M3 / M-Cubed

EO

Operational (nominal)

Northwest Nazarene University

Quick facts

Overview

| Mission type | EO |

| Agency | Northwest Nazarene University |

| Mission status | Operational (nominal) |

| Launch date | 18 Nov 2017 |

| CEOS EO Handbook | See M3 / M-Cubed summary |

MakerSat: A CubeSat Mission Designed for In-Space 3D Print and Assembly

Spacecraft Launch Mission Status Multi-user Science Boards Structure and assembly References

MakerSat is a technology proof-of-concept mission from NNU (Northwest Nazarene University) of Nampa, Idaho, USA, that will demonstrate microgravity additive manufacturing, assembly, and deployment of a CubeSat from the ISS (International Space Station). MakerSat is a 1U multi-project satellite, supporting up to four science payloads that can be developed by four independent teams. In the upcoming MakerSat mission, one university science team will measure the mass loss of several additively-manufactured polymers in orbit. The materials are expected to undergo mass loss due to monoatomic oxygen radicals, ultraviolet (UV) radiation, ionizing radiation, and outgassing. A high school science team payload of Caldwell High School will also be flown. The MakerSat concept will be demonstrated with two launches: 1) 2)

•MakerSat-0 will be placed in a near-circular orbit through the ELaNa (Educational Launch of Nanosatellites) program in preparation for the eventual launch of MakerSat-1 from the ISS. 3)

This project was made possible through funding by Idaho Space Grant Consortium and partnerships with Made in Space, Near Space Launch, NASA, NanoRacks and Plexus.

Overview

The relatively low cost and short development times of CubeSats and nanosatellites have provided researchers at universities and small companies unprecedented access to space. In contrast to typical large-satellite missions, CubeSat missions typically reduce cost and development time by using COTS (Commercial-off-the-Shelf ) components and launching with other missions on the same launch vehicle. The result has been a significant number of satellite-based research and commercial space endeavors using CubeSats. However, one of the issues that have limited further reductions in a CubeSat's cost and development-time, as well as flexibility in potential structural frame designs, is the fact that satellites must be manufactured on Earth and then launched into space. Consider how the launch affects each of these aspects:

1) Cost: The launch fee is typically one of the largest line-items in any CubeSat mission budget and is proportional to the payload mass.

2) Development time: The time from mission inception to launch is strongly affected by launch scheduling. Waiting for a launch can often add significant time to a CubeSat mission.

3) Structural frame design: The types of frames that can be used for a CubeSat are limited to those that can withstand the forces experienced in a typical high-g launch. If the high-g launch could be avoided, CubeSats would not be restricted to strong, rugged frames; instead, CubeSats could be made from a myriad of fragile frames that will work well in a microgravity environment, but not survive a launch.

One way to avoid these launch problems is to manufacture the CubeSat in space using the "stash and deploy" technique proposed by NanoRacks and Made In Space. 4) — Versatile electronic boards with different combinations of sensors could be manufactured on Earth, delivered to and stored on the ISS, assembled as needed with a custom frame printed in the AMF (Additive Manufacturing Facility) from Made In Space, and deployed using the NRCSD (NanoRacks CubeSat Deployer) or other proven CubeSat deployment means. Such an approach would reduce CubeSat cost (by reducing payload volume and mass), development time, and allow for a host of new frame designs that are only possible to create in a microgravity environment. In fact, it may be possible to use frame structures and sensors that might not even support their own weight on Earth.

Additive manufacturing, also known as 3D printing, is not new to the CubeSat research community. Examples of such research include the use of additive manufacturing to create CubeSat frames and structures with embedded electronics propulsion systems, 5) and radiation shields11. 6)

Work is also being done to fabricate spacecraft components outside the ISS using additive manufacturing and robotic assembly techniques. 7) However, to create a CubeSat onboard the ISS, a new approach to the structural design and assembly procedure must be developed.

Spacecraft

MakerSat will be the first CubeSat specifically designed to be additively manufactured, assembled by an ISS crew, and deployed into orbit all in a microgravity environment. MakerSat is an open-source, multi-user space research platform, available to students, teachers, and start-up companies permitting them to affordably implement their science in LEO (Low Earth Orbit). The goal is to have up to four teams design and program their science experiments in their makerspaces on Earth, and then upload their design/code files to the ISS for fabrication and deployment.

MakerSat has a 1U CubeSat frame made of four polyetherimide (PEI) 3D printed rails that simply snap and slide together with six PCB (Printed Circuit Board) assemblies without the use of tools. This approach makes it possible to assemble the satellite in approximately 5 minutes (on Earth) without the dangers or difficulties of any free-floating small parts (e.g., screws, nuts, or washers). After the ISS crew assembles the six MakerSat boards with the frame, the satellite can be powered via a USB connection and its functionality verified by the illuminations of several LEDs (the communications system would be disabled until deployed). Once the satellite's functionality has been verified, it is ready to be gently deployed (i.e., no high g-forces) from the ISS via the NRCSD or other proven CubeSat deployment means.

The MakerSat concept will be demonstrated with two satellites: MakerSat-0 and MakerSat-1. MakerSat-0 will be completely manufactured and assembled on Earth and launched into a sun-synchronous polar orbit through the ELaNa program via Virgin Galactic's LauncherOne vehicle. The frame will be 3D printed in Made In Space's terrestrial AMF. The objective of this launch is to provide a test-run for the eventual launch of MakerSat-1. MakerSat-1 will be completely manufactured, assembled, and launched from the ISS. Efforts to make the necessary arrangements for the assembly and launch of MakerSat-1 are ongoing.

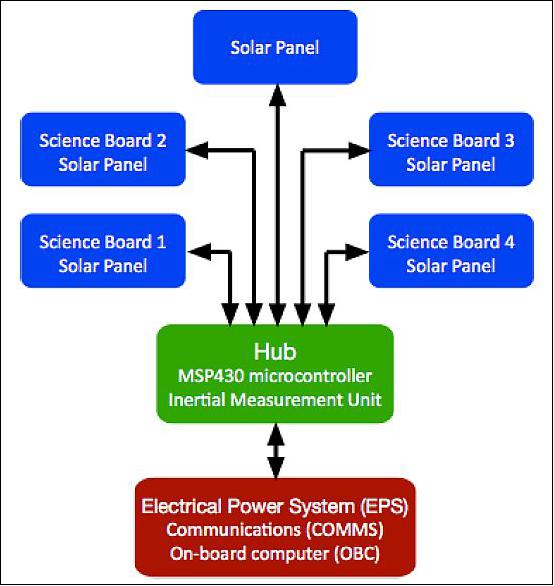

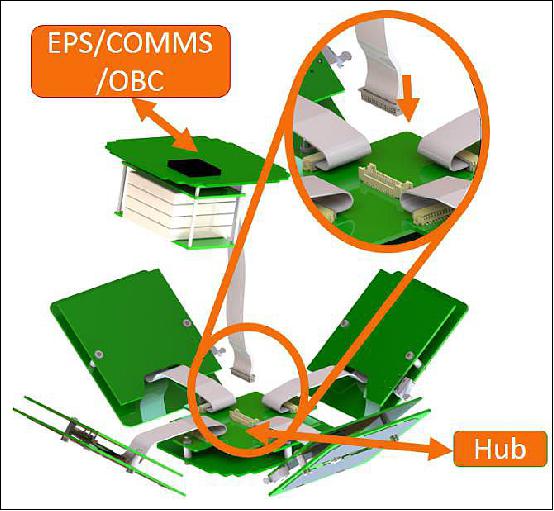

MakerSat multi-user architecture: MakerSat is a multi-project satellite that provides up to four science teams the opportunity to fly their experiments in space with very low project complexity and cost. All satellite power, control, computing, and radio communication tasks are made equally available to each of the four science boards by the core MakerSat system. Each science board can pass its data through a microcontroller on the Hub to the communication system (COMMS) for downlink. Figure 2 shows a block diagram of each MakerSat subsystem. The EPS (Electrical Power Subsystem), COMMS, and the OBC (On-Board Computer) are physically co-located, as shown in Figure 3.

Note: The term MakerSat is used when the information applies equally to both MakerSat-0 and MakerSat-1.

MakerSat-0 hardware description (Ref. 12):

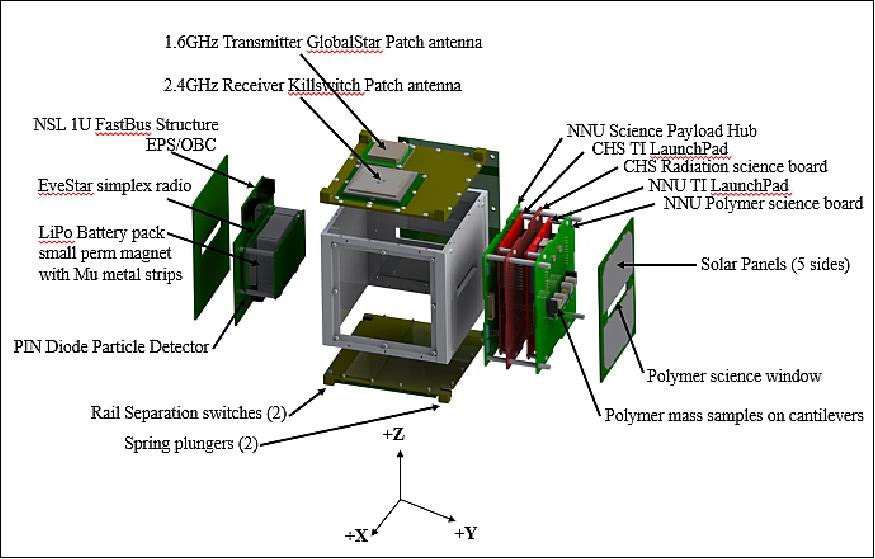

MakerSat-0 utilized a 1U FastBus aluminum box structure from NSL (Near Space Launch Inc.) as shown in Figure 1. It is quite robust and passed two rounds of shock testing plus the actual launch. Five of its six sides are covered with solar panels containing two triple-junction GaAs solar cells each, separated by a center science window slot, through which the polymer test samples, radiation sensor, RBF pin, and diagnostic ports protrude, directly exposed to the external space environment.

The NSL EPS/radio/battery unit is on the Y- side and the NNU/CHS (Northwest Nazarene University/Caldwell High School) science payload is on the Y+ side. The X, Y, and Z- solar cells are connected to provide 3.5 V, 0.4 A, 1.4 W into a boost circuit that charges the two LiPo 7.4 V batteries to a total capacity of 4.4 Ah. The Z+ side has both transmitter and receiver radio patch antennas for Globalstar.

The NSL EPS/OBC board uses a radiation-tolerant 8-bit PIC microcontroller with extensive flight history including TSAT, GEARRS1, and GEARRS2. The satellite uses a small permanent magnet and orthogonal mu-metal dampening strips as passive attitude control to slowly orient its Z axis to the Earth's polar magnetic field lines.

Most CubeSats use ground station radio uplinks to send commands to the satellite and radio downlinks to send data from the satellite. Such grounds stations often operate in the VHF and UHF amateur bands. The design and operation of a ground station adds significant cost and complexity to CubeSat mission planning and operations. To avoid these issues, MakerSat-0 utilizes an EyeStar simplex radio from NSL, which communicates between the CubeSat and GlobalStar's LEO satellite constellation, using an SMS text messaging protocol. This "bent-pipe" communication method provides a 24/7 data downlink to several ground receiving gateways located around the globe, tied to a secure NSL data server, from which the NNU and CHS students can view near-real-time (2 minute latency) health and science data from MakerSat-0 on their smartphones and laptops anytime, anywhere. The low data rate of 3Byte/s is adequate for MakerSat's small data volumes.

The NNU polymer and CHS radiation science experiment boards each utilize an ultra-low-power Texas Instruments MSP430 microcontroller "LaunchPad" development daughter board, containing radiation-tolerant, non-volatile FRAM memory. These two science boards are connected to a "Science Hub" board designed by NNU, providing shared control, data processing/buffering and radio communication to the science boards in a round-robin fashion.

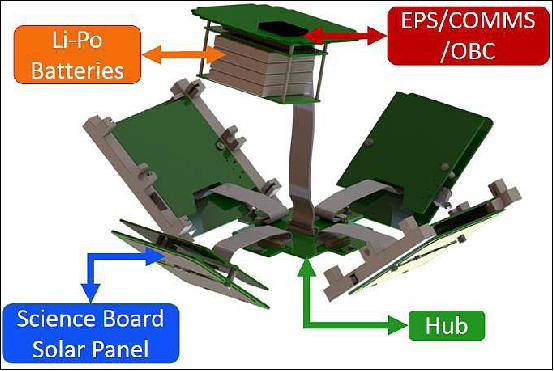

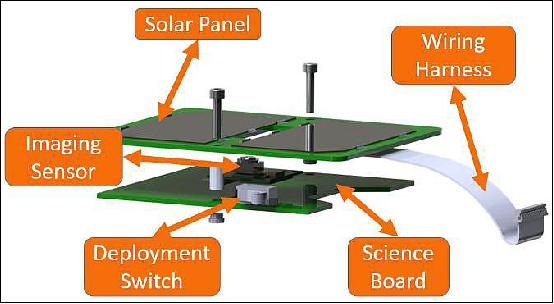

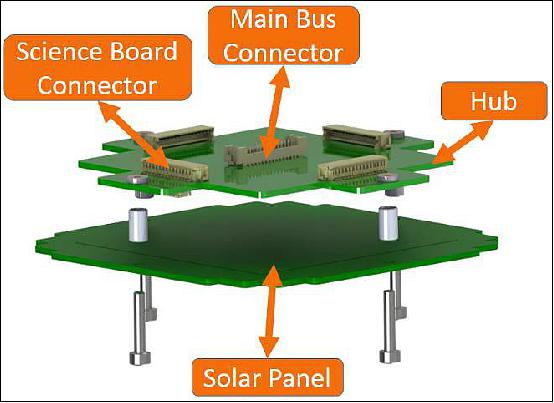

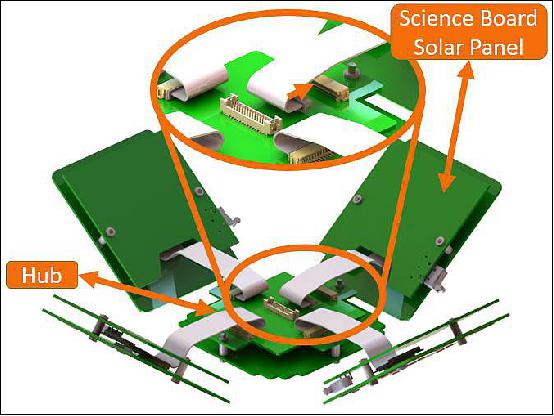

Also shown are the science /solar array board assemblies and the Hub/solar array assembly, detailed in Figure 4 and Figure 5, respectively. The science boards and the Hub are mounted to the back of the solar array boards (which face the outside of the satellite). The solar array boards contain cutouts (32mm x 9mm) that allow sensors (such as a camera) to be exposed directly to space. The EPS/COMMS/OBC board and the science/solar array and Hub/solar array board assemblies are pre-assembled on earth before being delivered to the ISS. This approach eliminates the need for tools and fasteners when the satellite is assembled on the ISS.

Instead of the EPS, COMMS, and OBC systems connecting directly to the science boards, as might be done in a conventional CubeSat design, the EPS/COMMS/OBC subsystems are routed through the Hub. This configuration eases assembly by providing a common connection point for all boards and allows the Hub to provide each science board equal access to the EPS, COMMS, and OBC subsystems. The following subsections will provide details of each.

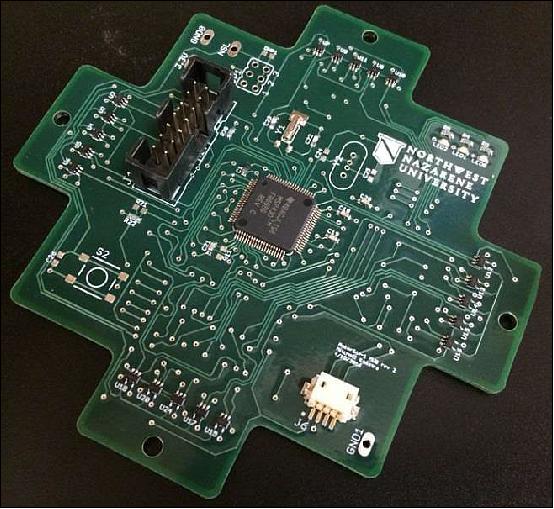

Hub: All of the electrical boards of MakerSat are connected through a Hub board, shown in Figure 6. The Hub board provides the following:

• A single connection point for all satellite boards simplifying assembly and reducing the probability of assembly errors.

• Sequencing control of all four science boards. The Hub operates in a peer-to-peer relationship with the OBC/EPS. The Hub can request the EPS to cycle power to any of the science boards to control their duty cycle.

• Computational power and additional memory that can be used by each science board. The computational power is provided by an ultra-low power MSP430FR6989 microcontroller with 128 kB of FLASH memory for flight code and 130 kB of non-volatile, FRAM (Ferroelectric Random Access Memory) for computations. The FLASH and FRAM technologies provide increased resistance to single event errors caused by ionizing radiation.

• The ability to relay data from the science boards to earth. The Hub gathers data from each science board, prepares it for transmission, and sends the data to the COMMS for transmission to Earth.

EPS/OBC, Solar Arrays, and Attitude Control

MakerSat uses an EPS/OBC board, solar array boards, lithium-polymer batteries, and passive attitude control provided by NSL (Near Space Launch, Inc.). The EPS/OBC uses an 8-bit PIC microcontroller with extensive flight history including TSAT (Taylor-Technology Satellite) of Taylor University (Upland Indiana), GEARRS-1 (Globalstar Experiment and Risk Reduction Satellite-1), and GEARRS-2 (both GEARRS CubeSats are of NSL). Each of these satellites was launched from the ISS, and hence, the boards and batteries have ISS approval. The EPS/OBC receives requests from the Hub to cycle power to the science boards, provides over current protection to all MakerSat boards, and uses energy from the solar arrays to charge the batteries.

The solar arrays are constructed using 28% UTJ (Ultra-efficient Triple-Junction) solar cells from Spectrolab, each providing 433mA at 2.35VDC. Each cell covers one-half of a 1U face and MakerSat uses two cells connected in series on each solar array board to provide 4.7 VDC at 433 mA (~2W) from each board, assuming full illumination and operation at the maximum power point. Each of the five solar array boards is connected in parallel. The EPS uses PPT (Peak Power Tracking) to regulate the current extracted from the solar cell array so such that the array remains at its peak power point. The EPS charges four lithium-polymer batteries, configured as two series pairs of batteries in parallel. Together, they provide 4.4Ah at 7.4V. The batteries have flight history onboard the ISS.

Passive attitude control for MakerSat is provided by a permanent magnet, aligned in the z-axis of the satellite that will slowly align the satellite to the Earth's magnetic field. The satellite's rotation is dampened by three orthogonal µ-metal strips mounted on the OBC/EPS board.

COMMS (Communications System)

COMMS is one of the most critical and challenging components of any CubeSat design. Many CubeSat missions use a ground station-to-CubeSat radio link for both sending commands to the satellite and receiving data from the satellite. Such grounds stations often operate in the 435 MHz (UHF) amateur frequency band. While this approach is straightforward, the design and operation of a ground station adds significant complexity to mission planning and ground operations. Furthermore, because of the low transmit power allowed in the UHF band, the gain of the ground station antenna must be relatively high and, hence, the ground station must track the satellite and point its antenna accordingly.

To avoid these issues, MakerSat uses an EyeStar Simplex radio, provided by NSL, which communicates with the GlobalStar satellite constellation to provide a 24/7 data downlink with near global coverage to 14 ground gateways. The data received by the ground-gateways is made available to each participating science team via an Internet portal. The data can be accessed on-demand anywhere in the world. MakerSat will transmit two types of packets from the EyeStar radio:

• Satellite Health Packet: an 18-byte packet will be transmitted at a regular interval to report the temperature and bus voltage of the satellite.

• Payload Packet: a 39-byte packet containing the data from the science boards will be transmitted at regular intervals.

The data rate is expected to be 50-100 kB/day, which is primarily limited by the expected power budget and data rate costs. Using the flight-proven Simplex radio ensures that a beacon will still be received independent of other satellite subsystems. This beacon will indicate satellite functionality in the event of Hub or science board failure.

Launch

The MakerSat-0 1U CubeSat was launched as a secondary payload on Nov. 18, 2017 on a Delta-2-7920 vehicle of ULA (United Launch Alliance) from VAFB, CA. The primary mission was the JPSS-1 spacecraft of NOAA, developed at NASA. 8) 9)

MakerSat-0 was selected in 2016 by CSLI (CubeSat Launch Initiative) of NASA to be launched as part of the ELaNa (Educational Launch of Nanosatellite) program. It was baselined to fly in 2018 on the ELaNa-20 mission on a LauncherOne rocket of Virgin Galactic; however, the MakerSat-0 mission has moved up to a March 2017 launch on the ELaNa-14 mission on a Delta-2-7920 vehicle of ULA from VAFB. The primary payload is the JPSS-1 spacecraft of NASA/NOAA. 10) 11)

Orbit: Elliptical sun-synchronous orbit with a perigee of 480 km and an apogee at 830 km, inclination = 97.7º.

Secondary Payloads (ELaNa-14)

• RadFxSat (Radiation Effects Satellite, Fox-1B), a 1U CubeSat of AMSAT and Vanderbilt University, Nashville, TN, USA.

• EagleSat, a 1U CubeSat of ERAU (Embry-Riddle Aeronautical University), Prescott, AZ, USA.

• MakerSat-0, a 1U CubeSat of NNU (Northwest Nazarene University) of Nampa, Idaho, USA.

• MiRaTA (Microwave Radiometer Technology Acceleration), a 3U CubeSat of MIT (Massachusetts Institute of Technology), Cambridge, MA, USA.

• Buccaneer RRM (Buccaneer Risk Mitigation Mission), a 3U CubeSat technology mission of UNSW (University of New South Wales), Canberra, Australia and DST (Defence Science and Technology) group. The goal is to calibrate JORN (Jindalee Over-the-Horizon Radar Network).

Mission Status

• August 2018: For the past nine months, MakerSat-0 has been operating in a sun-synchronous polar orbit with a 97min period, 830 km x 480 km, an inclination of 97.71º, and LTAN of 13:20 hours. It has already travelled 110 million miles in 3900 orbits and is expected to orbit for at least eight years. MakerSat-0 hosts two onboard experiments: an ionizing radiation particle counter built by Caldwell High School (CHS) students and a 3D printed polymer degradation experiment built by NNU (Northwest Nazarene University) students. - Four different 3D printed polymer samples (ABS, Nylon12, PEI/PC, and PLA) are being exposed to long term spaceflight and are experiencing ongoing erosion and mass loss due to monoatomic oxygen radicals, outgassing, extreme temperatures, ultraviolet (UV) radiation, solar & cosmic ionizing radiation, and even micrometeor impacts. 12)

- MakerSat-0 began sending voltage and temperature health beacon data packets only 50 minutes after deployment (in Nov.2017), transmitting four 36 byte beacon packets every 90 minutes. MakerSat-0 is the first satellite using a GlobalStar radio to be placed in a polar orbit, so the packet reception over the frequently traversed polar regions that have fewer satellites and gateways was unknown prior to this mission. During the first 200 mission days, 3200 beacon packets were transmitted, but only 394 complete packets were received (12%). It was observed from the partial packets received that the data reception rate would be improved to the 90% range if the packets were made half as long (18 bytes).

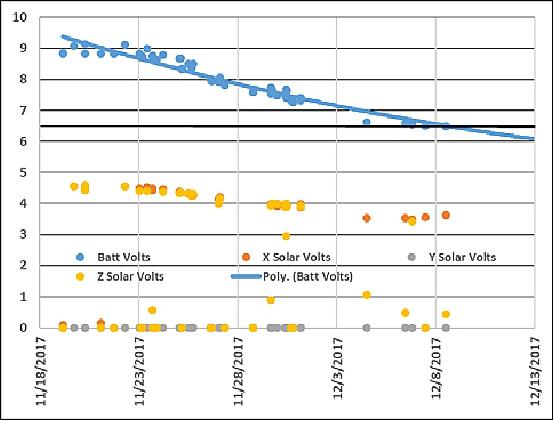

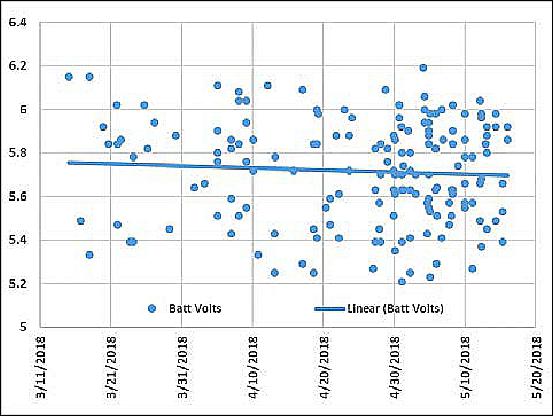

- The first beacon data received after the Nov. 18 launch showed that the two Y solar cells were no longer functional, and were probably cracked at launch due to mechanical or thermal shock. This reduced the solar energy collection capability of the satellite by 40%, making each orbit negative with respect to the power budget. With no radio command uplink ability, we were unable to use less power per orbit. So, the battery gradually discharged from 9.1 V down to 6.5 V on Dec. 3, as shown in Figure 8. At this trigger voltage, the satellite went into safe mode and stopped doing science. However, the safe mode was not safe enough to allow the battery voltage to fully recharge before restarting science, so the battery voltage continued to fall down to the current range of 5.2-6.2 V, as shown in Figure 9. A gradual downward trend in average battery voltage is ongoing and will result in satellite failure at some point below 5 V. In this battery voltage range, the satellite OBC microcontroller reboots after every sunlit recharge period and then tries to perform 16 consecutive health beacon packet radio transmits. However, due to this high radio power consumption, the battery voltage rapidly depletes back to the reboot level again before it is able to complete these 16 packet transmits. So the satellite is in an infinite "solar-locked" rebooting loop, probably rebooting once every orbit, or 15 times a day. Nevertheless, we are continuing to receive several health beacon packets per day.

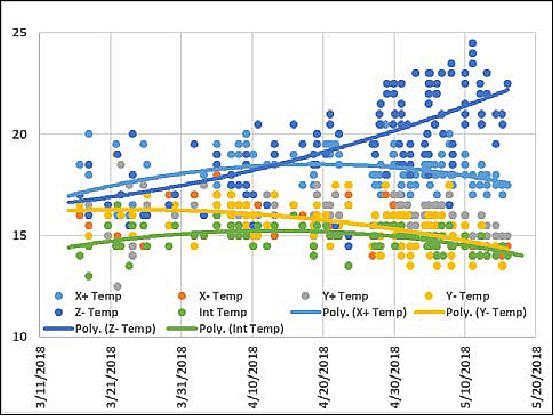

- The X,Y,Z surface temperatures and internal temperature varied from -15ºC in eclipse to +25ºC in sunlight on MakerSat-0, before it became "solar locked." Now that it is solar locked, it is active only in the sunlight. Figure 10 shows the temperatures of the various solar panels and the internal temperature vs. time. It appears that the passive attitude control magnet is gradually stabilizing the Z- surface toward the sun, causing it to heat to 22ºC, 5º to 7º warmer than the other surfaces which are becoming cooler.

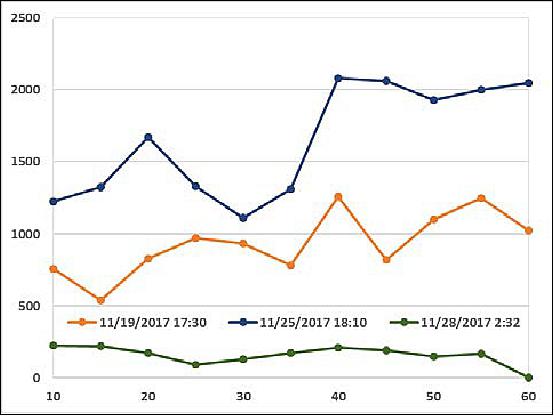

- Ionizing Radiation Experiment Data: The Caldwell HS science experiment board contained a PIN diode radiation particle detector coupled with an MSP430 microcontroller counter circuit to measure the ionizing radiation particle flux rate inside the shielded aluminum satellite cube, as shown in Figure 11. Most of the time this flux rate was nearly zero, but it was considerably higher when passing through the polar auroras or the SAMA (South Atlantic Magnetic Anomaly) and fluctuated over its 60 sec measurement period. Unfortunately, few Globalstar data packets were received from the polar aurora regions, but some were received from the SAMA region locations as mapped in Figure 12.

Sensor Complement

Multi-user Science Boards

MakerSat contains four science boards that can each contain an independent science experiment provided by different users. Each science board communicates to the Hub through a standard interface:

• ADC Interface: The EPS/OBC board contains an ADC (Analog-to-Digital Converter) that can be used to directly sample and transmit analog science data to the COMMS.

• GPIO (General Purpose Input/Output): Two 3.3 V digital logic lines are available for each science board to communicate with the Hub microcontroller.

• Serial Communication: Each science board can choose to send serial data to the Hub microcontroller using either the I2C or SPI interfaces.

The science boards are supplied 3.3 VDC from the EPS and the Hub microcontroller controls the duty cycle of the science boards. Furthermore, the Hub uses analog switches to isolate the I2C and SPI lines of science boards that are powered down.

The science boards on MakerSat-0 will consist of one imaging sensor board, two polymer mass loss experiment boards, and one board designed and built by Caldwell High School in Caldwell, Idaho. The MakerSat-1 science boards are not yet finalized. The following will briefly describe the imaging sensor board and polymer mass loss experiment boards for MakerSat-0.

Imaging sensor board: A COTS image sensor will be integrated into one of the science boards and used to take images of the Earth while in orbit. The images will be compressed, routed through the Hub to the communication system, and transmitted to earth via the GlobalStar network. Two challenges presented with this task are object recognition and image compression. First, since the satellite may tumble in orbit and the downlink bandwidth is limited, only images that contain definitive objects (such as the Earth) will be stored and forwarded to earth. Images that contain only the black of space will be discarded. Second, compressing the images will require light-weight algorithms since the MSP430FR6989 only has 130 kB of FRAM.

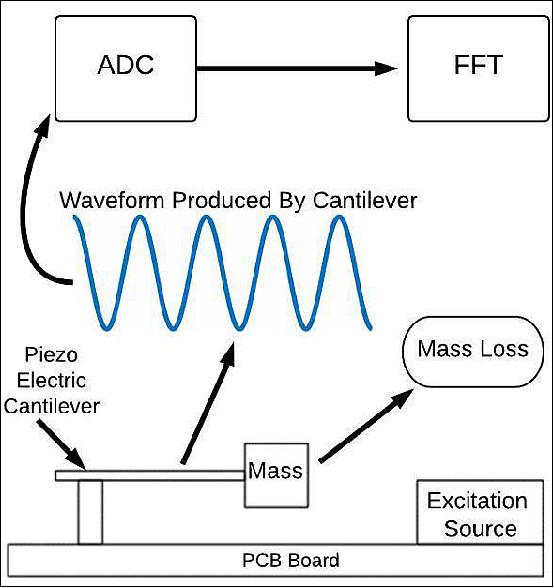

Polymer mass loss experiment board: The use of 3D printed polymers in space can be difficult because the space environment degrades the polymer. This degradation can happen through monoatomic oxygen radicals, UV radiation, ionizing radiation and outgassing. MakerSat will measure the mass loss of several different 3D printed polymers at regular intervals during orbit when the polymers are exposed to the conditions of space. The mass loss will be measured by placing samples of 3D printed polymers on the end of multiple cantilevers and measuring the resulting change in the resonant vibrational frequency of each cantilever. The resonant vibrational frequency fres of each cantilever beam is inversely related to the square root of the mass at the end of the beam,

where E is Young's modulus, I is the beam's moment of inertia, L is the length of the beam, and m is the mass on the end of the beam. By measuring the resonant frequency of the cantilever, the mass of the 3D printed polymer can be determined.

A diagram of the polymer mass loss experiment is shown in Figure 13 . The 3D printed polymer to be tested is attached to the end of a piezoelectric cantilever and excited by a vibration source. The resonant frequency of the voltage output by the cantilever is related to the mass of the 3D printed polymer by equation (1). By comparing the resonant frequency of the 3D printed polymer to the resonant frequency of a reference mass, the change in mass due to space exposure can be determined.

The sensor being used is a piezoelectric cantilever which provides an output voltage proportional to the deflection of the cantilever beam. The 3D printed polymer sample is attached to the end of the piezoelectric cantilever (Figure 13). The cantilever and the vibration source are soldered in close proximity to the same, rigid printed circuit board. When the vibration source excites the cantilever, the resulting voltage is sampled by an ADC and the spectrum of the signal is analyzed, using a FFT (Fast-Fourier Transform) or a similar algorithm, to determine the resonant frequency. The cantilever's response at the resonant frequency is then used to determine the mass of the 3D printed polymer, according to equation (1). This procedure will be repeated many times throughout the course of the MakerSat mission providing mass loss measurements as a function of time.

It is important to note that the experiment described above will be done differentially. In other words, the resonant frequency of several 3D printed polymers and a known reference mass, made of a material that will not degrade in a LEO, will be determined. By taking the measurements at the same time and positioning the reference mass close to the samples under test, systematic errors common to the measurements can be removed by normalizing the data to the reference mass. Systematic errors include degradation of the piezoelectric cantilevers and thermal effects.

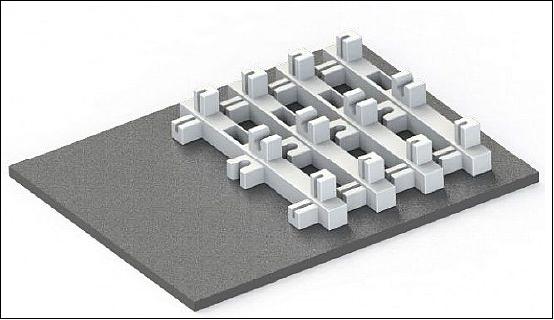

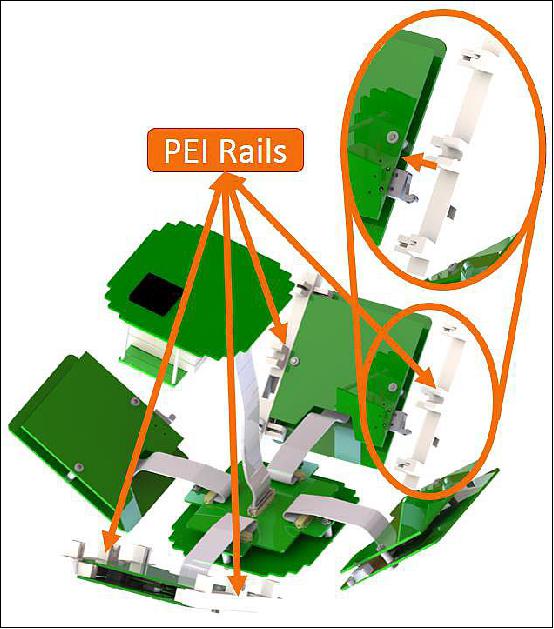

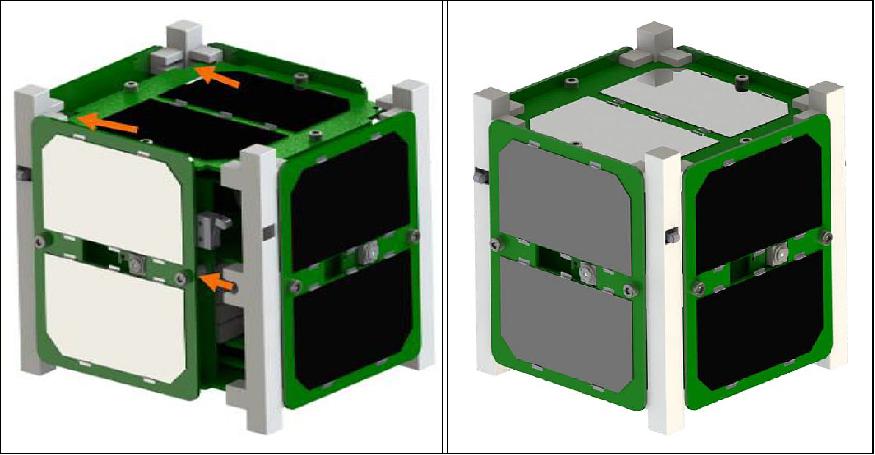

MakerSat Structure and Assembly

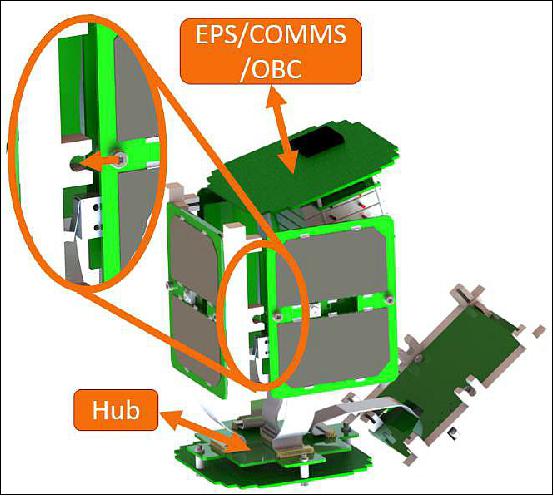

The MakerSat concept will be demonstrated with two satellites: MakerSat-0 and MakerSat-1. MakerSat-0 will be completely manufactured and assembled on Earth while MakerSat-1 will be manufactured, assembled, and launched from the ISS. MakerSat-1 uses a simple snap-together design that can be completed in approximately 5 minutes (on Earth). The MakerSat-1 design uses four PEI (Polyetherimide) rails, shown in Figure 14, to form the frame of the satellite which can be printed in the AMF. The rails contain snaps and slots that allow satellite boards to be assembled with no free-floating fasteners or tools. Furthermore, the rails are interchangeable reducing the chance of an assembly error and can be printed without support material (Ref. 1).

The MakerSat-1 hardware, which includes the EPS/OBC/COMM board, the Hub assembly, and four solar panel/science board assemblies, will be manufactured on earth and stored on the ISS until assembled by the astronaut crew. The wiring harnesses that connect each board can be pre-installed on earth. Pre-assembling the boards on earth makes in-space assembly much faster and safer by avoiding the use of free-floating connectors, tools, and fasteners. The entire satellite can be assembled in six steps:

1) Connect the solar panel/science board assemblies and the EPS/OBC/COMM module to the Hub, as shown in Figure 15 and Figure 16.

2) Remove the 3D printed rails from the print bed of the AMF, shown in Figure 7, and snap them into the solar panel/science board assemblies shown in Figure 17. Notice the slots for deployment switches in each rail. The rails should create an audible popping sound when correctly snapped onto the boards.

3) Snap two solar panel/science board assemblies into rails as shown in Figure 18.

4) Slide the Hub assembly and EPS/COMM module into respective slots in rails, shown in Figure 12 and Figure 13.

5) Line up remaining solar panel/science board assembly and snap into place as shown in Figure 20 (Left). The mechanical assembly is now complete, as shown in Figure 20 (Right).

6) Connect a USB cable from the satellite to a USB power source to power up the Hub board and test the satellite's functionality. LED indicators visible from the outside of the satellite will show astronauts whether or not the satellite is functional. The COMMS will not be operational until the satellite is deployed.

MakerSat-0 and MakerSat-1 use the same electronic boards. However, since MakerSat-0 will be assembled terrestrially, it will require a more rigid structure to survive the launch forces. To account for this, the snapping feature from MakerSat-1 will be replaced with through-hole mounts to eliminate the risk of structural failure during launch. It is also important to note that MakerSat-1 will not account for standard CubeSat spring plungers in the ends of the rails. Insertion of these plungers on the ISS poses a risk to the crew.

In summary, MakerSat is the first CubeSat specifically designed to be additively manufactured, assembled by an ISS crew, and deployed, all in a microgravity environment. The concept is to 3D print a satellite frame (uploaded from earth) on the ISS and assemble the CubeSat from a cache of core electrical boards and up to four experiment boards provided by students, teachers, and start-up companies. In this way, a CubeSat can be configured and assembled on-demand with significantly reduced development time.

The MakerSat concept will be demonstrated with two launches: MakerSat-0 and MakerSat-1. MakerSat-0 will be completely manufactured in the terrestrial AMF from Made In Space, assembled on earth, and launched into a sun-synchronous polar orbit through the ELaNa XX program. MakerSat-0 will contain four science boards: one to image the Earth, two to measure the mass loss of 3D printed polymers in orbit, and one provided by Caldwell High School, in Caldwell, Idaho.

MakerSat-0 will serve as a test-run for the eventual launch of MakerSat-1 from the ISS. MakerSat-1 will be completely manufactured, assembled, and launched from the ISS. Efforts to arrange the launch of MakerSat-1 are ongoing. The outcome of successful MakerSat missions will be an approach to designing satellites with reduced cost, reduced development time, and greater flexibility in structural design since the satellite will not be subjected to a high g-force launch.

References

1) Braden Grim, Mitch Kamstra, Aaron Ewing, Connor Nogales, Joshua Griffin, Stephen Parke, "MakerSat: A CubeSat Designed for In-Space Assembly," Proceedings of the 30th Annual AIAA/USU SmallSat Conference, Logan UT, USA, August 6-11, 2016, paper: SSC16-SSC16-WK-29, URL: http://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=3444&context=smallsat

2) Connor Nogales, Aaron Ewing, Grant Johnson, Braden Grim, Mitch Kamstra, Joshua Griffin, Steve Parke, "MakerSat: A CubeSat Designed for In-Space 3D Print and Assembly," NNU, 2016 SmallSat Poster website 1, URL: https://engineering.nnu.edu/files/download/d77cf52320eaa97

3) "NASA selects NNU for CubeSat space missions," Northwest Nazarene University, March 3, 2016, URL: https://web.archive.org/web/20161203235737/http://news.nnu.edu/story/nasa-selects-nnu-for-cubesat-space-missions

4) B. Kohlenberg, "Made In Space and Nanoracks Take First Steps Towards On-Orbit Satellite Manufacturing, Assembly and Deployment," August 11, 2015, URL: http://www.madeinspace.us/made-in-space-and-nanoracks-take-first-steps-towards-on-orbit-satellite-manufacturing-assembly-and-deployment/

5) Greg Toy , Debby Hawksworth, "The Next Generation of Space Manufacturing: Model Based and Digitally Assured," Proceedings of the AIAA/USU Conference on Small Satellites, Logan, UT, USA, August 8-13, 2015, paper: SSC15-XI-4, URL: http://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=3238&context=smallsat

6) Jonathan Wrobel, Robert Hoyt, Jesse Cushing, Mark Jaster, Nestor Voronka, Jeffrey Slostad, Lenny Paritsky, "Versatile Structural Radiation Shielding and Thermal Insulation through Additive Manufacturing," Proceedings of the AIAA/USU Conference on Small Satellites, Logan, UT, USA, Aug. 10-15, 2013, paper: SSC13-III-3, URL: http://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=2926&context=smallsat

7) Robert P. Hoyt, Jesse I. Cushing, Jeffrey T. Slostad, Greg Jimmerson, Todd Moser, Greg Kirkos, Mark L. Jaster, Nestor R. Voronka, "SpiderFab: An Architecture for Self-Fabricating Space Systems," AIAA SPACE 2013 Conference and Exposition, San Diego, CA, USA, AIAA 2013-5509, doi: 10.2514/6.2013-5509

8) Steve Cole, John Leslie, "NASA Launches NOAA Weather Satellite Aboard United Launch Alliance Rocket to Improve Forecasts," NASA, 18 Nov. 2017, Release 17-086, URL: https://www.nasa.gov/press-release/nasa-launches-noaa-weather-satellite-aboard-united-launch-alliance-rocket-to-improve

9) "ELaNa XIV CubeSats Launch on JPSS-1 Mission," NASA, 18 Nov. 2017, URL: https://www.nasa.gov/feature/elana-xiv-cubesat-launch-on-jpss-1-mission

10) "NASA Announces Seventh Round of Candidates for CubeSat Space Missions," NASA, Feb. 18, 2016, URL: http://www.nasa-usa.de/feature/nasa-announces-seventh-round-of-candidates-for-cubesat-space-missions

11) Information provided by Stephen Parke of NNU, Nampa, Idaho.

12) Connor Nogales, Braden Grim, Mitch Kamstra, Benjamin Campbell, Aaron Ewing, Robert Hance, Dr. Joshua Griffin, Dr. Stephen Parke, "MakerSat-0: 3D-Printed Polymer Degradation First Data from Orbit," Proceedings of the 32nd Annual AIAA/USU Conference on Small Satellites, Logan UT, USA, Aug. 4-9, 2018, paper:SSC18-WKIII-01, URL: https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=4246&context=smallsat

The information compiled and edited in this article was provided by Herbert J. Kramer from his documentation of: "Observation of the Earth and Its Environment: Survey of Missions and Sensors" (Springer Verlag) as well as many other sources after the publication of the 4th edition in 2002. - Comments and corrections to this article are always welcome for further updates (eoportal@symbios.space).

Spacecraft Launch Mission Status Multi-user Science Boards Structure and assembly References Back to top