JWST (James Webb Space Telescope)

Non-EO

ESA

NASA

Operational (nominal)

Quick facts

Overview

| Mission type | Non-EO |

| Agency | ESA, NASA, CSA |

| Mission status | Operational (nominal) |

| Launch date | 25 Dec 2021 |

JWST (James Webb Space Telescope)

Concept Launch Mission Status Observatory Sensor Complement Spacecraft Bus and Sunshield Spinoff Technologies References

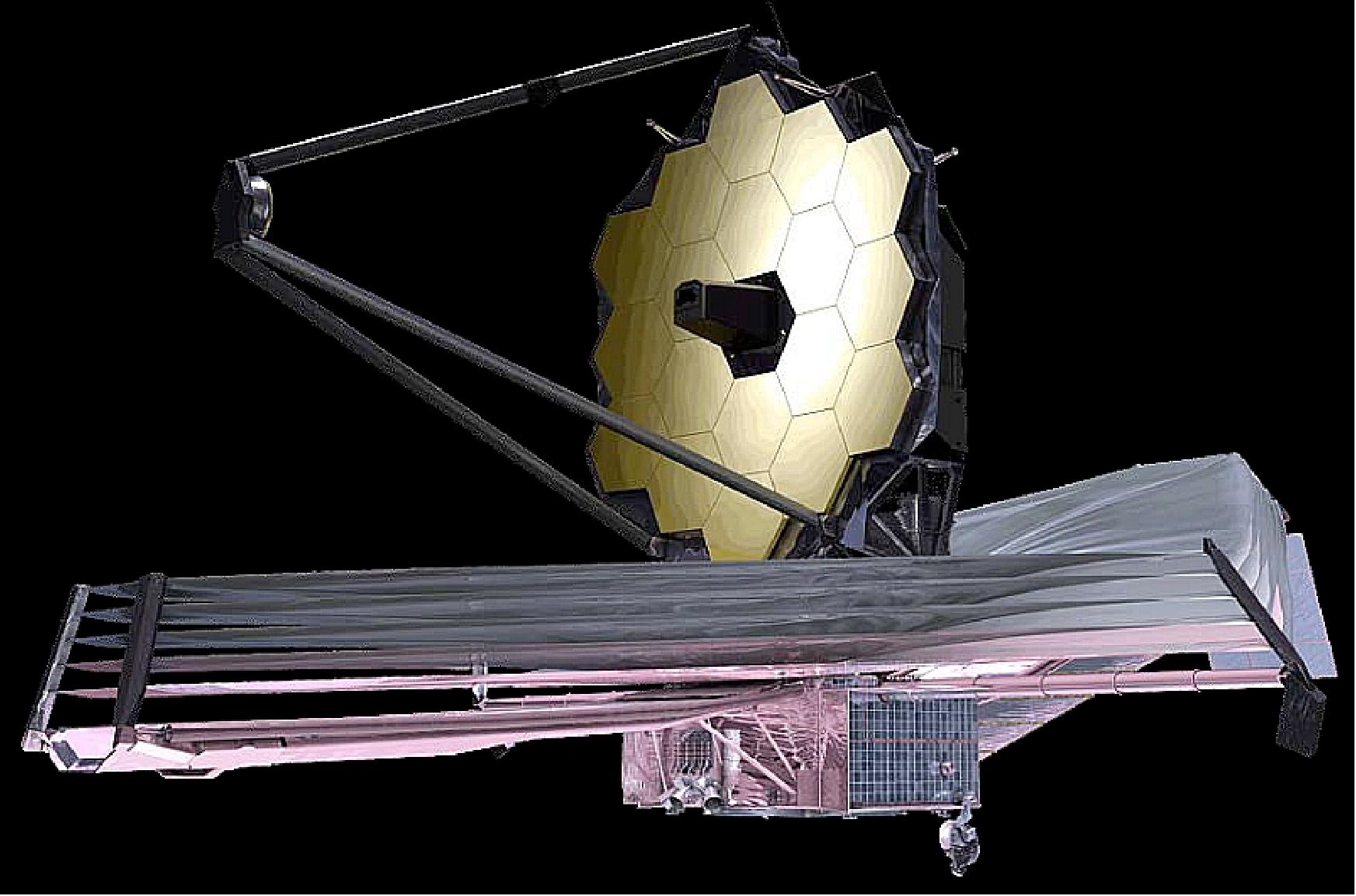

JWST is an orbiting optical observatory and a key element in NASA's Origins Program, optimized for observations in the infrared region of the electromagnetic spectrum. It is considered the successor mission of HST (Hubble Space Telescope) while operating over a different spectral range. At the NIR and MWIR wavelengths, it benefits from operating at intrinsically lower backgrounds than any comparably sized telescope on the ground. JWST, previously known as NGST (Next Generation Space Telescope), will be the premier space facility for astronomers in the decade following its launch. The overall objectives are to study the first stars and galaxies after the big bang. Major science goals (themes) of the mission are to find answers to the following questions: 1) 2)

• What is the shape of the Universe?

• How do galaxies evolve?

• How do stars and planetary systems form and interact?

• How did the Universe built up its present chemical/elemental composition?

• What is the nature of dark matter?

The radiation from the very distant objects to be observed is practically all in the infrared region. Many of the early events happened when the Universe was between 1 million and 1 billion years old, a period that is not known to earthlings (the dark ages of the Universe). To accomplish the goals of the science themes, the main JWST design requirement calls for the detection of objects up to 400 times fainter than those observable by current ground-based or spaceborne observatories.

Historical background: Large next-generation projects with high-performance observation requirements take about two decades (and more) from first studies to launch. Initial planning for the new mission started in 1989 (visions, conceptual studies). The goal was to have a successor mission for HST ready for launch well before 2010.

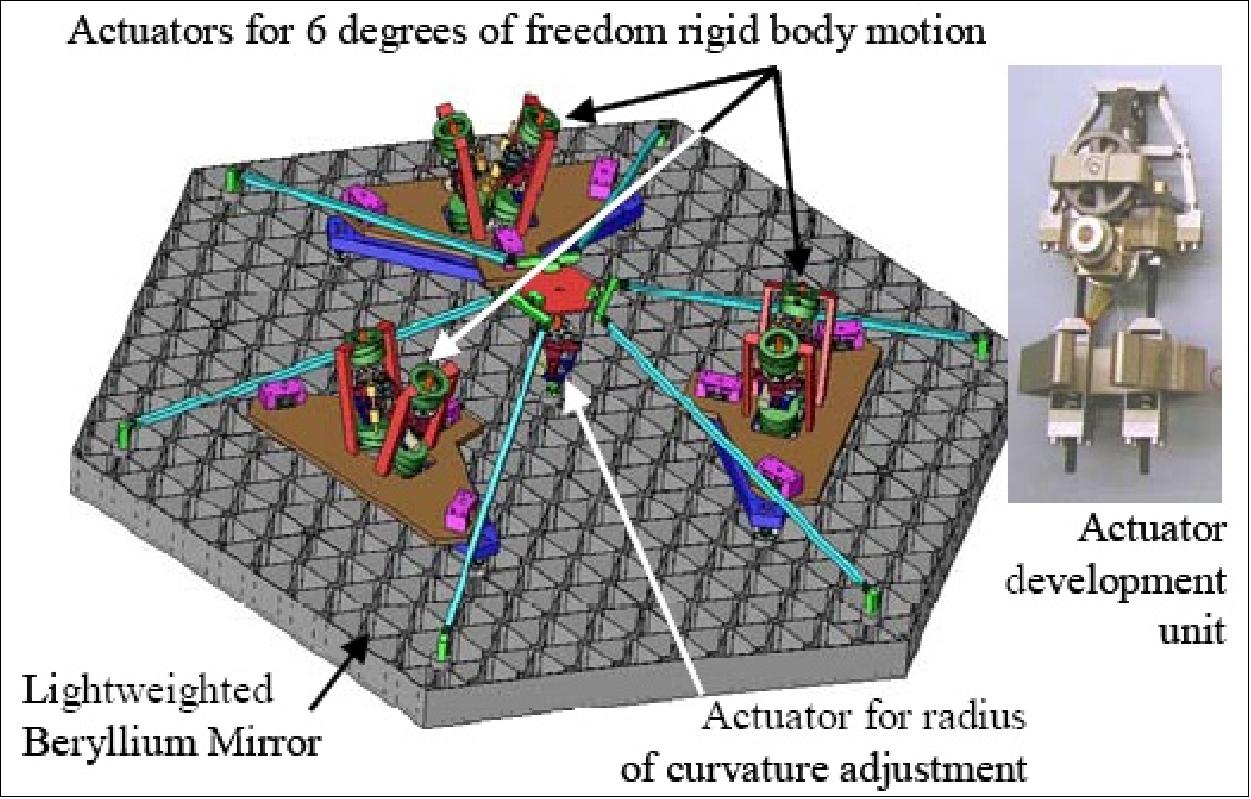

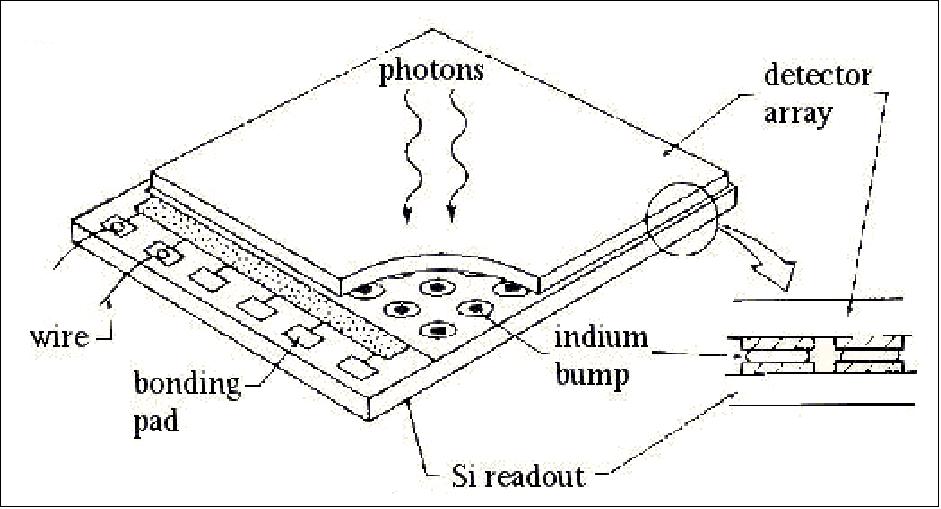

In the mid-1990s, a telescope design with an 8 m aperture was considered. The challenge was to come up with a lower cost for the large telescope than for previous much smaller space telescopes. This involved conceptual studies by industry. In 1996, a committee report was written, based on these studies: "Next Generation Space Telescope, Visiting a Time When Galaxies Were Young." This report established also a roadmap to NGST activities, defining the new building blocks and to search for enabling technologies and concepts - in particular in the fields of large-aperture lightweight mirrors that are actively controlled, of advanced detector designs, of suitable cooling techniques for all critical components, and of precision metrology to achieve the goal of measuring ultra precise stellar positions.

A broad range of talent on a national and international level and from many institutions, academia and industry was directly involved in the NGST detailed definition phase (Phase A) including simulations and feasibility studies. In 1997, an ad hoc Science Working Group was formed which came up with thematic science goals and developed a so-called "Design Reference Mission" (DRM), representing a hypothetical suite of key science observing programs [stating the expected physical properties (number density and brightness), the desired observation modes (wavelength band, spectral resolution, number of revisits), and a minimum operational life of 2.5 years to complete the mission] for NGST - which provided a yardstick for technology testing. DRM was and is the primary tool against which any JWST architectures are being measured. The shear complexity of the project and the performance requirements demanded a technology development and validation strategy to address and demonstrate a critical path to a workable design of the mission. 3) 4) 5) 6)

In 2000/1, the NGST project experienced a rescoping of the telescope size (from 8 m aperture to 6.5 m) to keep projected costs in bounds. There were also some technology maturity uncertainties.

The project started in 2002 with a Mission Definition Review. NASA began to realize that the critical technologies had reached a level of sufficient maturity to justify a go-ahead with the next phase of the project.

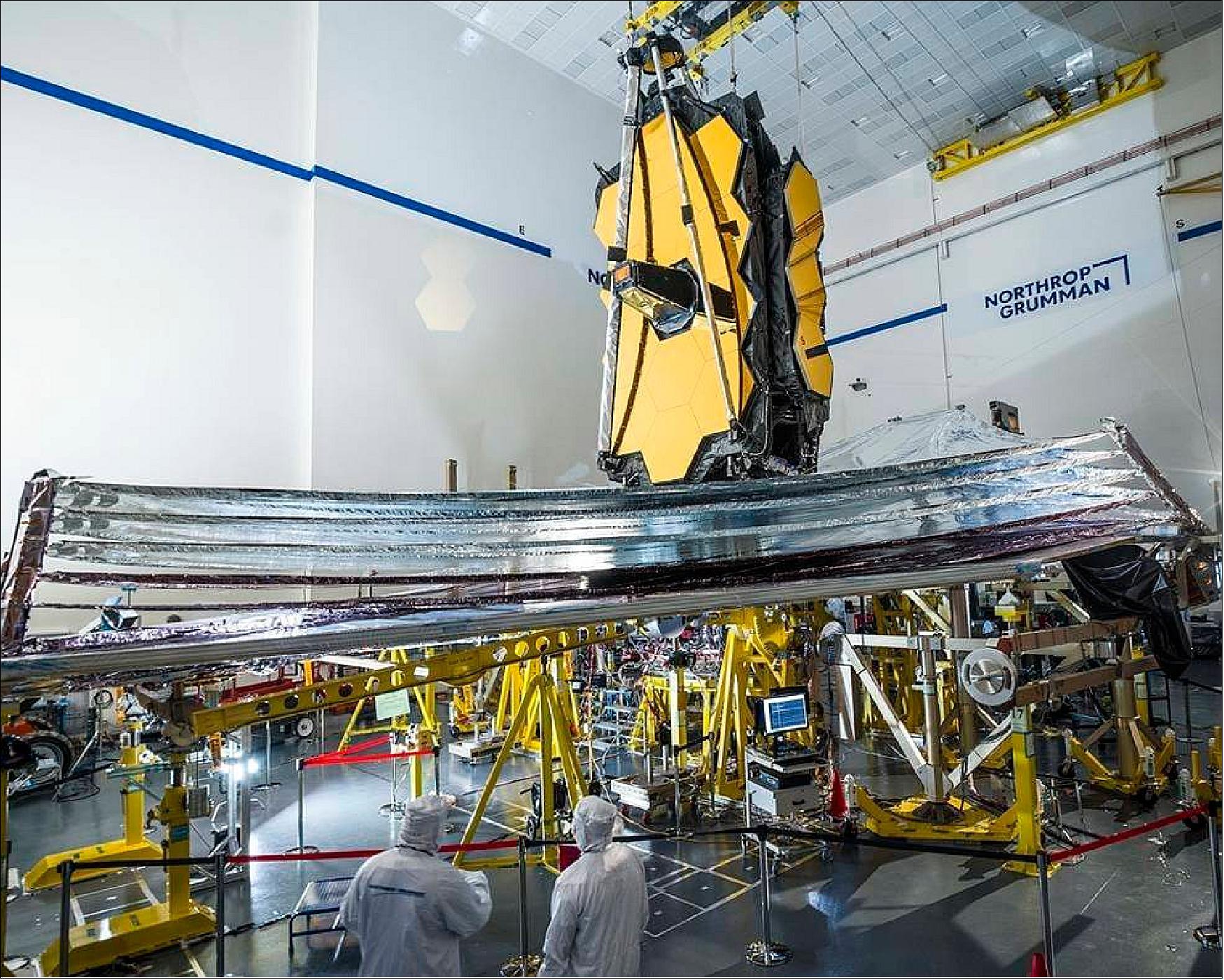

In September 2002, NASA renamed NGST to JWST (James Webb Space Telescope) in honor of James E. Webb (1906-1992), NASA's second administrator during the Apollo Program of the 1960s (1961-1968). At the same time in Sept. 2002, NASA awarded the prime contract of the JWST observatory development (spacecraft, telescope, integration and testing) to Northrop Grumman Space Technology (formerly TRW) of Redondo Beach, CA.

In the fall of 2003 ICR(Initial Confirmation Review) was given, starting the Phase B of the JWST project. The C/D Phase started in 2008.

The CDR (Critical Design Review) of the JWST (James Webb Space Telescope) is planned for December 2013 (Ref. 69).

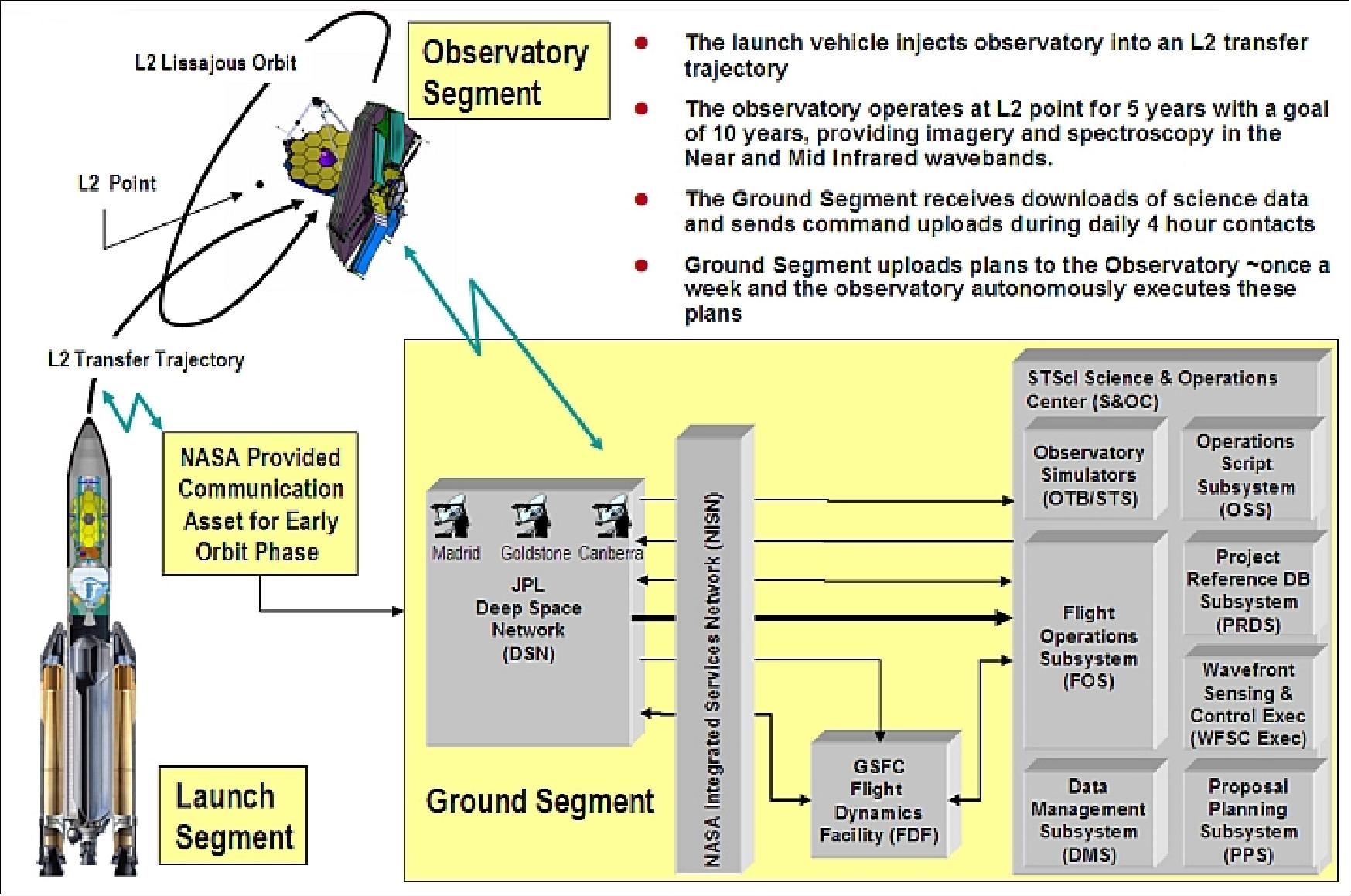

Project partners: NASA leads an international partnership in the joint JWST mission that includes ESA (European Space Agency) and CSA (Canadian Space Agency). Both agencies (ESA, CSA) collaborated in the JWST project already at an early planning stage (1996). Aside from instrument contributions, ESA will also launch the JWST spacecraft on an Ariane 5 launcher as agreed to with NASA. NASA/GSFC is managing the JWST project, while STScI (Space Telescope Science Institute) of Baltimore, MD, is responsible for JWST science and mission operations, as well as ground station development (STScI is the same organization that is operating the Hubble Space Telescope). A formal JWST and LISA (Laser Interferometer Space Antenna) cooperation agreement between NASA and ESA was signed on June 18, 2007 at the International Paris Air Show at Le Bourget, France. 7) 8) 9) 10) 11)

A most interesting and valuable side effect of the technology development effort for JWST is that these new technologies will also be available to many other space projects (astronomy, space science, Earth observation, etc.) providing potentially a quantum step in observation performance.

Mission Concept

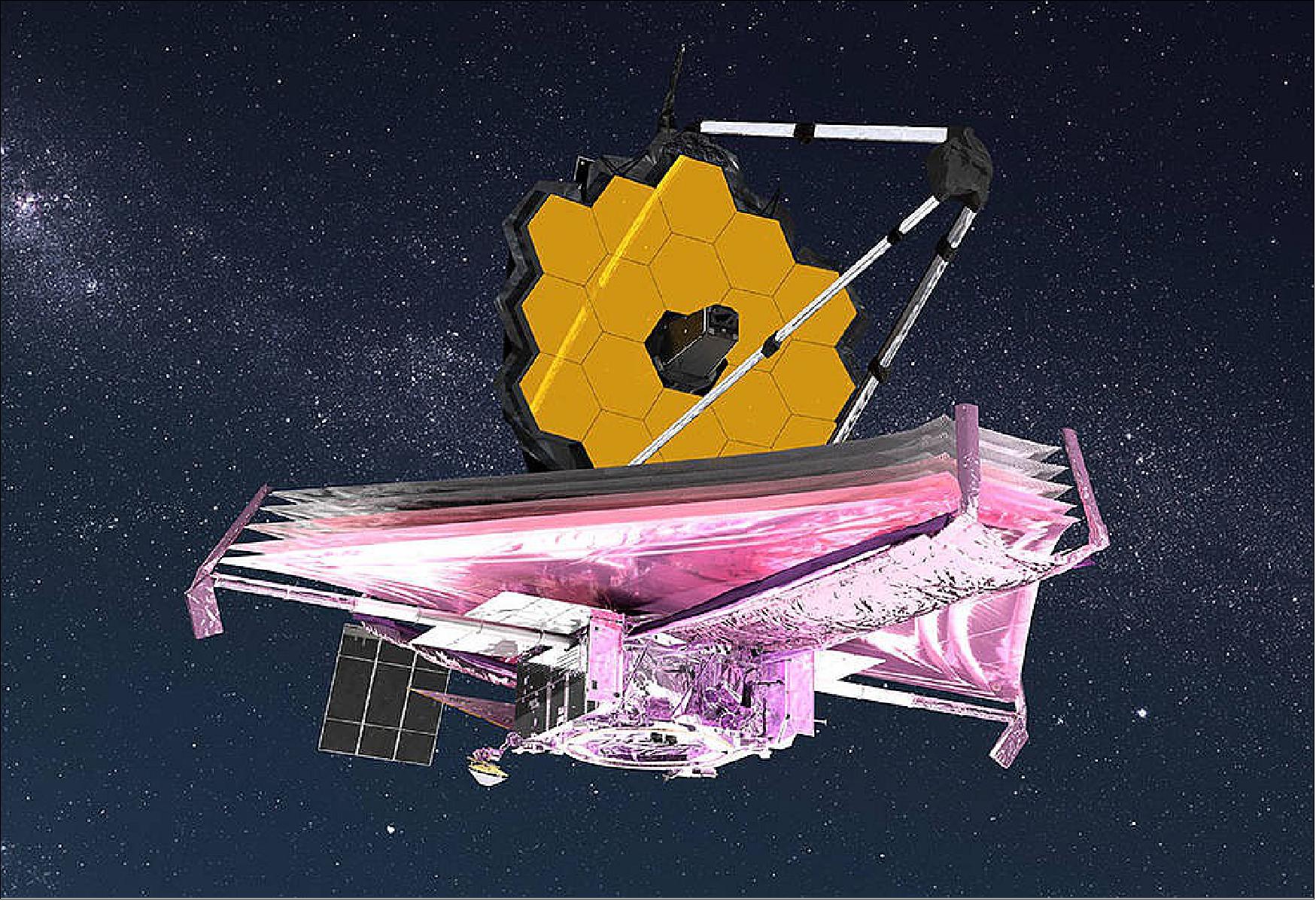

The JWST mission concept is an ambitious and most challenging development program, requiring a lot of innovative technology introduction as well as conceptual breakthroughs on various levels to meet the proposed observational performances. The objectives of the science themes can only be met by a combination of a large-aperture telescope in space (6.5 m φ ), a very low detection temperature to eliminate noise, and an ideal observing environment (elimination of stray light).

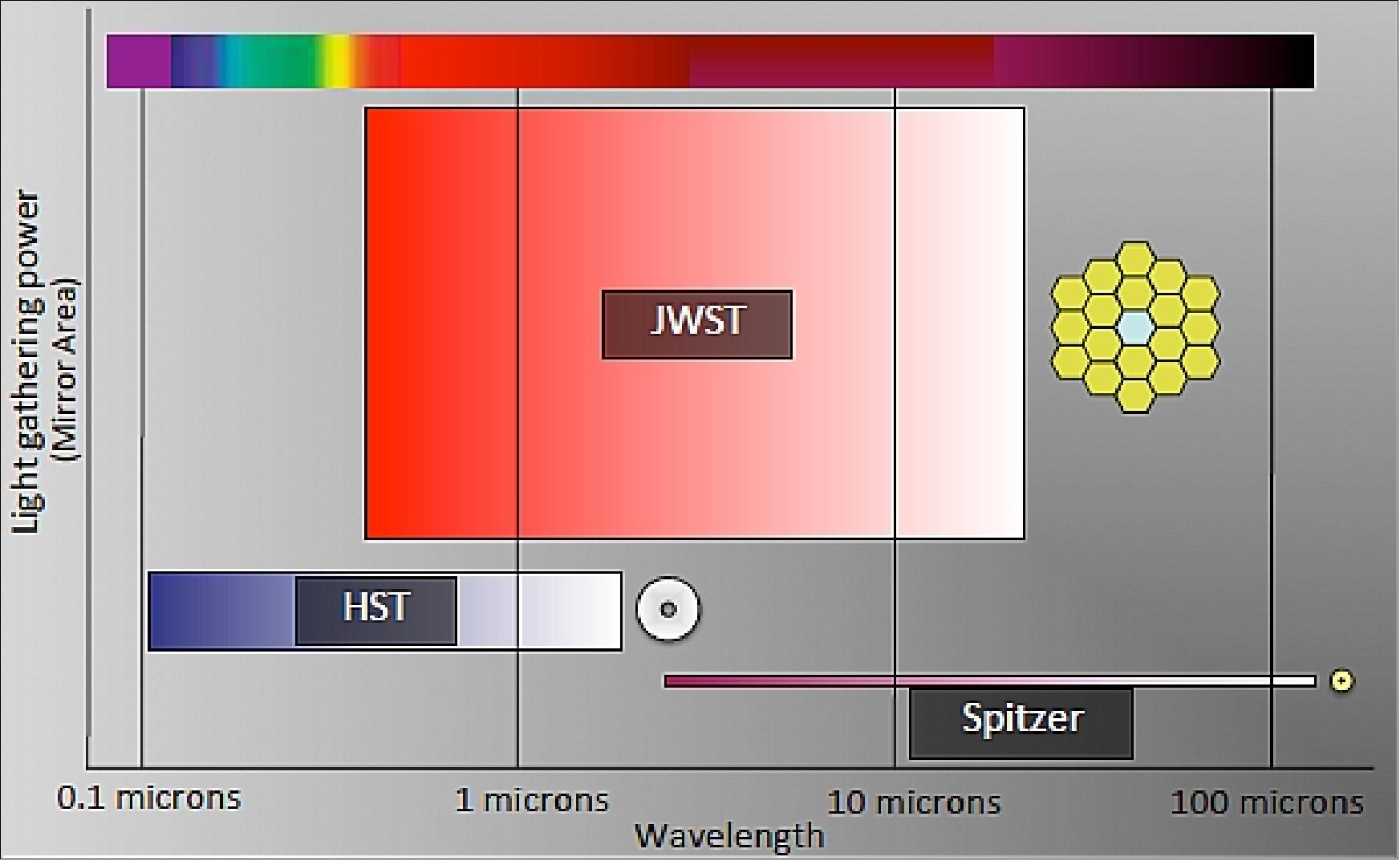

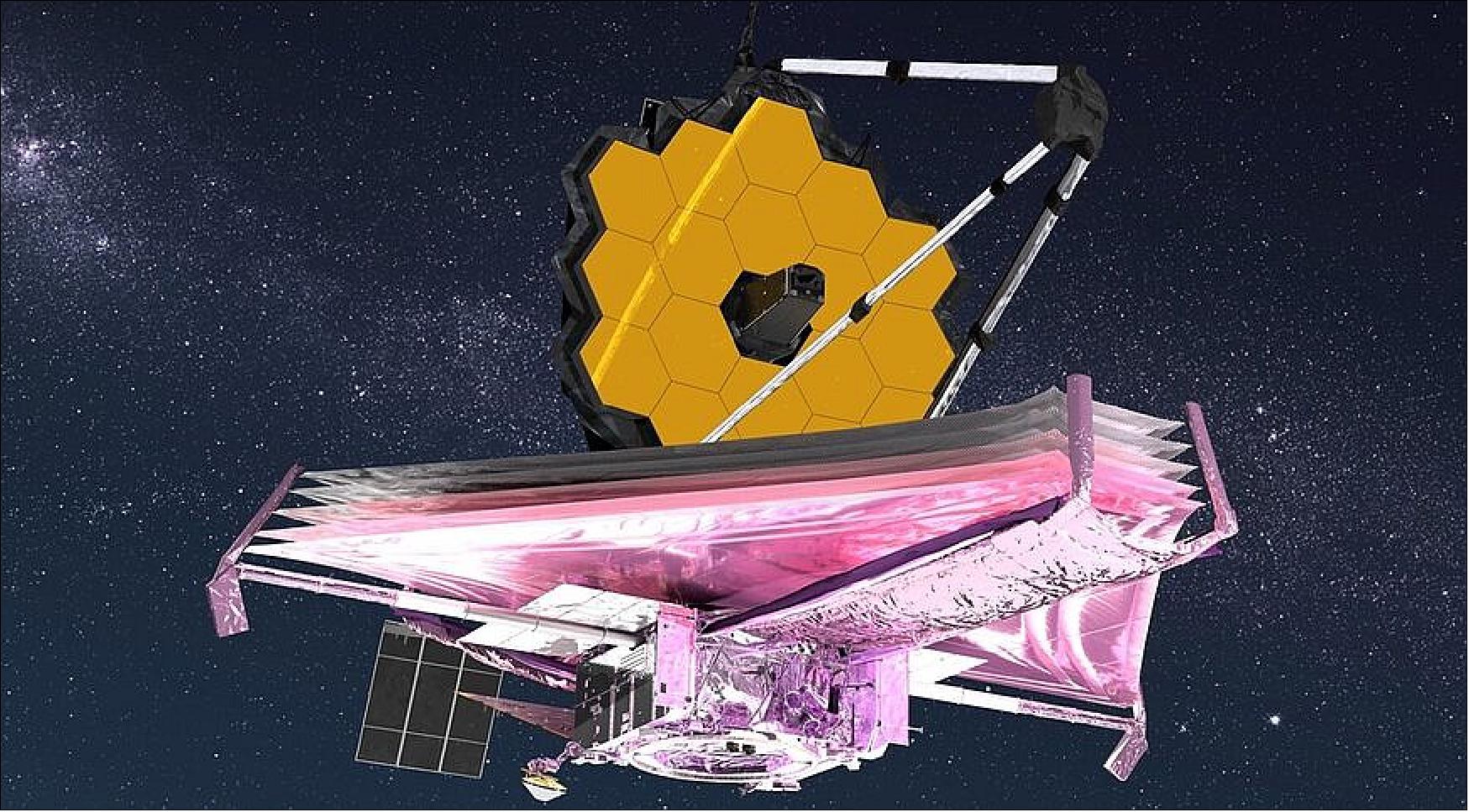

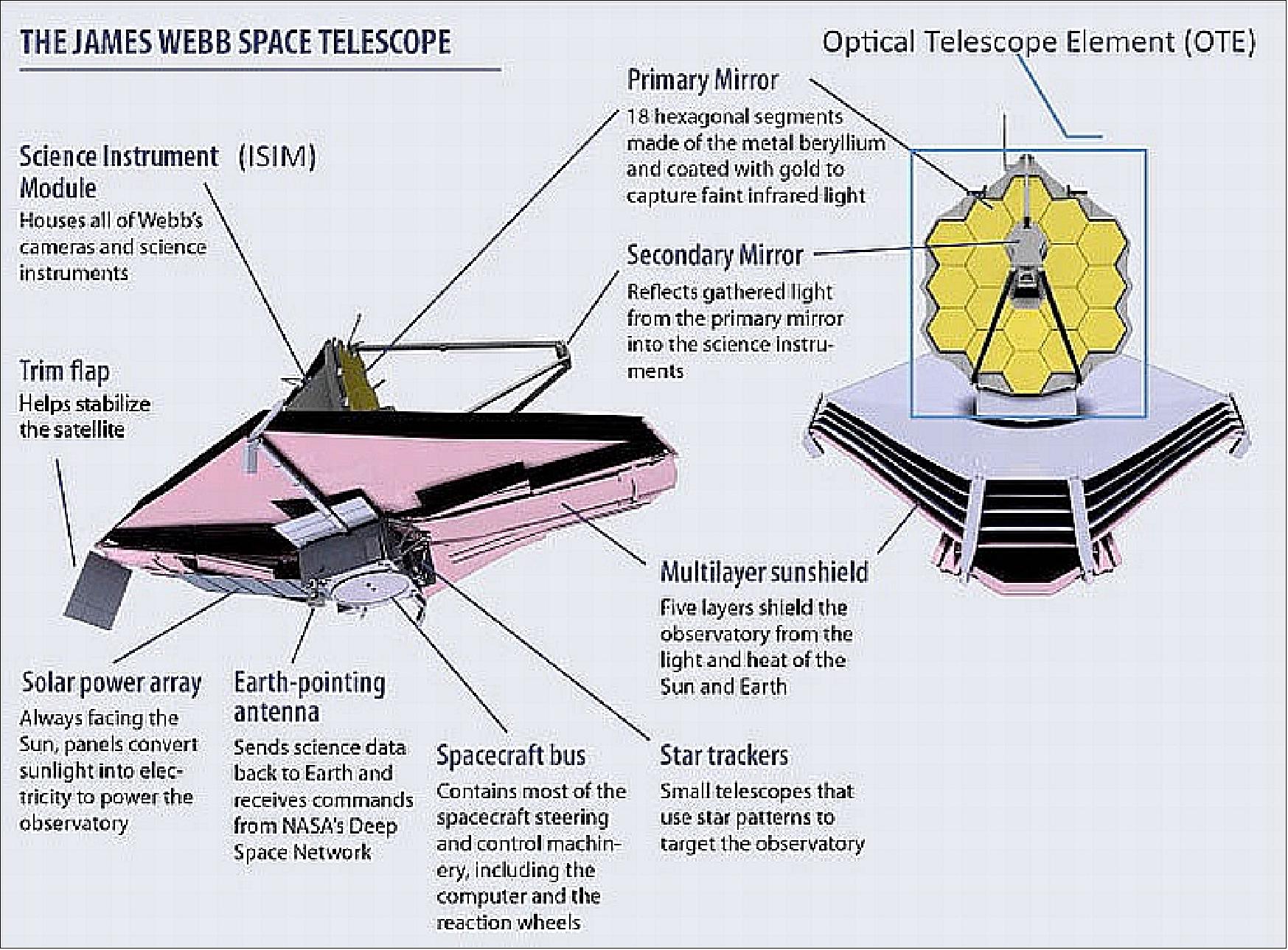

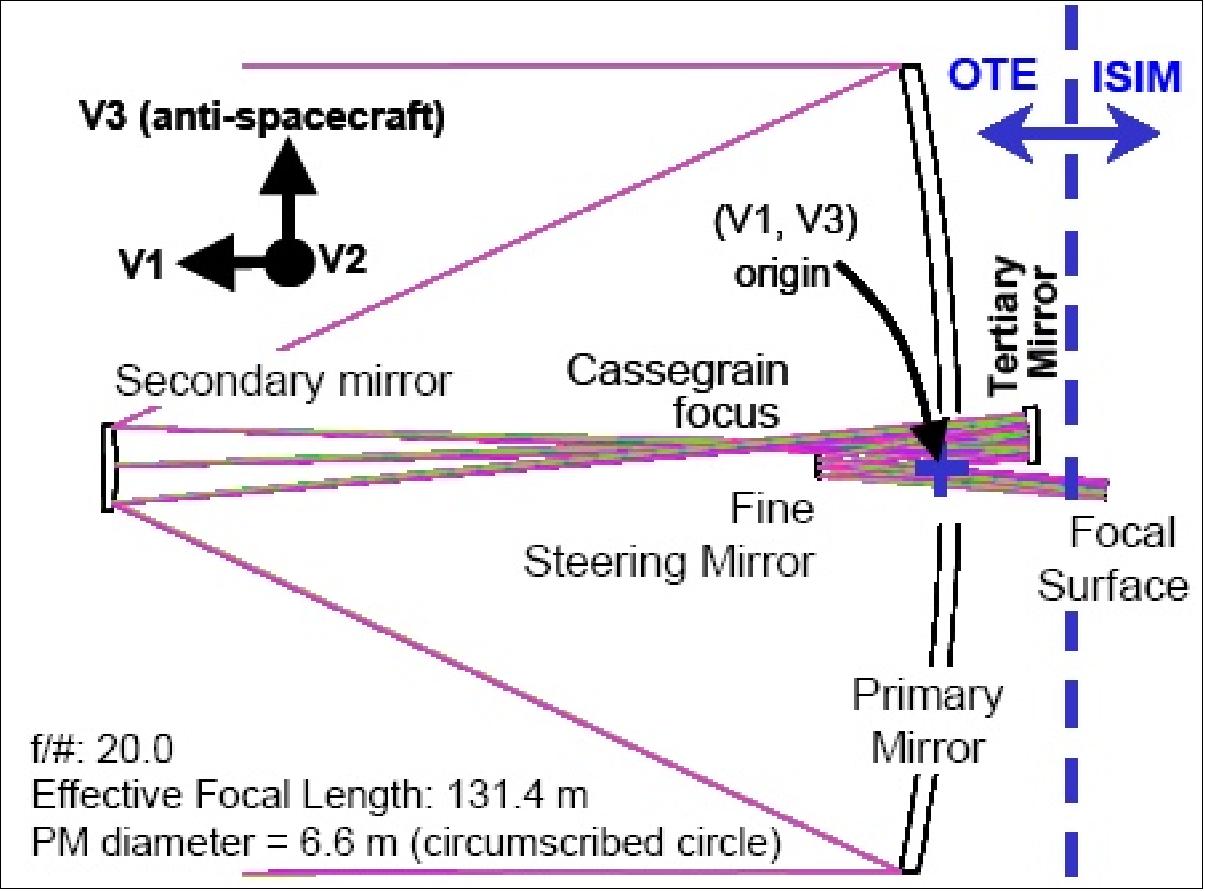

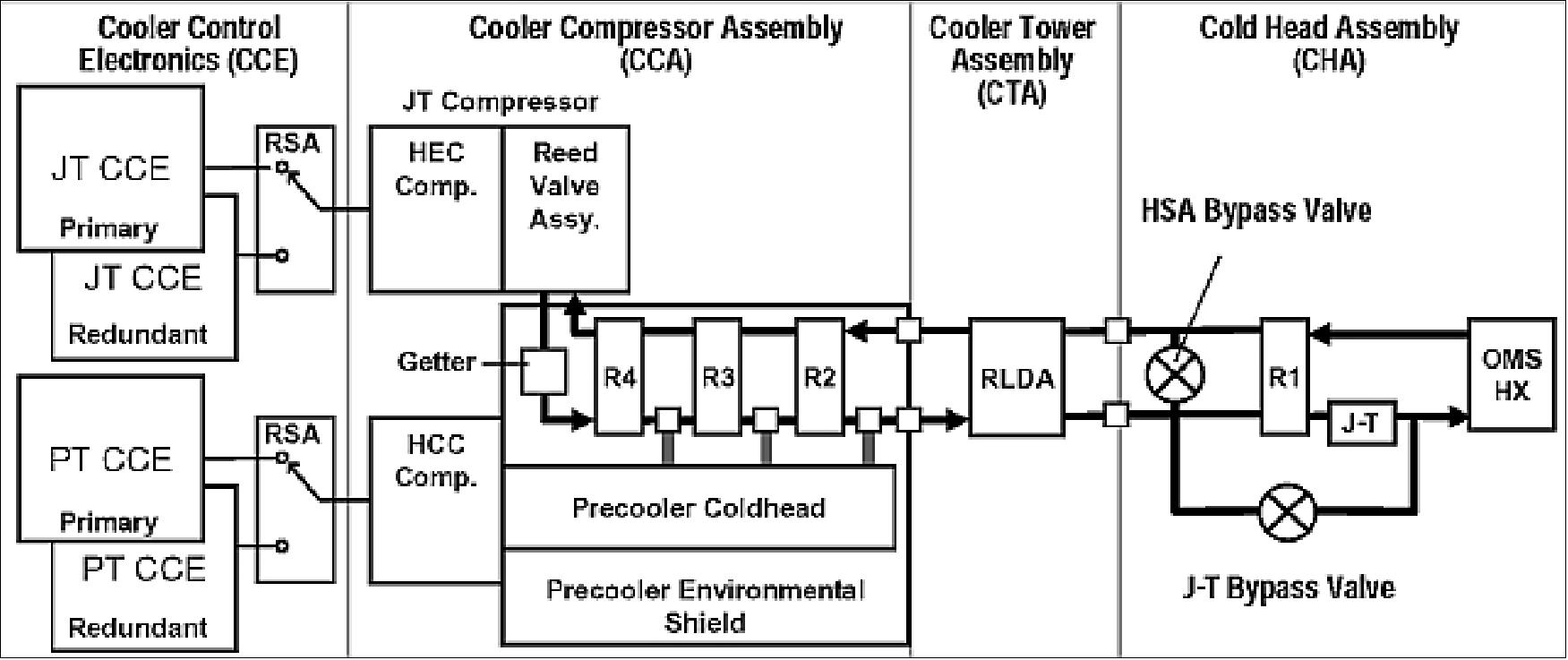

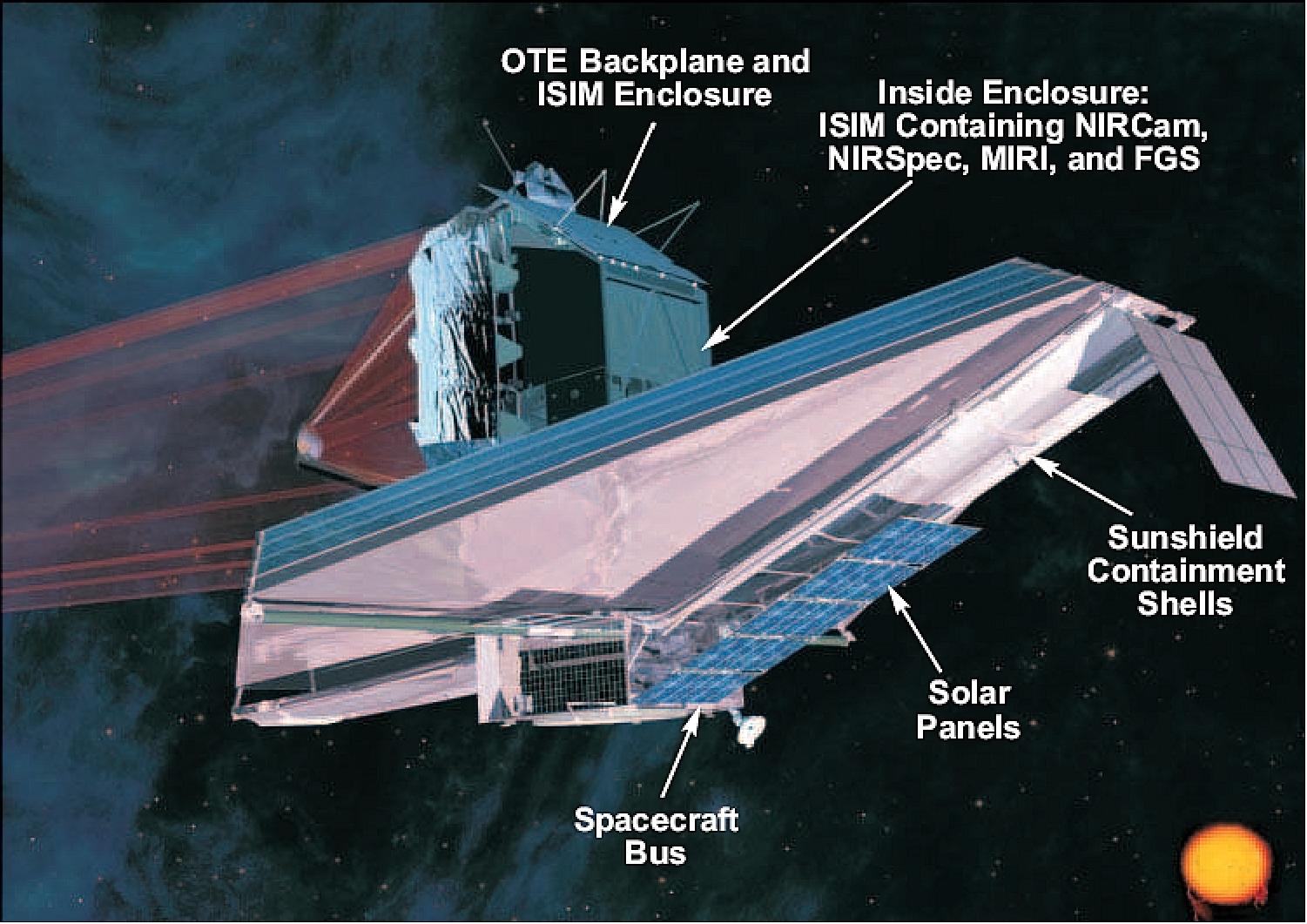

The observatory will be shielded from the sun and Earth by a large deployable sunshade, the entire telescope assembly will be passively cooled to about 37 K, giving JWST exceptional performance in the near-infrared and mid-infrared wavebands. The baseline wavelength range for the instrumentation is 0.6 - 28 µm, and the telescope will be diffraction-limited above 2 µm. The sensitivity of the telescope will be limited only by the natural zodiacal background, and should exceed that of ground-based and other space-based observatories by factors of 10 to 100,000, depending on the wavelength and type of observation. The JWST observatory will have a 5 year design life (with a goal of 10 years of operations) and will not be serviceable by astronauts (as is Hubble). The total mass of JWST at launch is estimated to be 6,500 kg.

Like Hubble, the JWST will be used by a broad astronomical community to observe targets ranging from objects within our Solar System to the most remote galaxies seen during their formation in the early universe.

Major enabling technologies are:

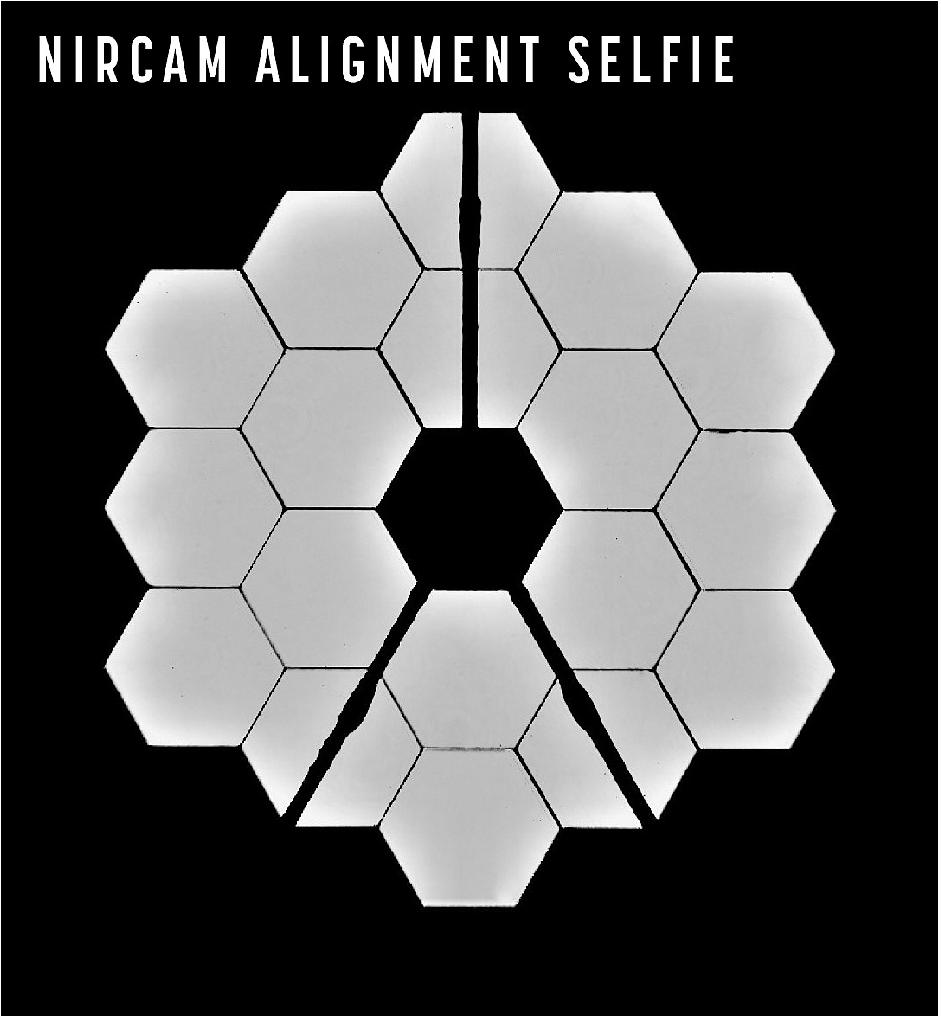

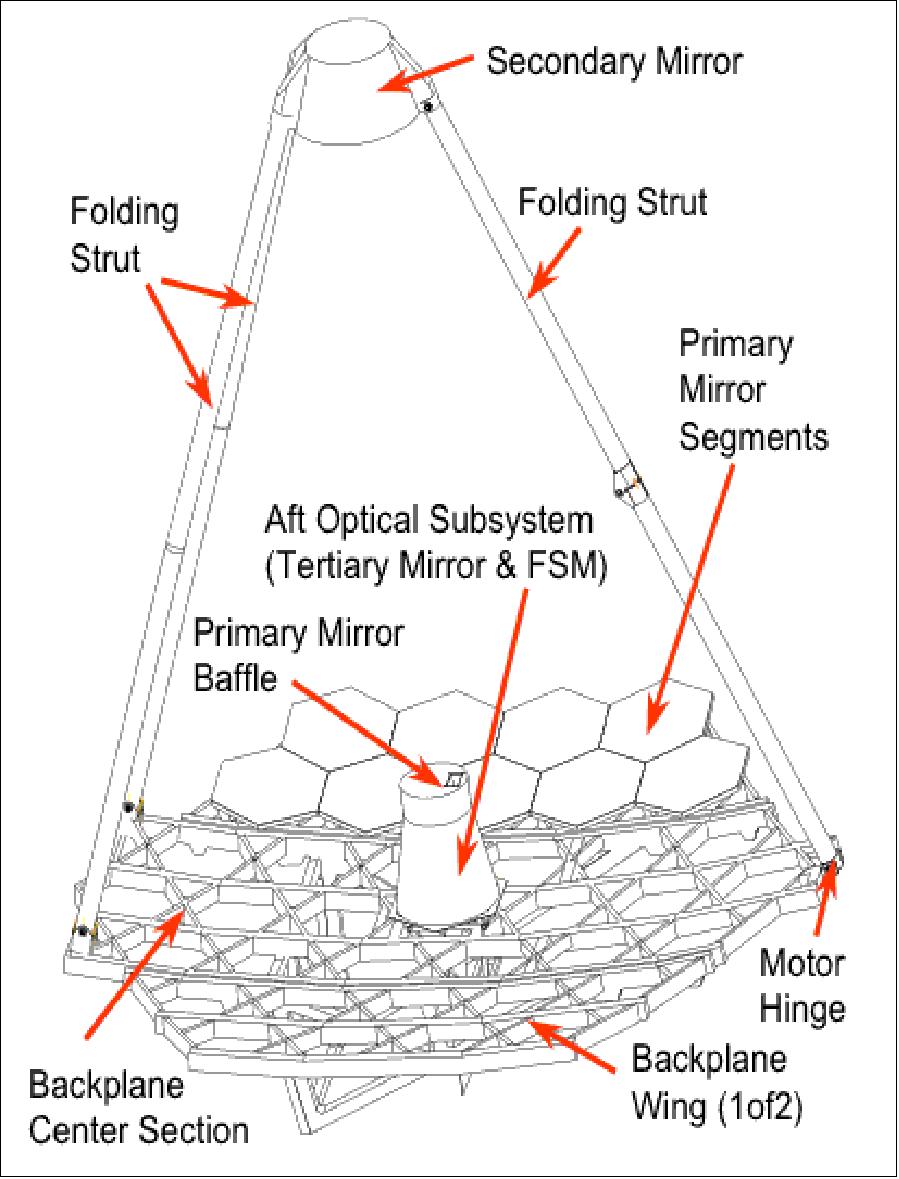

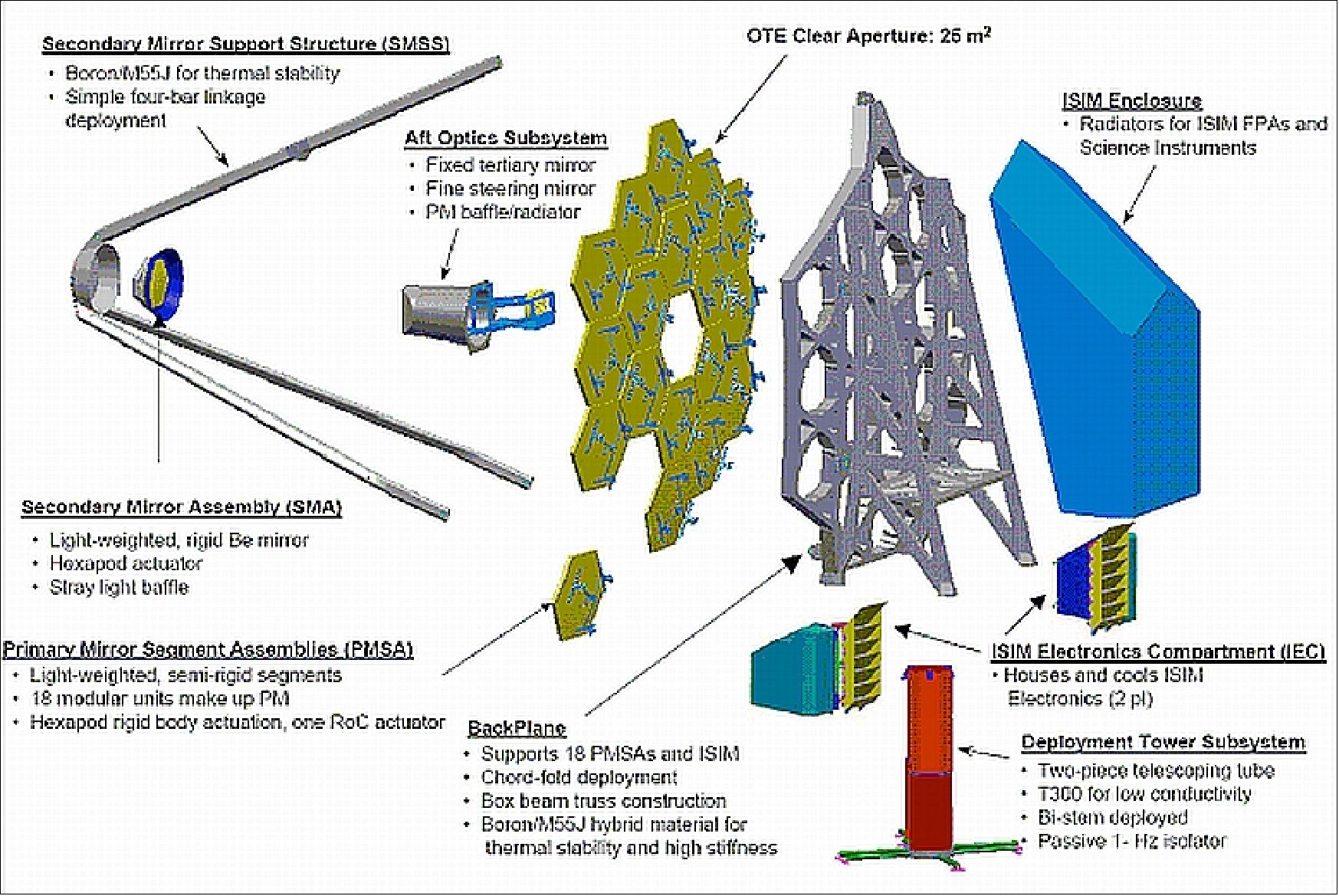

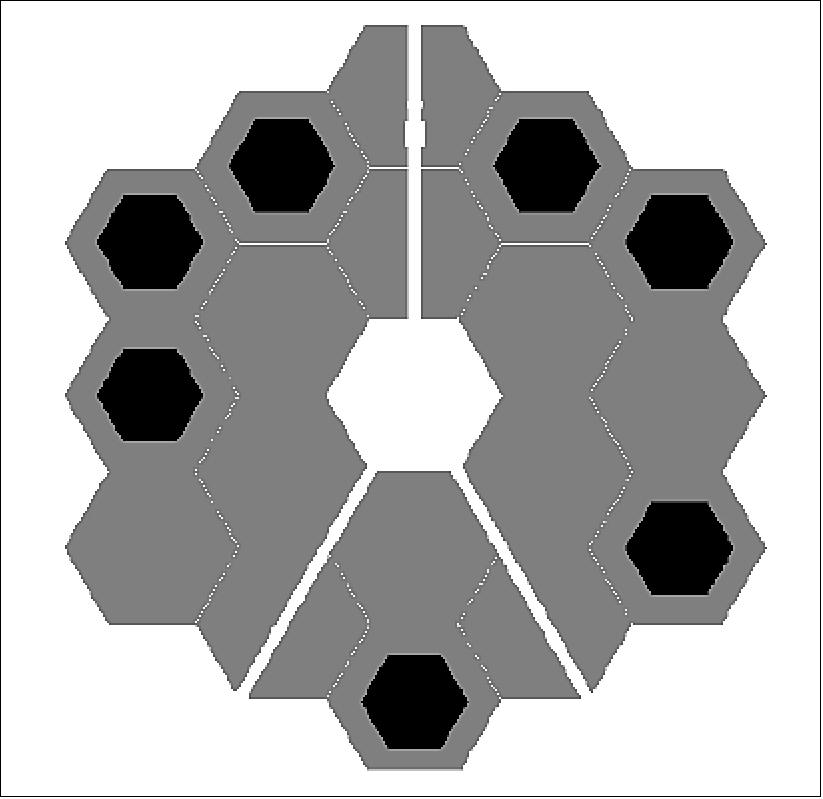

• Large deployable and lightweight beryllium mirrors (a folding 6.5 meter mirror made up of 18 individual segments, adjustable by cryogenic actuators). To fit inside the launch vehicle, the large space telescope prime mirror must be folded in sections for launch, then unfolded (deployed) precisely into place after launch, making it the first segmented optical system deployed in space.

• Deployment of large structures. Once in space, the multilayer sunshield that was folded over the optics during launch will deploy to its full size and keep the telescope shadowed from the sun.

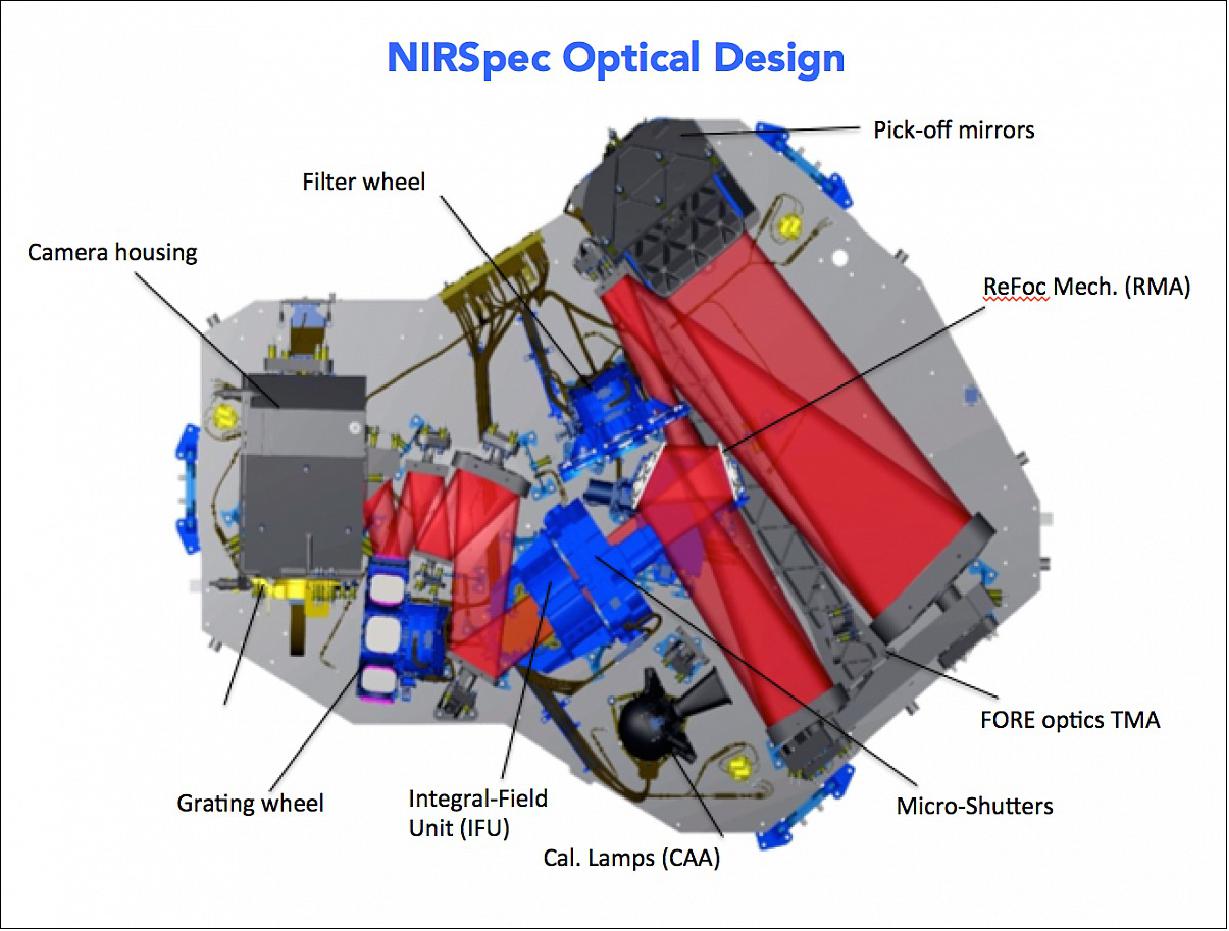

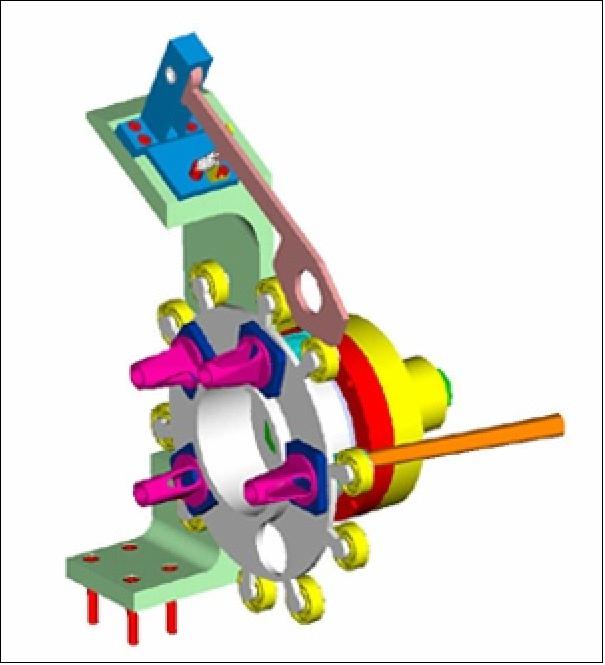

• Introduction of MEMS technology to the microshutter system of the NIRSpec instrument. The programmable microshutters to allow object selection for the spectrograph.

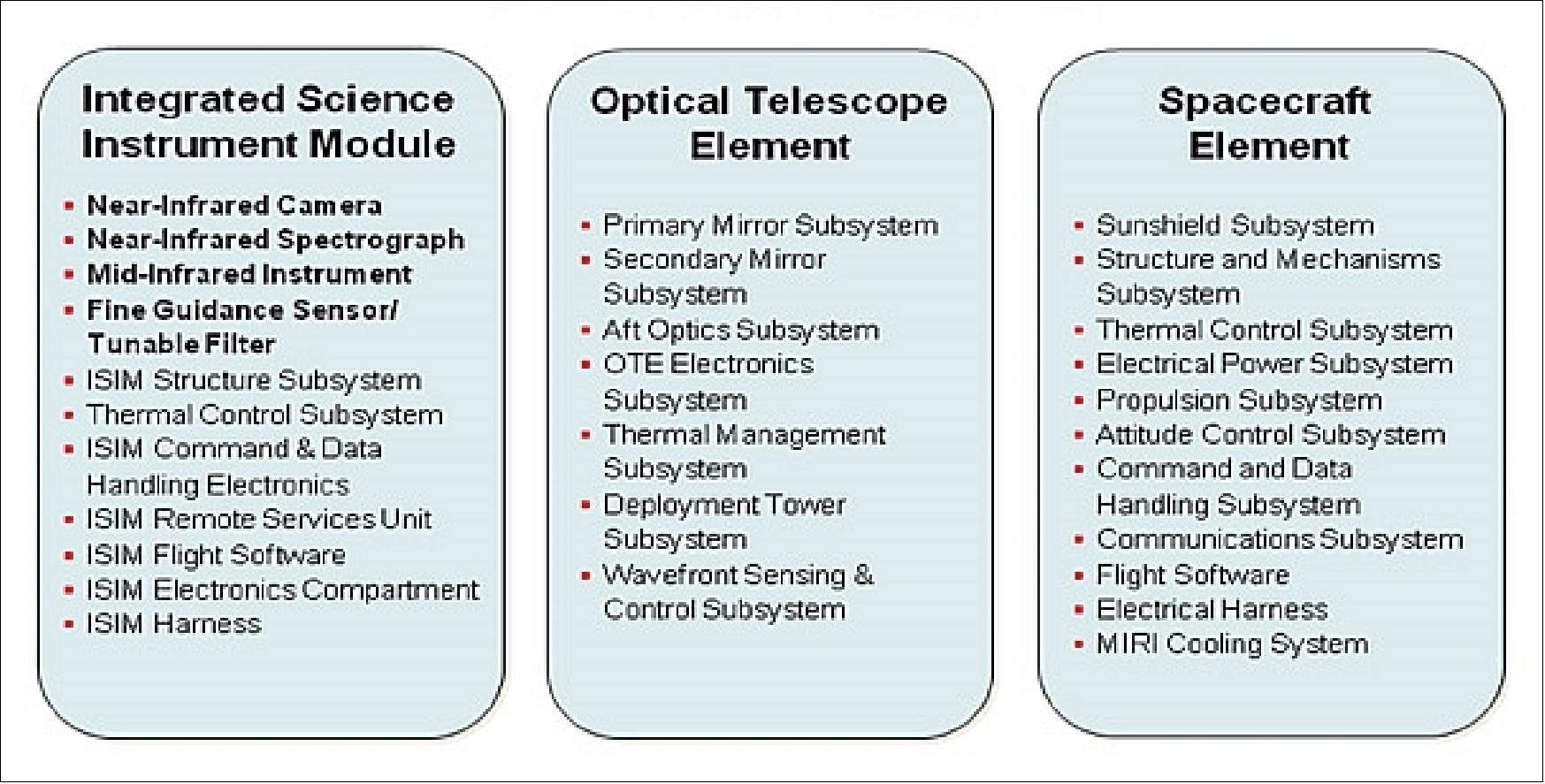

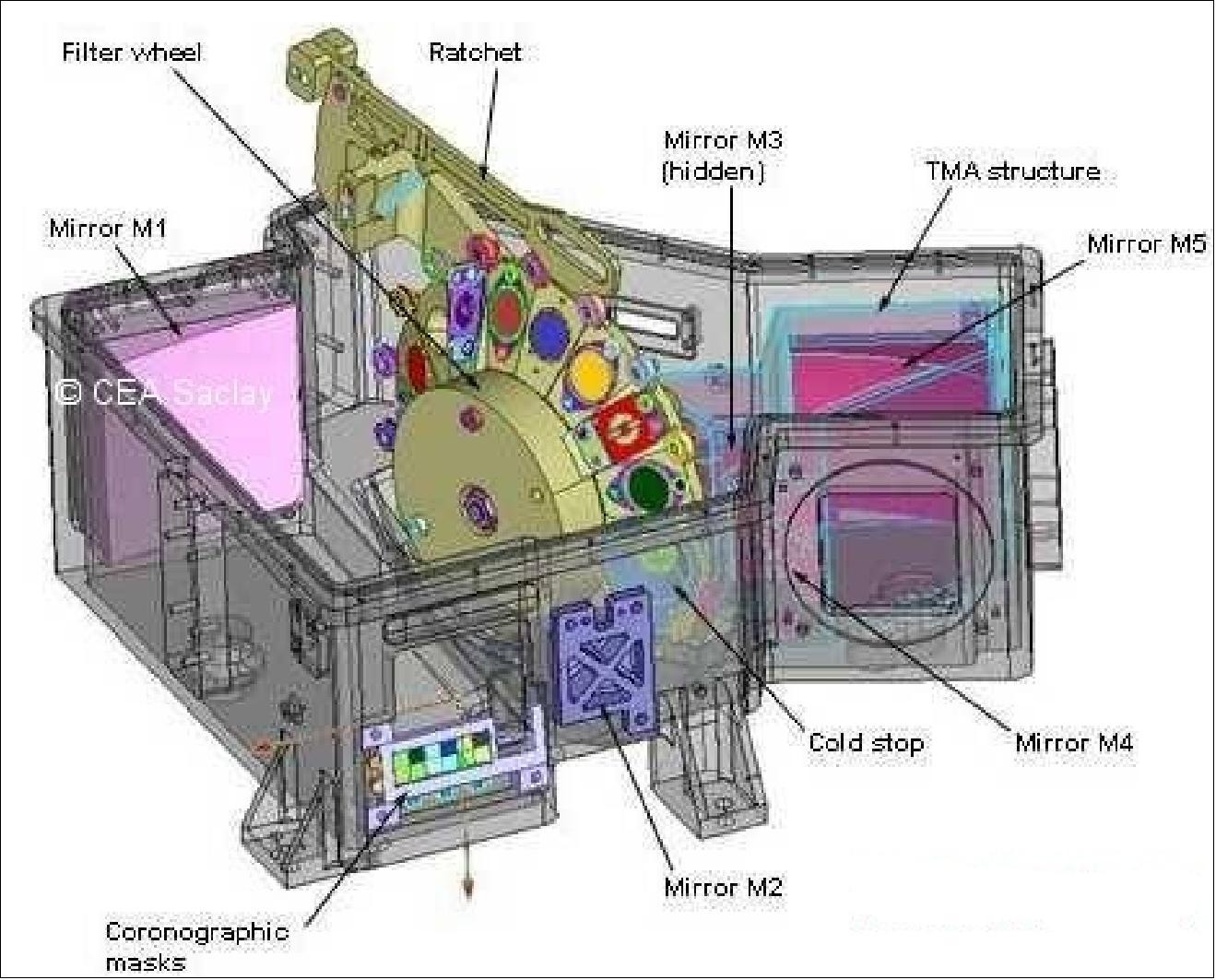

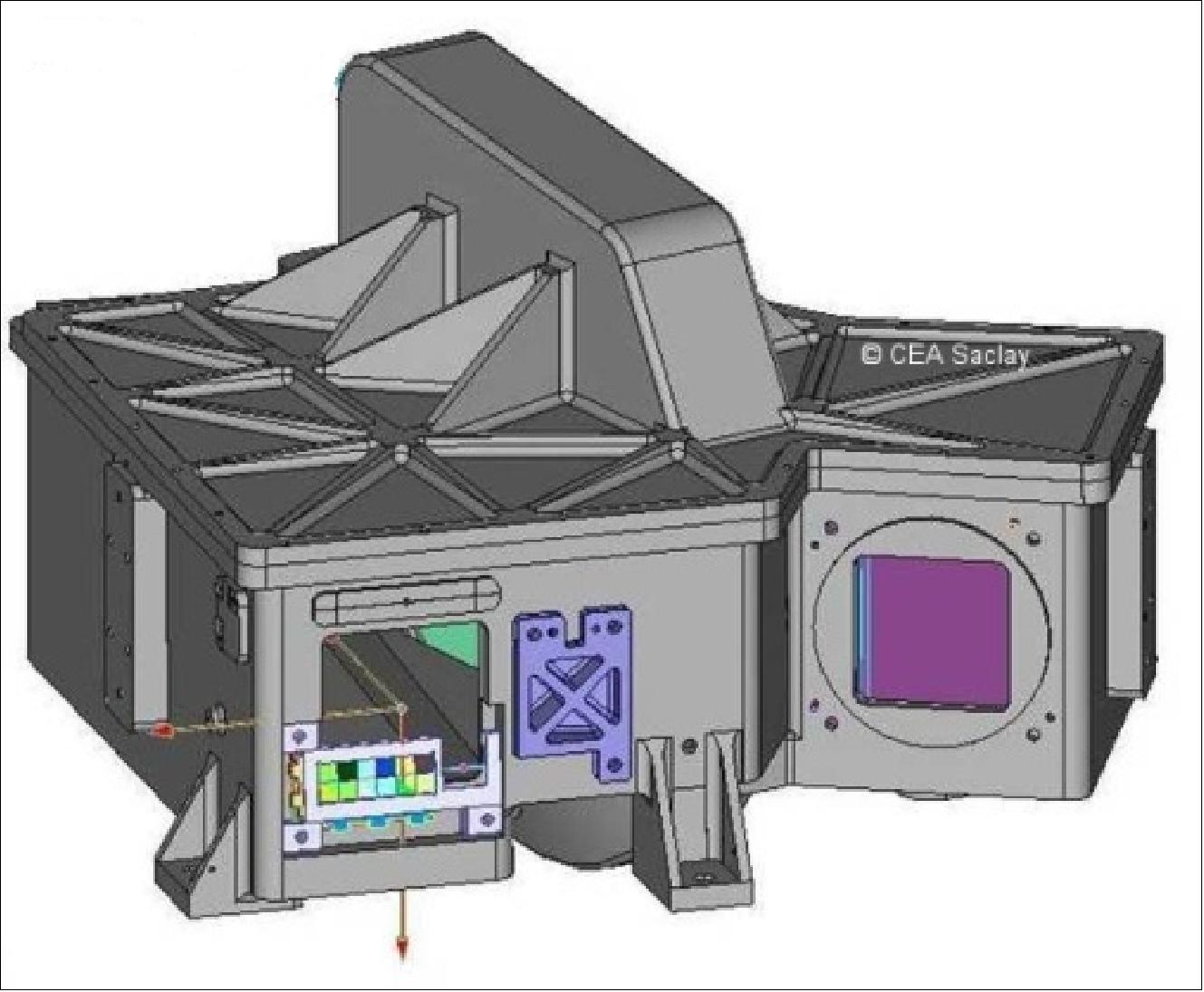

Overview of Payload Instruments

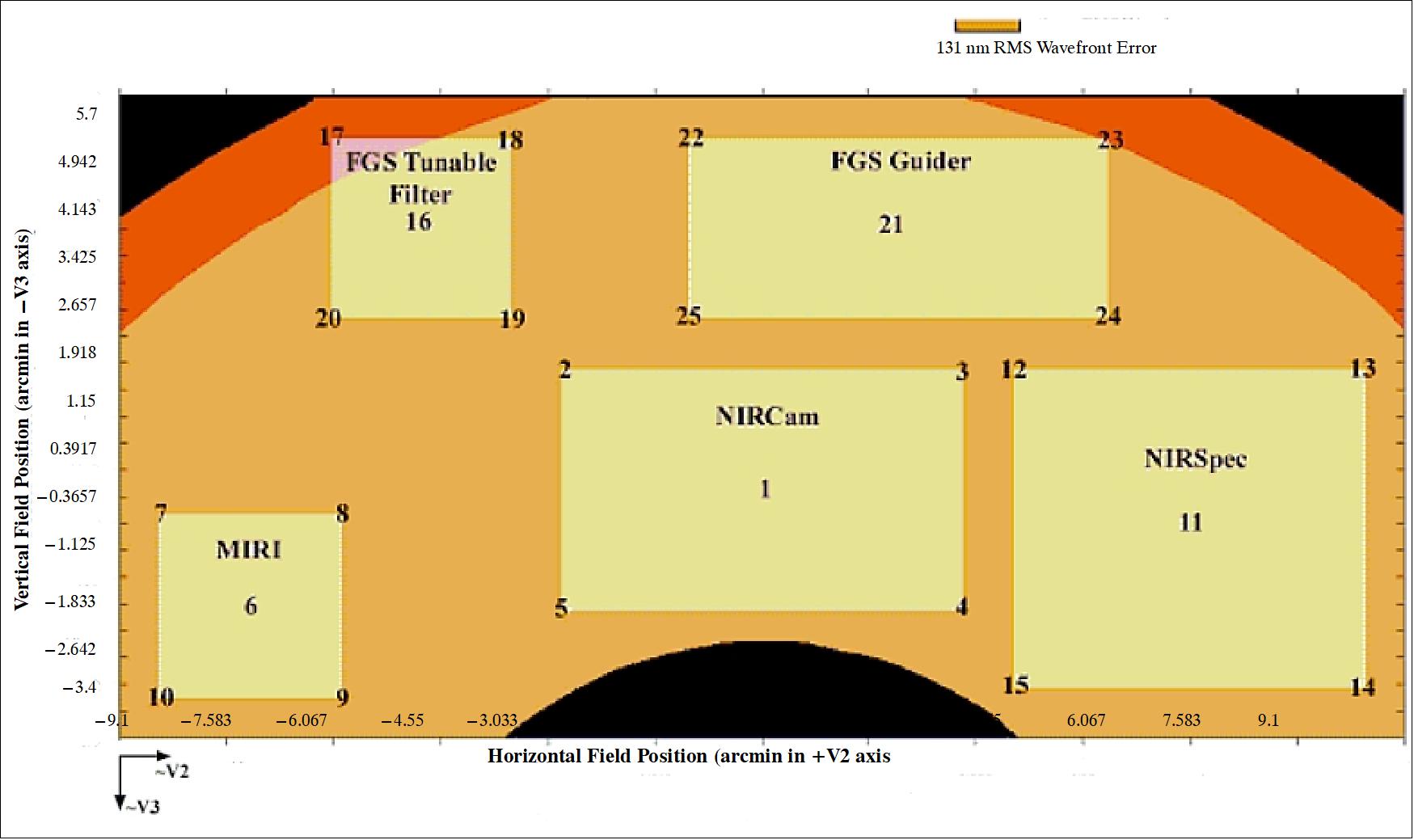

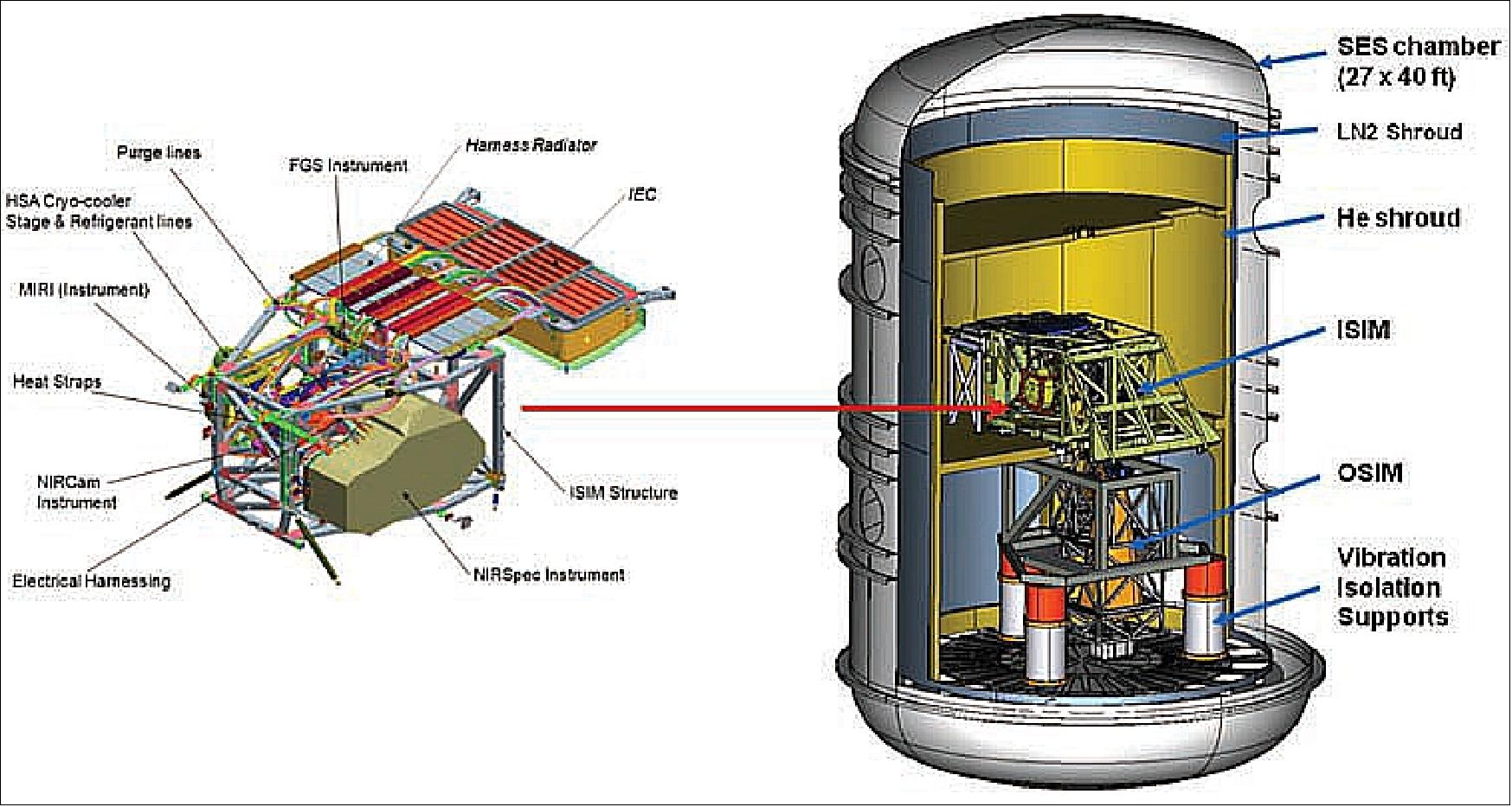

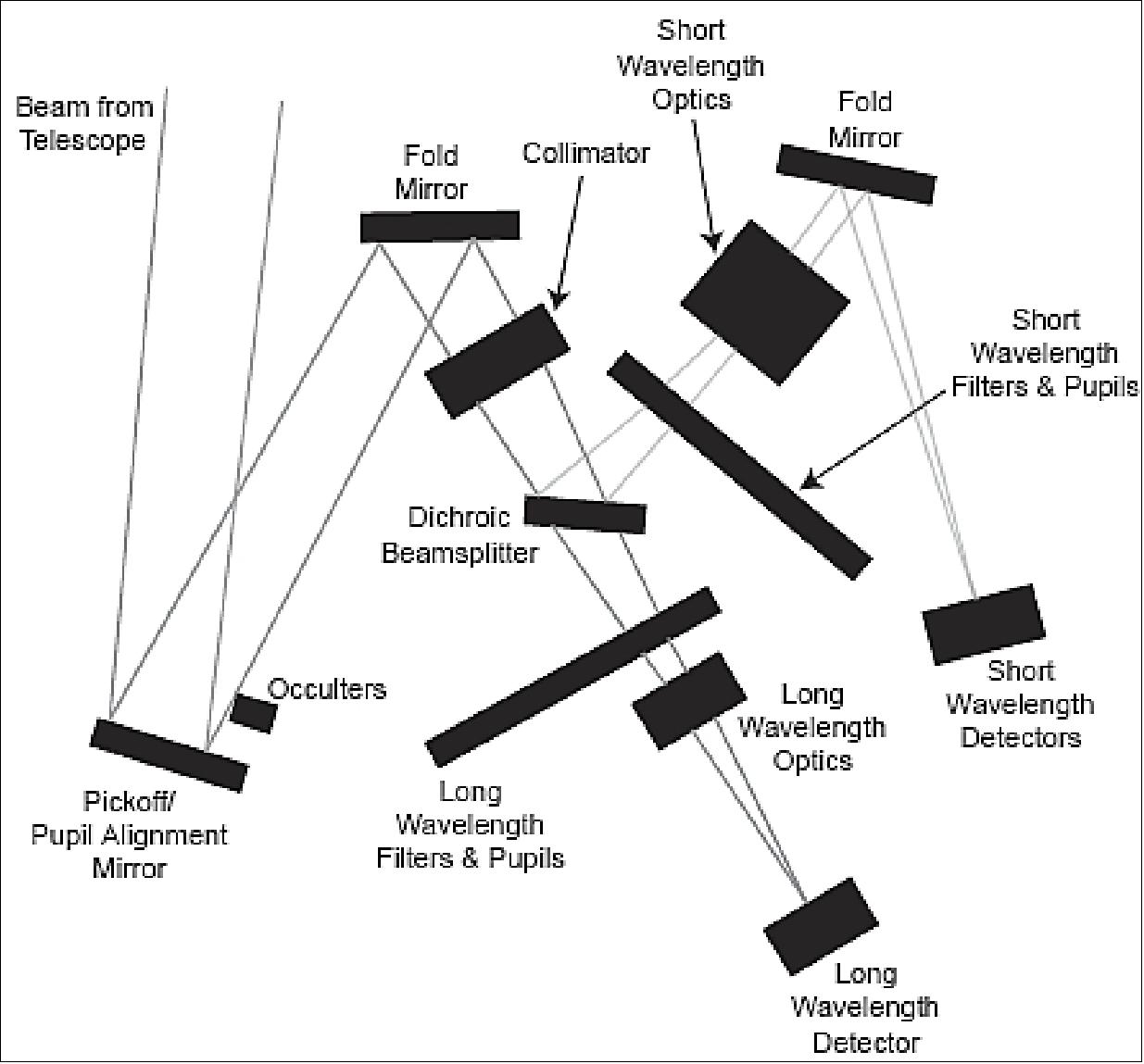

• NIRCam (Near-Infrared Camera), funded by NASA with the University of Arizona as prime contractor. CSA is participating in the development of the NIRCam instrument.

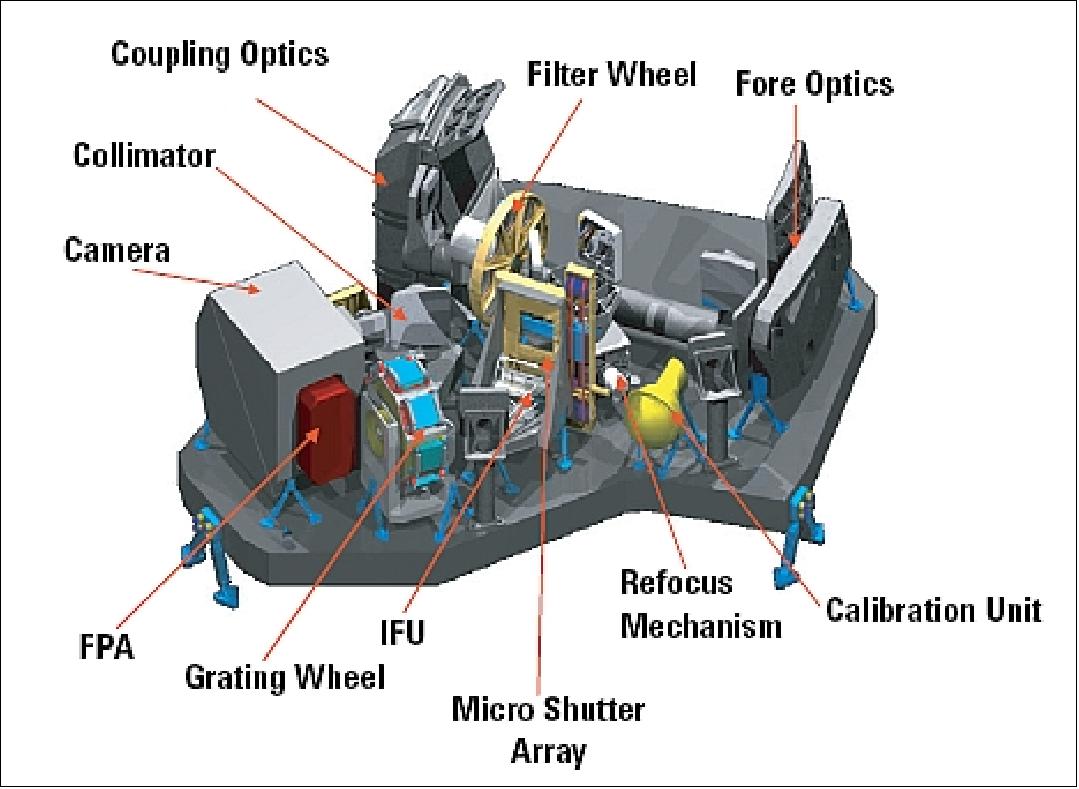

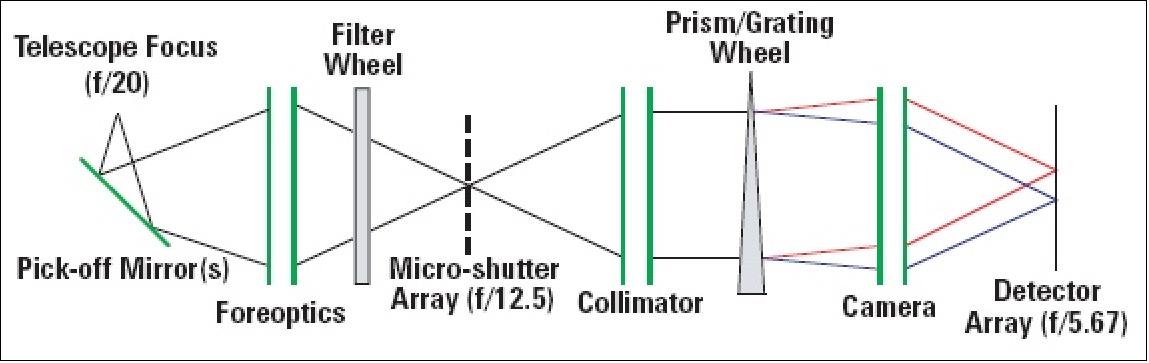

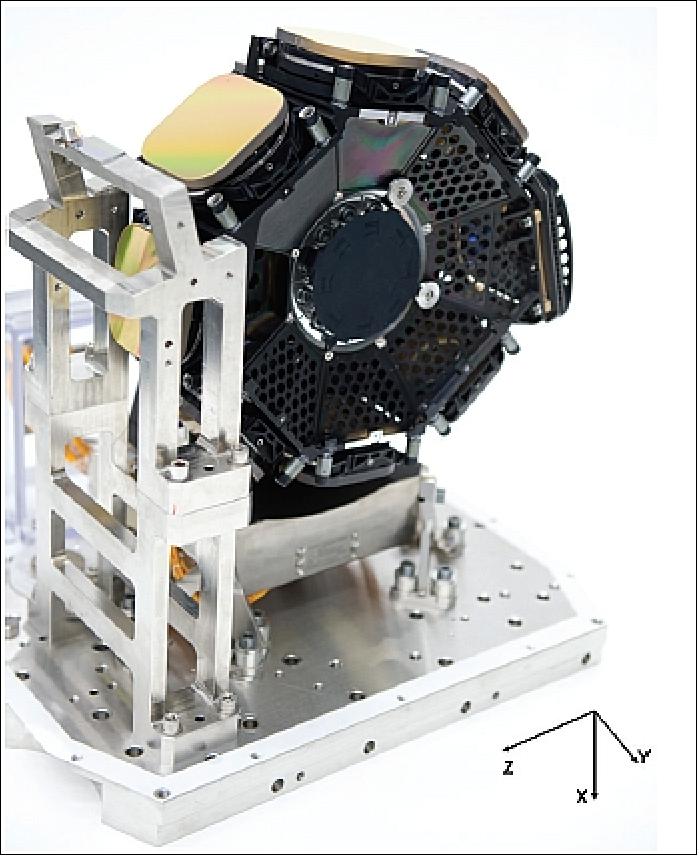

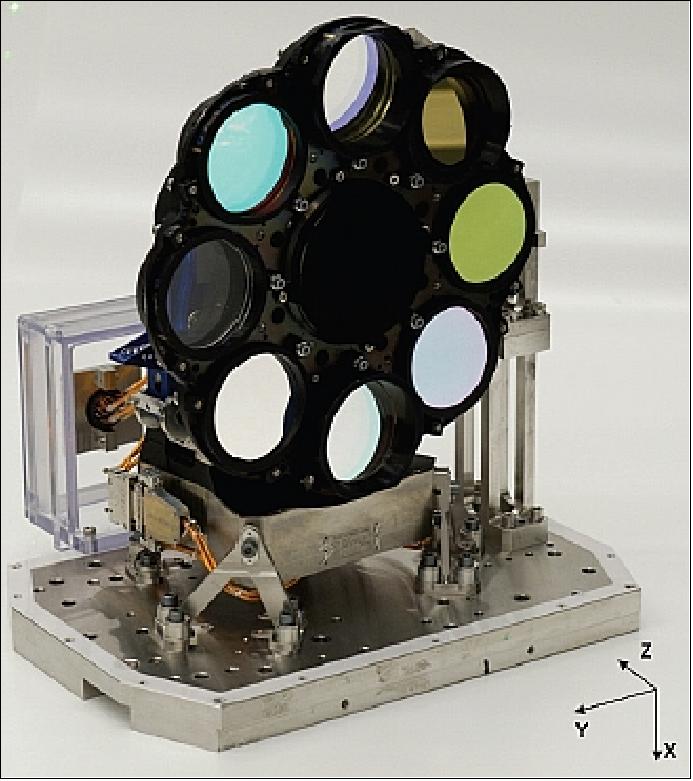

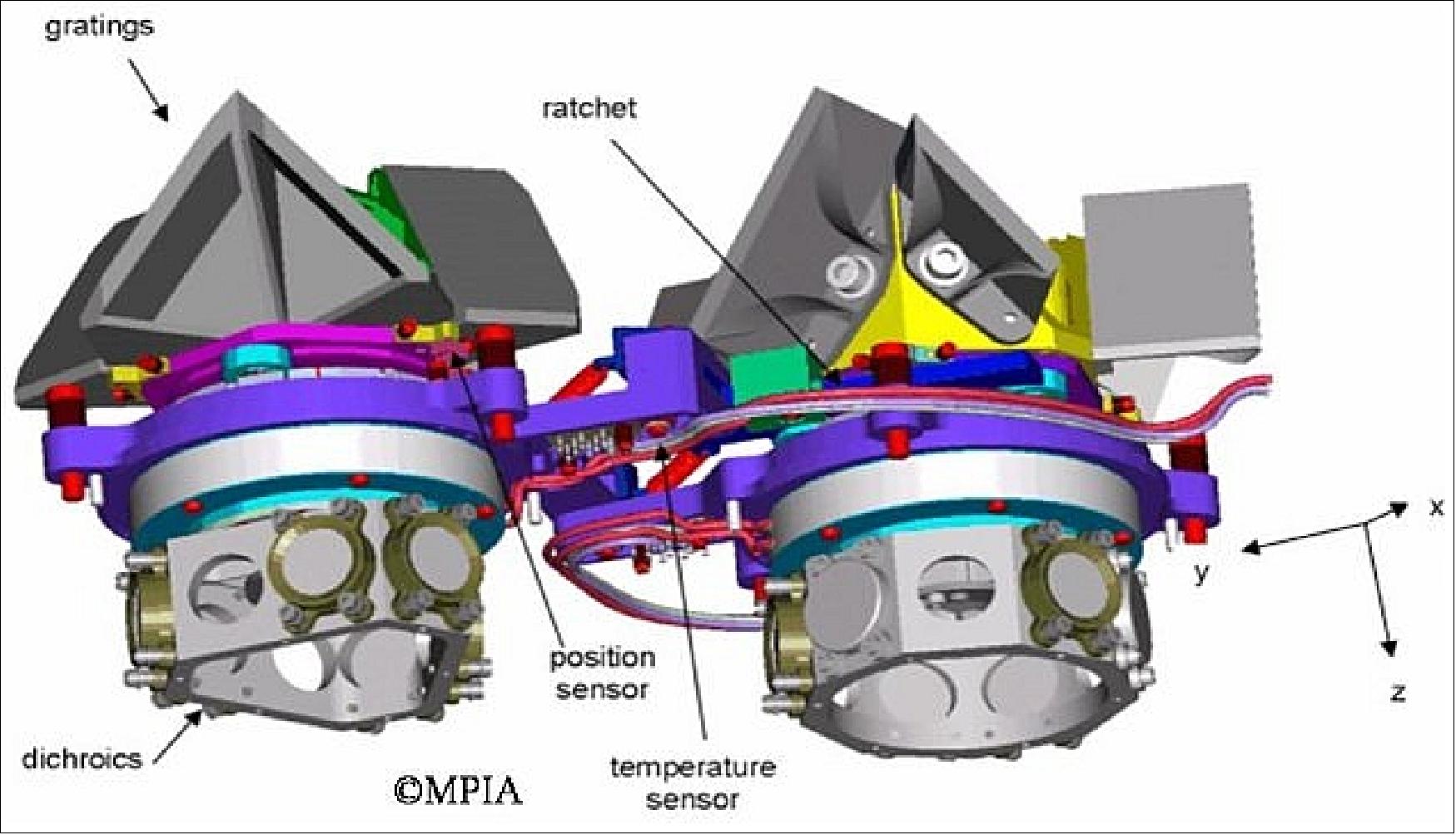

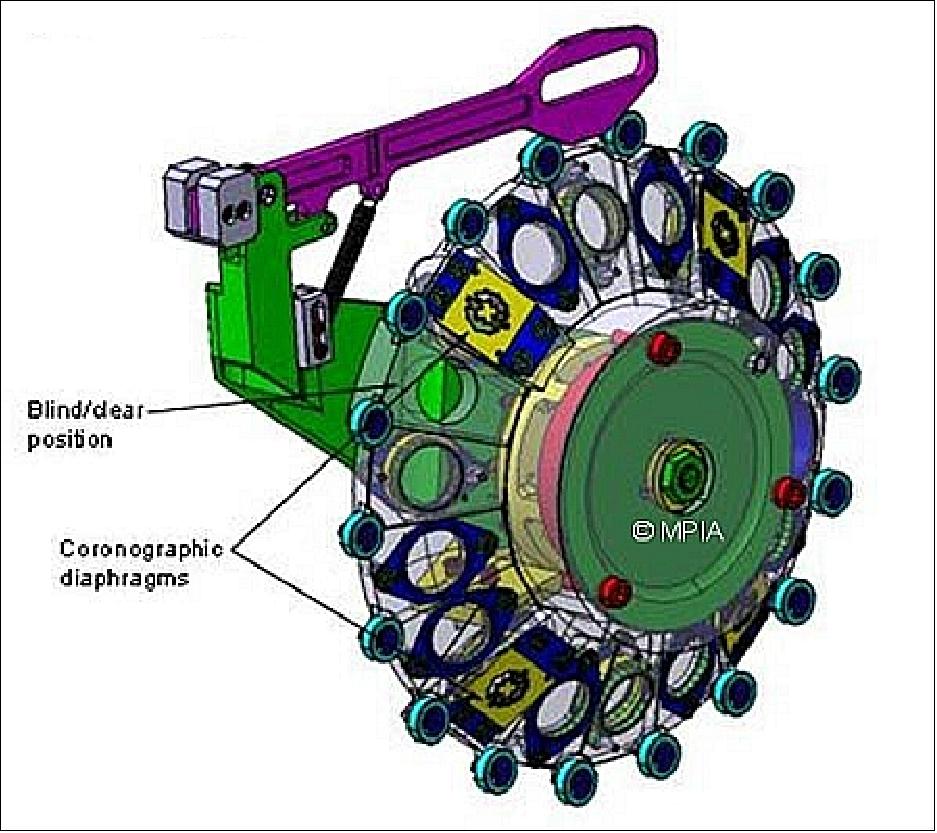

• NIRSpec (Near-Infrared multi-object Spectrograph), funded by ESA with EADS Astrium GmbH as prime contractor (the detector arrays and a micro-shutter are supplied by NASA/GSFC)

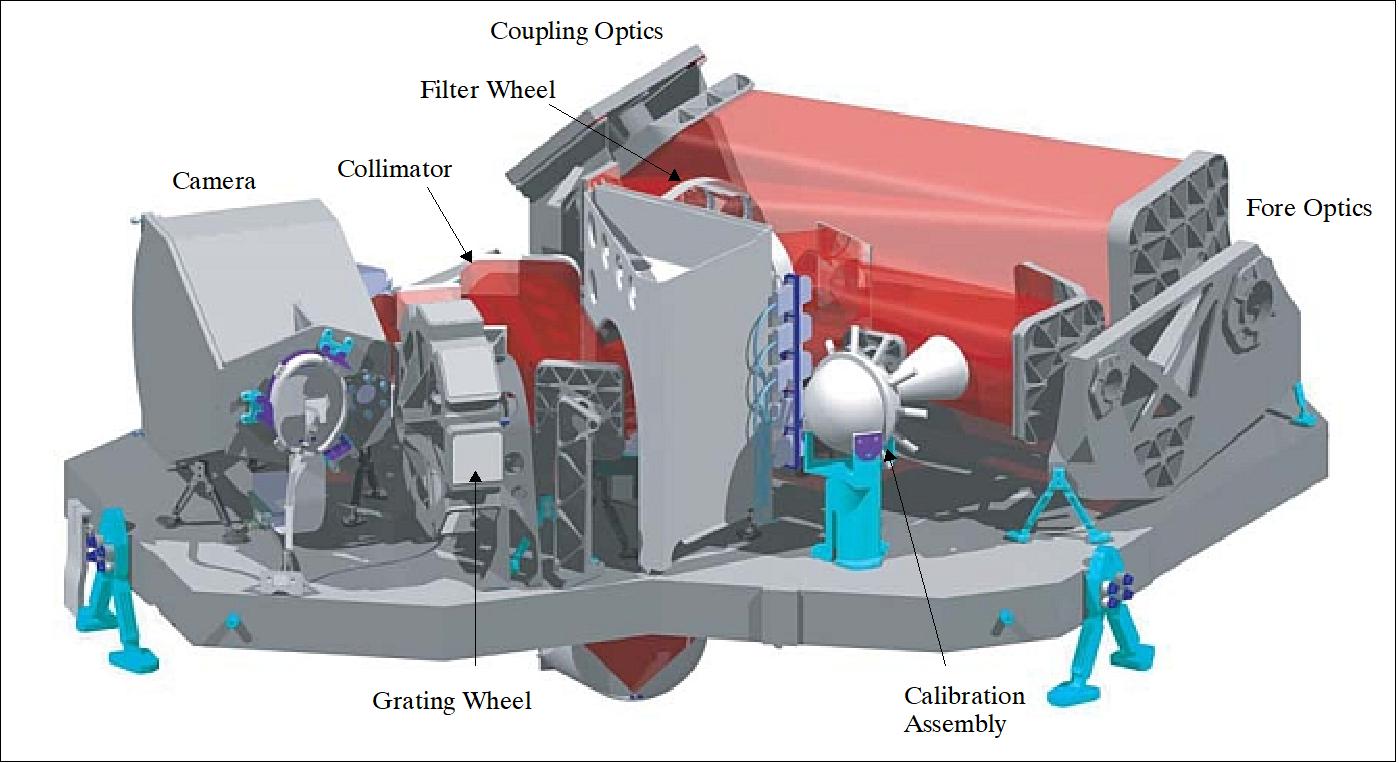

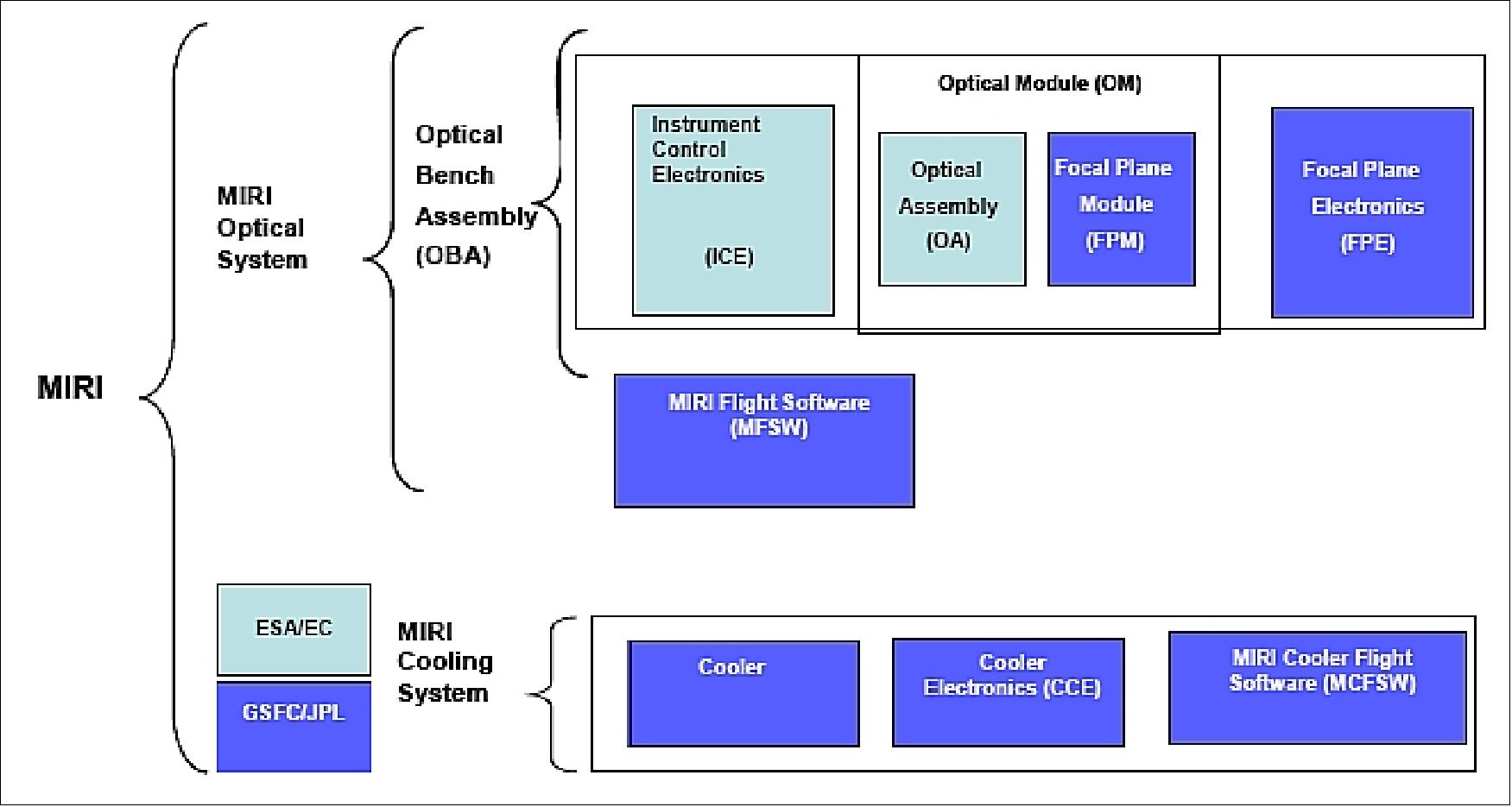

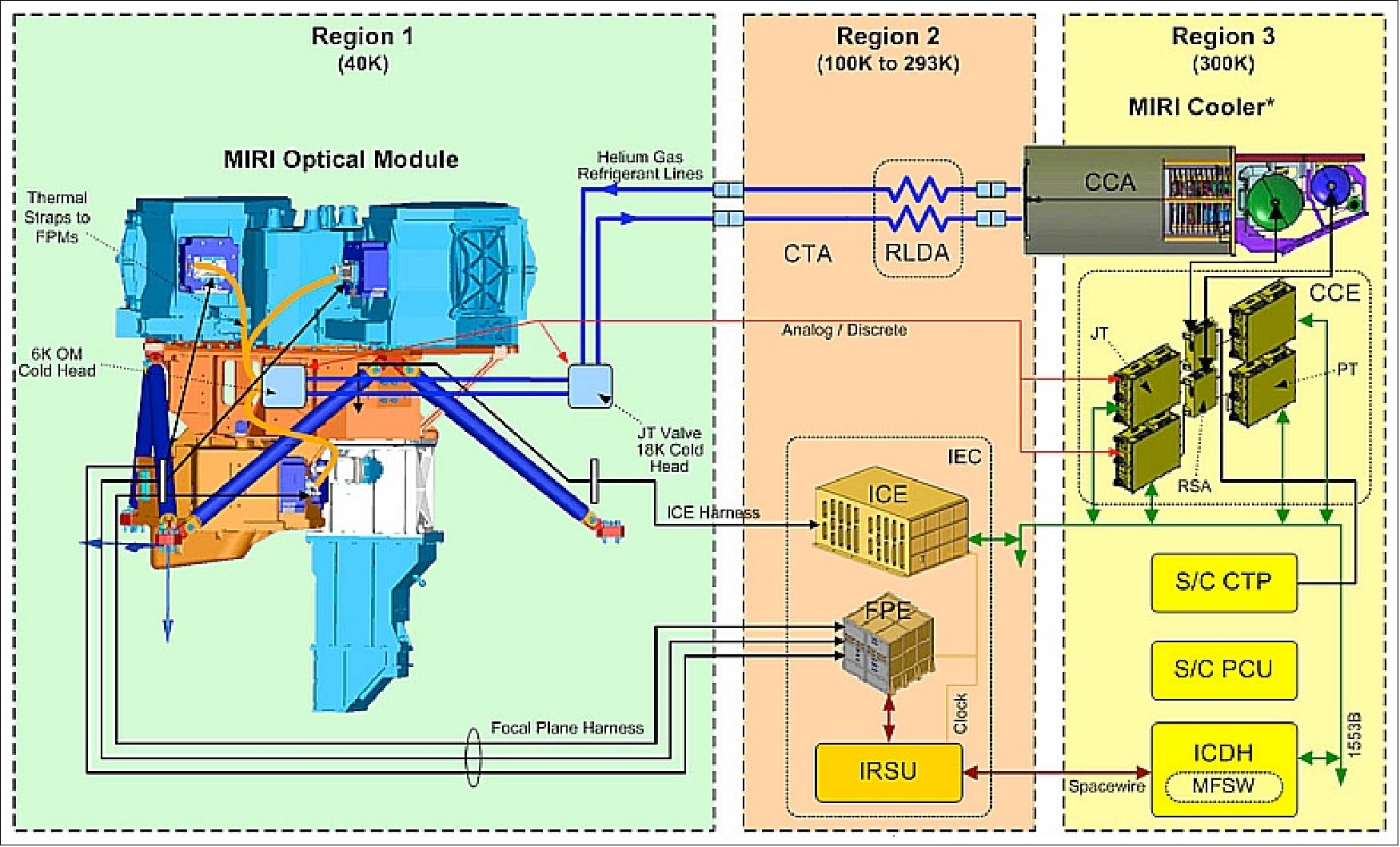

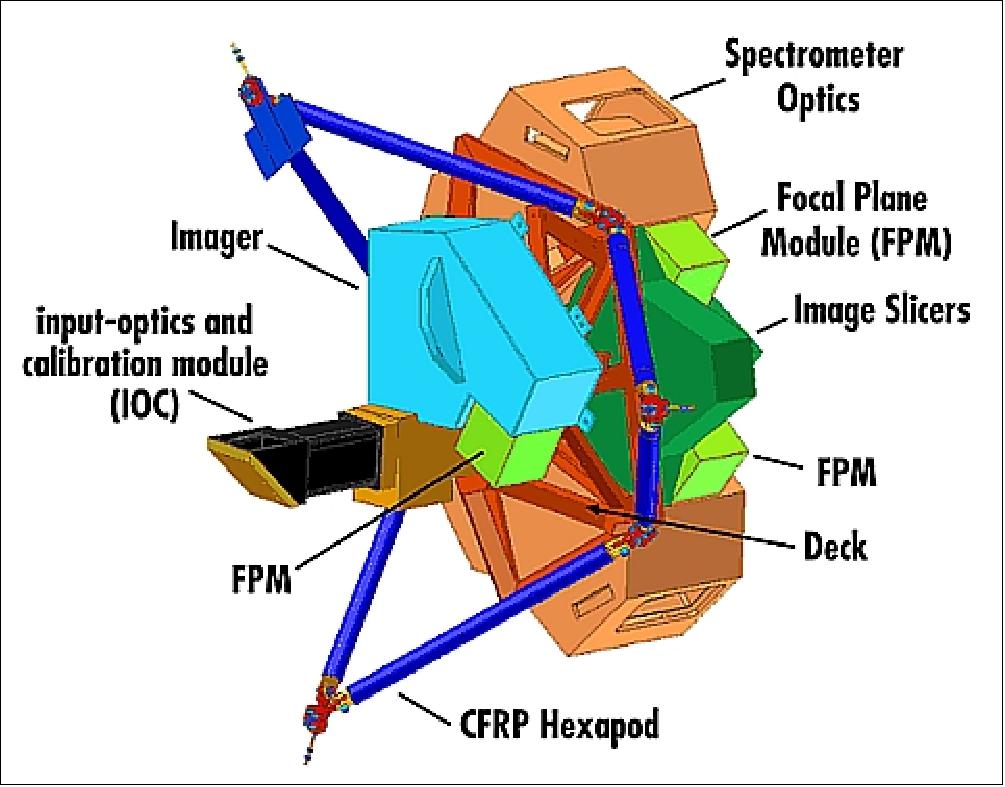

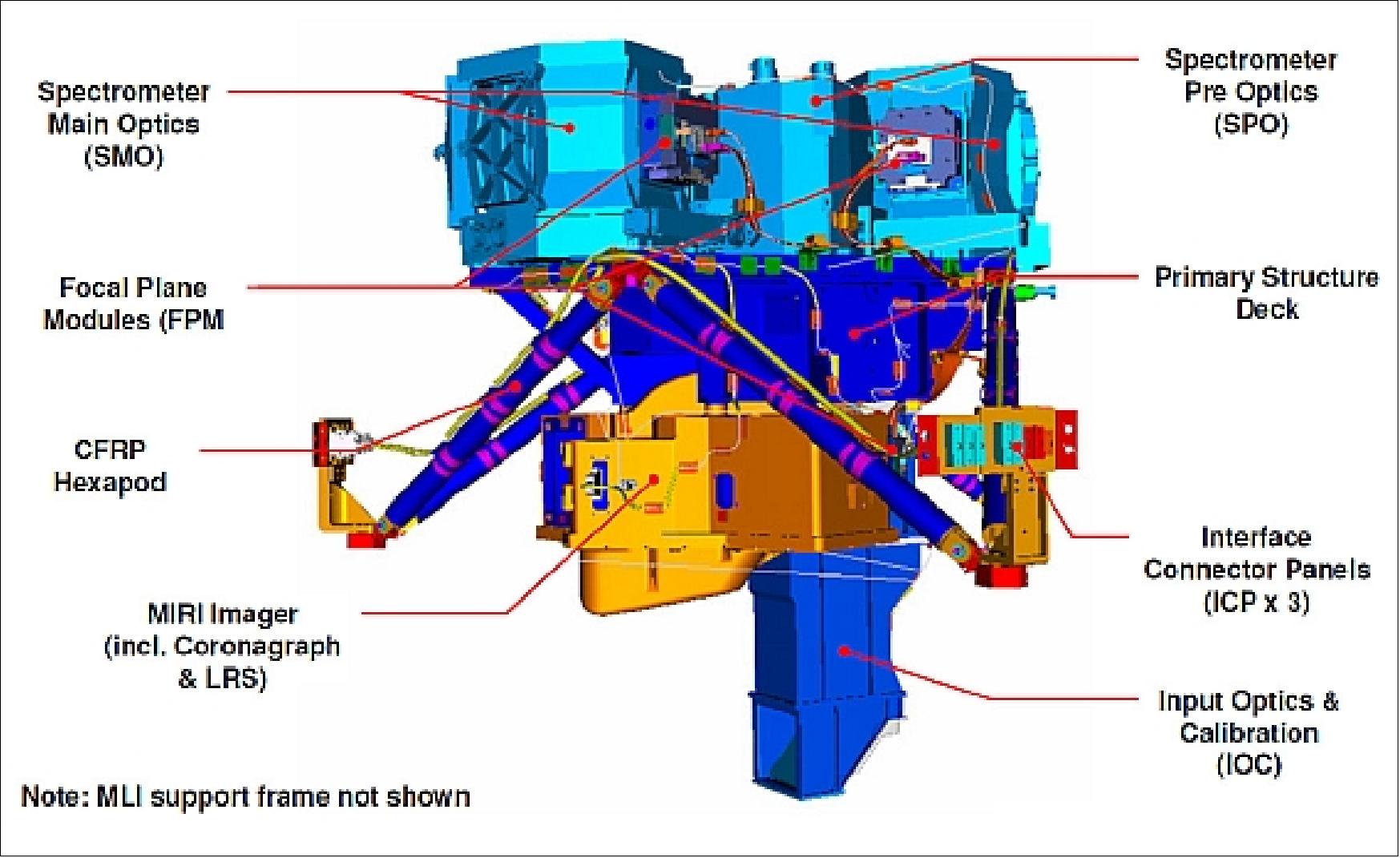

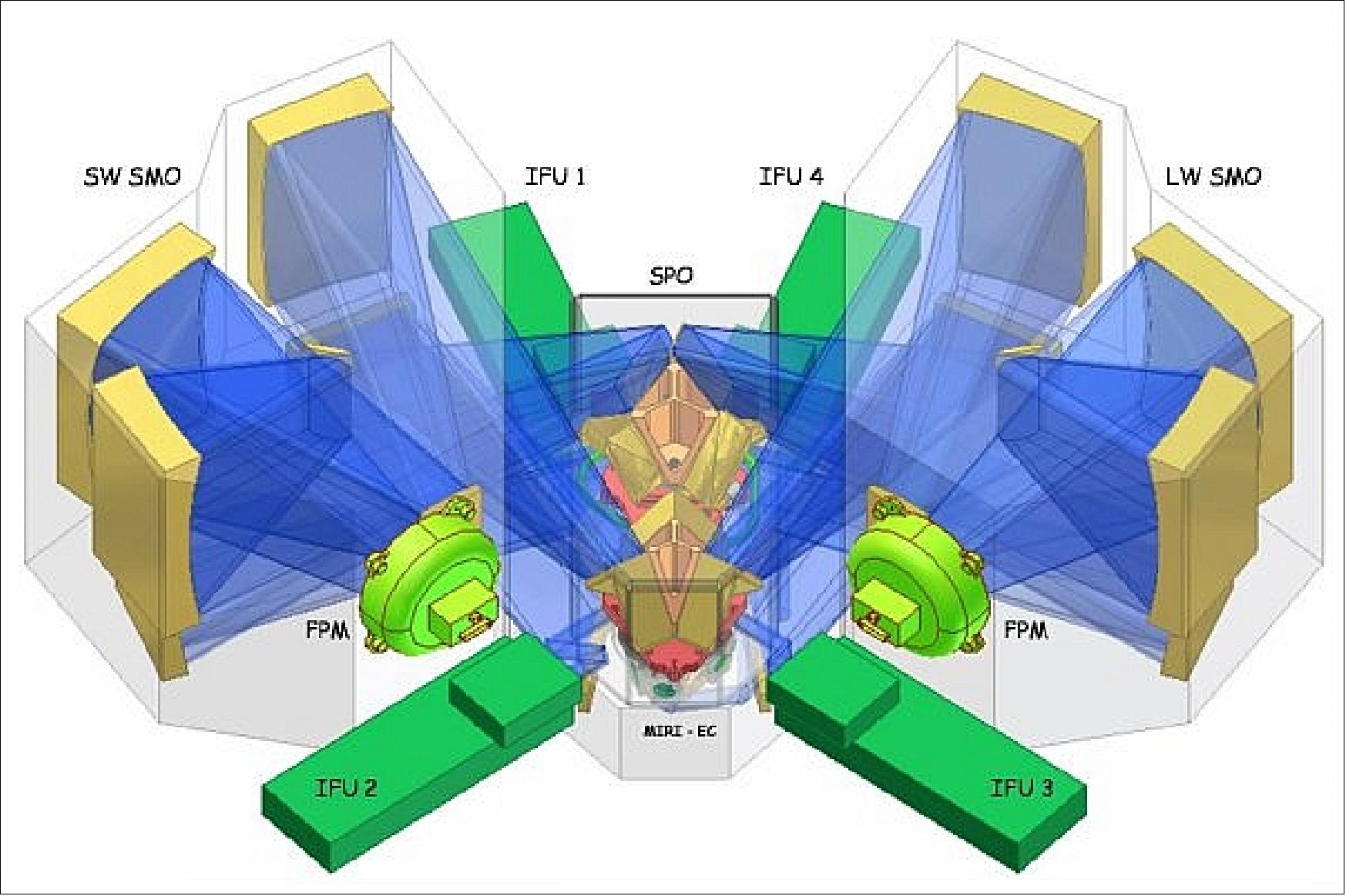

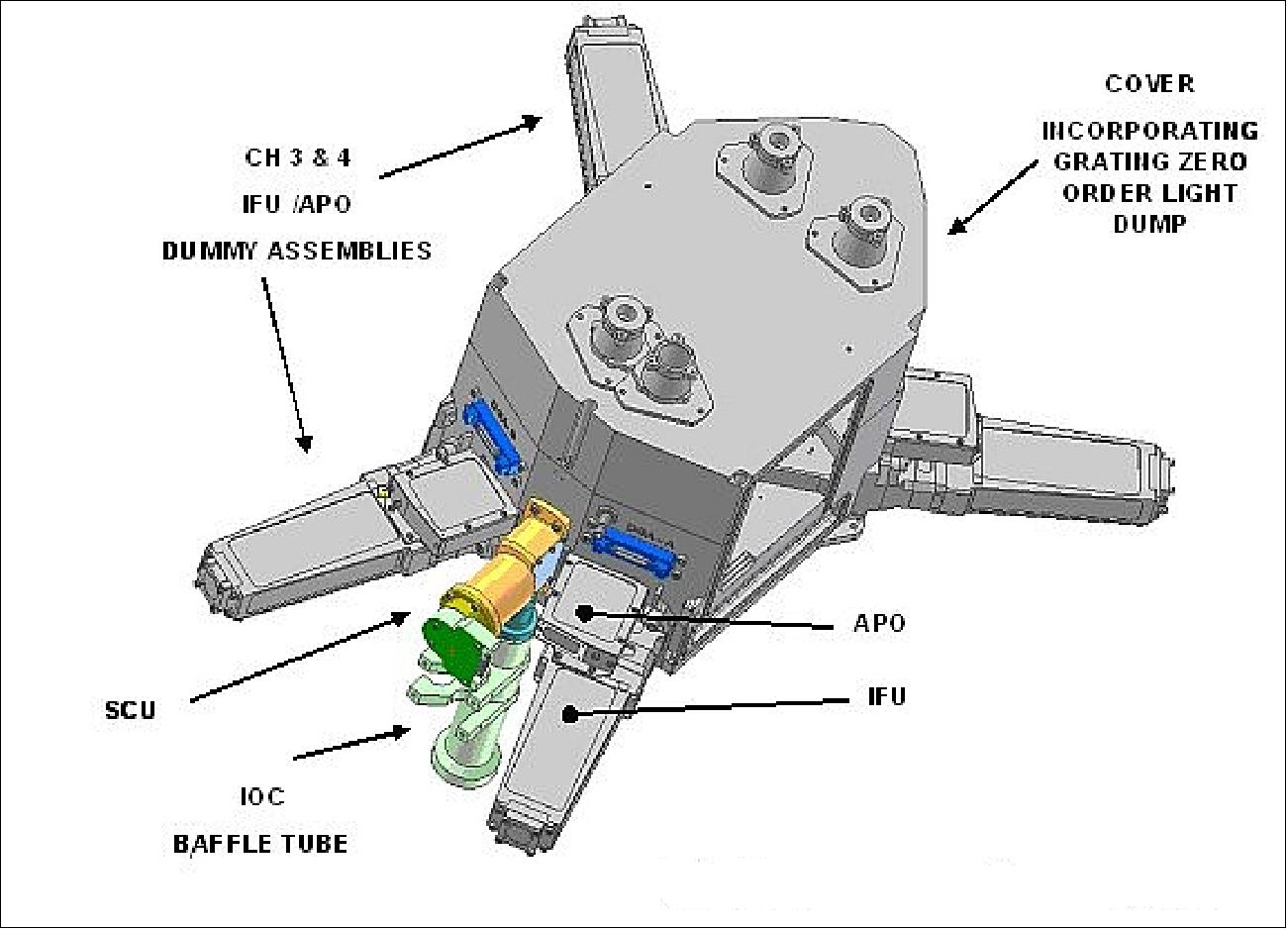

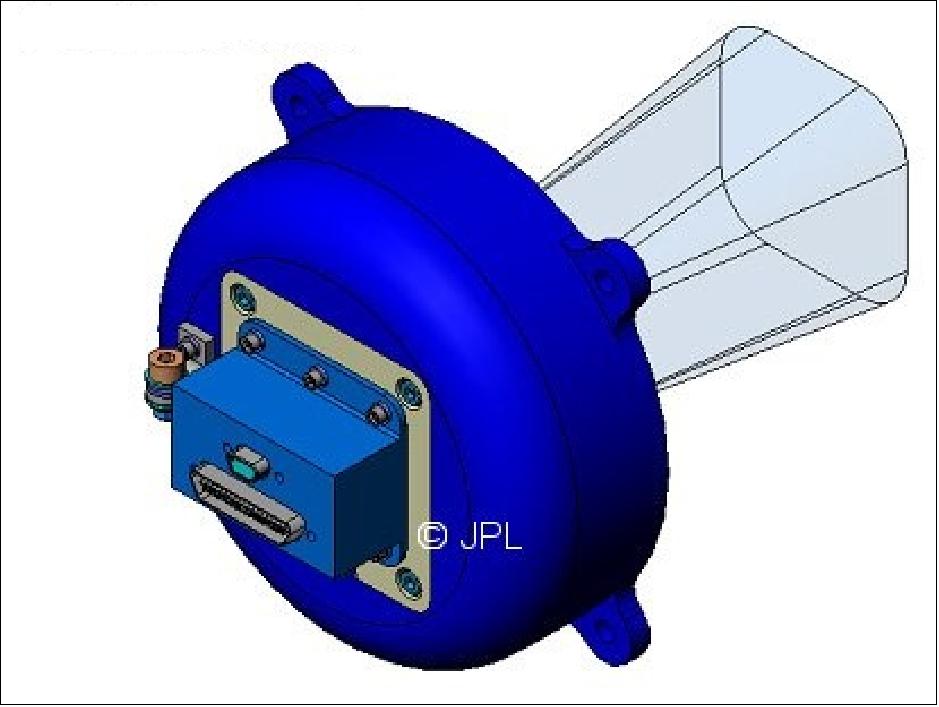

• MIRI (Mid-Infrared Camera-Spectrograph) a joint instrument of JPL and ESA. The instrument (about 50%) is being provided by ESA member states, coordinated but not funded by ESA.

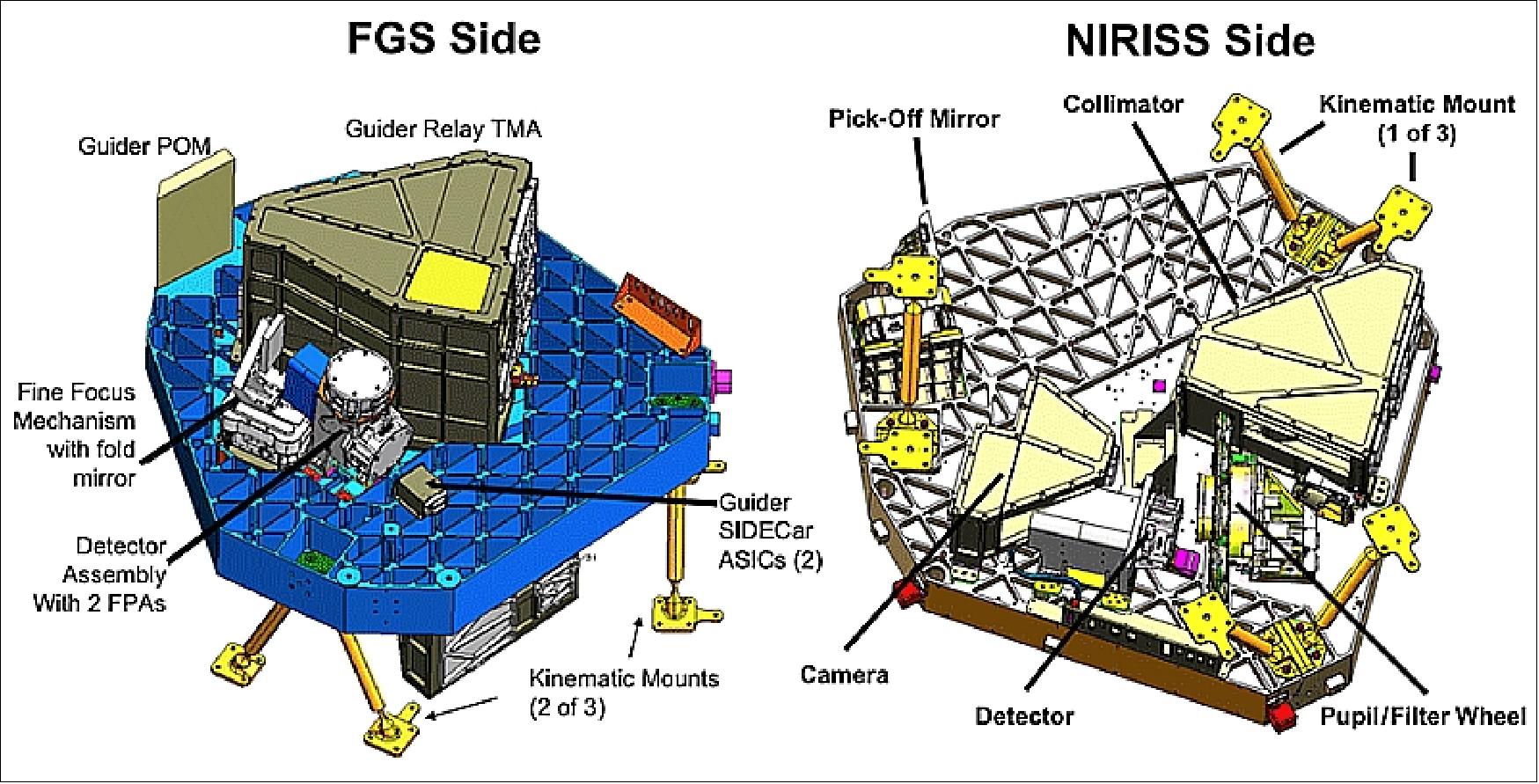

• FGS (Fine Guidance Sensor) with TFI (Tunable Filter Imager), funded by CSA (Canadian Space Agency)

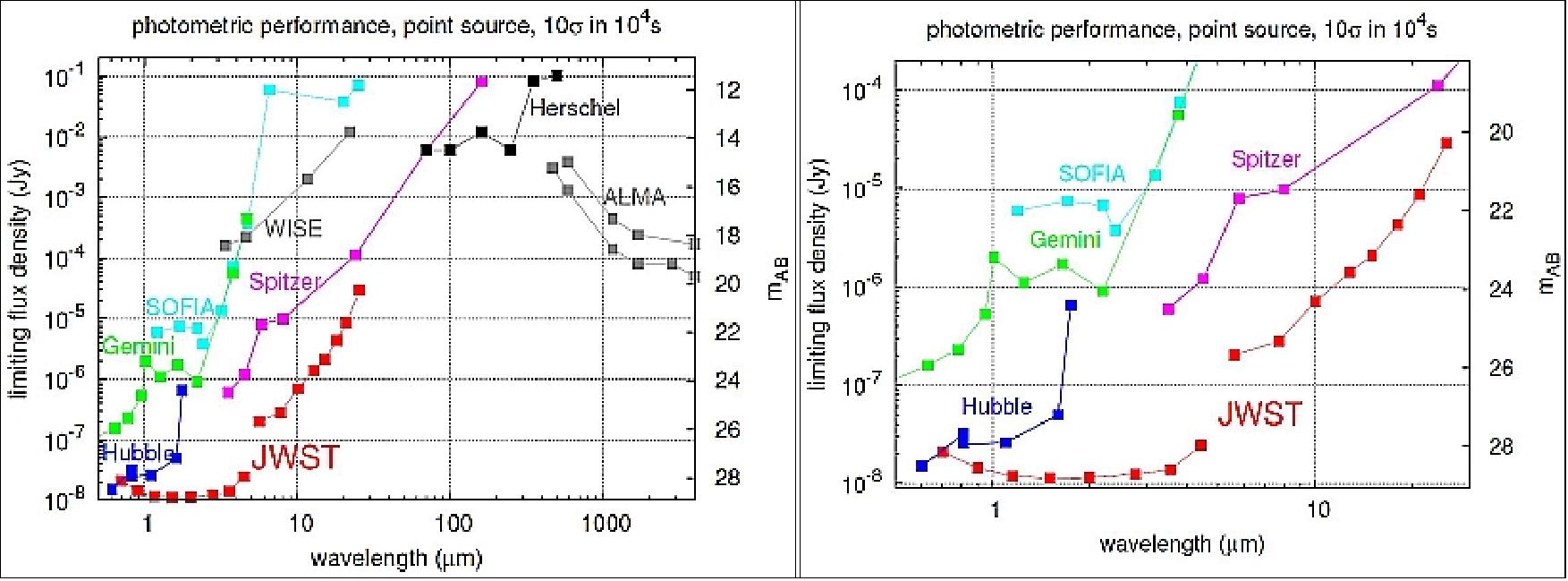

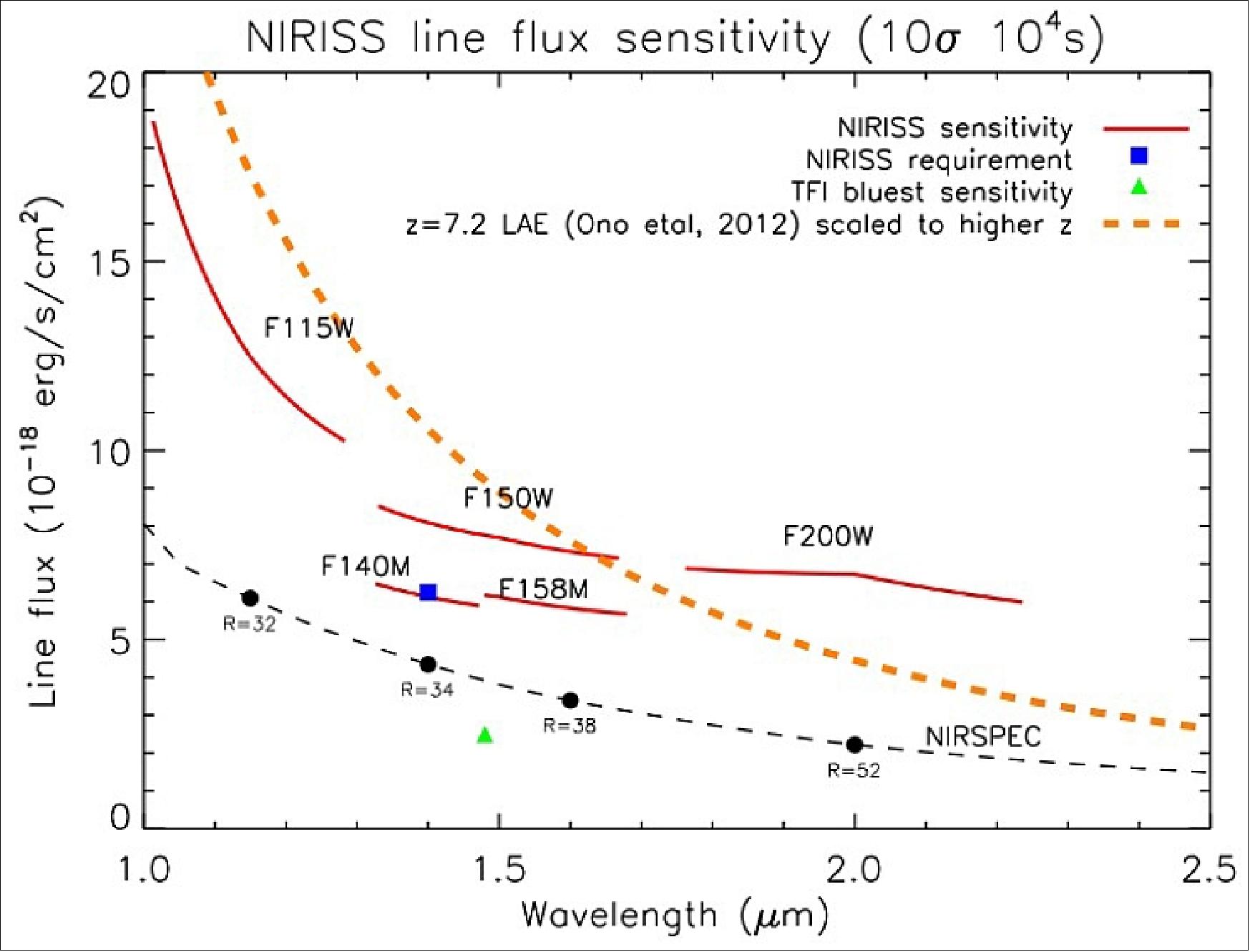

Legend to Figure 1: Plotted is the faintest flux for a point source that can be detected at 10 sigma in a 104 s integration. The fluxes are given in Janskies as well as AB magnitudes. 12)

Launch

On Saturday, December 25 (Christmas), 2021 at 9:20 am local time (12:20 UTC), an Ariane 5 rocket lifted off from the Guiana Space Center, Europe's Spaceport in Kourou, French Guiana (South America), injecting the Webb Space Telescope, developed by NASA in partnership with ESA and the Canadian Space Agency (CSA), into its transfer orbit. The telescope was successfully separated from the launcher 27 minutes after liftoff. 14) 15)

The telescope now embarks on a voyage lasting 29 days to reach the second Lagrange point.

• On the third day, the heat shield will begin to deploy. On the eleventh day, the secondary mirror will begin positioning.

• Between the 13th and 14th day, the primary mirror, comprising 18 hexagonal segments and measuring 6.5 meters in diameter, will be assembled.

• The telescope is slated to arrive at its final destination, 1.5 million kilometers from Earth, approximately 29 days after launch.

The space agencies of the United States (NASA), Europe (ESA) and Canada (CSA) teamed up to develop this telescope. Europe played an important role in this mission, with ESA providing the launch onboard Ariane 5, as well as the Nirspec spectrometer built by Airbus. The astrophysics department of the Saclay-based CEA (French Alternative Energies and Atomic Energy Commission) and the Paris Observatory designed the MIRI camera. This is the most ambitious telescope ever sent into space.

"Today's launch is the mission of the decade," said Stephane Israël, Chief Executive Officer of Arianespace, "one that demonstrates the reliability of Arianespace's launch services in the eyes of the international space community. It's a great honor for us to have been chosen for this launch, which will enable humanity to take a giant step forward in its knowledge of the Universe. The mission demanded 20 years of preparation hand in hand with NASA. It's the third launch we have performed for the American space agency, clearly illustrating the advantage of large-scale international collaboration in space. I would like to thank ESA, NASA and CSA for entrusting us with their invaluable payload. To launch on Christmas morning 42 years after the takeoff of the first Ariane from this same Kourou site ... What a great end of year present for the space community gathered today for this launch.

NASA: A joint effort with ESA (European Space Agency) and the Canadian Space Agency, the Webb observatory is NASA's revolutionary flagship mission to seek the light from the first galaxies in the early universe and to explore our own solar system, as well as planets orbiting other stars, called exoplanets. 16)

"The James Webb Space Telescope represents the ambition that NASA and our partners maintain to propel us forward into the future," said NASA Administrator Bill Nelson. "The promise of Webb is not what we know we will discover; it's what we don't yet understand or can't yet fathom about our universe. I can't wait to see what it uncovers!"

Ground teams began receiving telemetry data from Webb about five minutes after launch. The Arianespace Ariane 5 rocket performed as expected, separating from the observatory 27 minutes into the flight. The observatory was released at an altitude of approximately 870 miles (1,400 km). Approximately 30 minutes after launch, Webb unfolded its solar array, and mission managers confirmed that the solar array was providing power to the observatory. After solar array deployment, mission operators will establish a communications link with the observatory via the Malindi ground station in Kenya, and ground control at the Space Telescope Science Institute in Baltimore will send the first commands to the spacecraft.

Engineers and ground controllers will conduct the first of three mid-course correction burns about 12 hours and 30 minutes after launch, firing Webb's thrusters to maneuver the spacecraft on an optimal trajectory toward its destination in orbit about 1 million miles from Earth.

"I want to congratulate the team on this incredible achievement – Webb's launch marks a significant moment not only for NASA, but for thousands of people worldwide who dedicated their time and talent to this mission over the years," said Thomas Zurbuchen, associate administrator for the Science Mission Directorate at NASA Headquarters in Washington. "Webb's scientific promise is now closer than it ever has been. We are poised on the edge of a truly exciting time of discovery, of things we've never before seen or imagined."

The world's largest and most complex space science observatory will now begin six months of commissioning in space. At the end of commissioning, Webb will deliver its first images. Webb carries four state-of-the-art science instruments with highly sensitive infrared detectors of unprecedented resolution. Webb will study infrared light from celestial objects with much greater clarity than ever before. The premier mission is the scientific successor to NASA's iconic Hubble and Spitzer space telescopes, built to complement and further the scientific discoveries of these and other missions.

"The launch of the Webb Space Telescope is a pivotal moment – this is just the beginning for the Webb mission," said Gregory L. Robinson, Webb's program director at NASA Headquarters. "Now we will watch Webb's highly anticipated and critical 29 days on the edge. When the spacecraft unfurls in space, Webb will undergo the most difficult and complex deployment sequence ever attempted in space. Once commissioning is complete, we will see awe-inspiring images that will capture our imagination."

The telescope's revolutionary technology will explore every phase of cosmic history – from within our solar system to the most distant observable galaxies in the early universe, to everything in between. Webb will reveal new and unexpected discoveries and help humanity understand the origins of the universe and our place in it.

NASA Headquarters oversees the mission for the agency's Science Mission Directorate. NASA's Goddard Space Flight Center in Greenbelt, Maryland, manages Webb for the agency and oversees work on the mission performed by the Space Telescope Science Institute, Northrop Grumman, and other mission partners. In addition to Goddard, several NASA centers contributed to the project, including the agency's Johnson Space Center in Houston, Jet Propulsion Laboratory in Southern California, Marshall Space Flight Center in Huntsville, Alabama, Ames Research Center in California's Silicon Valley, and others.

Orbit

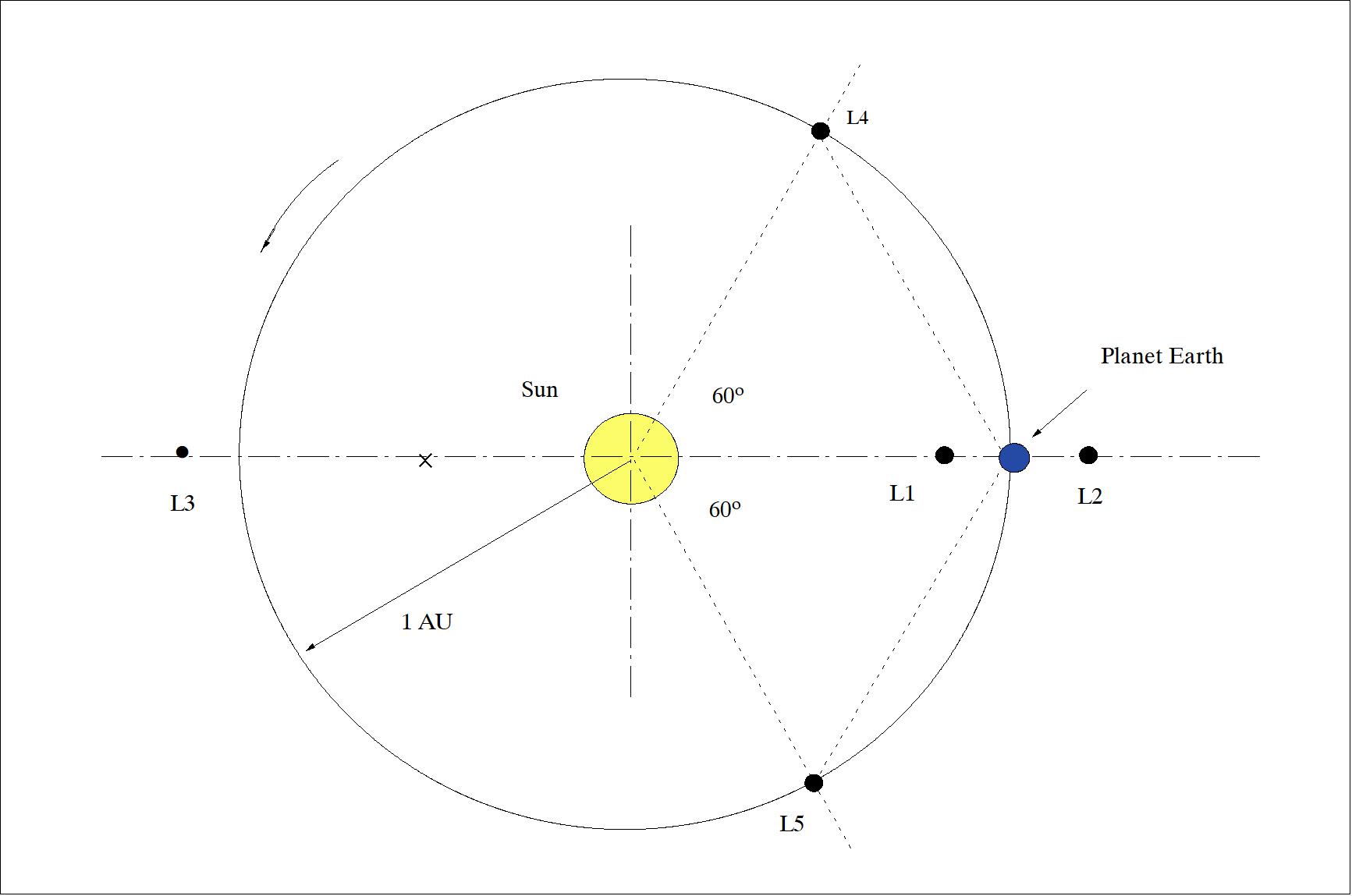

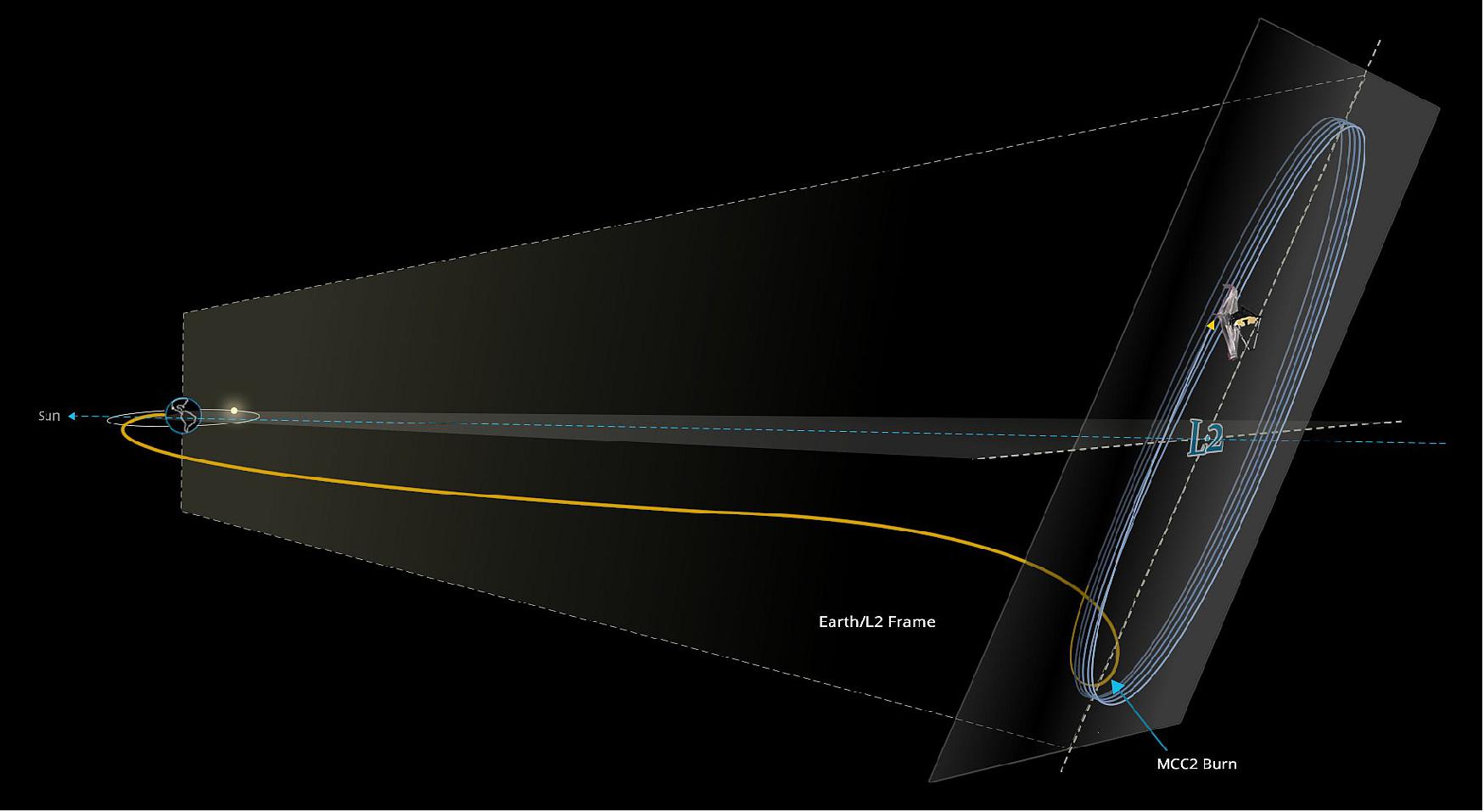

The orbit of JWST has been selected to be at L2. The spacecraft will be in a Lissajous (or halo) orbit about the Lagrangian point L2. In the Sun‐Earth system the L2 point is on the rotating Sun-Earth axis about the same distance away as L1 (1.5 million km, representing 1/100 the distance from Earth to the Sun) but at the opposite side of the Earth. The L1 location is inside the Earth orbit while the L2 location is outside the Earth orbit.

The halo orbit of JWST is in a plane slightly out of the ecliptic plane. This orbit avoids Earth and moon eclipses of the sun. The halo orbit period is about 6 months. Nominal station keeping maneuvers will be performed every half orbit (i.e. in intervals of about 3 months).

The L2 location is considered to offer the most advantageous viewing for astronomical targets (looking toward the universe) due to nearly constant lighting conditions (minimum of stray light). Another advantage of the L2 location is that it offers a stable thermal environment. The telescope is kept in perpetual shadow by looking into the deep space direction. The deep space provides a 2.7 K black body radiation. This ideal heat sink is being used to provide the passive cooling for the payload to a temperature range of about 37 K, shielded from sunlight (entering the spacecraft from the opposite direction) by a five-layer sunshield [passive cooling is the most elegant and economical method available to obtain the required operating temperatures for infrared detection].

JWST Deployment Sequence

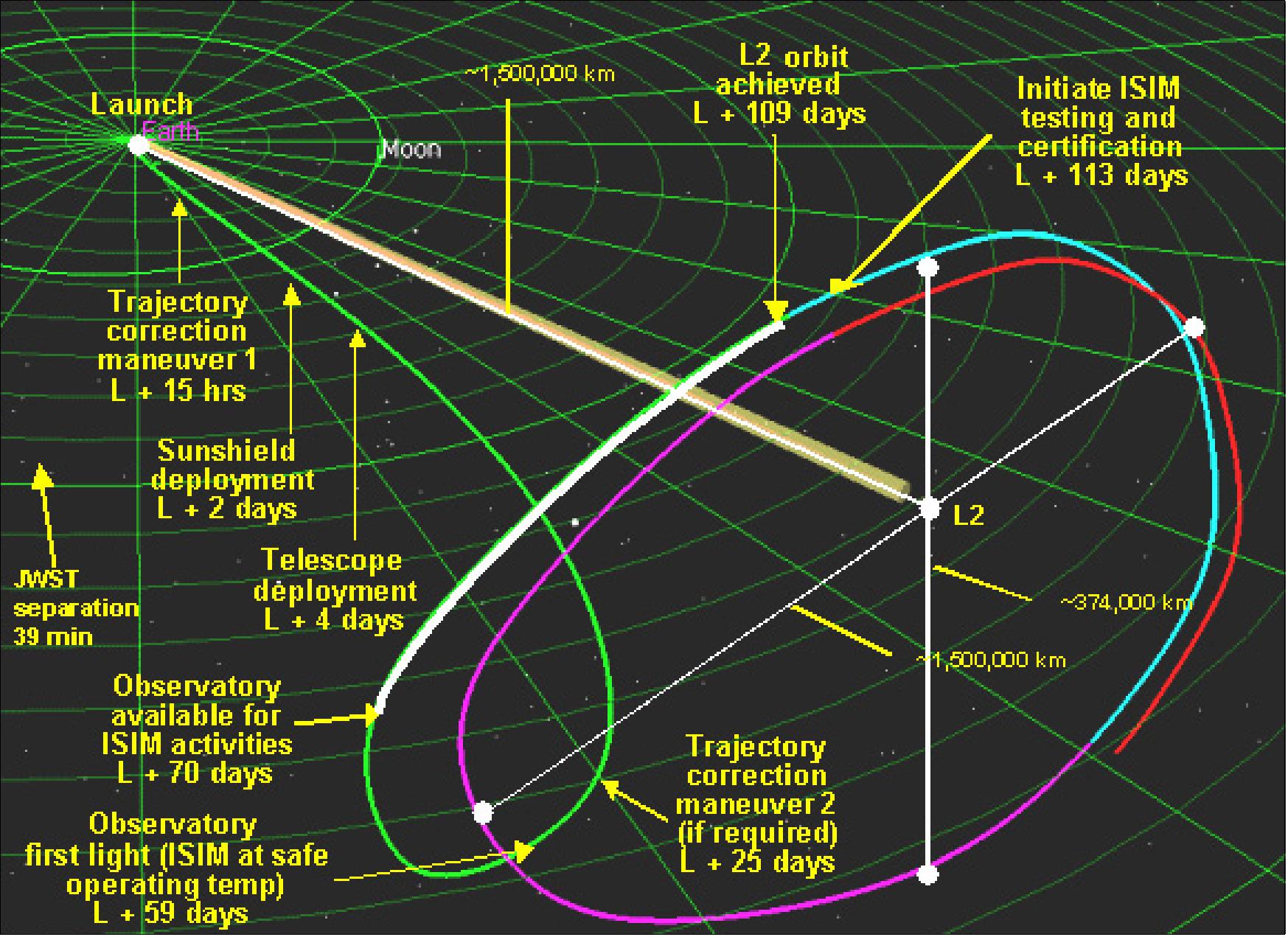

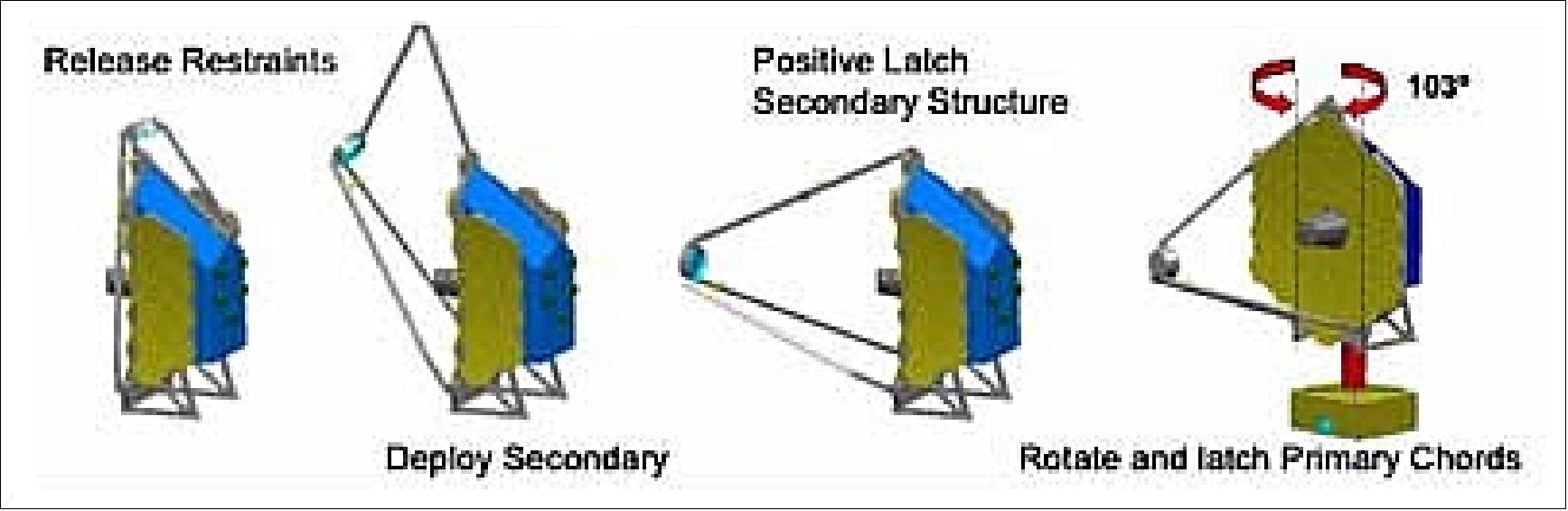

During the transfer orbit to L2 different elements of the JWST will be deployed and commissioning will start. The observatory has five deployment stages involving the following elements: 18)

1) Deployment of spacecraft appendages (solar arrays, high gain antenna)

2) Deployment of the sunshield (unfolding 2 days after launch)

3) Extension of the tower

4) Deployment of the secondary mirror (positioned on a tripod structure)

5) Deployment of the primary mirror wings

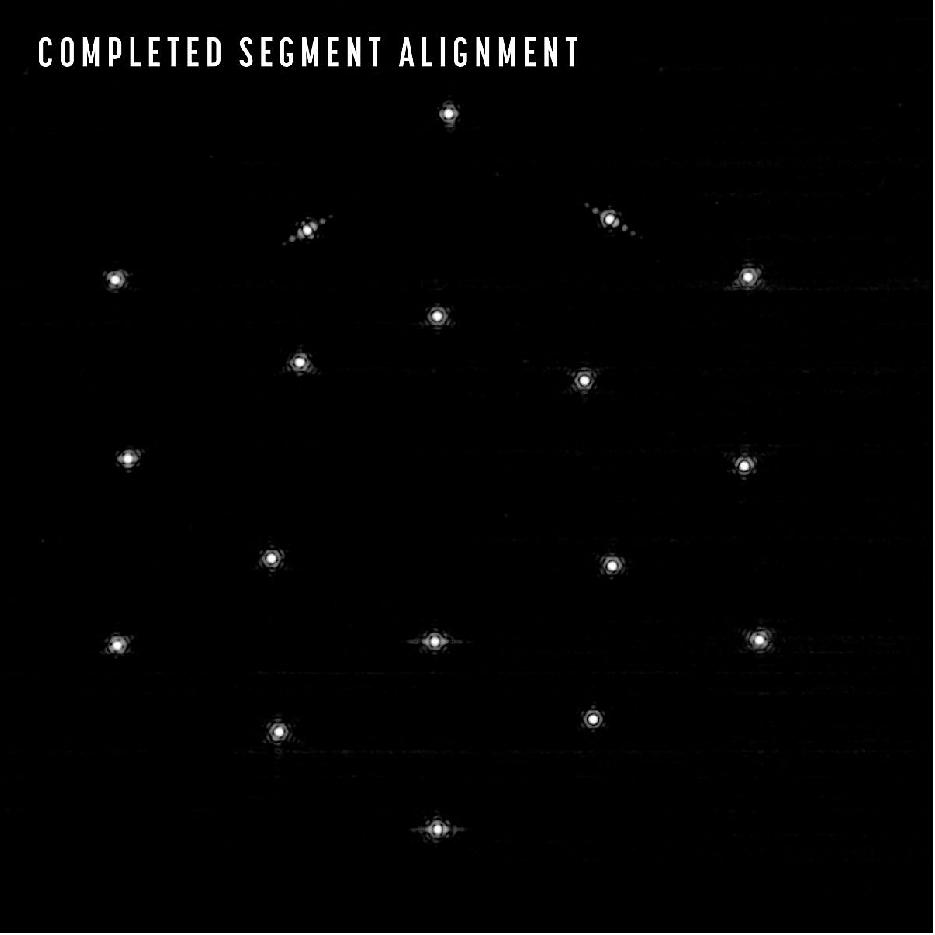

The deployment of the solar arrays and the high gain antenna is scheduled for the first day to provide the capabilities of onboard power generation and a spacecraft communications link. The unfolding of the sunshield will occur two days after launch, while the timeline for secondary and primary mirror deployment is foreseen after four days. "First light" will occur about 28 days after launch, initiating wavefront sensing and control activities to align the mirror segments. Instrument checkout will start 37 days after launch, well before the final L2 orbit insertion is obtained after 106 days. This is being followed by full commissioning procedures expected to last until about 6 months after launch. 19)

JWST Mission Status

• July 12, 2022: The dawn of a new era in astronomy is here as the world gets its first look at the full capabilities of NASA's James Webb Space Telescope, a partnership with ESA (European Space Agency) and CSA (Canadian Space Agency). 20) 21)

- "Today, we present humanity with a groundbreaking new view of the cosmos from the James Webb Space Telescope – a view the world has never seen before," said NASA Administrator Bill Nelson. "These images, including the deepest infrared view of our universe that has ever been taken, show us how Webb will help to uncover the answers to questions we don't even yet know to ask; questions that will help us better understand our universe and humanity's place within it.

- "The Webb team's incredible success is a reflection of what NASA does best. We take dreams and turn them into reality for the benefit of humanity. I can't wait to see the discoveries that we uncover – the team is just getting started!"

- NASA explores the unknown in space for the benefit of all, and Webb's first observations tell the story of the hidden universe through every phase of cosmic history – from neighboring planets outside our solar system, known as exoplanets, to the most distant observable galaxies in the early universe.

- "This is a singular and historic moment," said Thomas Zurbuchen, associate administrator for NASA's Science Mission Directorate. "It took decades of drive and perseverance to get us here, and I am immensely proud of the Webb team. These first images show us how much we can accomplish when we come together behind a shared goal, to solve the cosmic mysteries that connect us all. It's a stunning glimpse of the insights yet to come."

- "This is a singular and historic moment," said Thomas Zurbuchen, associate administrator for NASA's Science Mission Directorate. "It took decades of drive and perseverance to get us here, and I am immensely proud of the Webb team. These first images show us how much we can accomplish when we come together behind a shared goal, to solve the cosmic mysteries that connect us all. It's a stunning glimpse of the insights yet to come."

Image description continued

- Called the Cosmic Cliffs, Webb's seemingly three-dimensional picture looks like craggy mountains on a moonlit evening. In reality, it is the edge of the giant, gaseous cavity within NGC 3324, and the tallest "peaks" in this image are about 7 light-years high. The cavernous area has been carved from the nebula by the intense ultraviolet radiation and stellar winds from extremely massive, hot, young stars located in the center of the bubble, above the area shown in this image.

- The blistering, ultraviolet radiation from the young stars is sculpting the nebula's wall by slowly eroding it away. Dramatic pillars tower above the glowing wall of gas, resisting this radiation. The "steam" that appears to rise from the celestial "mountains" is actually hot, ionized gas and hot dust streaming away from the nebula due to the relentless radiation.

- Webb reveals emerging stellar nurseries and individual stars that are completely hidden in visible-light pictures. Because of Webb's sensitivity to infrared light, it can peer through cosmic dust to see these objects. Protostellar jets, which emerge clearly in this image, shoot out from some of these young stars. The youngest sources appear as red dots in the dark, dusty region of the cloud. Objects in the earliest, rapid phases of star formation are difficult to capture, but Webb's extreme sensitivity, spatial resolution, and imaging capability can chronicle these elusive events.

- These observations of NGC 3324 will shed light on the process of star formation. Star birth propagates over time, triggered by the expansion of the eroding cavity. As the bright, ionized rim moves into the nebula, it slowly pushes into the gas and dust. If the rim encounters any unstable material, the increased pressure will trigger the material to collapse and form new stars.

- Conversely, this type of disturbance may also prevent star formation as the star-making material is eroded away. This is a very delicate balance between sparking star formation and stopping it. Webb will address some of the great, open questions of modern astrophysics: What determines the number of stars that form in a certain region? Why do stars form with a certain mass?

- Webb will also reveal the impact of star formation on the evolution of gigantic clouds of gas and dust. While the effect of massive stars – with their violent winds and high energy – is often apparent, less is known about the influence of the more numerous low-mass stars. As they form, these smaller stars create narrow, opposing jets seen here, which can inject a lot of momentum and energy into the clouds. This reduces the fraction of nebular material that seeds new stars.

- Up to this point, scientists have had very little data about the influence of the multitude of young and more energetic low-mass stars. With Webb, they will be able to obtain a full census of their number and impact throughout the nebula.

- Located roughly 7,600 light-years away, NGC 3324 was imaged by Webb's Near-Infrared Camera (NIRCam) and Mid-Infrared Instrument (MIRI).

- NIRCam – with its crisp resolution and unparalleled sensitivity – unveils hundreds of previously hidden stars, and even numerous background galaxies.

- In MIRI's view, young stars and their dusty, planet-forming disks shine brightly in the mid-infrared, appearing pink and red. MIRI reveals structures that are embedded in the dust and uncovers the stellar sources of massive jets and outflows. With MIRI, the hot dust, hydrocarbons, and other chemical compounds on the surface of the ridges glow, giving the appearance of jagged rocks.

- NGC 3324 was first catalogued by James Dunlop in 1826. Visible from the Southern Hemisphere, it is located at the northwest corner of the Carina Nebula (NGC 3372), which resides in the constellation Carina. The Carina Nebula is home to the Keyhole Nebula and the active, unstable supergiant star called Eta Carinae.

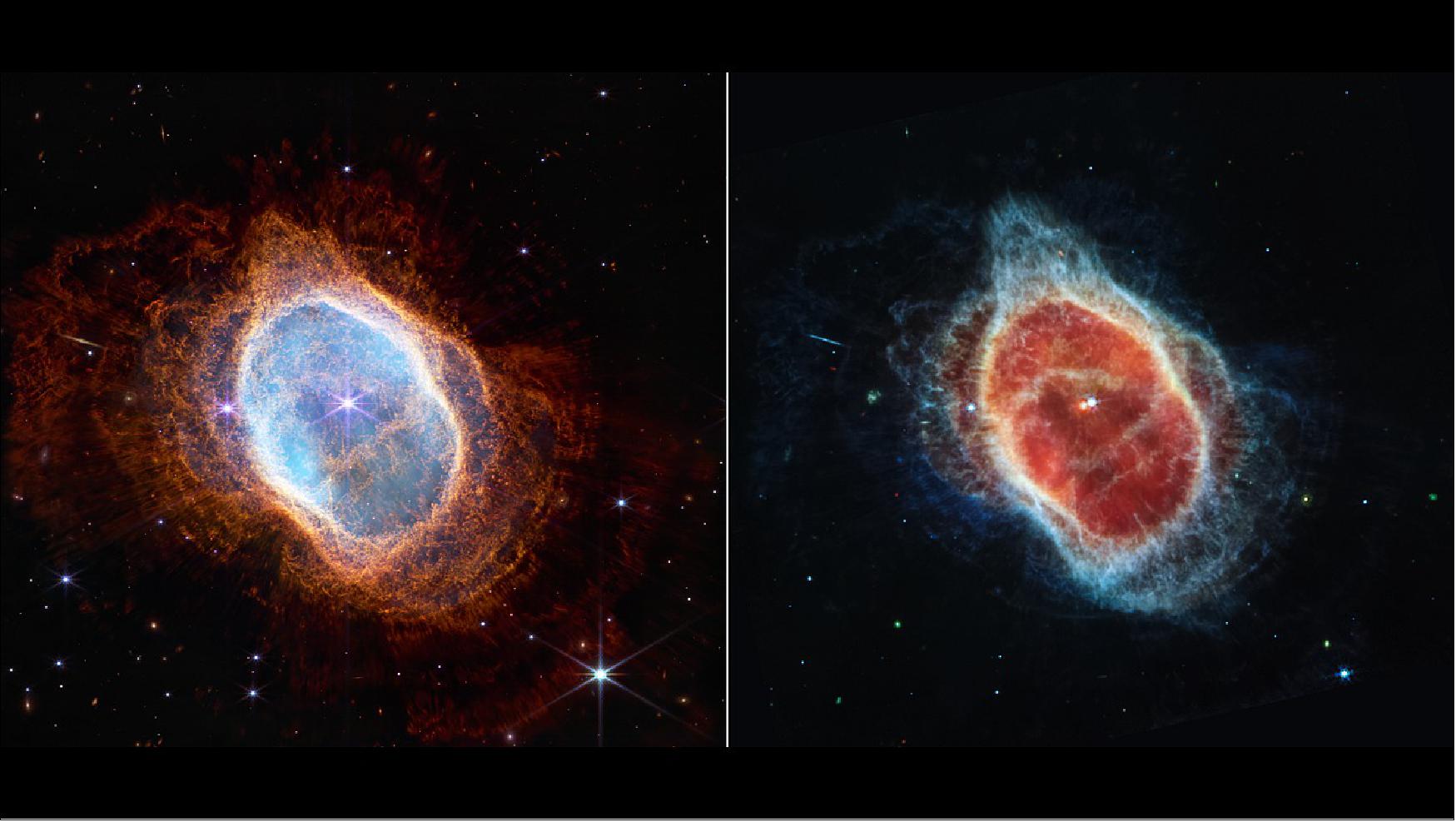

• July 12, 2022: NASA's James Webb Space Telescope has cast the Southern Ring Nebula in an entirely new light. By observing the nebula in mid-infrared wavelengths, Webb has unveiled the second, dusty star at the center of the nebula in far more detail. The star closely orbits its companion as it periodically ejects layers of gas and dust. Together, the swirling duo have created a fantastic landscape of asymmetrical shells. Webb's near-infrared light image hones in on "spotlights" from the stars, where light travels through holes in the nebula's dusty ejections. 22) 23)

Some stars save the best for last.

- The dimmer star at the center of this scene has been sending out rings of gas and dust for thousands of years in all directions, and NASA's James Webb Space Telescope has revealed for the first time that this star is cloaked in dust.

- Two cameras aboard Webb captured the latest image of this planetary nebula, cataloged as NGC 3132, and known informally as the Southern Ring Nebula. It is approximately 2,500 light-years away.

- Webb will allow astronomers to dig into many more specifics about planetary nebulae like this one – clouds of gas and dust expelled by dying stars. Understanding which molecules are present, and where they lie throughout the shells of gas and dust will help researchers refine their knowledge of these objects.

- This observation shows the Southern Ring Nebula almost face-on, but if we could rotate it to view it edge-on, its three-dimensional shape would more clearly look like two bowls placed together at the bottom, opening away from one another with a large hole at the center.

- Two stars, which are locked in a tight orbit, shape the local landscape. Webb's infrared images feature new details in this complex system. The stars – and their layers of light – are prominent in the image from Webb's Near-Infrared Camera (NIRCam) on the left, while the image from Webb's Mid-Infrared Instrument (MIRI) on the right shows for the first time that the second star is surrounded by dust. The brighter star is in an earlier stage of its stellar evolution and will probably eject its own planetary nebula in the future.

- In the meantime, the brighter star influences the nebula's appearance. As the pair continues to orbit one another, they "stir the pot" of gas and dust, causing asymmetrical patterns.

- Each shell represents an episode where the fainter star lost some of its mass. The widest shells of gas toward the outer areas of the image were ejected earlier. Those closest to the star are the most recent. Tracing these ejections allows researchers to look into the history of the system.

- Observations taken with NIRCam also reveal extremely fine rays of light around the planetary nebula. Starlight from the central stars streams out where there are holes in the gas and dust – like sunlight through gaps in a cloud.

- Since planetary nebulae exist for tens of thousands of years, observing the nebula is like watching a movie in exceptionally slow motion. Each shell the star puffed off gives researchers the ability to precisely measure the gas and dust that are present within it.

- As the star ejects shells of material, dust and molecules form within them – changing the landscape even as the star continues to expel material. This dust will eventually enrich the areas around it, expanding into what's known as the interstellar medium. And since it's very long-lived, the dust may end up traveling through space for billions of years and become incorporated into a new star or planet.

- In thousands of years, these delicate layers of gas and dust will dissipate into surrounding space.

- NASA Headquarters oversees the mission for the agency's Science Mission Directorate. NASA's Goddard Space Flight Center in Greenbelt, Maryland, manages Webb for the agency and oversees work on the mission performed by the Space Telescope Science Institute, Northrop Grumman, and other mission partners. In addition to Goddard, several NASA centers contributed to the project, including the agency's Johnson Space Center in Houston, Jet Propulsion Laboratory in Southern California, Marshall Space Flight Center in Huntsville, Alabama, Ames Research Center in California's Silicon Valley, and others.

- NIRCam was built by a team at the University of Arizona and Lockheed Martin's Advanced Technology Center.

- MIRI was contributed by ESA and NASA, with the instrument designed and built by a consortium of nationally funded European Institutes (The MIRI European Consortium) in partnership with JPL and the University of Arizona.

• On Monday, 11 July 2022, President Joe Biden released one of the James Webb Space Telescope's first images in a preview event at the White House in Washington. NASA, in partnership with ESA (European Space Agency) and CSA (Canadian Space Agency), will release the full set of Webb's first full-color images and spectroscopic data during a televised broadcast beginning at 10:30 a.m. EDT (14:30 UTC) on Tuesday, July 12, from NASA's Goddard Space Flight Center in Greenbelt, Maryland. 24) 25)

- This first image from NASA's James Webb Space Telescope is the deepest and sharpest infrared image of the distant universe to date. Known as Webb's First Deep Field, this image of galaxy cluster SMACS 0723 is overflowing with detail. Thousands of galaxies – including the faintest objects ever observed in the infrared – have appeared in Webb's view for the first time. This slice of the vast universe covers a patch of sky approximately the size of a grain of sand held at arm's length by someone on the ground.

- This deep field, taken by Webb's Near-Infrared Camera (NIRCam), is a composite made from images at different wavelengths, totaling 12.5 hours – achieving depths at infrared wavelengths beyond the Hubble Space Telescope's deepest fields, which took weeks.

• July 12, 2022: Stephan's Quintet, a visual grouping of five galaxies, is best known for being prominently featured in the holiday classic film, "It's a Wonderful Life." Today, NASA's James Webb Space Telescope reveals Stephan's Quintet in a new light. This enormous mosaic is Webb's largest image to date, covering about one-fifth of the Moon's diameter. It contains over 150 million pixels and is constructed from almost 1,000 separate image files. The information from Webb provides new insights into how galactic interactions may have driven galaxy evolution in the early universe. 26) 27)

- With its powerful, infrared vision and extremely high spatial resolution, Webb shows never-before-seen details in this galaxy group. Sparkling clusters of millions of young stars and starburst regions of fresh star birth grace the image. Sweeping tails of gas, dust and stars are being pulled from several of the galaxies due to gravitational interactions. Most dramatically, Webb captures huge shock waves as one of the galaxies, NGC 7318B, smashes through the cluster.

- Together, the five galaxies of Stephan's Quintet are also known as the Hickson Compact Group 92 (HCG 92). Although called a "quintet," only four of the galaxies are truly close together and caught up in a cosmic dance. The fifth and leftmost galaxy, called NGC 7320, is well in the foreground compared with the other four. NGC 7320 resides 40 million light-years from Earth, while the other four galaxies (NGC 7317, NGC 7318A, NGC 7318B, and NGC 7319) are about 290 million light-years away. This is still fairly close in cosmic terms, compared with more distant galaxies billions of light-years away. Studying such relatively nearby galaxies like these helps scientists better understand structures seen in a much more distant universe.

- This proximity provides astronomers a ringside seat for witnessing the merging and interactions between galaxies that are so crucial to all of galaxy evolution. Rarely do scientists see in so much detail how interacting galaxies trigger star formation in each other, and how the gas in these galaxies is being disturbed. Stephan's Quintet is a fantastic "laboratory" for studying these processes fundamental to all galaxies.

- Tight groups like this may have been more common in the early universe when their superheated, infalling material may have fueled very energetic black holes called quasars. Even today, the topmost galaxy in the group – NGC 7319 – harbors an active galactic nucleus, a supermassive black hole 24 million times the mass of the Sun. It is actively pulling in material and puts out light energy equivalent to 40 billion Suns.

- Webb studied the active galactic nucleus in great detail with the Near-Infrared Spectrograph (NIRSpec) and Mid-Infrared Instrument (MIRI). These instruments' integral field units (IFUs) – which are a combination of a camera and spectrograph – provided the Webb team with a "data cube," or collection of images of the galactic core's spectral features.

- Much like medical magnetic resonance imaging (MRI), the IFUs allow scientists to "slice and dice" the information into many images for detailed study. Webb pierced through the shroud of dust surrounding the nucleus to reveal hot gas near the active black hole and measure the velocity of bright outflows. The telescope saw these outflows driven by the black hole in a level of detail never seen before.

- In NGC 7320, the leftmost and closest galaxy in the visual grouping, Webb was able to resolve individual stars and even the galaxy's bright core.

- As a bonus, Webb revealed a vast sea of thousands of distant background galaxies reminiscent of Hubble's Deep Fields.

- Combined with the most detailed infrared image ever of Stephan's Quintet from MIRI and the Near-Infrared Camera (NIRCam), the data from Webb will provide a bounty of valuable, new information. For example, it will help scientists understand the rate at which supermassive black holes feed and grow. Webb also sees star-forming regions much more directly, and it is able to examine emission from the dust – a level of detail impossible to obtain until now.

- Located in the constellation Pegasus, Stephan's Quintet was discovered by the French astronomer Édouard Stephan in 1877.

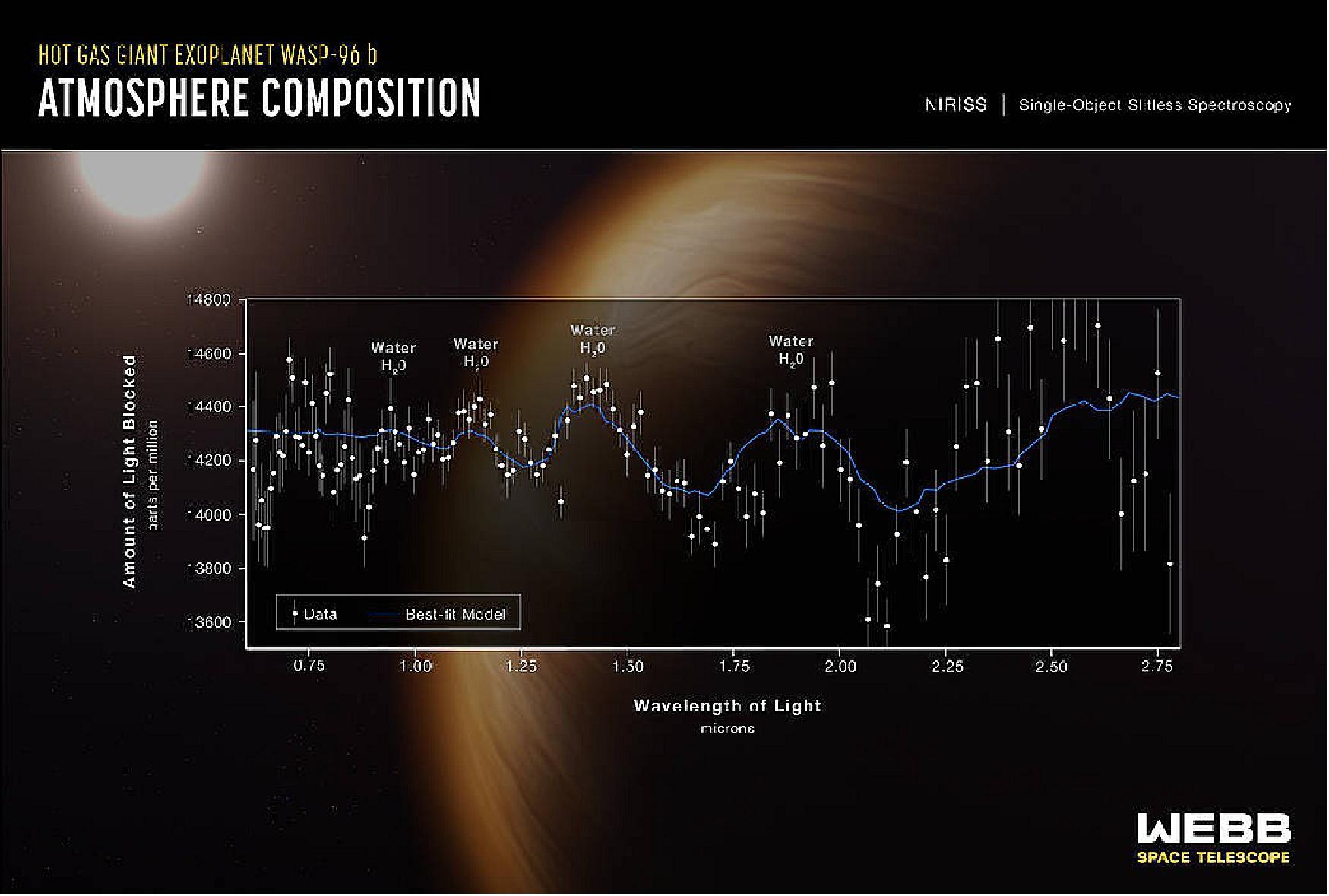

• July 12, 2022: NASA's James Webb Space Telescope has captured the distinct signature of water, along with evidence for clouds and haze, in the atmosphere surrounding a hot, puffy gas giant planet orbiting a distant Sun-like star. 28) 29)

- The observation, which reveals the presence of specific gas molecules based on tiny decreases in the brightness of precise colors of light, is the most detailed of its kind to date, demonstrating Webb's unprecedented ability to analyze atmospheres hundreds of light-years away.

- While the Hubble Space Telescope has analyzed numerous exoplanet atmospheres over the past two decades, capturing the first clear detection of water in 2013, Webb's immediate and more detailed observation marks a giant leap forward in the quest to characterize potentially habitable planets beyond Earth.

- WASP-96 b is one of more than 5,000 confirmed exoplanets in the Milky Way. Located roughly 1,150 light-years away in the southern-sky constellation Phoenix, it represents a type of gas giant that has no direct analog in our solar system. With a mass less than half that of Jupiter and a diameter 1.2 times greater, WASP-96 b is much puffier than any planet orbiting our Sun. And with a temperature greater than 1000°F, it is significantly hotter. WASP-96 b orbits extremely close to its Sun-like star, just one-ninth of the distance between Mercury and the Sun, completing one circuit every 3½ Earth-days.

- The combination of large size, short orbital period, puffy atmosphere, and lack of contaminating light from objects nearby in the sky makes WASP-96 b an ideal target for atmospheric observations.

- On June 21, Webb's Near-Infrared Imager and Slitless Spectrograph (NIRISS) measured light from the WASP-96 system for 6.4 hours as the planet moved across the star. The result is a light curve showing the overall dimming of starlight during the transit, and a transmission spectrum revealing the brightness change of individual wavelengths of infrared light between 0.6 and 2.8 µm.

- While the light curve confirms properties of the planet that had already been determined from other observations – the existence, size, and orbit of the planet – the transmission spectrum reveals previously hidden details of the atmosphere: the unambiguous signature of water, indications of haze, and evidence of clouds that were thought not to exist based on prior observations.

- A transmission spectrum is made by comparing starlight filtered through a planet's atmosphere as it moves across the star to the unfiltered starlight detected when the planet is beside the star. Researchers are able to detect and measure the abundances of key gases in a planet's atmosphere based on the absorption pattern – the locations and heights of peaks on the graph. In the same way that people have distinctive fingerprints and DNA sequences, atoms and molecules have characteristic patterns of wavelengths that they absorb.

- The spectrum of WASP-96 b captured by NIRISS is not only the most detailed near-infrared transmission spectrum of an exoplanet atmosphere captured to date, but it also covers a remarkably wide range of wavelengths, including visible red light and a portion of the spectrum that has not previously been accessible from other telescopes (wavelengths longer than 1.6 microns). This part of the spectrum is particularly sensitive to water as well as other key molecules like oxygen, methane, and carbon dioxide, which are not immediately obvious in the WASP-96 b spectrum but which should be detectable in other exoplanets planned for observation by Webb.

- Researchers will be able to use the spectrum to measure the amount of water vapor in the atmosphere, constrain the abundance of various elements like carbon and oxygen, and estimate the temperature of the atmosphere with depth. They can then use this information to make inferences about the overall make-up of the planet, as well as how, when, and where it formed. The blue line on the graph is a best-fit model that takes into account the data, the known properties of WASP-96 b and its star (e.g., size, mass, temperature), and assumed characteristics of the atmosphere.

- The exceptional detail and clarity of these measurements is possible because of Webb's state-of-the-art design. Its 270-square-foot gold-coated mirror collects infrared light efficiently. Its precision spectrographs spread light out into rainbows of thousands of infrared colors. And its sensitive infrared detectors measure extremely subtle differences in brightness. NIRISS is able to detect color differences of only about one thousandth of a micron (the difference between green and yellow is about 50 microns), and differences in the brightness between those colors of a few hundred parts per million.

- In addition, Webb's extreme stability and its orbital location around Lagrange Point 2 roughly a million miles away from the contaminating effects of Earth's atmosphere makes for an uninterrupted view and clean data that can be analyzed relatively quickly.

- The extraordinarily detailed spectrum – made by simultaneously analyzing 280 individual spectra captured over the observation – provides just a hint of what Webb has in store for exoplanet research. Over the coming year, researchers will use spectroscopy to analyze the surfaces and atmospheres of several dozen exoplanets, from small rocky planets to gas- and ice-rich giants. Nearly one-quarter of Webb's Cycle 1 observation time is allocated to studying exoplanets and the materials that form them.

- This NIRISS observation demonstrates that Webb has the power to characterize the atmospheres of exoplanets—including those of potentially habitable planets—in exquisite detail.

• July 8, 2022: NASA's James Webb Space Telescope, a partnership with ESA (European Space Agency) and CSA (Canadian Space Agency), will soon reveal unprecedented and detailed views of the universe with the upcoming release of its first full-color images and spectroscopic data. 30)

- The images will include some taken by Webb's MIRI instrument, which is managed by the Jet Propulsion Laboratory for NASA.

- Below is the list of cosmic objects that Webb targeted for these first observations, which will be released in NASA's live broadcast beginning at 10:30 a.m. EDT (7:30 a.m. PDT) Tuesday, July 12. Each image will simultaneously be made available on social media as well as on the agency's website.

- These listed targets below represent the first wave of full-color scientific images and spectra the observatory has gathered, and the official beginning of Webb's general science operations. They were selected by an international committee of representatives from NASA, ESA, CSA, and the Space Telescope Science Institute.

a) Carina Nebula: The Carina Nebula is one of the largest and brightest nebulae in the sky, located approximately 7,600 light-years away in the southern constellation Carina. Nebulae are stellar nurseries where stars form. The Carina Nebula is home to many massive stars several times larger than the Sun.

b) WASP-96b (spectrum): WASP-96b is a giant planet outside our solar system, composed mainly of gas. The planet, located nearly 1,150 light-years from Earth, orbits its star every 3.4 days. It has about half the mass of Jupiter, and its discovery was announced in 2014.

c) Southern Ring Nebula: The Southern Ring, or "Eight-Burst" nebula, is a planetary nebula – an expanding cloud of gas surrounding a dying star. It is nearly half a light-year in diameter and is located approximately 2,000 light-years away from Earth.

d) Stephan's Quintet: About 290 million light-years away, Stephan's Quintet is located in the constellation Pegasus. It is notable for being the first compact galaxy group ever discovered in 1787. Four of the five galaxies within the quintet are locked in a cosmic dance of repeated close encounters.

e) SMACS 0723: Massive foreground galaxy clusters magnify and distort the light of objects behind them, permitting a deep field view into both the extremely distant and intrinsically faint galaxy populations.

- The release of these first images marks the official beginning of Webb's science operations, which will continue to explore the mission's key science themes. Teams have already applied through a competitive process for time to use the telescope, in what astronomers call its first "cycle," or first year of observations.

- More information on how to join NASA for the release of Webb's first images is available online. For more about Webb's status, visit the "Where Is Webb?" tracker.

- The James Webb Space Telescope is the world's premier space science observatory. Webb will solve mysteries in our solar system, look beyond to distant worlds around other stars, and probe the mysterious structures and origins of our universe and our place in it.

• July 7, 2022: Three of the four science instruments on NASA's James Webb Space Telescope have completed their commissioning activities and are ready for science. 31)

- Each of Webb's instruments has multiple modes of operation, which need to be tested, calibrated, and ultimately verified before they can begin to conduct science. The latest instrument to complete this process, the Near-Infrared Spectrograph (NIRSpec), has four key modes the team officially confirmed as ready to go.

- "We made it: NIRSpec is ready for science! This is an amazing moment, the result of the hard work of so many JWST and NIRSpec people and teams over more than two decades. I am just so proud of everyone," said Pierre Ferruit, Webb project scientist with ESA (European Space Agency) and principal investigator for NIRSpec. "Now is time for science, and I am eager to see the first scientific results coming from NIRSpec observations. I have no doubt they will be fantastic. Big thanks to all who made this possible across the years – great job!"

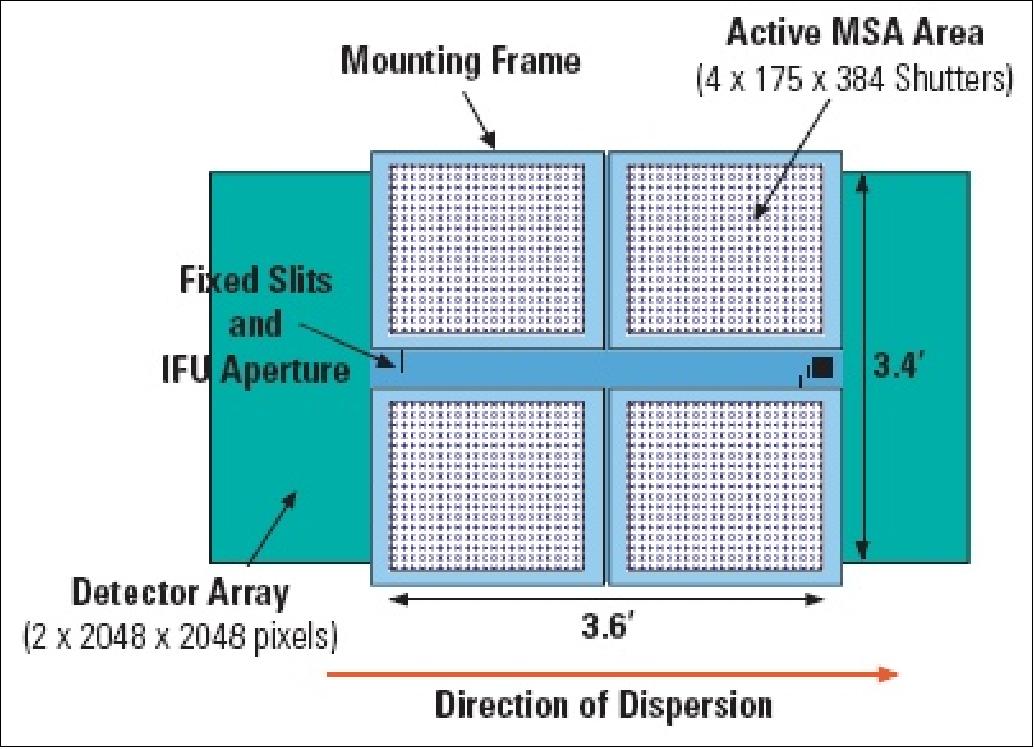

- The final mode verified for NIRSpec was the multi-object spectroscopy mode, a key capability that allows Webb to capture spectra, or rainbows of infrared light, from hundreds of different cosmic targets at once. In multi-object spectroscopy mode, NIRSpec can individually open and close about 250,000 small shutters, all just the width of a human hair, to view some portions of the sky while blocking others. By controlling this "microshutter array," Webb can observe multiple specific targets while reducing interference from others.

- The confirmation of NIRSpec's multi-object spectroscopy mode marks the first time this capability has been verified for use from space. It will allow NIRSpec to characterize everything from the faintest objects in the universe to the formation of galaxies and star clusters.

- NIRSpec was built for ESA by a consortium of European companies led by Airbus Defence and Space, with NASA's Goddard Space Flight Center in Greenbelt, Maryland, providing its detector and microshutter subsystems.

- Out of 17 total instrument modes across Webb's four instruments, only one mode remains to be verified, for the Near-Infrared Camera (NIRCam). When the team confirms this remaining mode, the months-long process of preparing Webb for science will formally be complete.

- Webb's commissioning process culminates on July 12, with the release of the telescope's first full-color images and spectroscopic data, and the official beginning of its science mission.

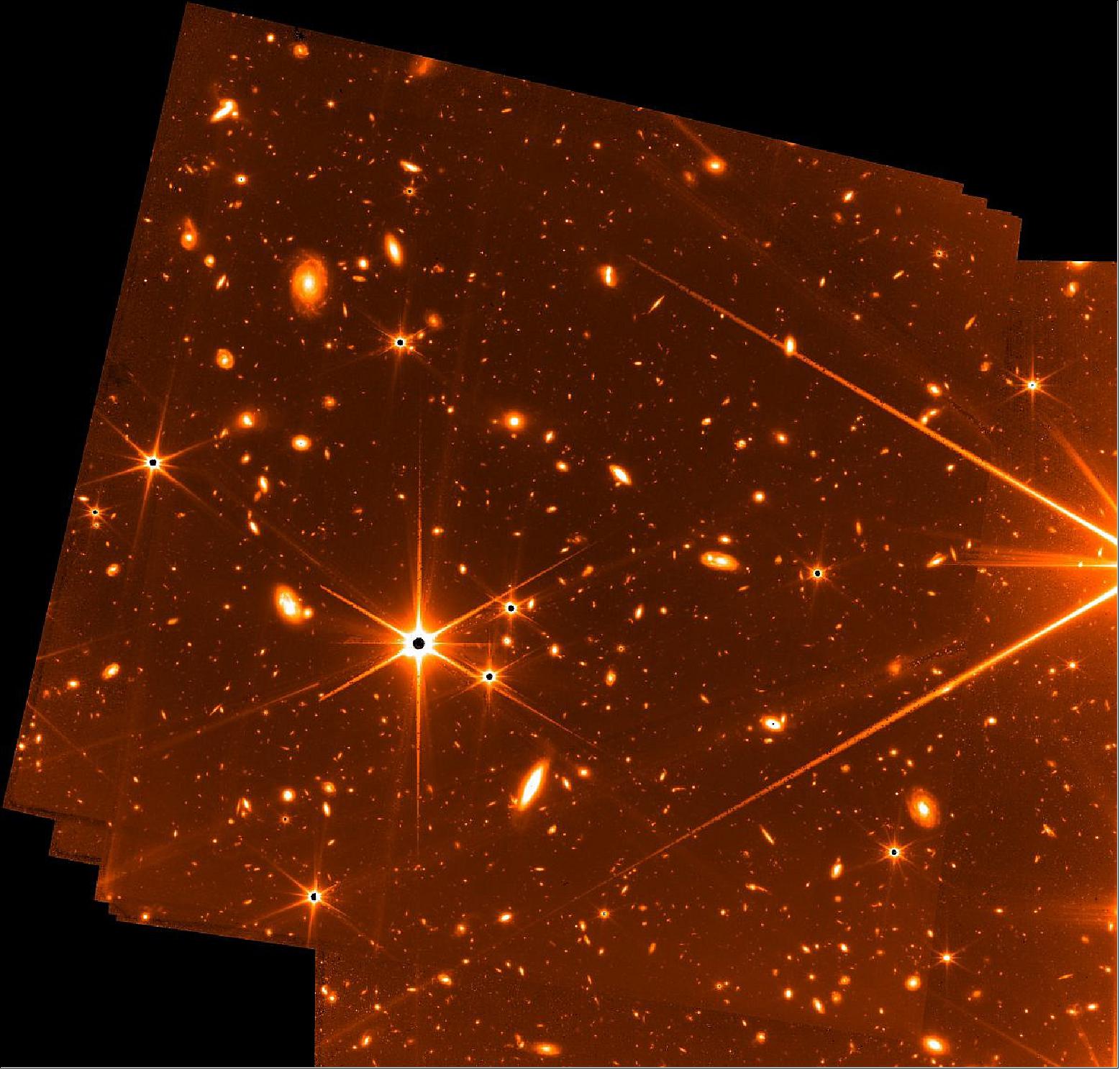

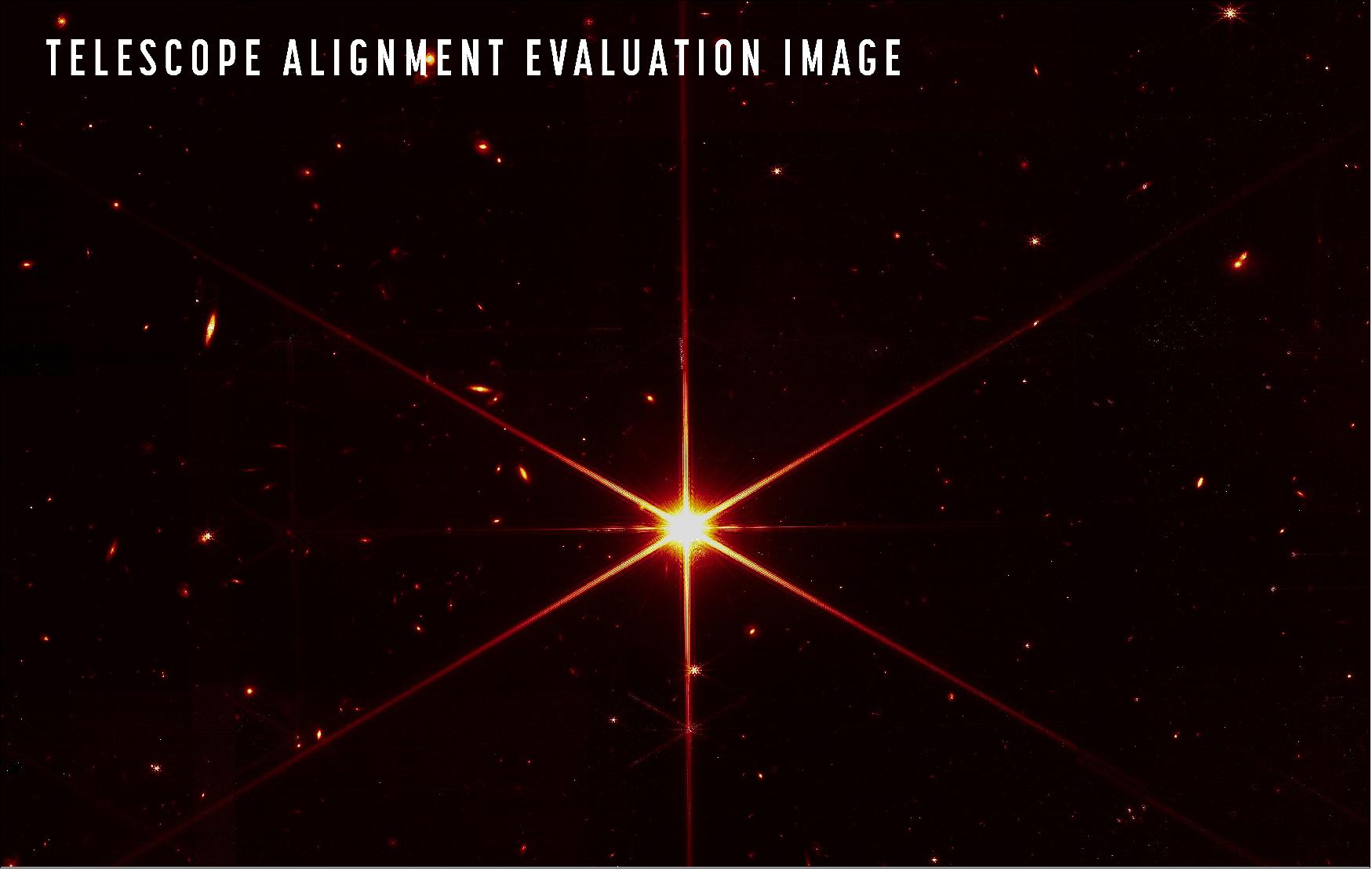

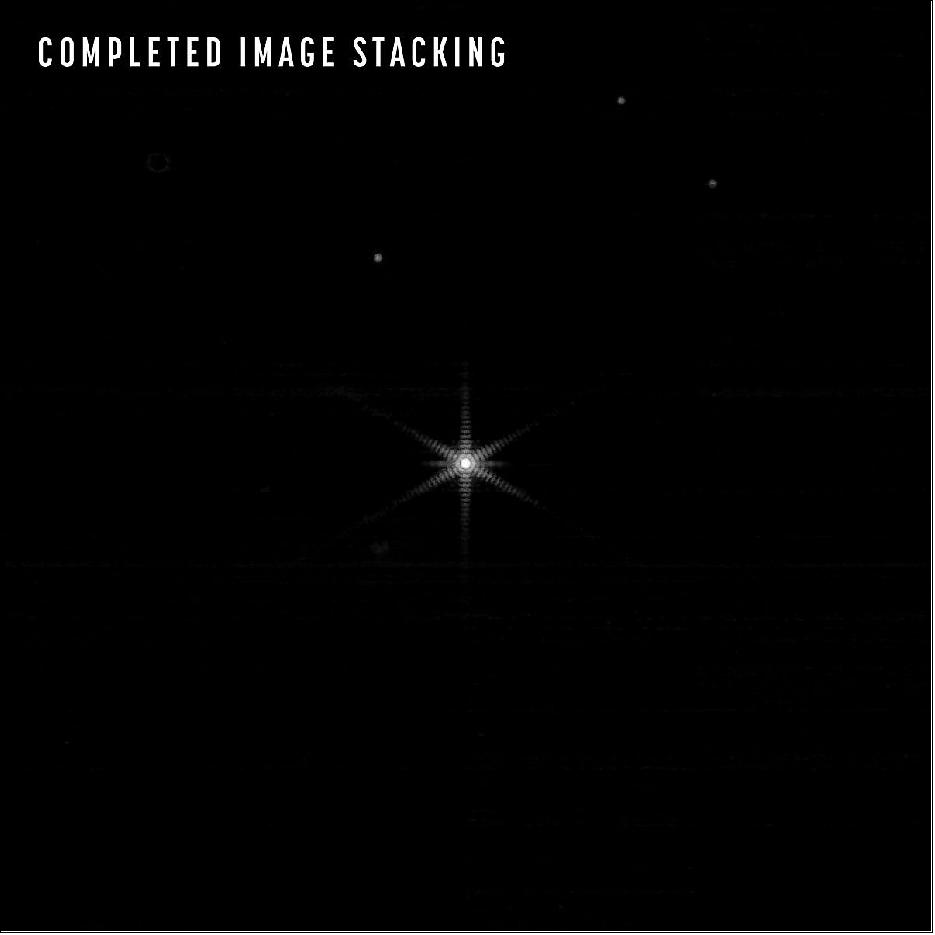

• July 6, 2022: We are less than one week away from the release of the first full-color images from NASA's James Webb Space Telescope, but how does the observatory find and lock onto its targets? Webb's Fine Guidance Sensor (FGS) – developed by the Canadian Space Agency – was designed with this particular question in mind. Recently it captured a view of stars and galaxies that provides a tantalizing glimpse at what the telescope's science instruments will reveal in the coming weeks, months, and years. 32)

- FGS has always been capable of capturing imagery, but its primary purpose is to enable accurate science measurements and imaging with precision pointing. When it does capture imagery, the imagery is typically not kept: Given the limited communications bandwidth between L2 and Earth, Webb only sends data from up to two science instruments at a time. But during a week-long stability test in May, it occurred to the team that they could keep the imagery that was being captured because there was available data transfer bandwidth.

- The resulting engineering test image has some rough-around-the-edges qualities to it. It was not optimized to be a science observation; rather, the data was taken to test how well the telescope could stay locked onto a target, but it does hint at the power of the telescope. It carries a few hallmarks of the views Webb has produced during its postlaunch preparations. Bright stars stand out with their six, long, sharply defined diffraction spikes – an effect due to Webb's six-sided mirror segments. Beyond the stars, galaxies fill nearly the entire background.

- The result – using 72 exposures over 32 hours – is among the deepest images of the universe ever taken, according to Webb scientists. When FGS' aperture is open, it is not using color filters like the other science instruments – meaning it is impossible to study the age of the galaxies in this image with the rigor needed for scientific analysis. But even when capturing unplanned imagery during a test, FGS is capable of producing stunning views of the cosmos.

- "With the Webb telescope achieving better-than-expected image quality, early in commissioning we intentionally defocused the guiders by a small amount to help ensure they met their performance requirements. When this image was taken, I was thrilled to clearly see all the detailed structure in these faint galaxies. Given what we now know is possible with deep broad-band guider images, perhaps such images, taken in parallel with other observations where feasible, could prove scientifically useful in the future," said Neil Rowlands, program scientist for Webb's Fine Guidance Sensor, at Honeywell Aerospace.

- Because this image was not created with a science result in mind, there are a few features that are quite different than the full-resolution images that will be released July 12. Those images will include what will be – for a short time at least – the deepest image of the universe ever captured, as NASA Administrator Bill Nelson announced on June 29.

- The FGS image is colored using the same reddish color scheme that has been applied to Webb's other engineering images throughout commissioning. In addition, there was no "dithering" during these exposures. Dithering is when the telescope repositions slightly between each exposure. In addition, the centers of bright stars appear black because they saturate Webb's detectors, and the pointing of the telescope didn't change over the exposures to capture the center from different pixels within the camera's detectors. The overlapping frames of the different exposures can also be seen at the image's edges and corners.

- In this engineering test, the purpose was to lock onto one star and to test how well Webb could control its "roll" – literally, Webb's ability to roll to one side like an aircraft in flight. That test was performed successfully – in addition to producing an image that sparks the imagination of scientists who will be analyzing Webb's science data, said Jane Rigby, Webb's operations scientist at NASA's Goddard Space Flight Center in Greenbelt, Maryland.

- "The faintest blobs in this image are exactly the types of faint galaxies that Webb will study in its first year of science operations," Rigby said.

- While Webb's four science instruments will ultimately reveal the telescope's new view of the universe, the Fine Guidance Sensor is the one instrument that will be used in every single Webb observation over the course of the mission's lifetime. FGS has already played a crucial role in aligning Webb's optics. Now, during the first real science observations made in June and once science operations begin in mid-July, it will guide each Webb observation to its target and maintain the precision necessary for Webb to produce breakthrough discoveries about stars, exoplanets, galaxies, and even moving targets within our solar system.

• June 22, 2022: Two research teams will use the telescope's powerful instruments to capture and characterize some of the earliest galaxies in the universe. 33)

- The universe was a very different place for several hundred million years after the big bang. It wasn't yet transparent like it is today – neutral gas made it semi-opaque. This is a period when the first galaxies in the universe were beginning to form. Telescopes have spotted many distant galaxies – but none earlier than 400 million years after the big bang. What were galaxies that existed even earlier like? Two research teams using the James Webb Space Telescope will wield its state-of-the-art instruments to reveal an untold number of details about this early period in the universe for the first time – and revise what we know about some of the earliest chapters of galaxy evolution.

- For decades, telescopes have helped us capture light from galaxies that formed as far back as 400 million years after the big bang – incredibly early in the context of the universe's 13.8-billion-year history. But what were galaxies like that existed even earlier, when the universe was semi-transparent at the beginning of a period known as the Era of Reionization? NASA's next flagship observatory, the James Webb Space Telescope, is poised to add new riches to our wealth of knowledge not only by capturing images from galaxies that existed as early as the first few hundred million years after the big bang, but also by giving us detailed data known as spectra. With Webb's observations, researchers will be able to tell us about the makeup and composition of individual galaxies in the early universe for the first time.

- The Next Generation Deep Extragalactic Exploratory Public (NGDEEP) Survey, co-led by Steven L. Finkelstein, an associate professor at the University of Texas at Austin, will target the same two regions that make up the Hubble Ultra Deep Field – locations in the constellation Fornax where Hubble spent more than 11 days taking deep exposures. To produce its observations, the Hubble Space Telescope targeted nearby areas of the sky simultaneously with two instruments – slightly offset from one another – known as a primary and a parallel field. "We have the same advantage with Webb," Finkelstein explained. "We're using two science instruments at once, and they will observe continuously." They will point Webb's Near-Infrared Imager and Slitless Spectrograph (NIRISS) on the primary Hubble Ultra Deep Field, and Webb's Near-Infrared Camera (NIRCam) on the parallel field, getting twice the bang for their "buck" of telescope time.

- For the imaging with NIRCam, they'll observe for over 125 hours. With each passing minute, they'll obtain more and more information from deeper and deeper in the universe. What do they seek? Some of the earliest galaxies that formed. "We have really good indications from Hubble that there are galaxies in place at a time 400 million years after the big bang," Finkelstein said. "The ones we see with Hubble are pretty big and very bright. It's highly likely there are smaller, fainter galaxies that formed even earlier that are waiting to be found."

- This program will use only about one-third of the time Hubble has spent to date on similar investigations. Why? In part, this is because Webb's instruments were designed to capture infrared light. As light travels through space toward us, it stretches into longer, redder wavelengths due to the expansion of the universe. "Webb will help us push all the boundaries," said Jennifer Lotz, a coinvestigator on the proposal and director of the Gemini Observatory, part of the National Science Foundation's NOIRLab (National Optical-Infrared Astronomy Research Laboratory). "And we're going to release the data immediately to benefit all researchers."

- These researchers will also focus on identifying the metal content in each galaxy, especially in smaller and dimmer galaxies that haven't yet been thoroughly examined – specifically with the spectra Webb's NIRISS instrument delivers. "One of the fundamental ways that we trace evolution across cosmic time is by the amount of metals that are in a galaxy," explained Danielle Berg, an assistant professor at the University of Texas at Austin and a co-investigator on the proposal. When the universe began, there was only hydrogen and helium. New elements were formed by successive generations of stars. By cataloging the contents of each galaxy, the researchers will be able to plot out precisely when various elements existed and update models that project how galaxies evolved in the early universe.

![Figure 16: This Hubble Space Telescope image, known as the Hubble Ultra Deep Field, reveals about 10,000 galaxies and combines ultraviolet, visible, and near-infrared light. Two programs that will use the James Webb Space Telescope will add more detail to this image, capturing thousands of additional galaxies in a fuller range of infrared light. Webb will return both imagery and data known as spectra, providing more details about some of the earliest galaxies to exist in the universe for the first time [image credits: Science: NASA, ESA, Steven V.W. Beckwith (STScI), HUDF Team (STScI)]](https://www.eoportal.org/ftp/satellite-missions/j/JWST_130722/JWST_Auto55.jpeg)

Peeling Back New Layers

- Another program, led by Michael Maseda, an assistant professor at the University of Wisconsin-Madison, will examine the primary Hubble Ultra Deep Field using the microshutter array within Webb's Near-Infrared Spectrograph (NIRSpec). This instrument returns spectra for specific objects depending on which miniature shutters researchers open. "These galaxies existed during the first billion years in the history of the universe, which we have very little information about to date," Maseda explained. "Webb will provide the first large sample that will give us the chance to understand them in detail."

- We know these galaxies exist because of extensive observations this team has made – along with an international research team – with the ground-based Very Large Telescope's Multi Unit Spectroscopic Explorer (MUSE) instrument. Although MUSE is the "scout," identifying smaller, fainter galaxies in this deep field, Webb will be the first telescope to fully characterize their chemical compositions.

- These extremely distant galaxies have important implications for our understanding of how galaxies formed in the early universe. "Webb will open a new space for discovery," explained Anna Feltre, a research fellow at the National Institute for Astrophysics in Italy and a co-investigator. "Its data will help us learn precisely what happens as a galaxy forms, including which metals they contain, how quickly they grow, and if they already have black holes."

- This research will be conducted as part of Webb's General Observer (GO) programs, which are competitively selected using a dual-anonymous review, the same system that is used to allocate time on the Hubble Space Telescope.

• June 1, 2022: NASA's James Webb Space Telescope, a partnership with ESA (European Space Agency) and the Canadian Space Agency (CSA), will release its first full-color images and spectroscopic data on July 12, 2022. As the largest and most complex observatory ever launched into space, Webb has been going through a six-month period of preparation before it can begin science work, calibrating its instruments to its space environment and aligning its mirrors. This careful process, not to mention years of new technology development and mission planning, has built up to the first images and data: a demonstration of Webb at its full power, ready to begin its science mission and unfold the infrared universe. 34)

- "As we near the end of preparing the observatory for science, we are on the precipice of an incredibly exciting period of discovery about our universe. The release of Webb's first full-color images will offer a unique moment for us all to stop and marvel at a view humanity has never seen before," said Eric Smith, Webb program scientist at NASA Headquarters in Washington. "These images will be the culmination of decades of dedication, talent, and dreams – but they will also be just the beginning."

Behind the Scenes: Creating Webb's First Images

- Deciding what Webb should look at first has been a project more than five years in the making, undertaken by an international partnership between NASA, ESA, CSA, and the Space Telescope Science Institute (STScI) in Baltimore, home to Webb's science and mission operations.

- "Our goals for Webb's first images and data are both to showcase the telescope's powerful instruments and to preview the science mission to come," said astronomer Klaus Pontoppidan, Webb project scientist at STScI. "They are sure to deliver a long-awaited ‘wow' for astronomers and the public."

- Once each of Webb's instruments has been calibrated, tested, and given the green light by its science and engineering teams, the first images and spectroscopic observations will be made. The team will proceed through a list of targets that have been preselected and prioritized by an international committee to exercise Webb's powerful capabilities. Then the production team will receive the data from Webb's instrument scientists and process it into images for astronomers and the public.

- "I feel very privileged to be a part of it," said Alyssa Pagan, a science visuals developer at STScI. "Typically, the process from raw telescope data to final, clean image that communicates scientific information about the universe can take anywhere from weeks to a month," Pagan said.

What Will We See?

- While careful planning for Webb's first full-color images has been underway for a long time, the new telescope is so powerful that it is difficult to predict exactly how the first images will look. "Of course, there are things we are expecting and hoping to see, but with a new telescope and this new high-resolution infrared data, we just won't know until we see it," said STScI's lead science visuals developer Joseph DePasquale.

- Early alignment imagery has already demonstrated the unprecedented sharpness of Webb's infrared view. However, these new images will be the first in full color and the first to showcase Webb's full science capabilities. In addition to imagery, Webb will be capturing spectroscopic data – detailed information astronomers can read in light. The first images package of materials will highlight the science themes that inspired the mission and will be the focus of its work: the early universe, the evolution of galaxies through time, the lifecycle of stars, and other worlds. All of Webb's commissioning data – the data taken while aligning the telescope and preparing the instruments – will also be made publicly available.

What's Next?

- Science! After capturing its first images, Webb's scientific observations will begin, continuing to explore the mission's key science themes. Teams have already applied through a competitive process for time to use the telescope, in what astronomers call its first "cycle," or first year of observations. Observations are carefully scheduled to make the most efficient use of the telescope's time.

- These observations mark the official beginning of Webb's general science operations – the work it was designed to do. Astronomers will use Webb to observe the infrared universe, analyze the data collected, and publish scientific papers on their discoveries.

- Beyond what is already planned for Webb, there are the unexpected discoveries astronomers can't anticipate. One example: In 1990 when the Hubble Space Telescope launched, dark energy was completely unknown. Now it is one of the most exciting areas of astrophysics. What will Webb discover?

- The James Webb Space Telescope is the world's premier space science observatory. Webb will solve mysteries in our solar system, look beyond to distant worlds around other stars, and probe the mysterious structures and origins of our universe and our place in it. Webb is an international program led by NASA with its partners, ESA (European Space Agency) and the Canadian Space Agency.

• May 26, 2022: Researchers will train Webb's high-precision spectrographs on two intriguing rocky exoplanets. 35)

- With its mirror segments beautifully aligned and its scientific instruments undergoing calibration, NASA's James Webb Space Telescope is just weeks away from full operation. Soon after the first observations are revealed this summer, Webb's in-depth science will begin.

- Among the investigations planned for the first year are studies of two hot exoplanets classified as "super-Earths" for their size and rocky composition: the lava-covered 55 Cancri e and the airless LHS 3844 b. Researchers will train Webb's high-precision spectrographs on these planets with a view to understanding the geologic diversity of planets across the galaxy, and the evolution of rocky planets like Earth.

Super-Hot Super-Earth 55 Cancri e

- 55 Cancri e orbits less than 1.5 million miles from its Sun-like star (one twenty-fifth of the distance between Mercury and the Sun), completing one circuit in less than 18 hours. With surface temperatures far above the melting point of typical rock-forming minerals, the day side of the planet is thought to be covered in oceans of lava.

- Planets that orbit this close to their star are assumed to be tidally locked, with one side facing the star at all times. As a result, the hottest spot on the planet should be the one that faces the star most directly, and the amount of heat coming from the day side should not change much over time.

- But this doesn't seem to be the case. Observations of 55 Cancri e from NASA's Spitzer Space Telescope suggest that the hottest region is offset from the part that faces the star most directly, while the total amount of heat detected from the day side does vary.

![Figure 18: The illustration is showing what exoplanet 55 Cancri e could look like, based on current understanding of the planet. 55 Cancri e is a rocky planet with a diameter almost twice that of Earth orbiting just 0.015 astronomical units from its Sun-like star. Because of its tight orbit, the planet is extremely hot, with dayside temperatures reaching 4,400º Fahrenheit (about 2,400º Celsius). Although previous studies have ruled out a thick hydrogen, carbon dioxide, or water atmosphere, it is possible that the planet has a substantial atmosphere made of oxygen or nitrogen, or a very thin atmosphere of mineral vapor, such as silicon oxide. - Researchers think that if the planet is tidally locked, the lit surface must be permanently molten. If the planet is not locked, it would experience day-night cycles, with the surface heating up and melting during the day, and cooling and solidifying at night. The extreme heat during the day would also cause some of the molten rock to vaporize, forming a very tenuous mineral vapor atmosphere. In the evening, this vapor would condense and fall as a rain of lava back onto the surface, where it would turn solid overnight. - Spectroscopic observations using Webb's Near-Infrared Camera (NIRCam) and Mid-Infrared Instrument (MIRI) will help determine whether or not the planet has an atmosphere, and if so, what that atmosphere is made of. The observations will also help determine whether or not the planet is tidally locked [image credit: ARTWORK: NASA, ESA, CSA, Dani Player (STScI)]](https://www.eoportal.org/ftp/satellite-missions/j/JWST_130722/JWST_Auto54.jpeg)

Does 55 Cancri e Have a Thick Atmosphere?

- One explanation for these observations is that the planet has a dynamic atmosphere that moves heat around. "55 Cancri e could have a thick atmosphere dominated by oxygen or nitrogen," explained Renyu Hu of NASA's Jet Propulsion Laboratory in Southern California, who leads a team that will use Webb's Near-Infrared Camera (NIRCam) and Mid-Infrared Instrument (MIRI) to capture the thermal emission spectrum of the day side of the planet. "If it has an atmosphere, [Webb] has the sensitivity and wavelength range to detect it and determine what it is made of," Hu added.

Or Is It Raining Lava in the Evening on 55 Cancri e?

- Another intriguing possibility, however, is that 55 Cancri e is not tidally locked. Instead, it may be like Mercury, rotating three times for every two orbits (what's known as a 3:2 resonance). As a result, the planet would have a day-night cycle.

- "That could explain why the hottest part of the planet is shifted," explained Alexis Brandeker, a researcher from Stockholm University who leads another team studying the planet. "Just like on Earth, it would take time for the surface to heat up. The hottest time of the day would be in the afternoon, not right at noon."

- Brandeker's team plans to test this hypothesis using NIRCam to measure the heat emitted from the lit side of 55 Cancri e during four different orbits. If the planet has a 3:2 resonance, they will observe each hemisphere twice and should be able to detect any difference between the hemispheres.

- In this scenario, the surface would heat up, melt, and even vaporize during the day, forming a very thin atmosphere that Webb could detect. In the evening, the vapor would cool and condense to form droplets of lava that would rain back to the surface, turning solid again as night falls.

Somewhat Cooler Super-Earth LHS 3844 b

- While 55 Cancri e will provide insight into the exotic geology of a world covered in lava, LHS 3844 b affords a unique opportunity to analyze the solid rock on an exoplanet surface.

- Like 55 Cancri e, LHS 3844 b orbits extremely close to its star, completing one revolution in 11 hours. However, because its star is relatively small and cool, the planet is not hot enough for the surface to be molten. Additionally, Spitzer observations indicate that the planet is very unlikely to have a substantial atmosphere.

What Is the Surface of LHS 3844 b Made of?

- While we won't be able to image the surface of LHS 3844 b directly with Webb, the lack of an obscuring atmosphere makes it possible to study the surface with spectroscopy.

- "It turns out that different types of rock have different spectra," explained Laura Kreidberg at the Max Planck Institute for Astronomy. "You can see with your eyes that granite is lighter in color than basalt. There are similar differences in the infrared light that rocks give off."

- Kreidberg's team will use MIRI to capture the thermal emission spectrum of the day side of LHS 3844 b, and then compare it to spectra of known rocks, like basalt and granite, to determine its composition. If the planet is volcanically active, the spectrum could also reveal the presence of trace amounts of volcanic gases.

- The importance of these observations goes far beyond just two of the more than 5,000 confirmed exoplanets in the galaxy. "They will give us fantastic new perspectives on Earth-like planets in general, helping us learn what the early Earth might have been like when it was hot like these planets are today," said Kreidberg.

- These observations of 55 Cancri e and LHS 3844 b will be conducted as part of Webb's Cycle 1 General Observers program. General Observers programs were competitively selected using a dual-anonymous review system, the same system used to allocate time on Hubble.

- The James Webb Space Telescope is the world's premier space science observatory. Webb will solve mysteries in our solar system, look beyond to distant worlds around other stars, and probe the mysterious structures and origins of our universe and our place in it. Webb is an international program led by NASA with its partners, ESA (European Space Agency) and the Canadian Space Agency.

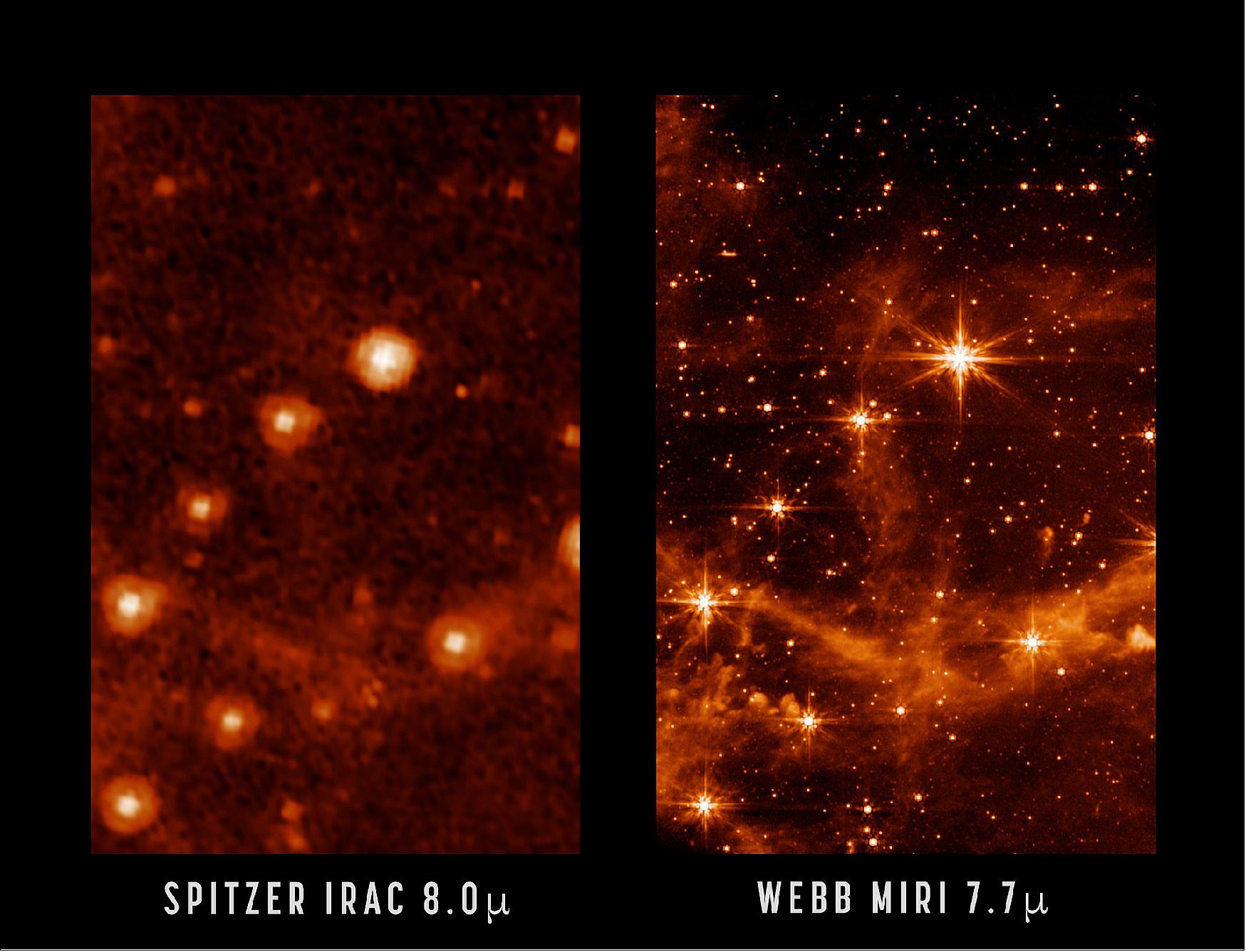

• May 9, 2022: The James Webb Space Telescope is aligned across all four of its science instruments, as seen in a previous engineering image showing the observatory's full field of view. Now, we take a closer look at that same image, focusing on Webb's coldest instrument: the Mid-Infrared Instrument (MIRI).

- For example, Webb's MIRI image shows the interstellar gas in unprecedented detail. Here, you can see the emission from ‘polycyclic aromatic hydrocarbons' – molecules of carbon and hydrogen that play an important role in the thermal balance and chemistry of interstellar gas. When Webb is ready to begin science observations, studies such as these with MIRI will help give astronomers new insights into the birth of stars and protoplanetary systems.

- In the meantime, the Webb team has begun the process of setting up and testing Webb's instruments to begin science observations this summer. Today at 17:00 CEST, Webb experts will preview these next two months of instrument preparations in a teleconference for media. Listen to the audio stream live at nasa.gov/live.

• May 5, 2022: NASA's James Webb Space Telescope is now experiencing all seasons – from hot to cold – as it undergoes the thermal stability test. Meanwhile, activities are underway for the final phase of commissioning: digging into the details of the science instruments, the heart of Webb. To complete commissioning, we will measure the detailed performance of the science instruments before we start routine science operations in the summer. 36)

- Today, the lead commissioning scientist for Webb, Scott Friedman of the Space Telescope Science Institute (STScI), gives us all the details on this final phase of commissioning.

- "With the telescope beautifully aligned and the observatory near its final cryogenic temperature, we are ready to begin the last group of activities before the science observations start: science instrument commissioning. Here I describe just a few of those activities.

- "The instruments, the Near-Infrared Camera (NIRCam), Near-Infrared Spectrometer (NIRSpec), Near-Infrared Imager and Slitless Spectrometer (NIRISS), Mid-Infrared Instrument (MIRI), and the Fine Guidance Sensor (FGS) have been powered up and safely cooled. We have operated their mechanisms and detectors, including filter wheels, grating wheels, and the NIRSpec microshutter assembly. The Webb optics team used images of isolated stars taken with each of the instruments to align the primary and secondary mirrors of the observatory. But we have more work to do before Webb is fully ready to embark on the ambitious science observations that will reveal the secrets of the universe.

- "We will now begin an extensive suite of calibrations and characterizations of the instruments using a rich variety of astronomical sources. We will measure the instruments' throughput – how much of the light that enters the telescope reaches the detectors and is recorded. There is always some loss with each reflection by the mirrors of the telescope and within each instrument, and no detector records every photon that arrives. We will measure this throughput at multiple wavelengths of light by observing standard stars whose light emission is known from data obtained with other observatories combined with theoretical calculations.

- "The astrometric calibration of each instrument maps the pixels on the detectors to the precise locations on the sky, to correct the small but unavoidable optical distortions that are present in every optical system. We do this by observing the Webb astrometric field, a small patch of sky in a nearby galaxy, the Large Magellanic Cloud. This field was observed by the Hubble Space Telescope to establish the coordinates of about 200,000 stars to an accuracy of 1 milliarcsec (less than 0.3 millionths of a degree). Calibrating this distortion is required to precisely place the science targets on the instruments' field of view. For example, to get the spectra of a hundred galaxies simultaneously using the NIRSpec microshutter assembly, the telescope must be pointed so that each galaxy is in the proper shutter, and there are a quarter of a million shutters!

- "We will also measure the sharpness of the stellar images, what astronomers call the ‘point spread function.' We already know the telescope is delivering to the instruments image quality that exceeds our prelaunch expectations, but each instrument has additional optics. These optics perform a function, such as passing the light through filters to get color information about the astronomical target or using a diffraction grating to spread the incoming light into its constituent colors. Measuring the point spread function within each instrument at different wavelengths provides an important calibration for interpreting the data.

- "We will test target acquisition for each instrument. For some observations, it is sufficient to point the telescope using the position of a guide star in the Fine Guidance Sensor and know the location of the science target relative to that guide star. This places the science target to an accuracy of a few tenths of an arcsecond. However, in some cases more precision is necessary, approximately a hundredth of an arcsecond. For example, for coronagraphy, the star has to be placed behind a mask so its light is blocked, allowing the nearby exoplanet to shine through. In time series observations, we measure how an exoplanet's atmosphere absorbs the stellar light during the hours it takes to pass in front of its star, allowing us to measure the properties and constituents of the planet's atmosphere. Both of these applications require that the instrument send corrections to the telescope pointing control system to put the science target precisely in the correct location within the instrument's field of view.

- "A final example of our instrument commissioning activities is observations of moving targets. Most astronomical objects are so far away that they appear to be stationary on the sky. However, this is not true of the planets, satellites and rings, asteroids, and comets within our own solar system. Observing these requires that the observatory change its pointing direction relative to the background guide stars during the observation. We will test this capability by observing asteroids of different apparent speeds using each instrument.

- "We are now in the last two months of Webb's commissioning before it is fully ready for its scientific mission. We still have important properties and capabilities of the instruments to test, measure, and demonstrate. When these are complete, we will be ready to begin the great science programs that astronomers and the public alike have been eagerly awaiting. We are almost there."

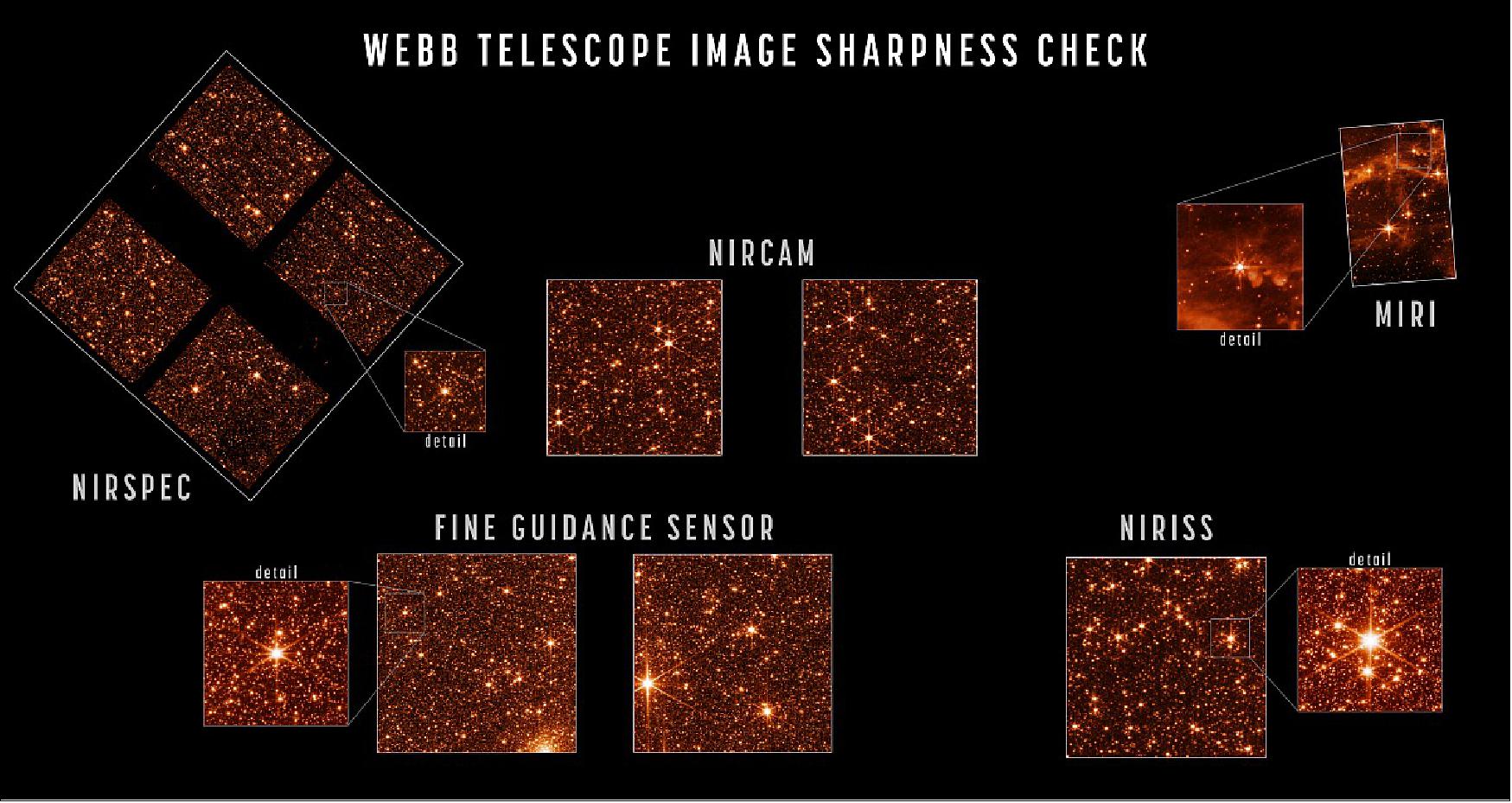

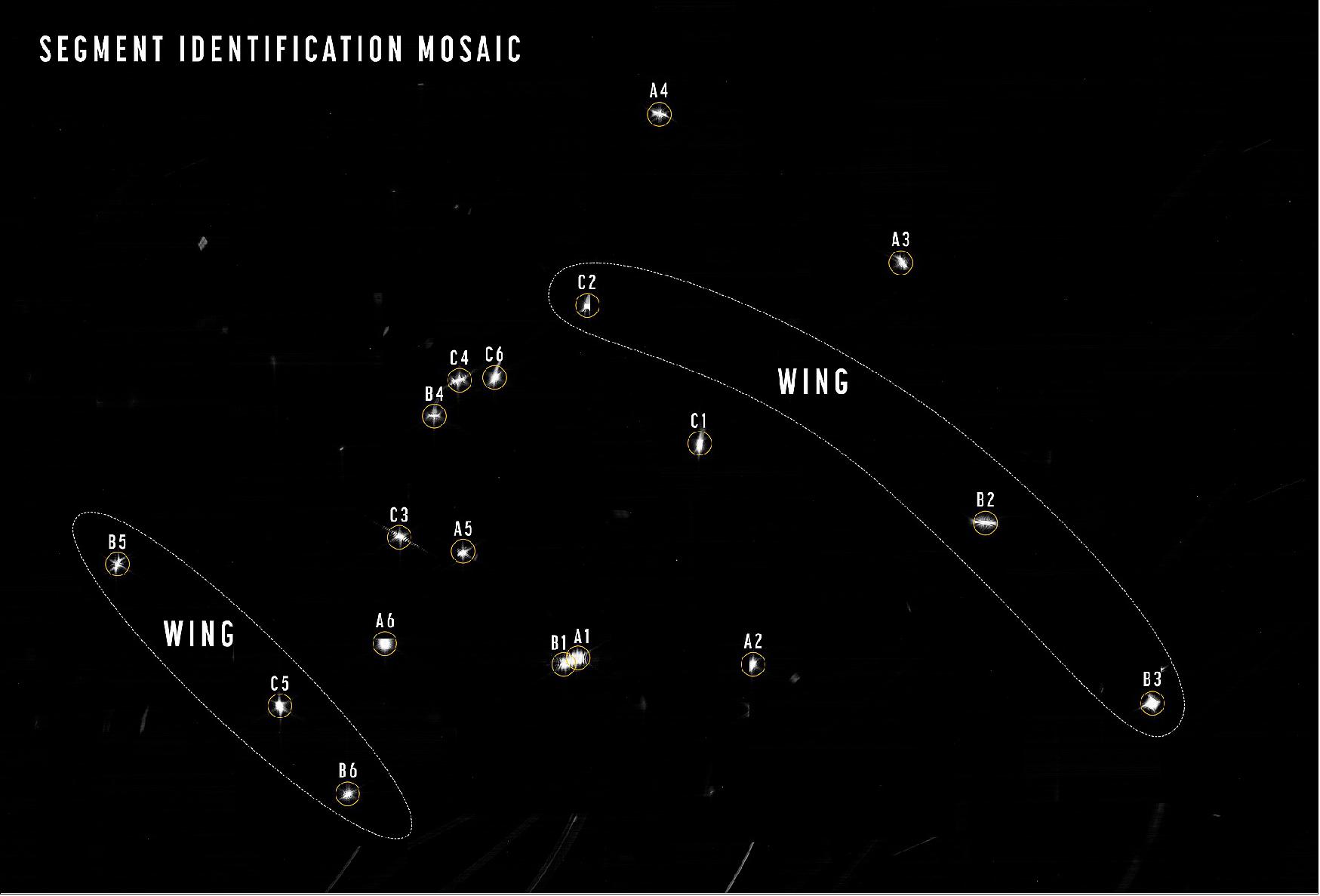

• April 28, 2022: Alignment of NASA's James Webb Space Telescope is now complete. After full review, the observatory has been confirmed to be capable of capturing crisp, well-focused images with each of its four powerful onboard science instruments. Upon completing the seventh and final stage of telescope alignment, the team held a set of key decision meetings and unanimously agreed that Webb is ready to move forward into its next and final series of preparations, known as science instrument commissioning. This process will take about two months before scientific operations begin in the summer. 37) 38)

- The alignment of the telescope across all of Webb's instruments can be seen in a series of images that captures the observatory's full field of view.

- "These remarkable test images from a successfully aligned telescope demonstrate what people across countries and continents can achieve when there is a bold scientific vision to explore the universe," said Lee Feinberg, Webb optical telescope element manager at NASA's Goddard Space Flight Center.