed horns.

- Rx FE (Receiver Frontends): This consists of 7 separate receivers for the different frequency groups of MWS. Three channels are direct detection receivers which directly filter the required channel frequencies and provide the detection and video amplification. The remaining four receivers are superheterodyne receivers which perform the down-conversion to generate an IF signal for the receiver backends. One of these receivers covers the 54 GHz channels and is cold redundant.

- Rx BE (Receiver Backends): These provide a total of 21 channel filters, detectors and video amplifiers for the superheterodyne channels.

- SPE (Signal Processing Electronics): This performs the digitization of the 24 receiver video signals. Each channel has programmable gain and offset adjustment to optimize the signal to the ADC dynamic range.

- Packetization: This collects the digitized data from the SPE and formats it into the required packet format for transmission to the spacecraft over a SpaceWire Bus.

- Instrument Control and Monitoring: This accepts telecommands from the spacecraft via the SpaceWire Bus and performs the necessary commanded functions. It collects housekeeping data from the instrument subsystems and transmits them to the spacecraft via the SpaceWire Bus. It also performs monitoring of the instrument health and implements the necessary recovery actions in the event of an anomaly (FDIR).

- Power Conversion and Distribution: This generates the required power rails for the instrument from the spacecraft primary power buses. It also switches and distributes the power to the different functions.

- Mechanical Structure and Harness: This includes the baseplate and support brackets for the instrument equipment. The harness provides the power and signal connections between the various equipment.

- Thermal Control: This provides thermal control in the normal operating modes and in safe mode using heaters and surfaces covered in SSM (Second Surface Mirrors) or MLI (Multilayer Insulation).

The MWS radiometer is designed and developed by Airbus Defence and Space Ltd, Portsmouth, UK, leading a core team of industrial partners: TAS-UK, Airbus DS GmbH and Airbus DS SAS.

SCA (Scatterometer Mission)

The Scatterometer (SCA) is one of the high priority payload instruments to provide vector surface wind observations over ocean, which constitute an important input to the NWP (Numerical Weather Prediction) as well as valuable information for tracking of extreme weather events. The secondary products derived from the scatterometer data are: 40)

- Land surface soil moisture

- Leaf area index

- Snow water equivalent

- Snow cover

- Sea-ice type

- Sea-ice extent.

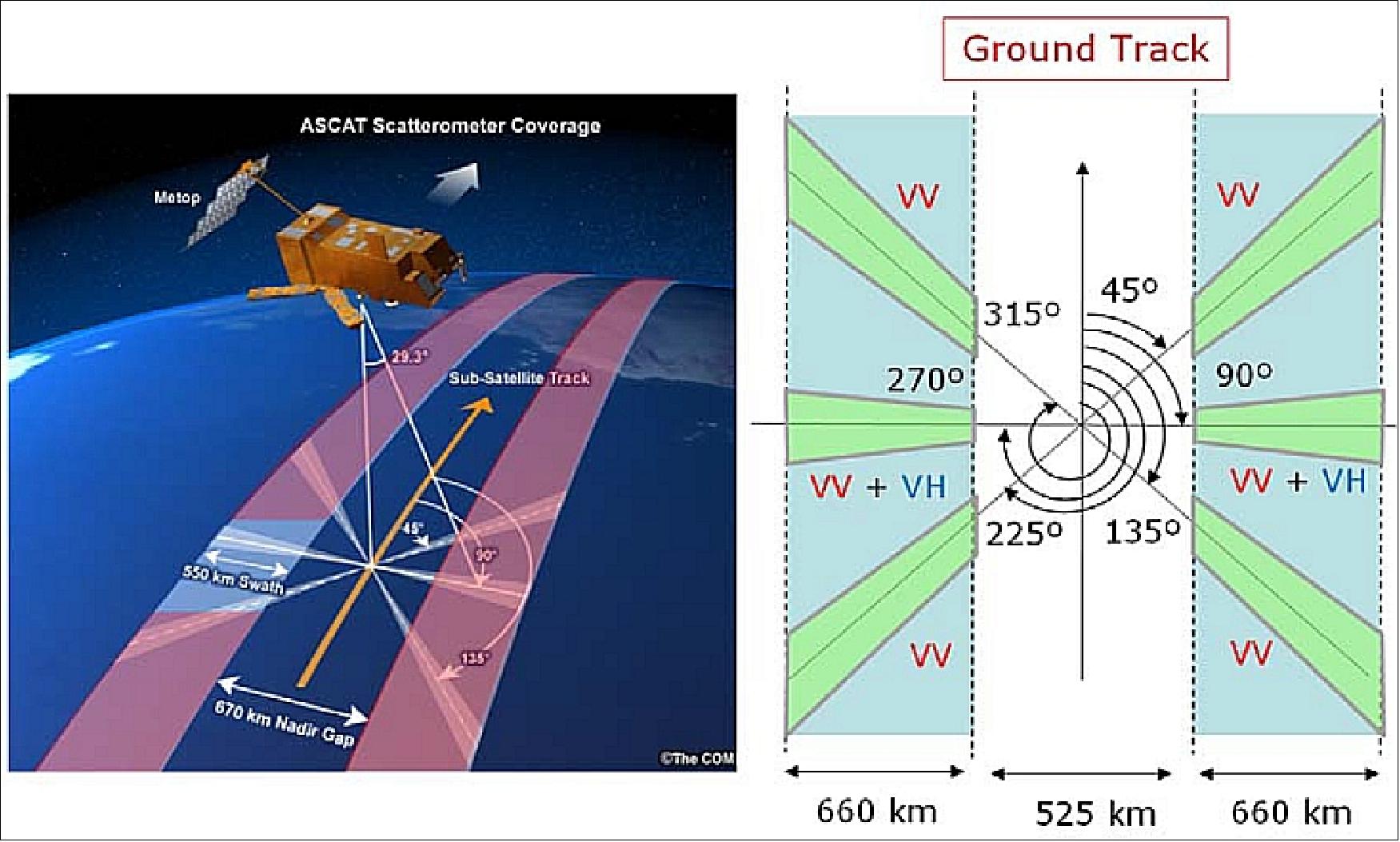

Instrument requirements: The SCA instrument is a real-aperture, pulsed imaging radar with six fixed fan beam-antennas. In this configuration, the principal elevation planes of the SCA antenna beams are oriented at 45º (Fore-left), 90º (Mid-left), 135º (Aft-left), 225º (Aft-right), 270º (Mid-right) and 315º (Fore-right) with respect to the flight direction, similar to MetOp’s ASCAT (Figure 24).

Each of the SCA beams shall acquire a continuous image of the normalized (per-unit-surface) radar backscatter coefficient of the ocean surface, called σο over a swath. Both sides of the subsatellite track are imaged each with three azimuth views, with an unavoidable observation gap below the satellite. A large number of independent looks are summed in range and azimuth (multi-looking), for each azimuth view, in order to achieve the specified radiometric resolution of the σο estimate on each measurement pixel.

The three σο measurements (σο triplet) are uniquely related to the 10 m vector wind through the GMF (Geophysical Model Function. The wind inversion is based on a search for minimum distances between the measured σο triplet and all the backscatter model solutions lying on the GMF surface, taking into account instrumental and geophysical noise sources . Due to measurement noise, multiple solutions are usually found (wind ambiguities), which have to be filtered out using the background wind information provided by a NWP model (ambiguity removal).

As compared to ASCAT, SCA shall have a smaller nadir gap by reducing the minimum incidence angle from 25º (ASCAT) to 20º. The main technical requirements of SCA are reported in Table 9 and compared to the ones of ASCAT. The major improvements to be brought by SCA with respect to ASCAT are the spatial resolution of 25 km x 25 km, the radiometric stability of ≤ 0.1 dB and the addition of VH polarization measurements on the mid beams.

Parameter | ASCAT | MetOp-SG SCA |

Frequency | 5.3 GHz | |

Polarization | VV for all beams | VV for all beams + VH for Mid-beams |

Azimuth views | 45º, 90º and 135º w.r.t. satellite track | |

Minimum incidence angle | 25º | 20º |

Horizontal resolution | Nominal: (50 km)2 | Nominal: (25 km)2 |

Horizontal sampling | Nominal: (25 km)2 | Nominal: (12.5 km)2 |

Radiometric resolution | ≤ 3 % for θi ≤ 25º at 4 m/s cross-wind (VV) | |

Radiometric stability | ≤ 0.2 dB | ≤ 0.1 dB |

Coverage | 97 % in 48 hrs | 99 % in 48 hrs |

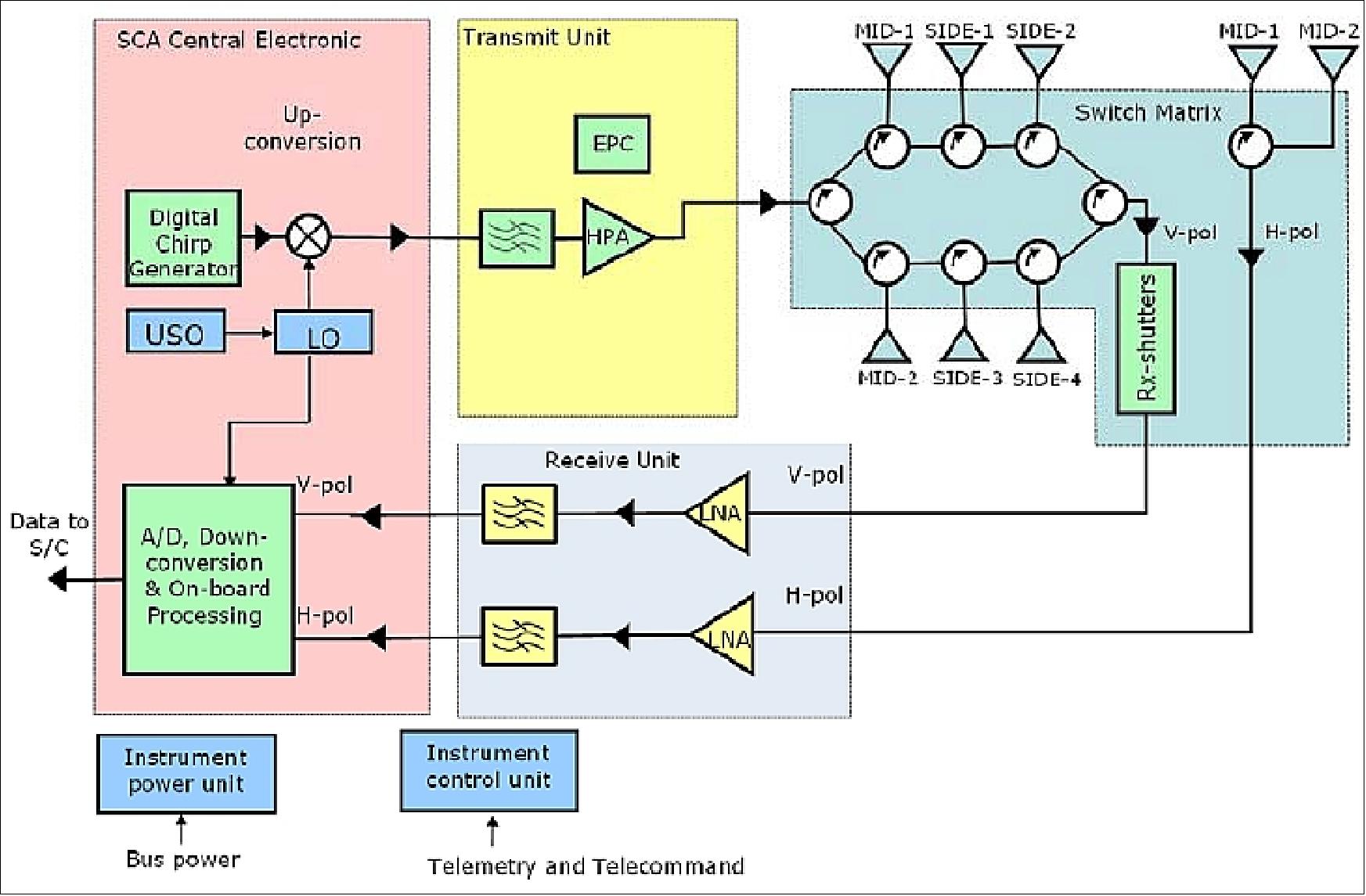

Instrument design: The SCA instrument has 6 antennas, 3 on both sides of the satellite ground-track. All antennas emit in vertical polarization. The 4 side antennas receive only vertically polarized signals, whereas the 2 mid antennas receive both V and H-polarized signals. For the mid antennas, two different concepts are under investigation: simultaneous / non- simultaneous reception of V and H-pol signals. The antennas consist of slotted waveguide arrays, connected through waveguides to the beam-switching matrix. For the Fore-/Aft-antenna assemblies, rotating RF-joints are required for enabling deployment.

The SCA antennas are considered a key component of the instrument, as they have direct impact on performance figures like e.g. radiometric stability. Their stability is therefore considered of utmost importance. The design of the SCA antennas is based on a aluminum support structure and RF elements are also made of aluminum.

A high level SCA block diagram is depicted in Figure 25. The baseband radar pulse is stored in the digital memory read-out and followed by the DAC (Digital-to-Analog Converter). The analog pulse is then up-converted to the carrier frequency by a quadrature mixer. The HPA (High Power Amplifier) is driven by a high voltage EPC (Electronics Power Conditioner). The HPA feeds the six antennas sequentially through the beam-switching matrix. The receive signal is amplified by the LNA (Low Noise Amplifier) and down-converted to the in-phase (I) and quadrature phase (Q) baseband signals. The digitized I and Q baseband signals are downlinked and further processed on ground.

An internal calibration loop measures the transmit pulses at the output of the HPA and that of the beam-switching matrix. The calibration pulses are also injected at the input of the beam-switching matrix and measured at the input of the LNA. Those measurements enable gain characterization of the transmit- and receive-chains, as well as losses of the components in the radar front-end. The necessity of measuring the pulses at the input ports of the antennas is a subject of further analysis in relation to meeting the radiometric stability requirement.

The instrument also measures the thermal noise in the absence of radar echo for determining the background noise level. After the noise estimation on ground, noise subtraction is performed for determining the unbiased ocean surface radar cross-section.

Two possible implementation configurations have been studied for the SCA instrument. These configurations are characterized by the presence of 6 slotted wave guide array antennas. Table 10 summarizes the instrument budgets. The ranges correspond to the budgets of the two concepts.

Mid antenna length | 3.20 m |

Side antenna length | 3.55-4.00 m |

Average power | 370-430 W |

Data rate | 3.2-5.1 Mbit/s |

Mass | 420-500 kg |

The use of a short, chirp-modulated transmit pulse was assumed for the design optimization. The optimization of the pulse length, taking into account the feasibility of the high power amplifier, has been subject of trade-offs in Phase A.

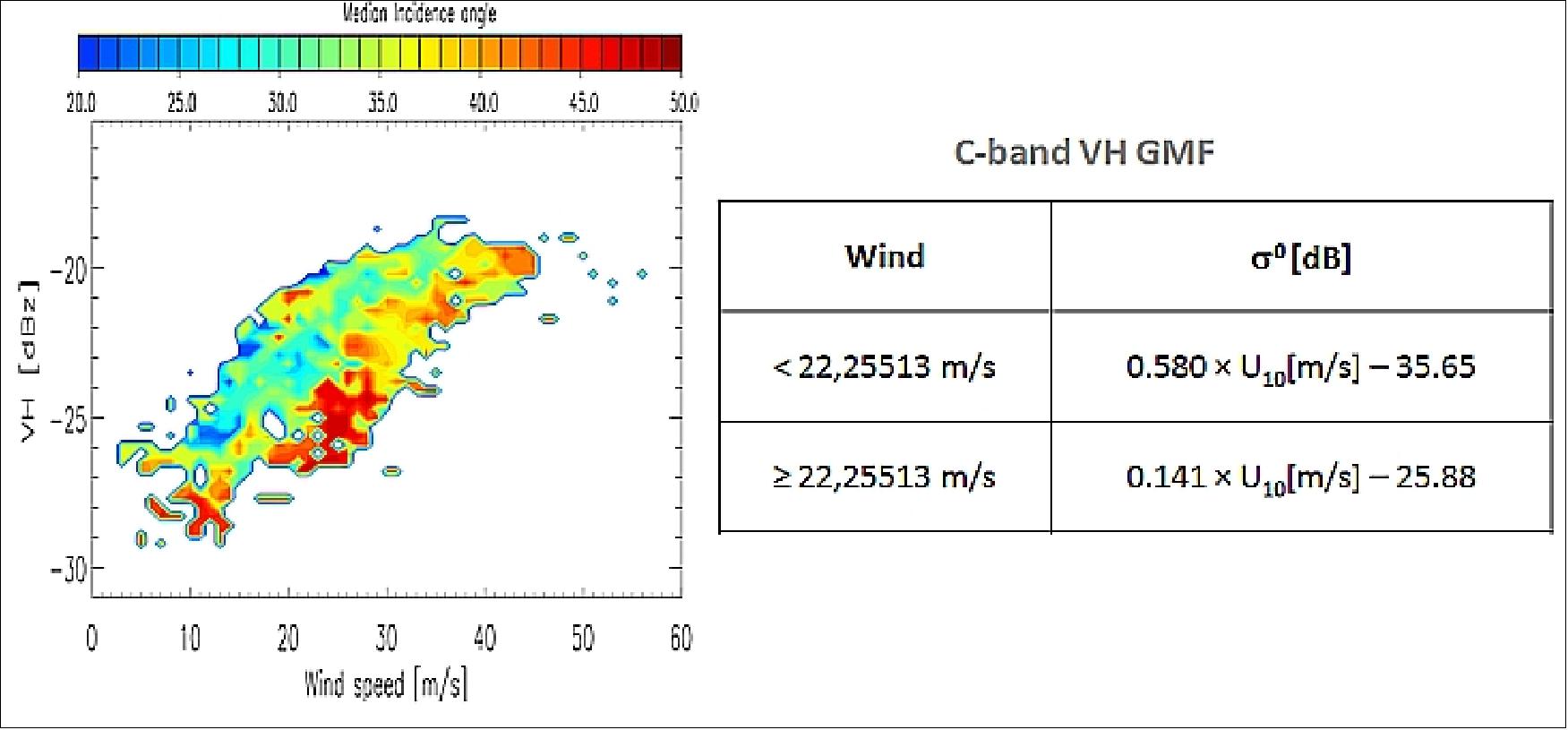

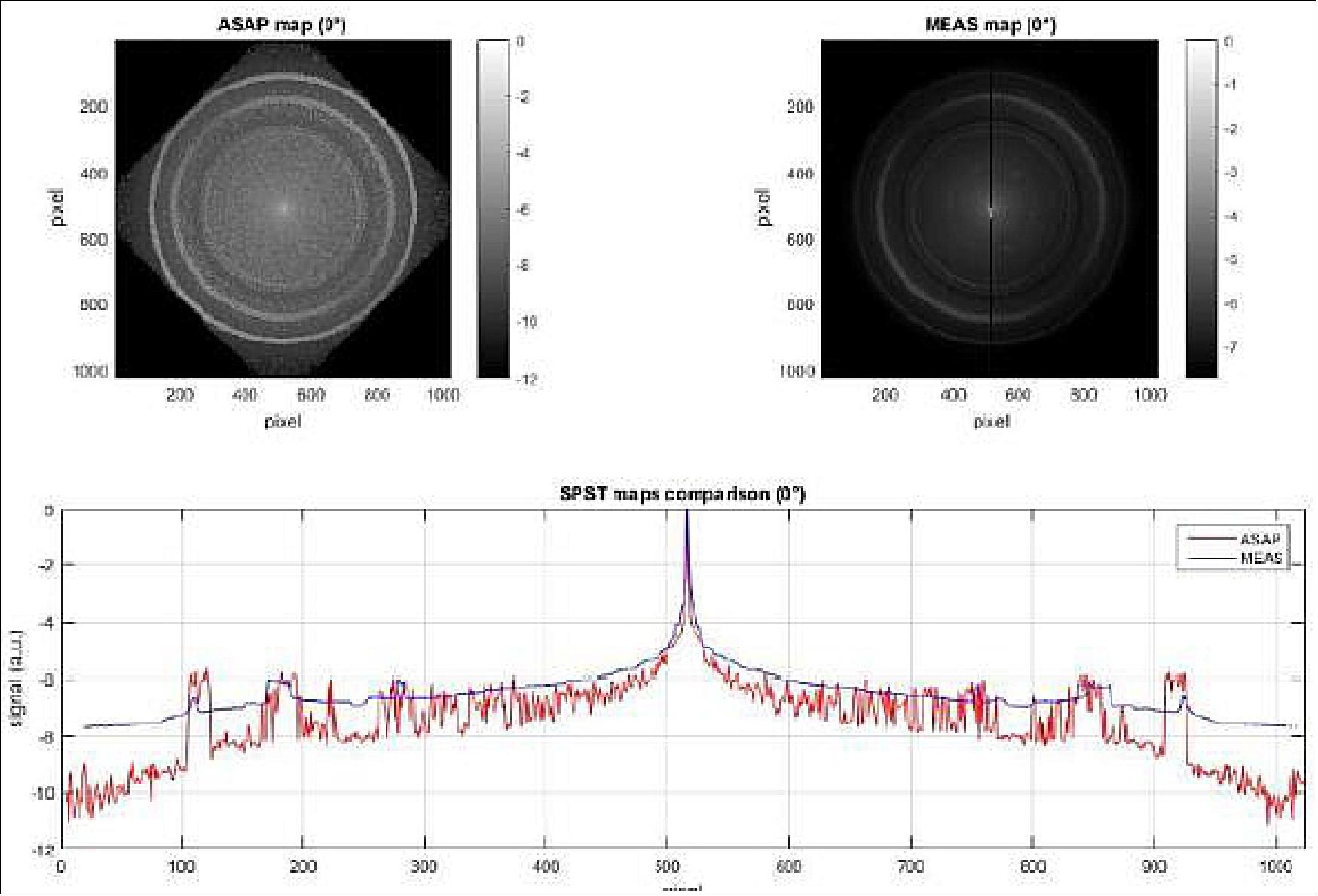

Instrument performance: The GMF (Geophysical Model Function) is an empirically derived function that relates backscatter measurements to surface wind vectors and viewing geometries in the form of σο= GMF (incidence angle, azimuth angle, wind vector). For C-band VV simulations, the project uses the CMOD5 model for ocean backscatter, which is valid for incidence angles ranging from 18 to 58º. For VH simulations, the project uses an empirical model function derived from the last RADARSAT-2 mission and from the NOAA SFMR (Stepped Frequency Microwave Radiometer) flight campaigns in VH polarization over hurricanes. These campaigns confirmed a linear tendency of σοVH with the wind-speed (as depicted in Figure 26) and a low sensitivity to both incidence and azimuth angles.

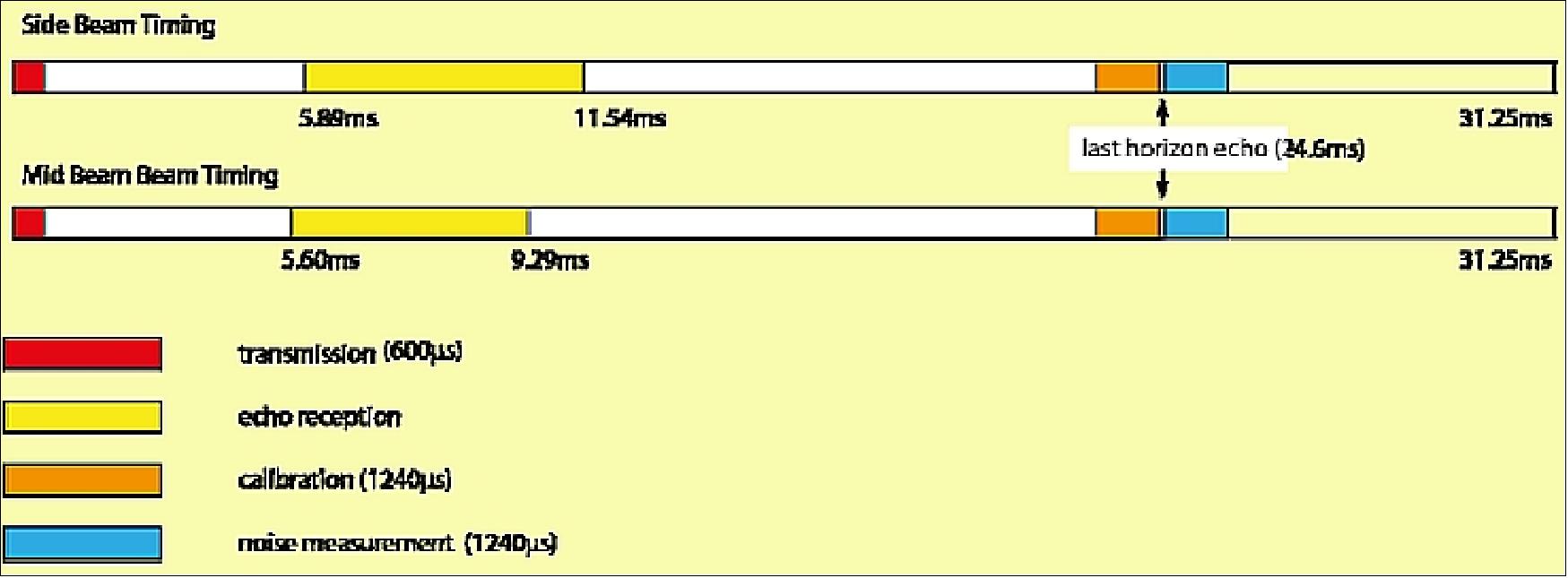

External calibration approach: The SCA timing is based on the use of transmission pulses which are much shorter than those of ASCAT (600 µs against 8.5 ms and 10.8 ms respectively). For sake of clarity, the SCA TX/RX timing is shown in Figure 27. The essential difference is that the transmit pulse length is now shorter than the noise measurement window. Therefore reception of a transponder response can, in principle, be accommodated within the noise measurement window. This window is ideally suited for calibration reception, as it is not contaminated by clutter. If a time delaying transponder is set-up to inject its signal into the noise measurement slot, then a transparent calibration method can be implemented.

For the transparent calibration, it is only necessary that the ground processing is aware of the presence of the transponder echoes within the noise window. Since SCA does not use an on-board processing, it is not necessary that the on-board software is aware of the presence of calibration signals. In the ground processor, the noise data packets containing transponder echoes will be separated from the nominal noise data stream and processed separately. The calibration processing is mostly identical to the ASCAT calibration processing, with the exception that signal demodulation and timing has to be adapted to SCA. Transponder echoes are present in the noise window for about 10 s per over flight. This is a small time interval when compared with 150 s noise integration time employed in the nominal ground processing. Therefore, there is no specific need to compensate for the lost noise measurements.

With the external calibration being transparent to the space segment, it is possible to continuously acquire calibration data and decide when new sets of calibration data need to be injected into the level 1b processor. Explicit calibration campaigns would no longer be needed. In principle, more than one transponder echo (up to three) could be received at the same time, when the transponders are aligned along the direction of an antenna footprint. As it can be seen from Figure 27, the duration of the noise window can easily be extended without impact on the overall timing concept if a larger margin for timing tolerances is desired.

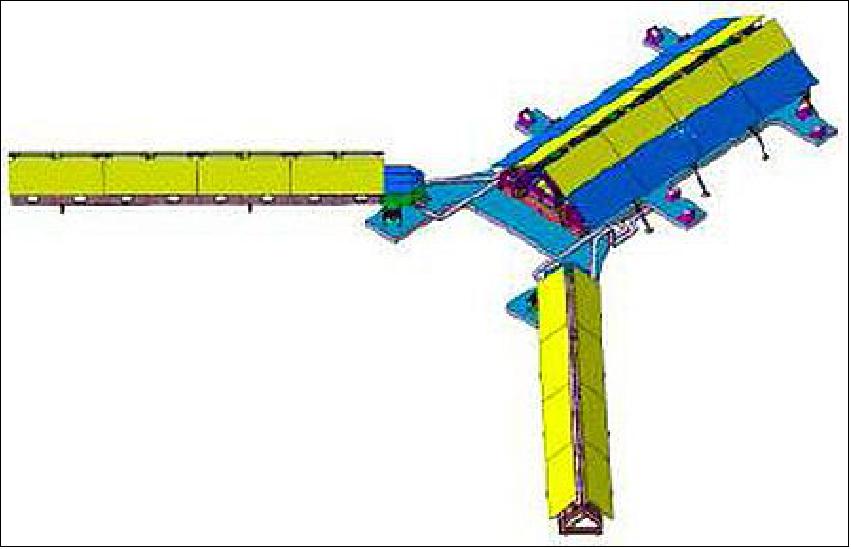

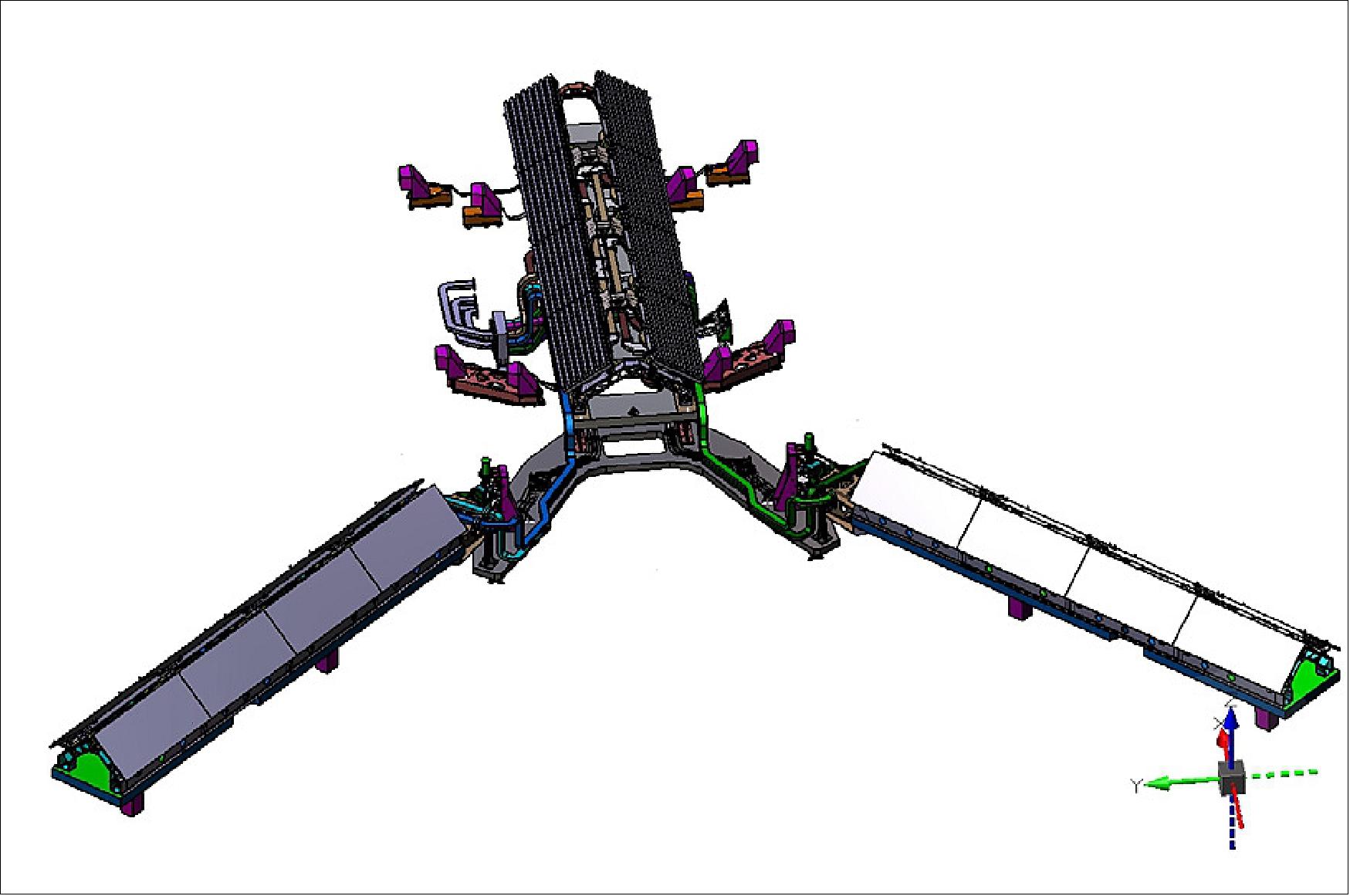

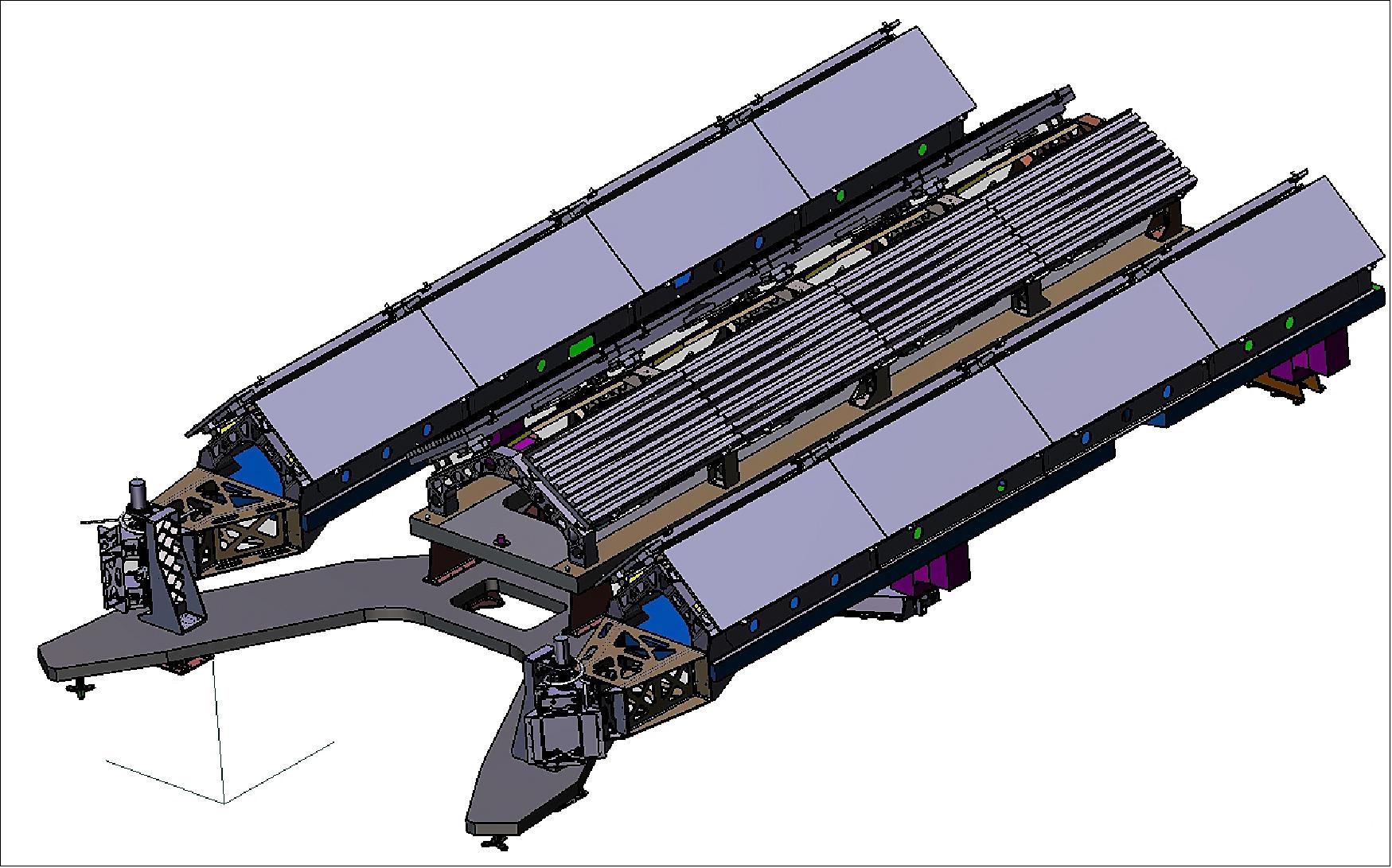

Instrument description: The SCA is a real aperture C-band (5.355 GHz) radar system which is a follow up of the ASCAT system developed in the late 90’s. It is subdivided into the SAS (SCA Antenna Subsystem) and the SES (SCA Electronic Subsystem). The SCA Instrument is being developed by Airbus DS in Germany and in Spain. 41)

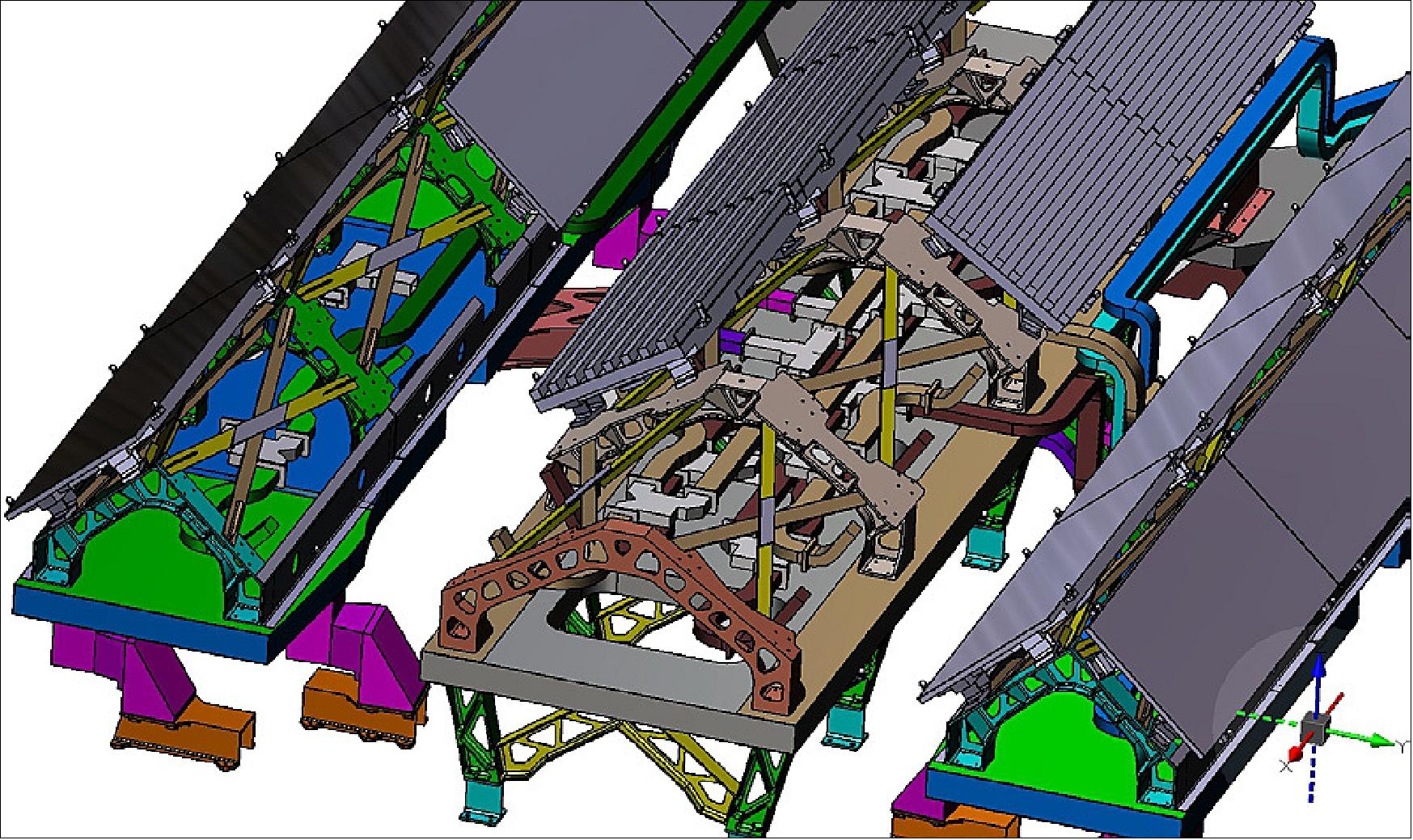

SAS (SCA Antenna Subsystem) is composed of 6 slotted waveguide antennas accommodated on three roof-top shaped antenna assemblies. The antennas comprise 2 dual polarized (H&V) and 4 single polarized (V) antennas, which generate narrow beams with low sidelobes in the azimuth (along track) direction and fan beams in the elevation (across track) direction. Each of the SAS arrays is connected to a switching front-end unit (SFE) which selects the operating antenna according the radar operating principle.

SAS is organized in a lambda configuration distributed on 3 antenna assemblies, called MAA (Mid Antenna Assembly) which holds the Mid left and right dual polarized antennas and Side Antenna Assemblies (SAA+Y and SAA-Y) which hold the Fore and Aft right and left array antennas.

The dimensions of the deployable antenna structure are of about 2m x 3.9m in stowed and 7 m x 6 m in deployed with a total mass of approximately 430 kg.

The main SAS elements are the following:

• MAA (Mid Antenna Assembly), which hosts dual polarized antenna panels and the two deployable Side Antenna Assemblies SAA+Y and SAA-Y that host V-polarized antenna panels.

• HDRMs (Hold Down and Release Mechanisms). The HDRMs are released by NEAs (Non Explosive Actuators).

• DLM (Deployment and Latch Mechanism) that are in charge of the deployment of the two SAA arms after release of the HDRMs.

• The Mechanical Support Structure comprising a U-shaped Baseplate Panel Structure and the Hold Down Release Mechanism Structure.

• The thermal hardware made of SLI (Single Layer Insulation) and MLI (Multi Layer Insulation) covering the exposed areas of the SAS with the objective of providing an adequate thermal environment to the SAS units.

The antenna assemblies, including their deployment and hold down mechanisms, are accommodated on the nadir panel of the MetOp-SG satellite B.

The mechanical structures of the SAS subassemblies (SAAs and MAA) are composed of aluminum brackets parts attached to supporting sandwich structures (each subassembly includes a sandwich panel). They are connected to a common U shaped support panel made of CFRP (Carbon Fiber Reinforced Polymer). Given the size of the SAS antenna and the tight mechanical requirements in terms of mechanical loads, stiffness, mass and frequency response, the design task of these units involves intensive simulation work in order to guarantee that the subassemblies (panels, mechanism) are submitted to mechanical loads compatible with their capabilities.

Thermal performance: The thermal load cases analyzed for SAS are intended to define both the design limits which the equipment has to withstand in orbit, as well as to assess the thermal ranges of each of the units during operation, information which is used to compute the elements deformations due to thermoelastic effects and from this, to derive the impact on the RF behavior.

The following list is a summary of the dimensioning cases:

- Hot/Cold nominal

- Cold Safe – Deployed

- Hot/Cold Stowed (DLM Heaters ON/OFF)

- Launch cases.

Mechanical performance: Given the size and mass of the SAS structure, the dynamic behavior of the SAS is strongly dominated by the design of the interfaces with the satellite. For the Mid Assembly the first fundamental mode is a translation in the longitudinal direction, and for the Side Assemblies the modal response is driven by the stiffness of the structure, the mechanisms (DDM and HD RM) and its distribution along the mounting panel of the spacecraft. Overall, the SAS first fundamental mode in stowed configuration is a torsion along the longitudinal direction of the SAAs at 64 Hz.

In deployed configuration, the main SAS mode is driven by the stiffness of the DLM and the offset of the Side Assemblies masses. The minimum frequency in this case is 2.32 Hz.

Quasi Static Load analysis over 18 cases has been conducted and safety margins have been calculated for each element of the antenna in all static load cases. Sine vibration analysis has been also performed and primary notching levels have been considered to avoid exceeding quasi-static load levels at the SAS interface with the spacecraft. Primary notching takes into account the direct reaction forces in the same direction that the input level. Acoustic coupled analysis has been also performed to derive the mechanical loads to the SAS elements.

With respect to the impact of the structure on the SAS antenna performances, the main input to RF comes from the TED (Thermoelastic Distortion) analysis. TED is performed in deployed SAS configuration and covers the 4min sampled EOL and BOL thermal cases defined by the thermal analysis. In total 150 TED cases have been run.

SAS performance: The SAS performances are driven by the Gain stability requirements for the antenna system. SAS thermal control design and mechanical design are intended to guarantee that thermoelastic effects on the antenna assemblies populated with the radiating panels maintain the antenna gain variation within the 0.1dB requisite.

The RF stability analysis of SAS covers both the TED effects on the radiation patterns, which translates into pointing error and pattern deformation effects, and also on the impact of temperature variations on the RF elements that form the antenna [BFN (Beamforming Network) and radiating panels].

In order to determine these two combined effects, the RF subsystem inputs are the outcomes of the TED and the thermal analysis, presented before. The radiation pattern impact is computed by mapping the TED distortion maps on the array factor of the slotted antenna panels, and from them the pattern effects in terms of antenna gain and sidelobe effects are derived. This process is performed for the 150 EOL/BOL TED cases, for each of the 8 arrays included in SAS.

SAS Development Status

Airbus Defence and Space (Spain) is in charge of the design of the SAS, as well as on the MAIT (Manufacturing Assembly Integration and Test) activities at antenna subsystem level, while the elements that compose the SAS have been submitted to an ITT process through the Best Practices protocol of ESA, which has been recently completed and is now being assigned to the last contractors.

The project development plan includes the design, manufacturing and test of three flight SAS models (PFM, FM2 and FM3) and one STM (Structural and Thermal Model). The STM is the qualification model of the complete thermomechanical subsystem and includes flight representative elements of all the components of the SAS.

In advance to the full SAS model built, each of the SAS subsystems (HDRM, DLM, radiating panels, BFN), has defined their lower tier qualification models and verification strategies in order to guarantee the development of flight model units fully qualified for the environmental boundary conditions defined.

The STM will be the first complete subsystem to be manufactured, integrated and tested for CDR (Critical Design Review). The large dimensions of the SAS involve large test facilities in Europe to perform the test campaign. The selected company in charge of the environmental test campaign is Intespace (Toulouse, France). The flight SAS model will also include the RF test campaign of the antennas.

RO (Radio Occultation sounding mission)

The main objective of the RO mission is to provide measurements of refractivity profiles in the troposphere and the lower stratosphere with a good vertical resolution and high accuracy. Refractivity profiles are then used for retrieving atmospheric temperature and humidity profiles as well information on surface pressure. High quality and global observations of atmospheric temperature and humidity profiles are of great importance for real time assimilation on NWP (Numerical Weather Prediction) and climate monitoring. 42)

A secondary objective of the RO mission is the retrieval of depth of the planetary boundary layer and the height (and structure) of the tropopause. Additionally, ionospheric TEC (Total Electron Content) and electron density profiles can be retrieved.

The RO instrument is equivalently called the GNSS (Global Navigation Satellite System) RO instrument, since it exploits the L-band radio-navigation GNSS signals to extract the required information on the Earth atmosphere.

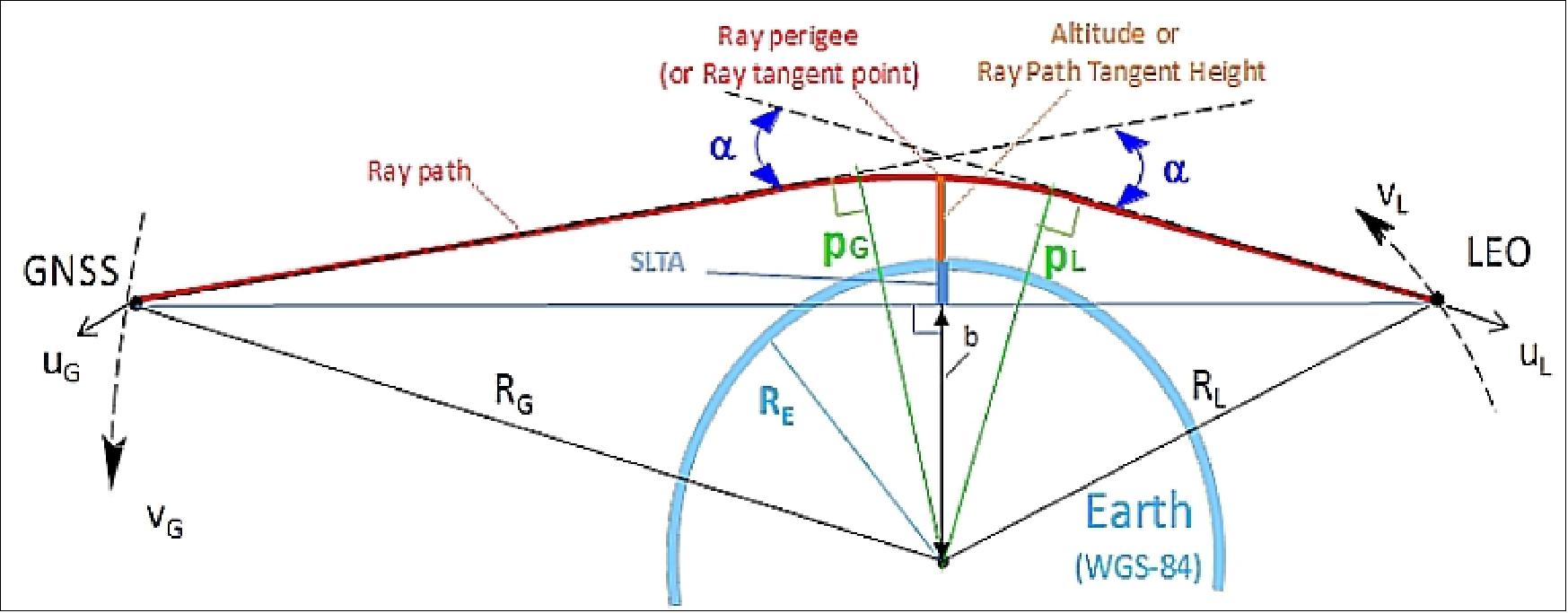

The RO instrument is a passive instrument measuring the time variation of the excess path length of GNSS signals as they are occulted by the atmosphere. As depicted in Figure 31, the excess path length is the path length difference between the straight line path (between the GNSS satellite and the RO sensor, light blue line in Figure 31) and the actual refracted path (red line in Figure 31) travelled by the signal when passing through the atmosphere (the path is refracted/bended due to vertical refractivity gradients of the atmosphere). The excess path length depends on the refractive index of the atmosphere which is a function of pressure, temperature and humidity. On board the RO sensor, the excess path length is simply obtained by measuring the received GNSS signal carrier phase (equivalent to a signal Doppler shift).

Legend to Figure 31: Shown are the bending angle (α) , the GNSS and LEO side impact parameters (pG and pL), the GNSS and LEO coordinate vectors (RG , RL ), the ray path (solid red line), the SLTA (Straight Line Tangent Altitude), Altitude or Ray Path Tangent Height (in orange), and the satellite side asymptotes of the ray path (dashed).

The RO Level 1b product, starting point for the derivation of instrument requirements, is defined as the geolocated, time-tagged neutral bending angle as a function of impact parameter, available for each occultation.

Main RO instrument requirements are listed in the following:

- Number of occultations per SAT: > 1300/day

- Bending angle accuracy: < 0.5 µrad @ 35 km (1σ)

- Minimum SLTA (Straight Line Tangent Altitude): < -300 km

- Carrier and Code Open-Loop in Dual Frequency

- Open-Loop and Closed-Loop parallel processing

- Altitude range: 0-80 km for atmosphere, 80 km- 500 km for ionosphere

- Tracking of GNSS constellations: GPS, Galileo, and optionally GLONASS, BeiDou.

System | Signal | Carrier Frequency (MHz) |

GPS | L1 C/A | 1575.42 |

GPS | L1C | 1575.42 |

GPS | L5 | 1176.45 |

Galileo | E1-B/C | 1575.42 |

Galileo | E5a | 1176.45 |

GLONASS | L1 OC | 1575.42* |

GLONASS | L5 OC | 1176.45* |

Compass-BeiDou | B1 | 1575.42* |

Compass-BeiDou | B2a | 1175.00* |

Instrument description: The RO instrument is mainly composed of 3 antennas (zenith, velocity and anti-velocity antennas), of a central electronics unit, and, if needed, depending on satellite configuration, by external LNA/filtering units for system noise figure minimization. The velocity and anti-velocity antennas are, respectively, looking in the velocity and anti-velocity satellite directions for tracking of rising and setting occultations. The central electronic unit is the core of the instrument. It performs signal filtering, down-conversion, signal processing, storage and instrument control tasks. The electronic unit is able to track new high-rate GPS, Galileo, GLONASS and Beidou signals as well as pilot signals. The signals are tracked by means of classical closed-loops, but also, in parallel, by carrier and code open-loops in order to deal with multipath conditions occurring in the lower troposphere. Tracking parameters such as sampling rate, integration time, loops bandwidth, are configurable anytime during the mission in order to guarantee maximum signal processing flexibility. The instrument operates both at L1 and L5 GNSS center frequencies in order to support the on-ground processing for correction of frequency-dependent ionospheric effects.

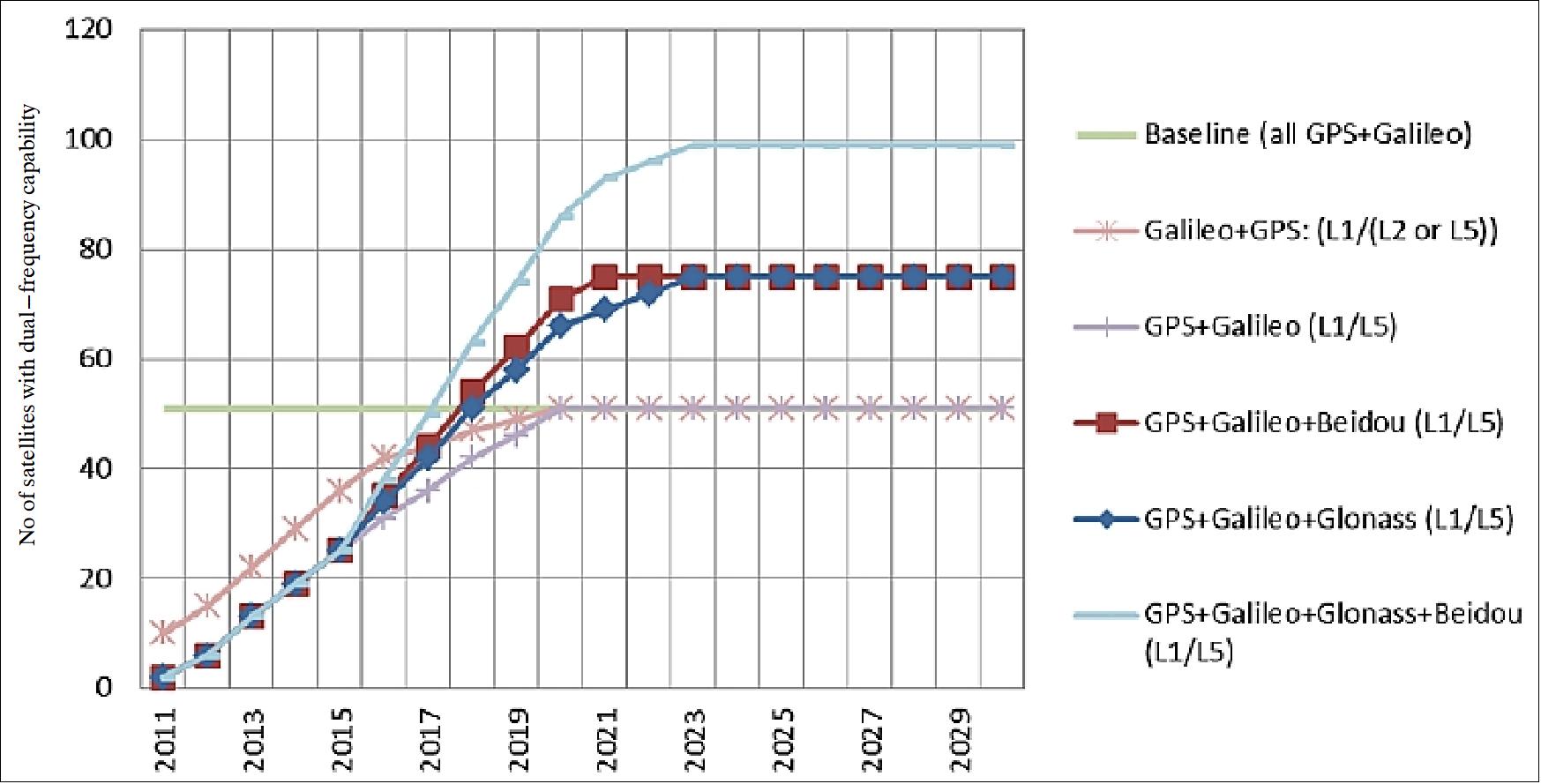

Predicted performance: The upcoming deployment of new GNSS constellations (i.e. Galileo, Beidou-Compass) and the improvement of associated signal characteristics make the MetOp-SG Radio Occultation sounding mission very attractive, considering the success of the current mission on board MetOp.

As an example, the coverage will improve up to three times thanks to the exploitation of Galileo and GLONASS (or Beidou/Compass) systems. With a single satellite it will be possible to achieve more than 1300 occultations per day. - In addition, the characteristics of novel signals such as the pilot signals, will guarantee higher quality observations on the lower troposphere regions. Novel design of open-loop acquisition schemes will also improve the quality and robustness of observations on the low troposphere. Other improvements come from the use of dual frequency channels with wide separation (i.e. L1 and L5), leading to better correction of the ionosphere.

Figure 32 shows the expected evolution of GNSS systems deployment, according to latest available public information.

All these features will be such that the radio occultation instrument will almost double the bending angle accuracy performance with respect first generation and will provide up to three times better Earth spatial-temporal sampling.

Parameter | MetOp GRAS | MetOp-SG |

Bending angle accuracy | <0.8 μrad @ 35km | <0.5 μrad @ 35 km |

Number of observations per satellite | ~ 650 occultations/day | ~ 1300 occultations/day (GPS, Gal) |

GNSS constellations | GPS only | GPS, Galileo, GLONASS, Compass |

Closed Loop | Yes, @ L1 and L2 | Yes, @ L1 and L5 |

Open Loop for low altitude tracking | Open Loop @ L1, | Open Loop @ L1 and L5, |

Use of pilot signals | No | Yes, yields to better performance in closed loop |

Minimum SLTA | -140 km, extendible | -300 km |

3MI (Multi-viewing, Multi-channel, Multi-polarization Imaging mission)

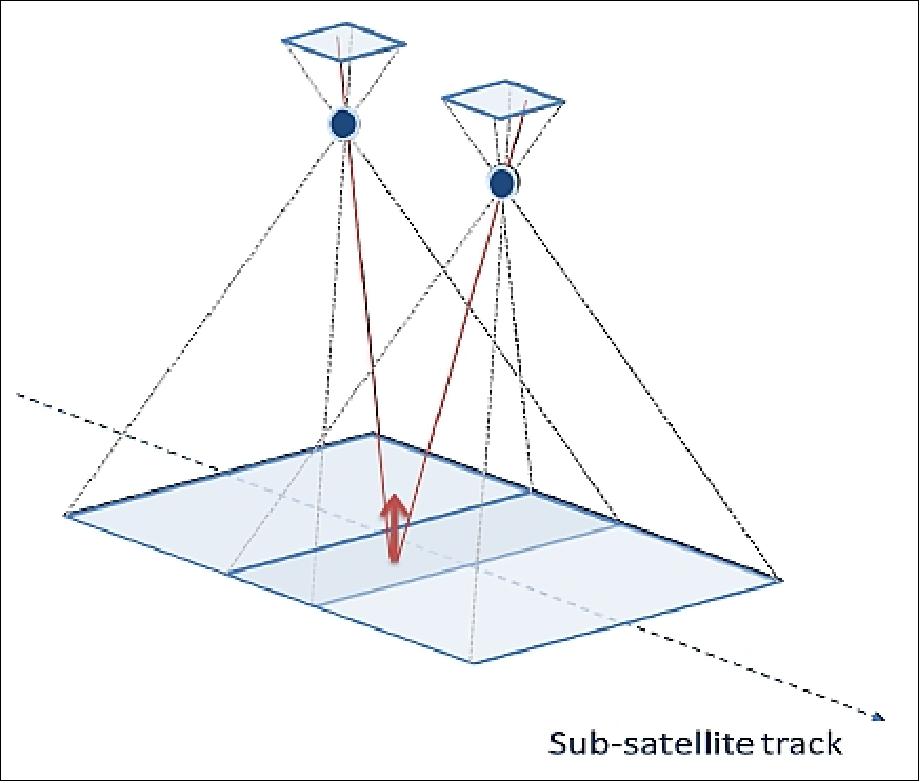

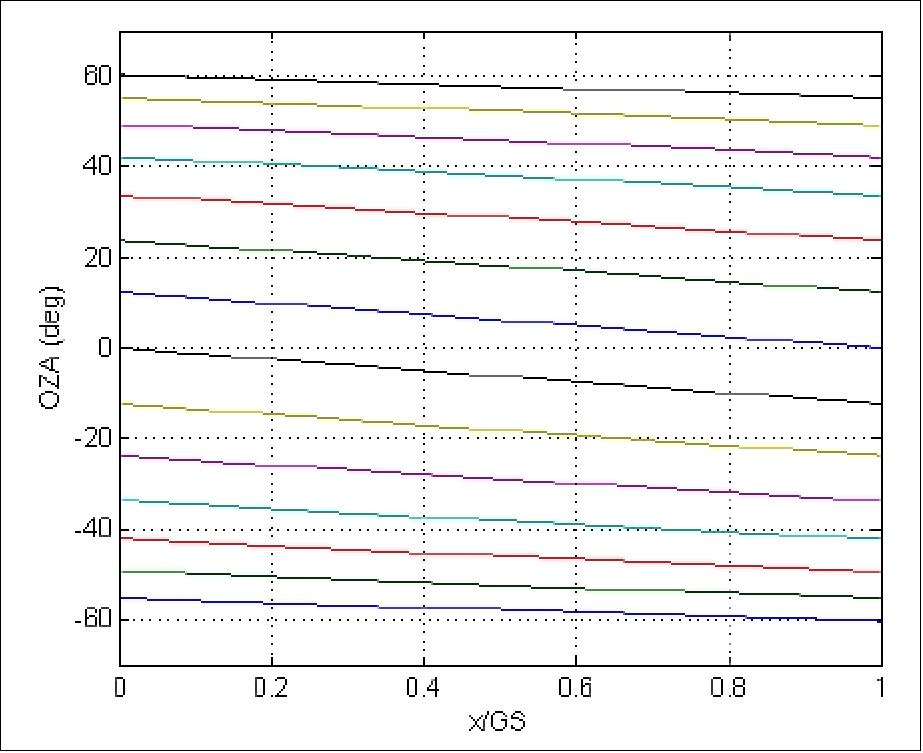

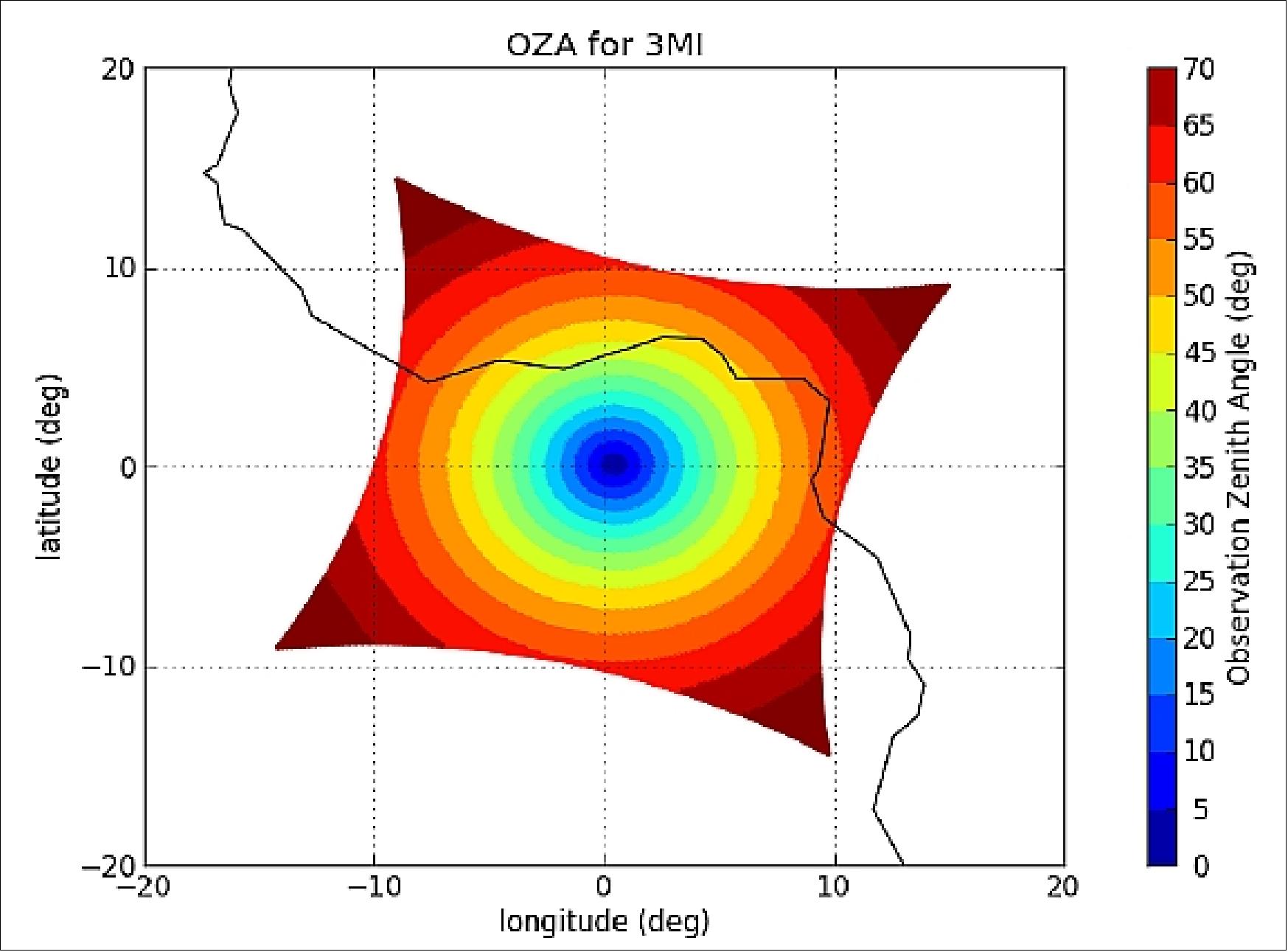

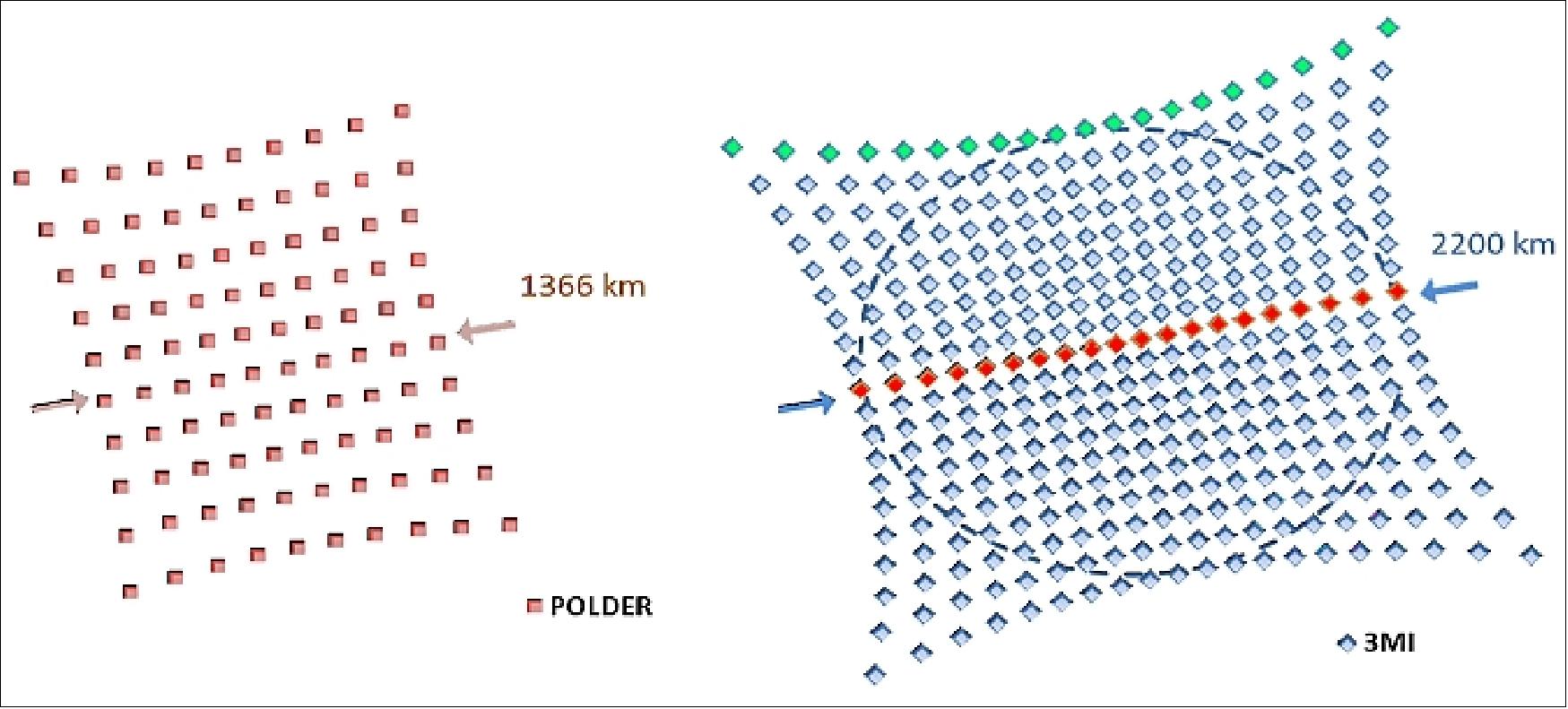

The primary 3MI mission objective is to provide aerosol characterization for climate monitoring, NWP (Numerical Weather Prediction), atmospheric chemistry and air quality. High quality aerosol imagery ,delivered by the 3MI mission, will facilitate the measurement of all essential aerosol parameters for climate records, such as aerosol optical depths, particle types and sizes, refractive index, sphericity and height index. When used as constrains to the models, these products will be used to provide improved AQI (Air Quality Index) and Aerosol Load Masses for different particles sizes (Ref. 26). 43) 44)

The measurement of surface albedo as well as improved cloud characterization are 3MI mission’s secondary objectives. The first will be facilitated via the observation of the surface BRDF (Bidirectional Reflectance and Distribution Function), made possible by the unique multi-angular measurement concept adopted. Similarly, while METimage will provide information on most cloud properties, the multi-viewing and multi-polarization measurements delivered by the 3MI mission will allow for accurate characterization of the extension, optical depth, particle size as well as asphericity factor and crystal orientation of cirrus clouds.

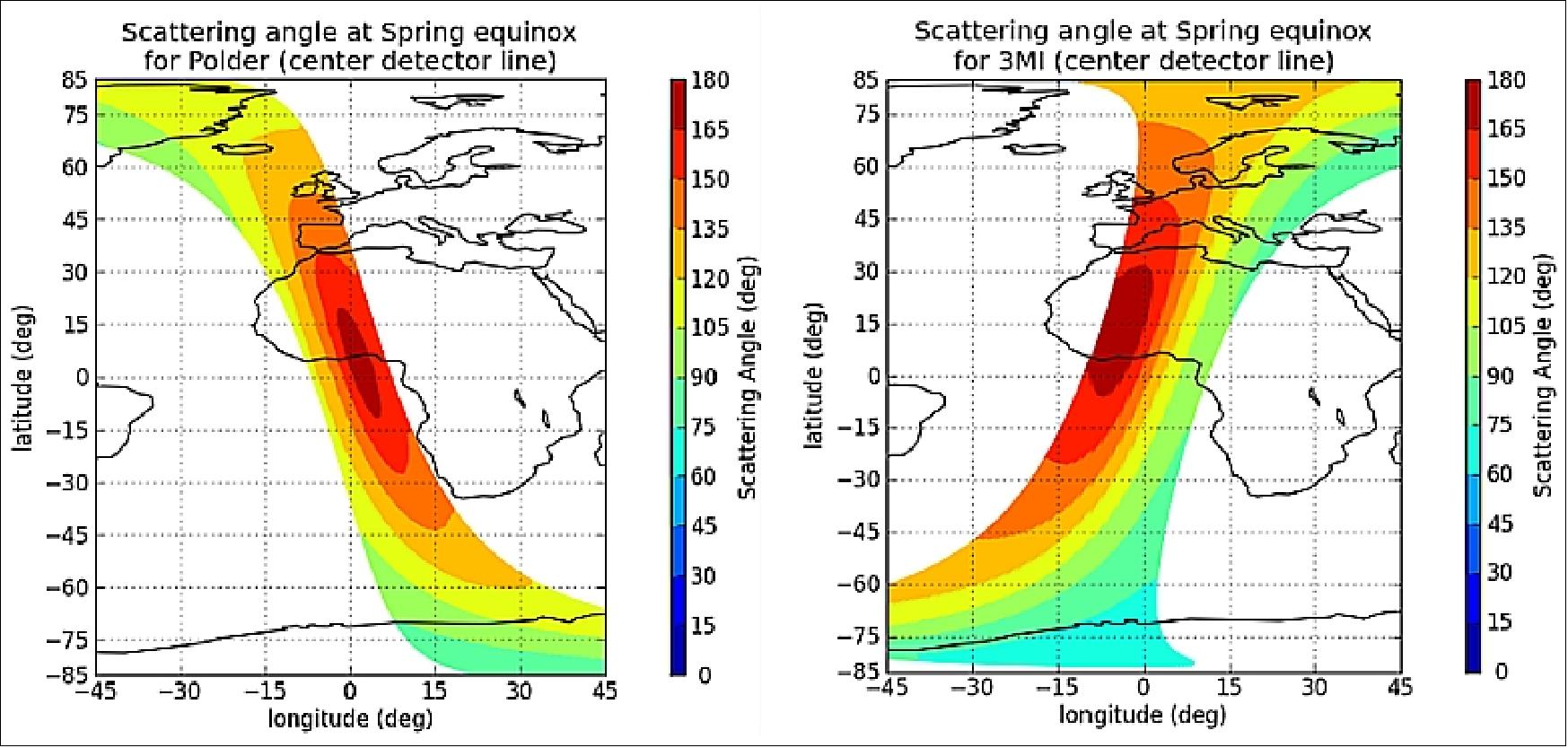

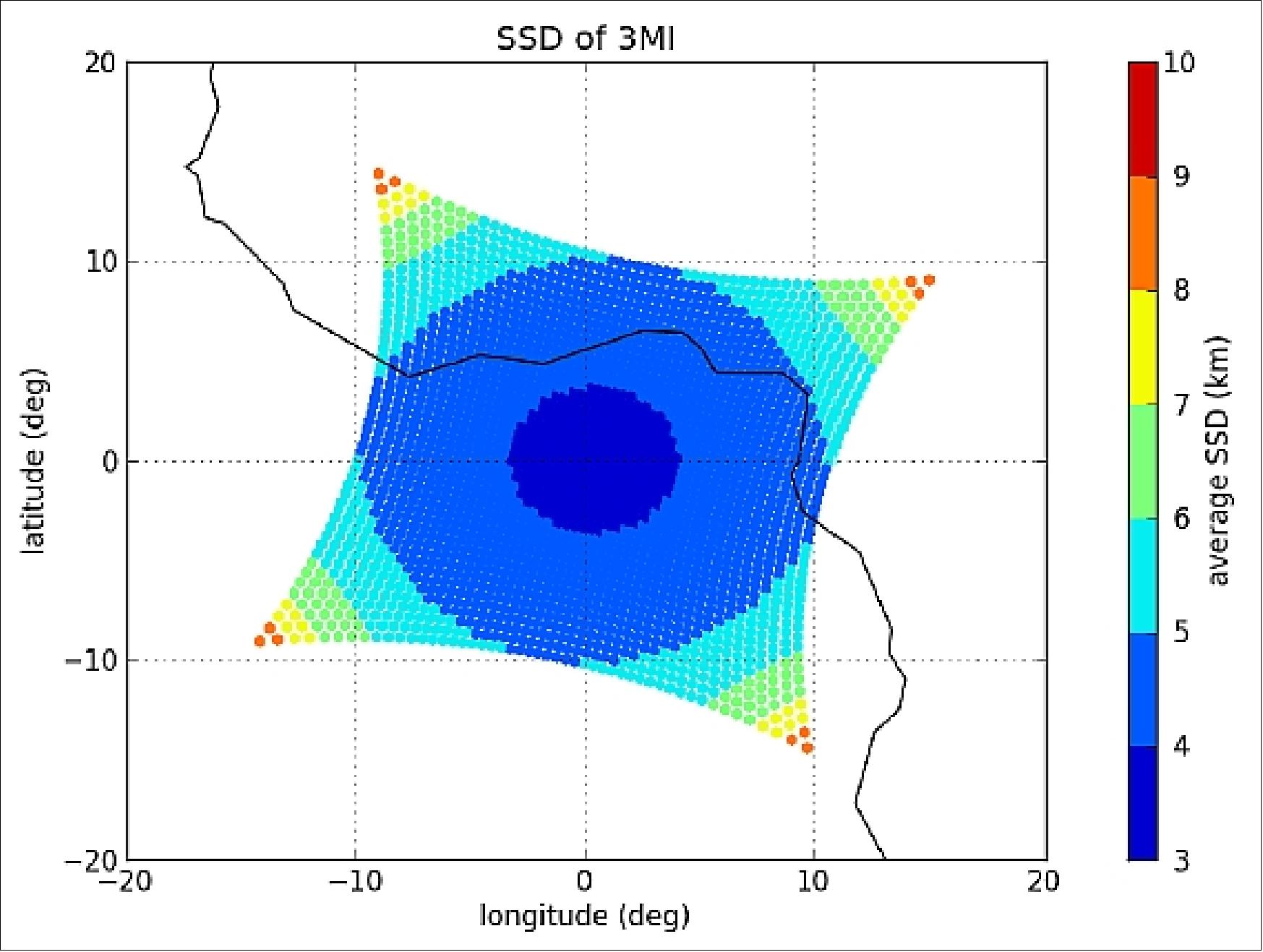

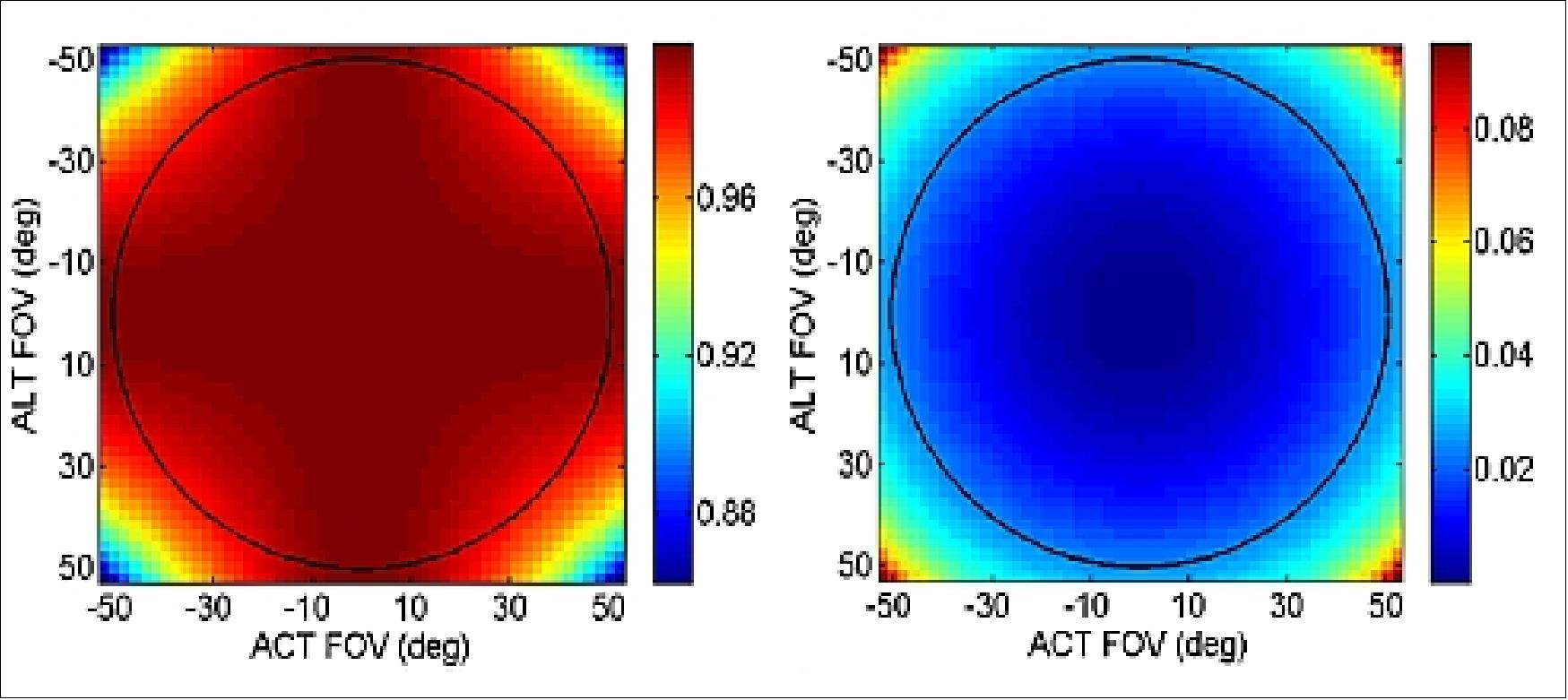

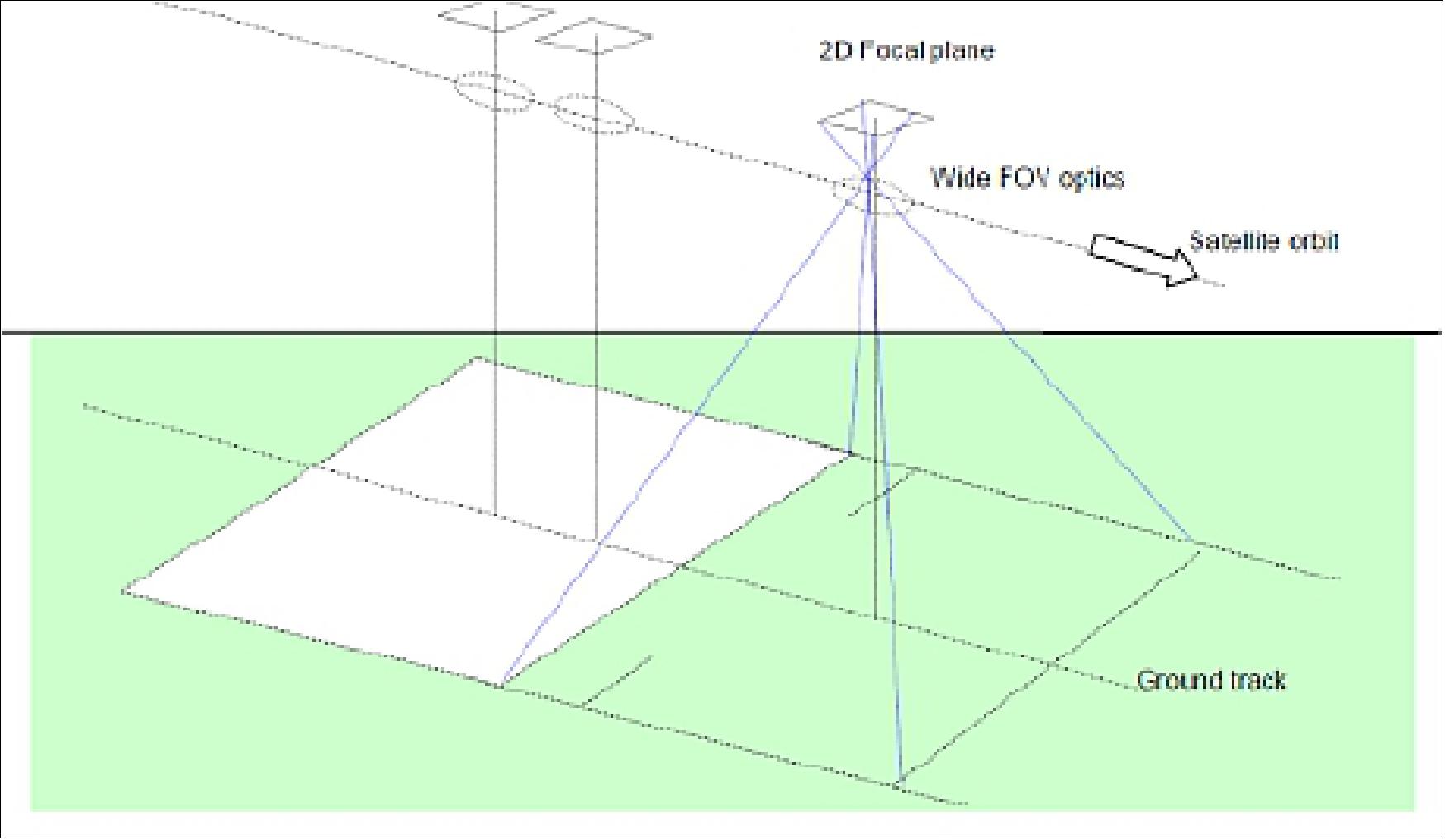

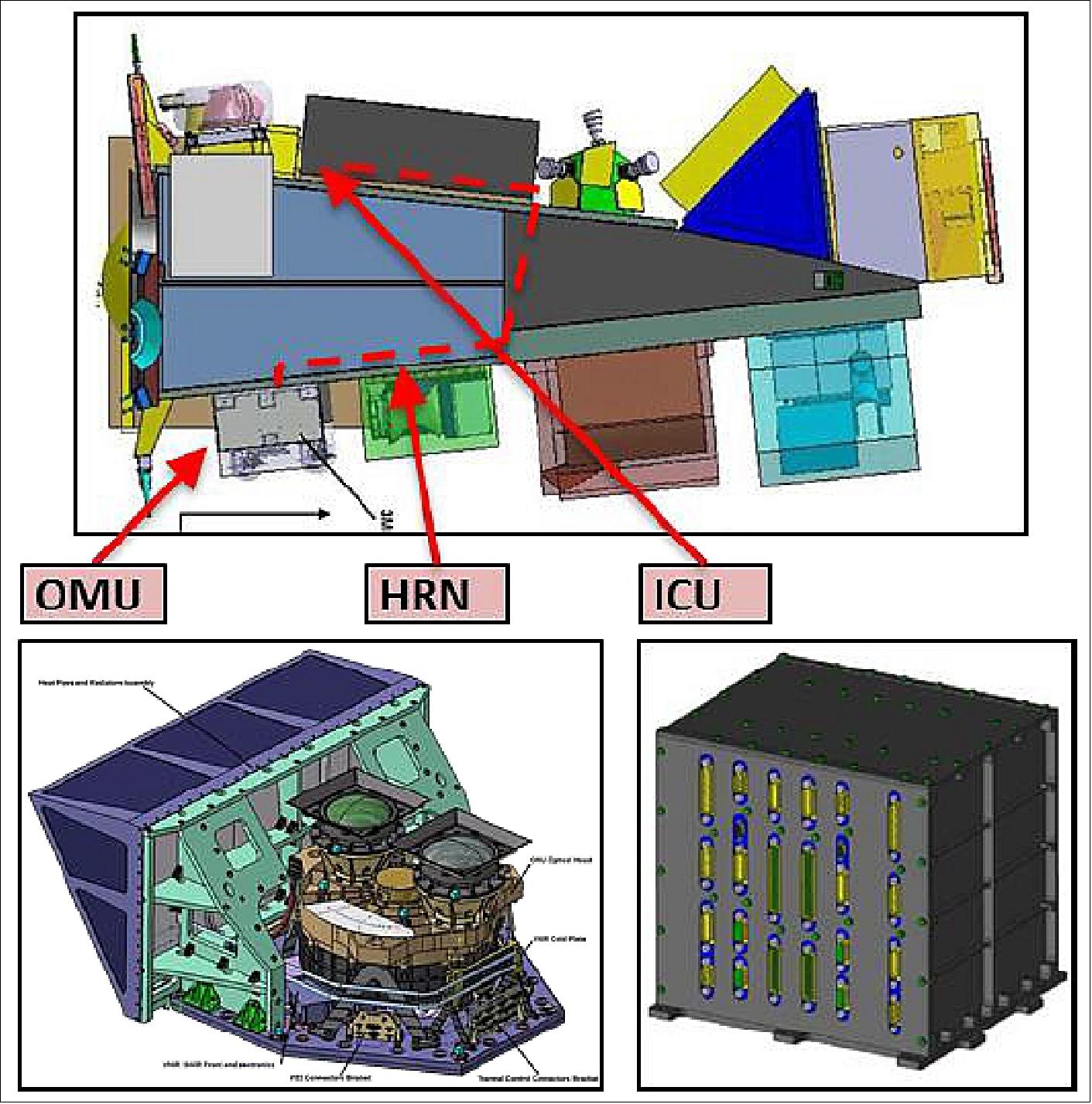

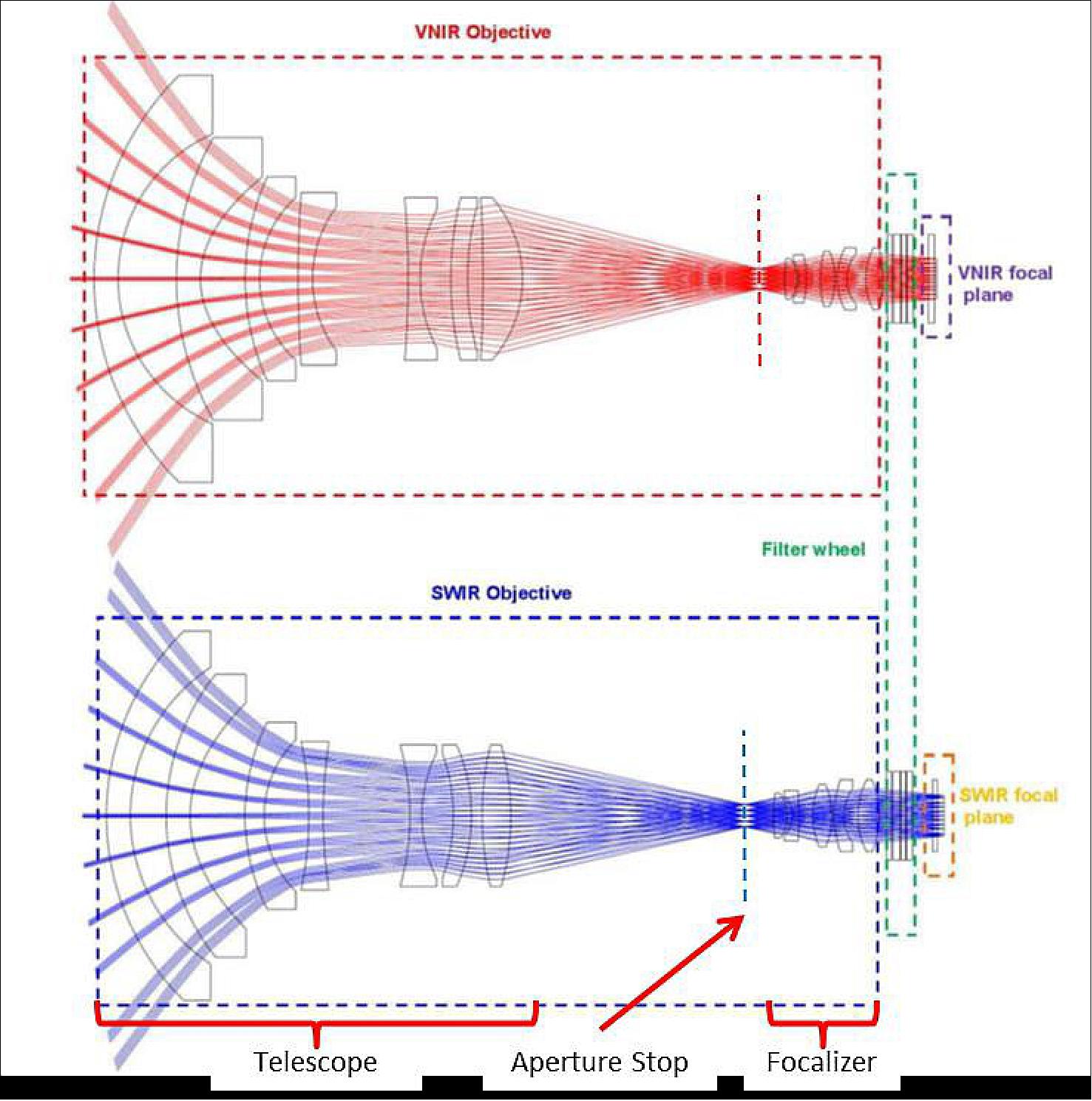

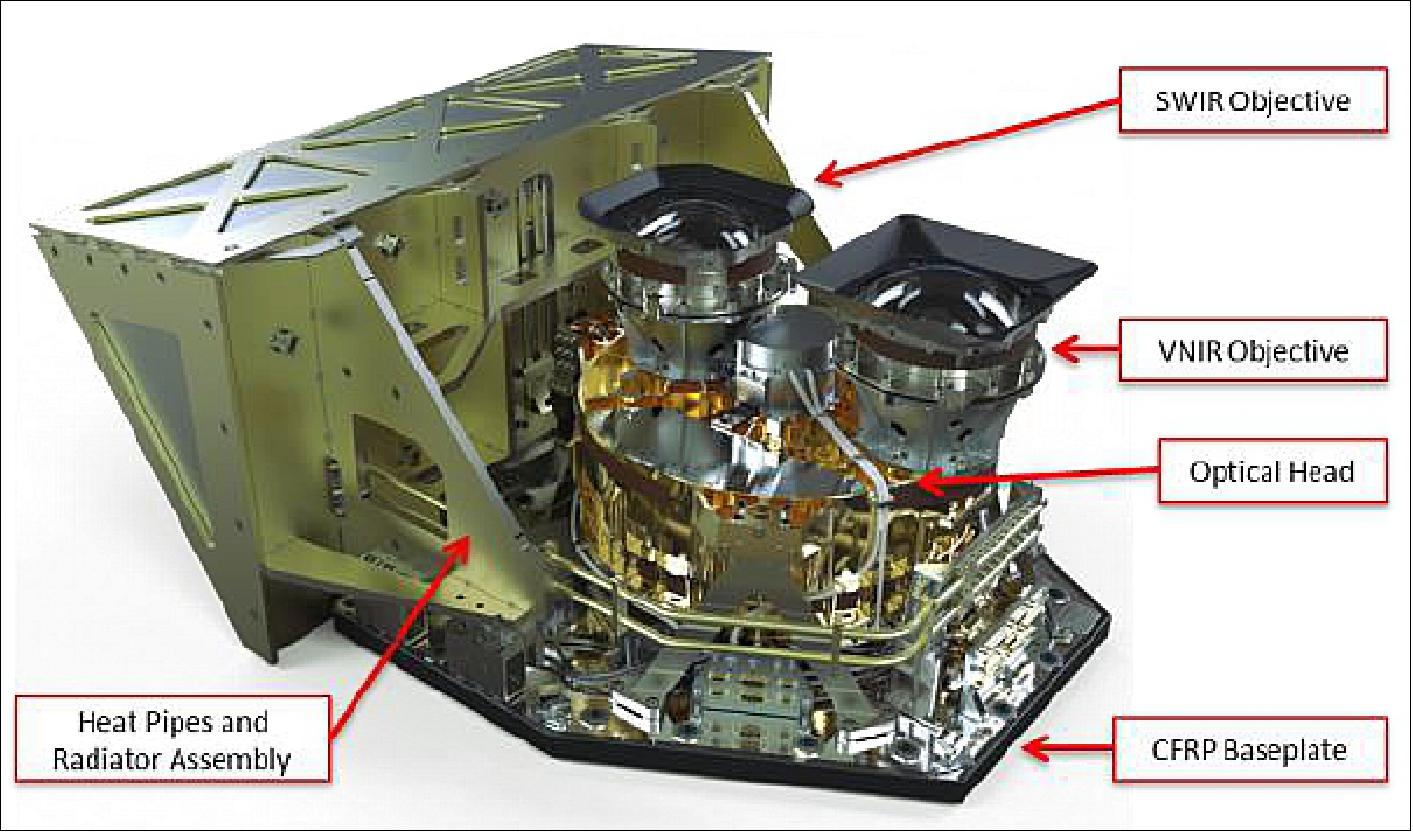

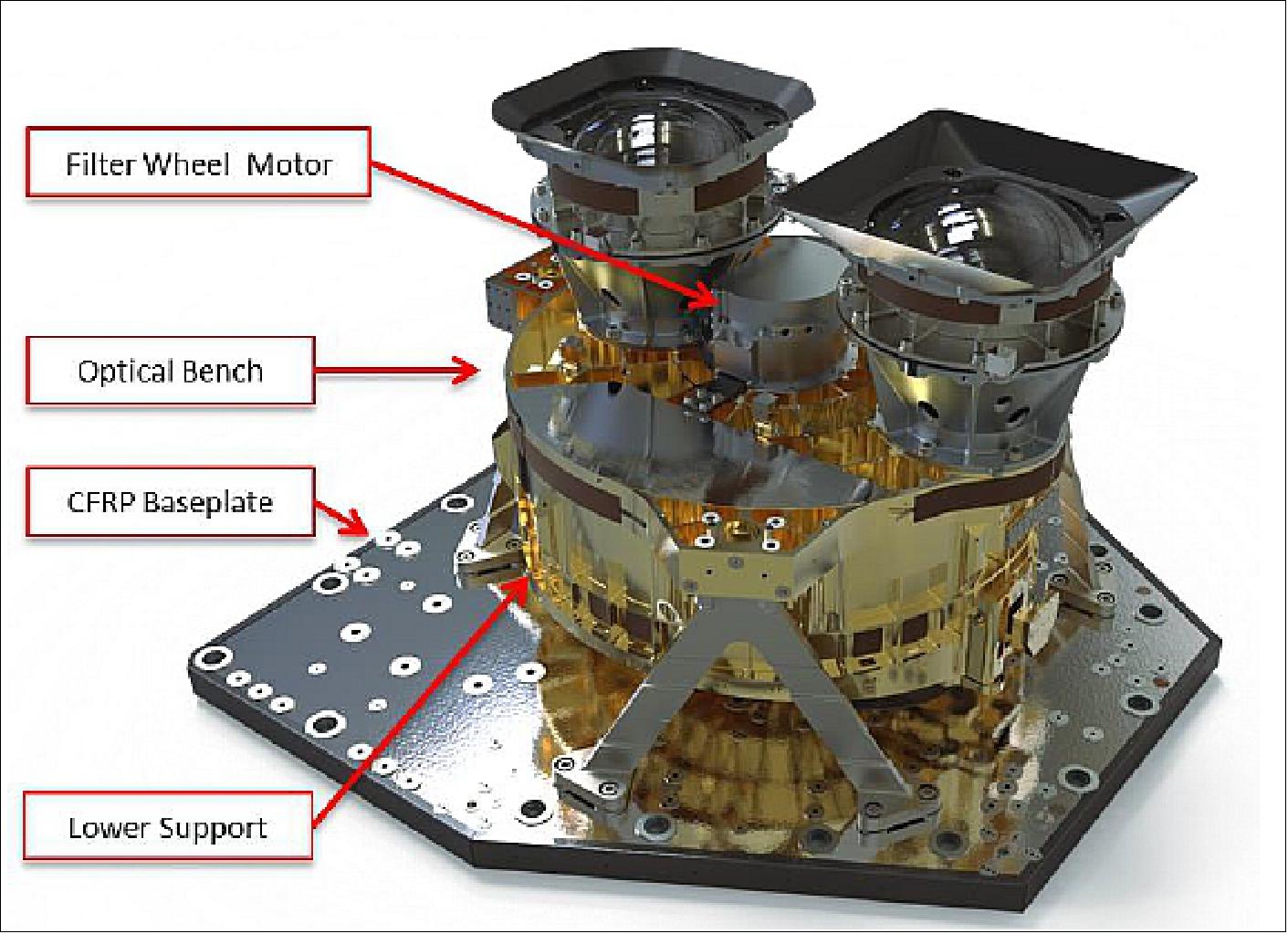

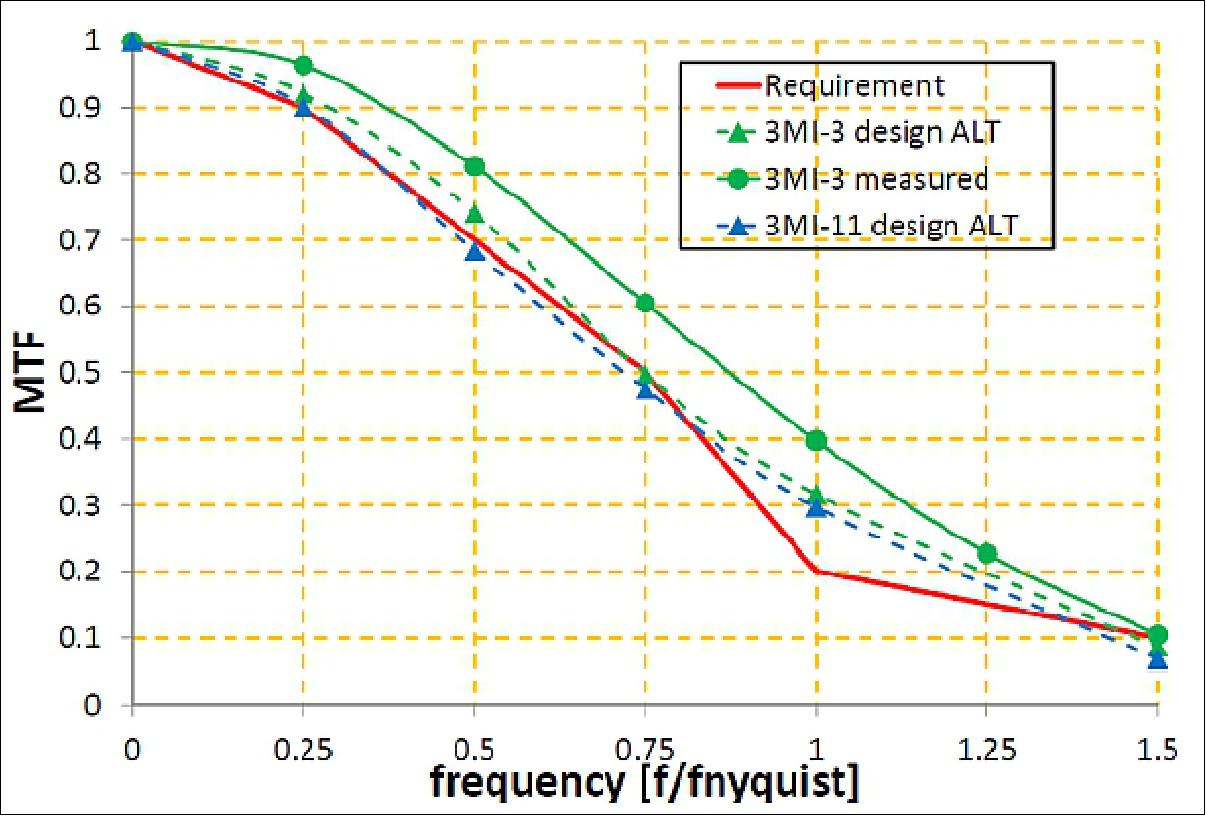

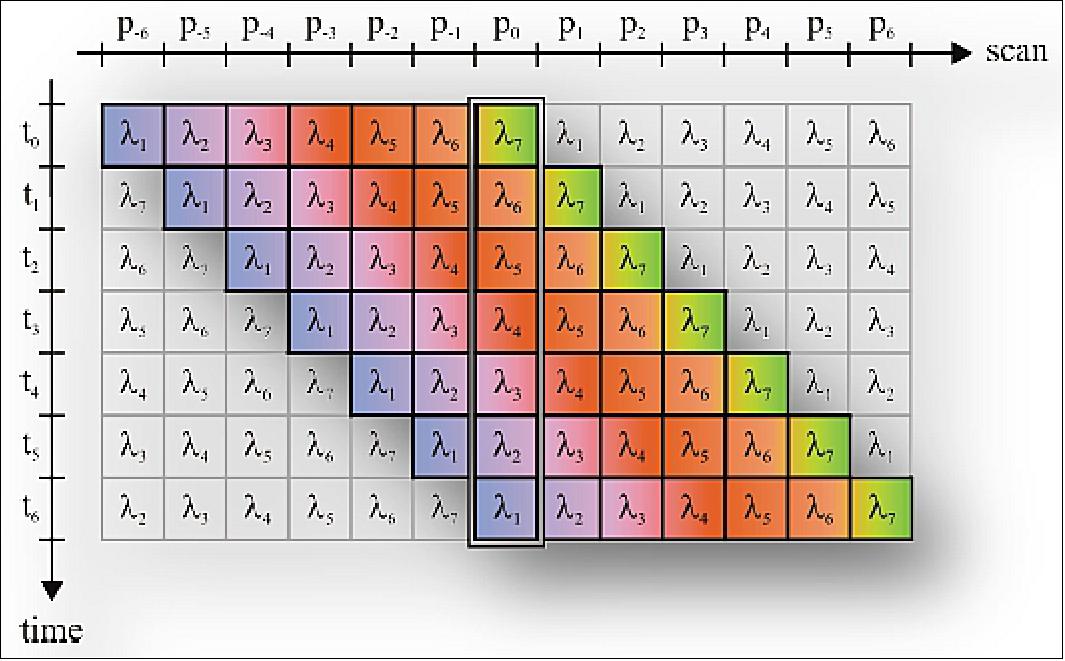

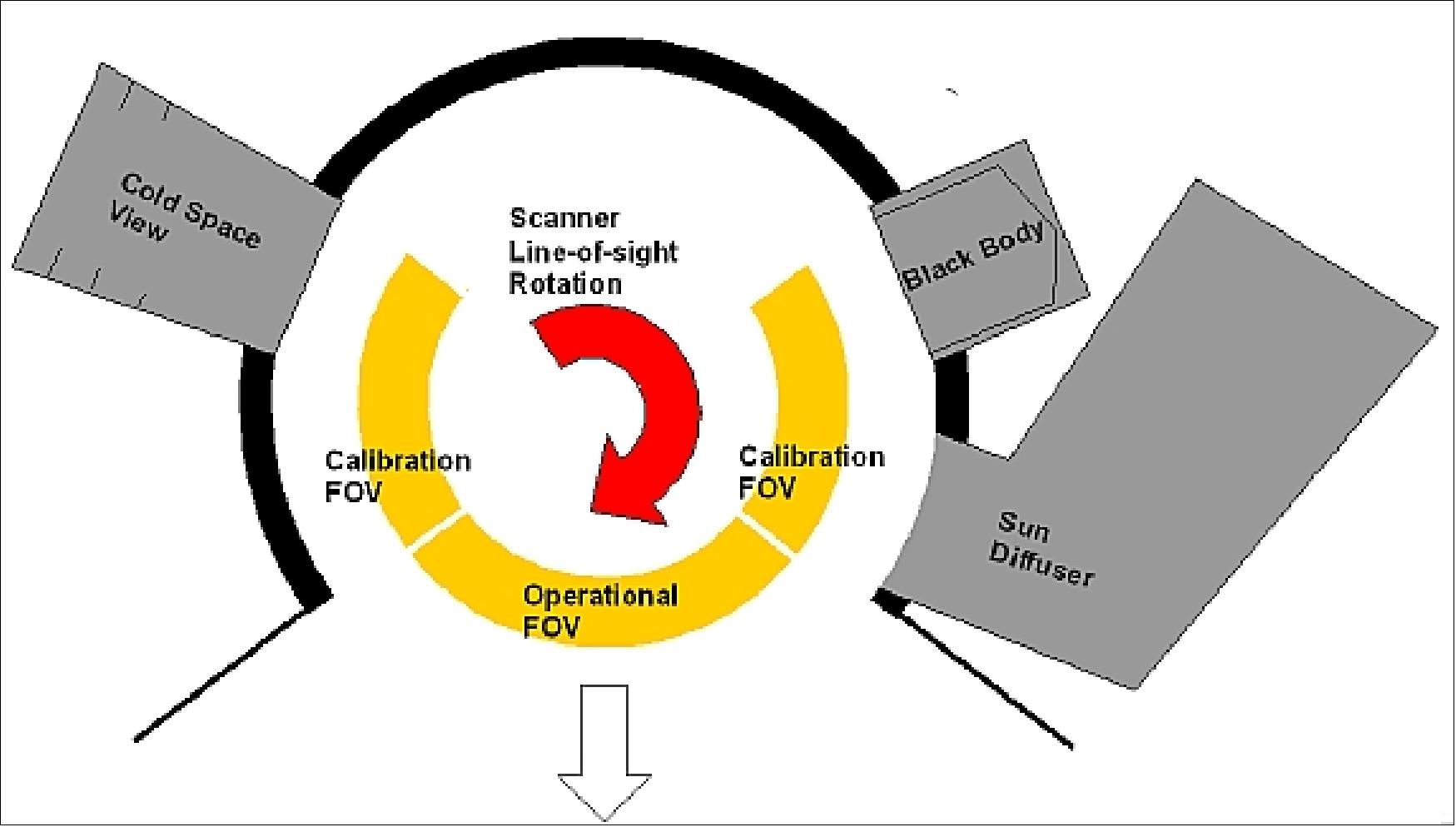

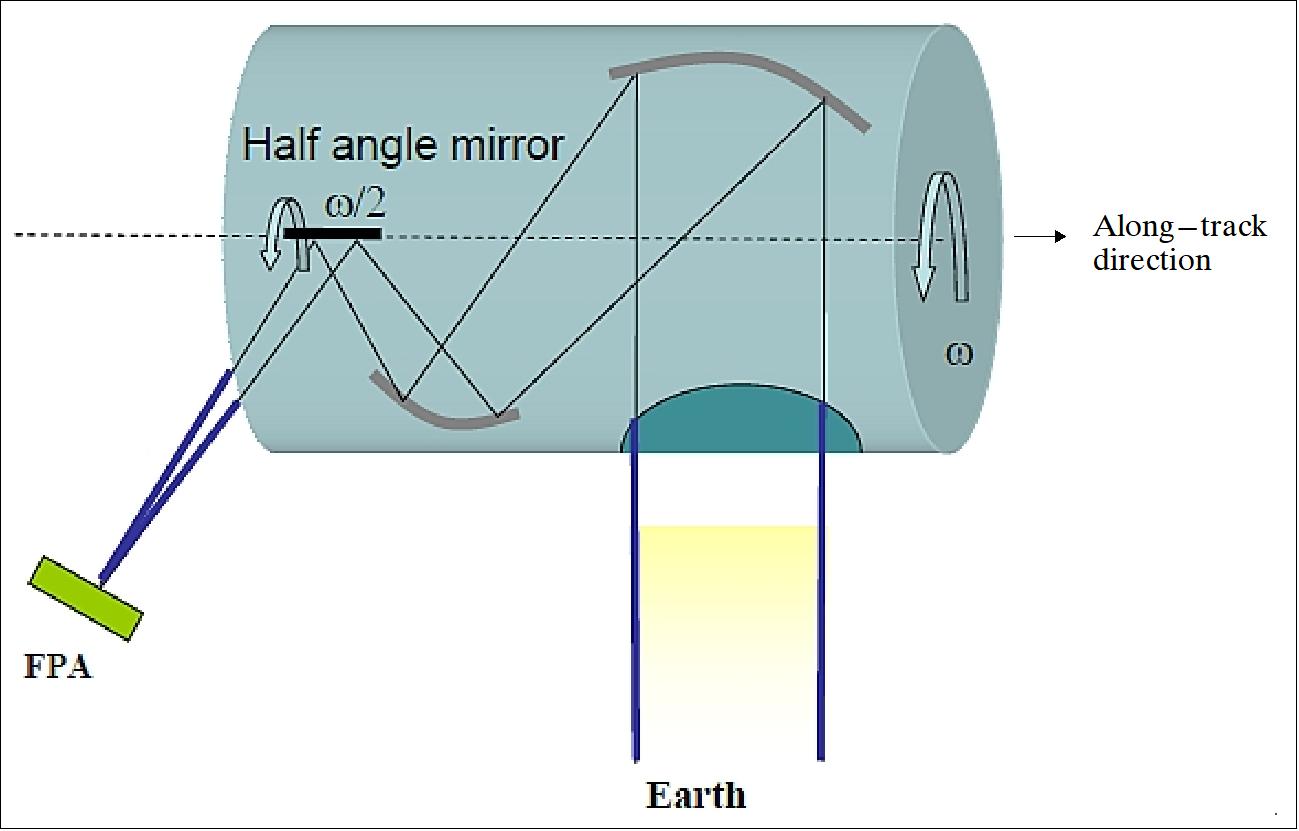

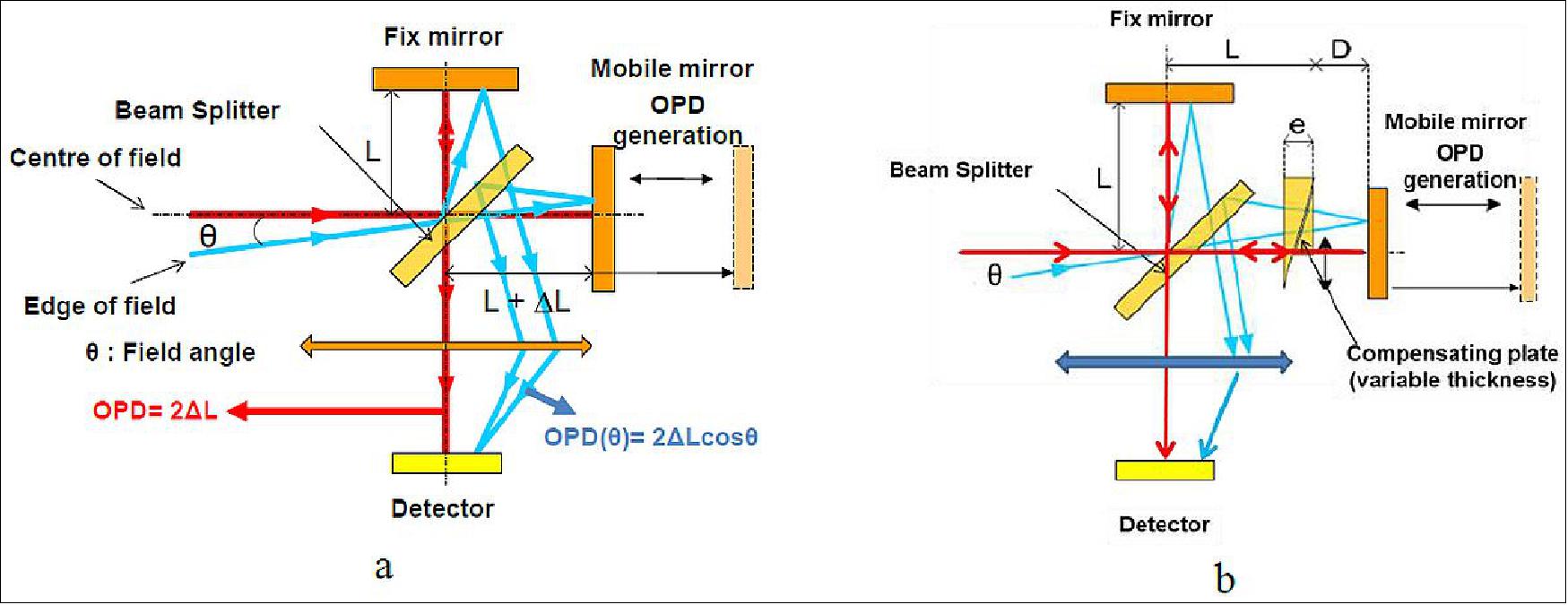

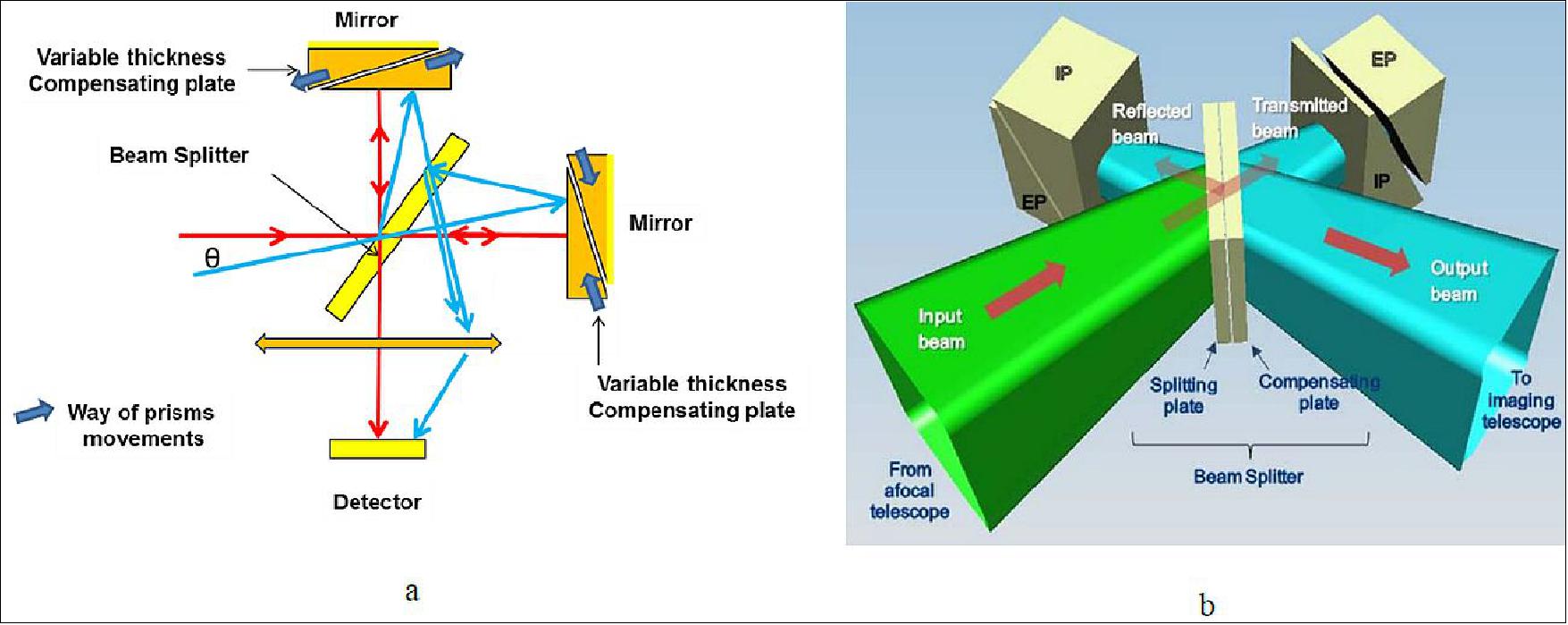

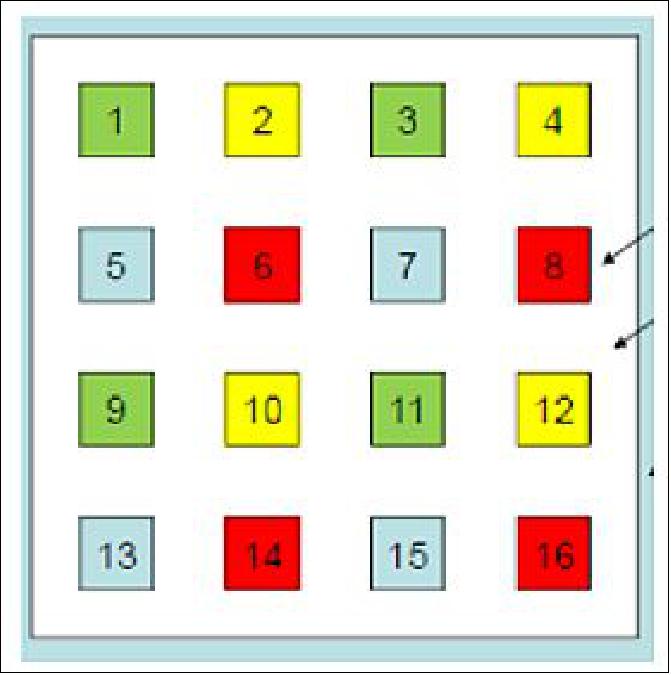

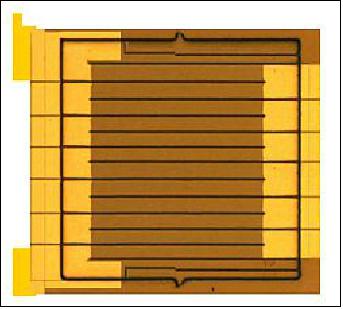

While currently, aerosol and cirrus parameters are mostly used in GCMs ( General Circulation Models) for climate simulation and prediction, utilization of these parameters is becoming increasingly important in operational NWP as the representation of radiative processes in the atmosphere is a recognized area of deficiency. Hence, the 3MI mission is expected to be of great benefit to both real-time and non-realtime user communities.