Artemis-I (Exploration Mission-1)

Non-EO

NASA

Quick facts

Overview

| Mission type | Non-EO |

| Agency | NASA |

| Launch date | 16 Nov 2022 |

| End of life date | 11 Dec 2022 |

Artemis I — Orion / EM-1 (Exploration Mission-1)

Orion Vehicle ESM Development Status Payloads References

In March 2018, NASA renamed the former Orion / EM-1 (Exploration Mission-1) to Artemis I. Artemis I will be the first integrated test of NASA’s deep space exploration systems: the Orion spacecraft, Space Launch System (SLS) rocket and the ground systems at Kennedy Space Center in Cape Canaveral, Florida. The first in a series of increasingly complex missions, Artemis I will be an uncrewed flight test that will provide a foundation for human deep space exploration, and demonstrate our commitment and capability to extend human existence to the Moon and beyond. 1)

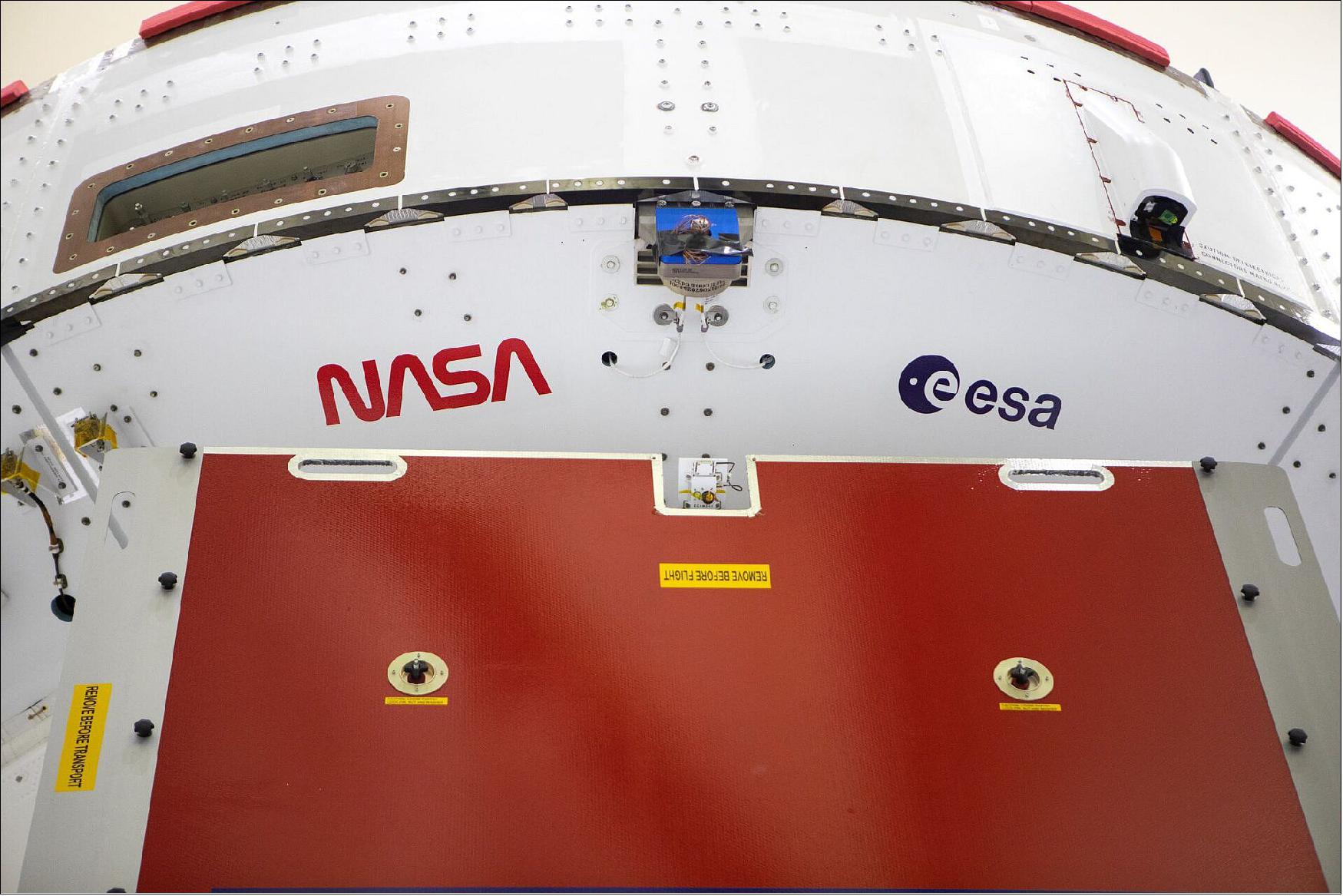

Orion EM-1, previously known as SLS-1 (Space Launch System-1) is NASA's first planned flight of the Space Launch System and the second uncrewed test flight of the Orion MPCV (Multi-Purpose Crew Vehicle). NASA, ESA, European and US Industry have teamed to develop the ORION spacecraft.

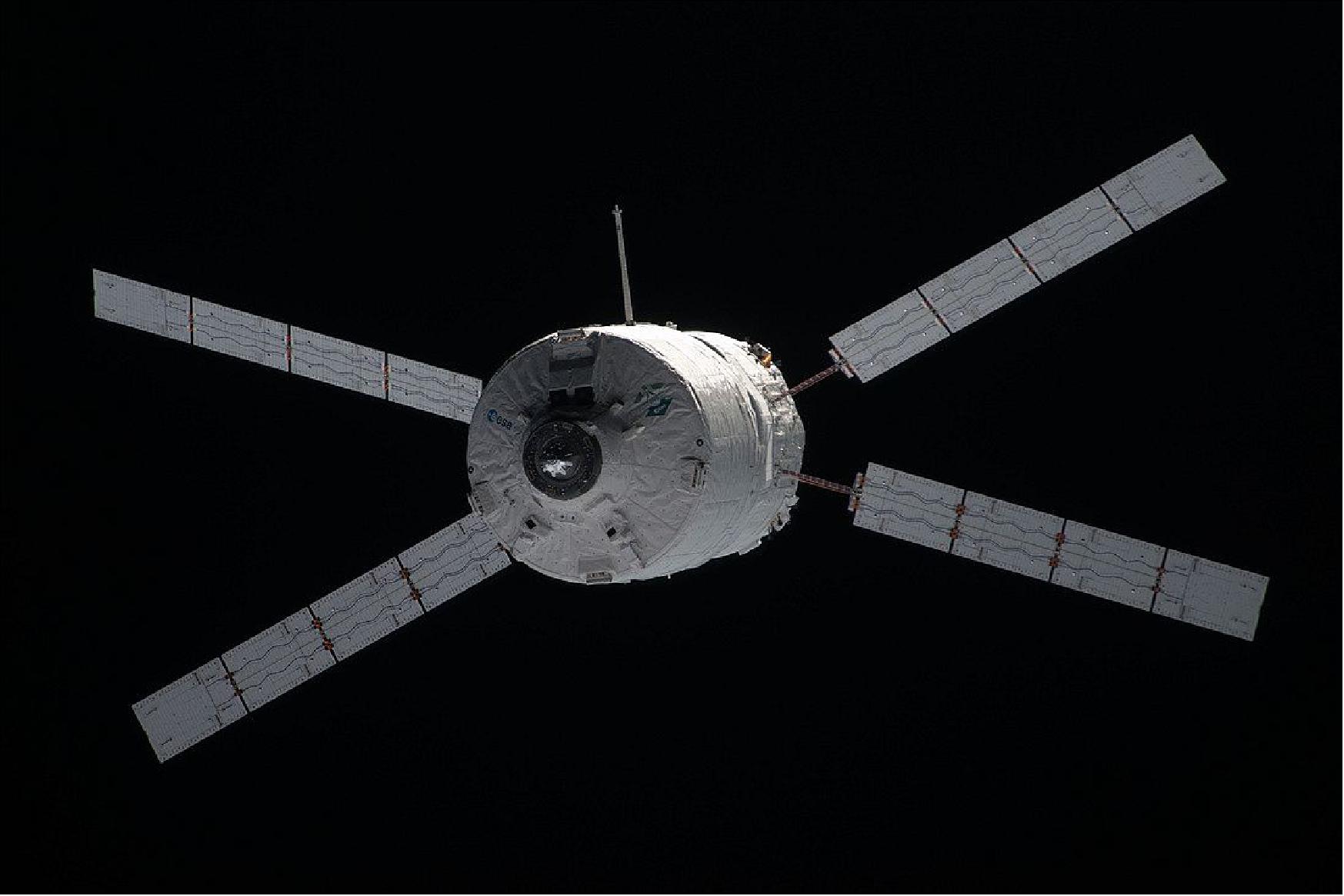

Under an agreement between NASA and ESA, ratified in December 2012, NASA’s new Orion vehicle for human space exploration missions includes the ESM (European Service Module), based upon the design and experience of ESA’s ATV (Automated Transfer Vehicle), the supply craft for the ISS (International Space Station).

ESA’s industrial prime contractor for ATV, Airbus Defence and Space of Bremen, Germany, is leading a European industrial consortium, developing this vehicle on behalf of ESA and working closely with NASA’s Orion US industrial prime contractor Lockheed Martin Space Systems.

Orion is the spacecraft that NASA intends to use to send humans and cargo into space beyond low earth orbit and to return them safely to Earth. It is being developed for crewed missions to cislunar space, asteroids, and then to Mars. The capsule is also planned as a backup vehicle for missions to the ISS (International Space Station). It will be launched by the NASA-developed SLS (Space Launch System) in 2019. 2) 3)

The first test flight of Orion was successfully completed in December 2014 with a Delta IV launch vehicle that launched the Orion Crew Module into a high elliptical orbit to demonstrate high-speed atmospheric Earth re-entry. This flight test did not include the ESM.

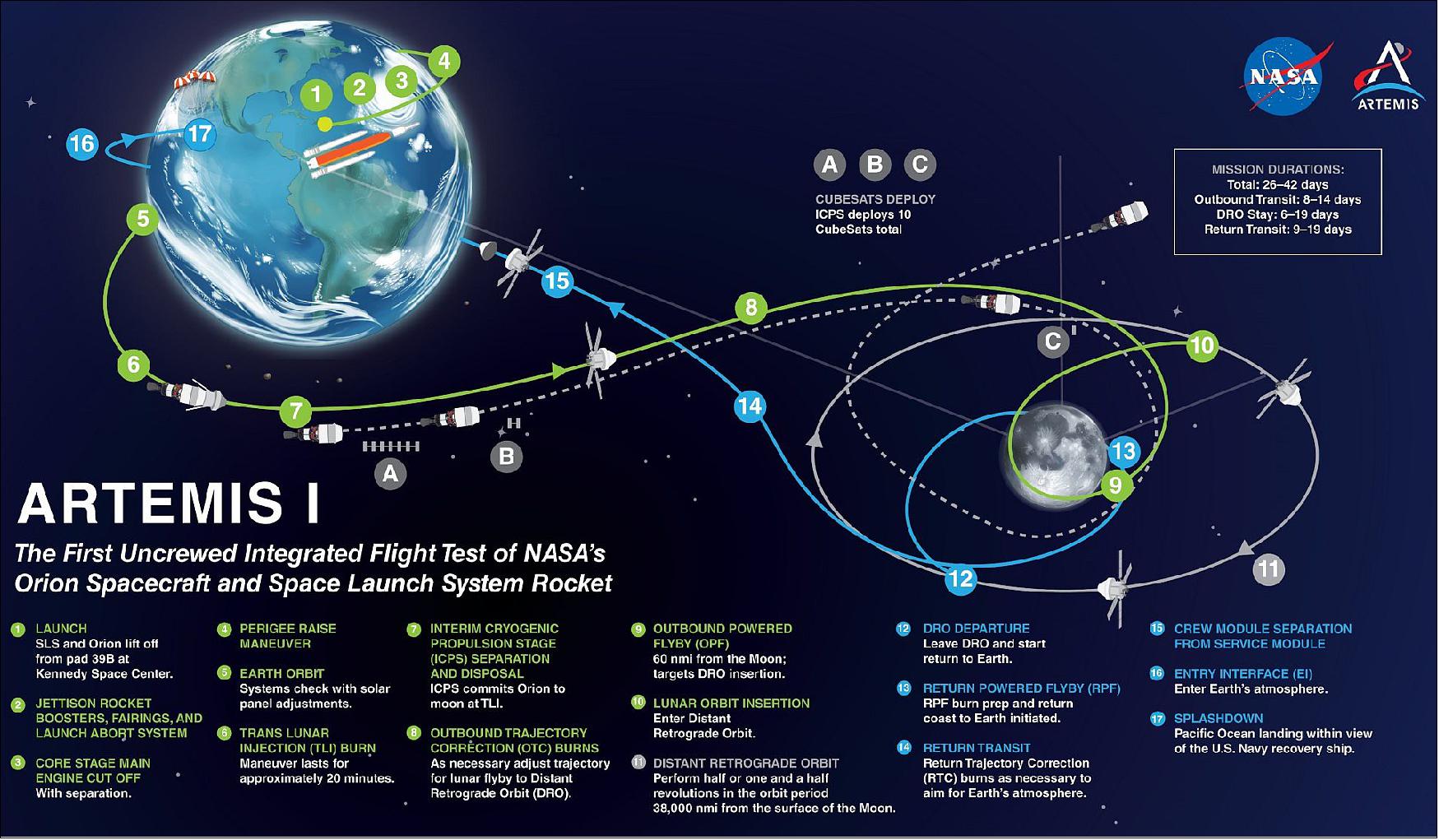

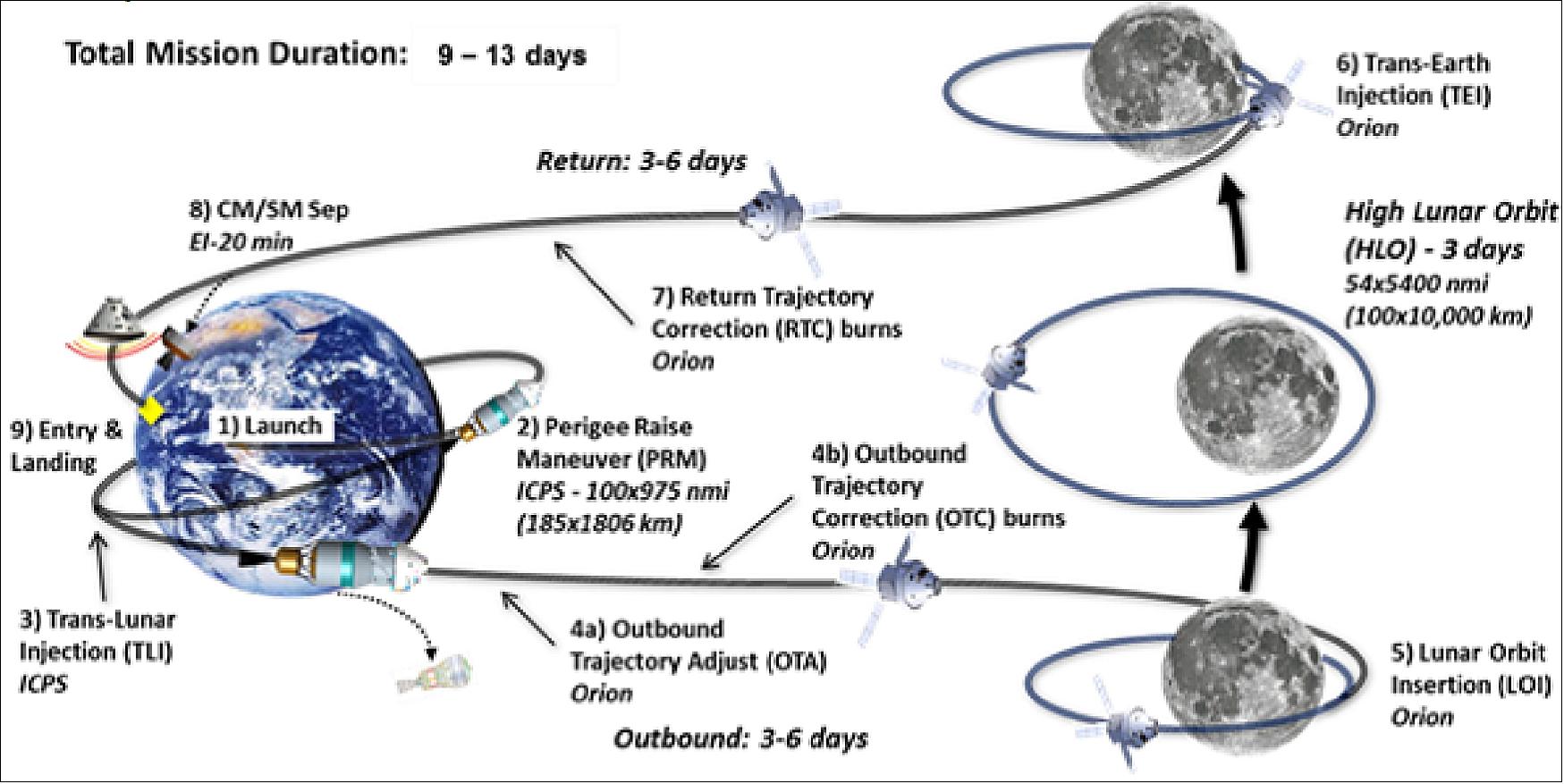

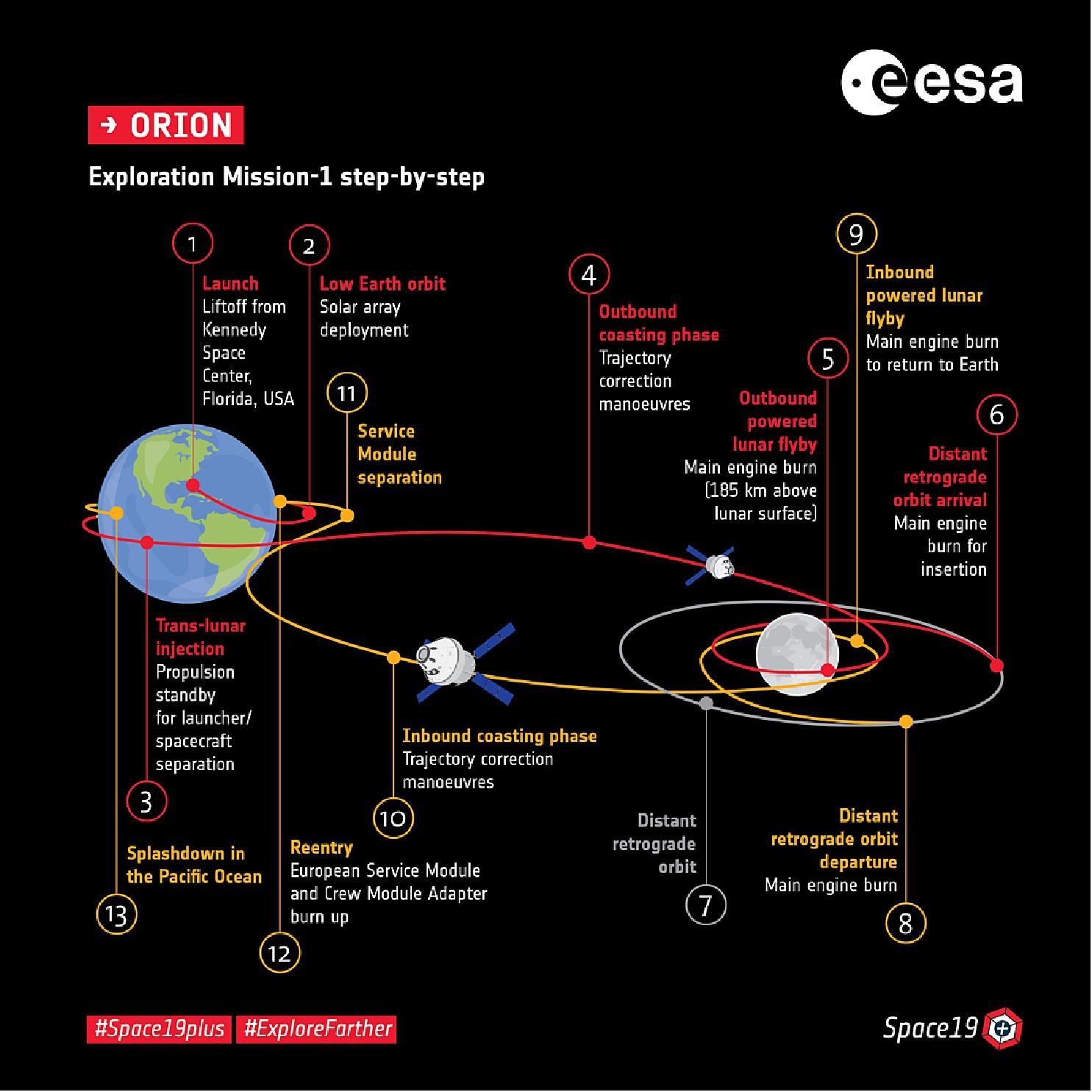

It is planned such that the Orion EM-1 flies a mission profile similar to what might be used in a future asteroid redirect mission. The un-crewed Orion travels to a lunar DRO (Distant Retrograde Orbit) mission (Figure 13), then returns on a trajectory calculated to achieve a high speed atmospheric entry on the order of ~11 km/s to demonstrate the performance and effectiveness of the Orion TPS (Thermal Protection System), as well as relevant environments prior to the first manned launch of the system. The total mission duration is 25 days (6 at destination). This will be the first flight of the ESM.

The NASA Exploration Program – Journey To Mars

The human exploration of space is a national policy of the government of the United States. The National Space Policy directs NASA to: 4) 5) 6)

• Set far reaching exploration milestones. By 2025, begin crewed missions beyond the moon, including sending humans to an asteroid. By the mid-2030s, send humans to orbit Mars and return them safely to Earth.

• Furthermore, the NASA Authorization Act of 2010, a law passed by the U.S. Congress and signed by the President, states that the “long term objective for human exploration of space should be the eventual international exploration of Mars.”

NASA is implementing this policy as the Journey to Mars, a journey that will be neither quick nor easy. 56 million kilometers away at its closest approach, with an atmosphere too thin for easy braking but too thick to ignore, with freezing surface temperatures, a minimal magnetic field for radiation protection, and communications delays with Earth of up to 40 minutes, Mars represents the current high frontier in human exploration.

Even though Mars is tremendously challenging, it has resources necessary for human exploration (oxygen, CO2 atmosphere, and water). These resources are critical to allow us to break the ties with Earth and become Earth Independent. The atmosphere, even though very thin by Earth standards, still provides some radiation shielding. Developing the ability to utilize the resources on Mars will be critical for the journey. We have calculated that roughly 20 mt of oxygen will be needed for the human Mars ascent vehicle to achieve orbit around Mars. Rather than carry all of the propellant and oxygen needed for a Mars ascent vehicle, we will generate that propellant from the materials available on Mars.

The challenges are too difficult to tackle all at once. Instead, NASA is breaking it down into more manageable objectives: the Earth Reliant phase, the Proving Ground phase, and the Earth Independent phase. Each phase builds upon the successes (and failures) of the previous one in a sustainable, repeatable, and in manner that allows for changes in technology or funding. In this approach NASA does not need to develop and control all aspects of the journey. NASA will utilize the private sector and international partners in critical roles of the journey and depend on these partners for successful achievement of the overall journey.

Earth Reliant: NASA is operating in the Earth Reliant phase of the Journey to Mars aboard the ISS (International Space Station) right now. The ISS, orbiting some 400 km above Earth, is mere hours away from the safety and comfort of our home planet. Aboard the space station, NASA and the other international partners are developing the technologies needed to sustain human life much farther away than 400 kilometers. A new and varied fleet of commercially produced and procured vehicles is taking over the duties of transportation of humans and cargo from Earth to ISS. NASA’s investments in this area promise to create new opportunities for the development of LEO, including broader use of the ISS as an orbital science laboratory and as a demonstration platform for future commercial space facilities as NASA moves towards the Proving Ground phase.

In the Earth Reliant phase, NASA is developing the “Mars-capable” systems that will be needed for long-duration stays outside of the comfortable frontier of LEO. Currently manifested or planned experiments and demonstrations include improved long-duration life support for Mars missions, advanced fire safety equipment, next-generation spacesuit technologies, high-data-rate communications, techniques to reduce logistics, large deployable solar arrays, in-space additive manufacturing, advanced exercise and medical equipment, radiation monitoring and shielding, human/robotic operations, and autonomous crew operations.

However, these “Mars-capable” systems are not only technological, but also biological- this work includes the development and demonstration of the human systems; the countermeasures, procedures, and adaptations the crew will need to survive and thrive in deep space. NASA’s Human Research Program is actively working on identifying, mitigating, and eliminating the risks of spaceflight to the human body aboard ISS, while acknowledging that some risks- like radiation- can only be fully quantified with long-duration human exposure to the environment outside the Van Allen belt. NASA astronauts and others will also gain experience on a variety of management, operations, and maintenance styles and techniques are they begin flying to orbit onboard the Boeing and SpaceX crew vehicles.

We have a lot to learn from the Earth Reliant time on ISS. We have continuously been surprised by problems that arise on ISS, especially in the life support systems. NASA performed extensive ground testing on these systems only to be surprised by their actual performance in space. For example, the water systems were much more susceptible to bio-films and blockage than ground tests showed. Carbon dioxide removal system beds have more problems with dust generation and valve fouling than anticipated. We need to discover and solve these problems on ISS before venturing into deep space with these systems. ISS is the perfect platform for these development and testing activities.

In this Earth Reliant phase- when regular interaction and management from the ground is possible - NASA and its commercial partners will continue to return benefits to humanity on Earth while developing the skills to go farther. NASA intends to begin short-duration cislunar while ISS is still operating. It is a fundamental tenant of human spaceflight that continuity of operations be persevered, in order to maintain our progress in a sustained manner.

Earth Independence will also require a new operating philosophy with our crews. Today, the ground crews often serve as an additional ISS crew member. Many robotic activities are done from the ground while the ISS crew sleeps. During space walks the ground serves as an extra set of eyes and ears for the crew. As crews move into deep space, the crews must become more autonomous. Here again, ISS is an excellent platform to practice crew independence before it is required. Time delays between Earth and ISS can be added to simulate the real time delays associated with communication distances as will be experienced at Mars distances.

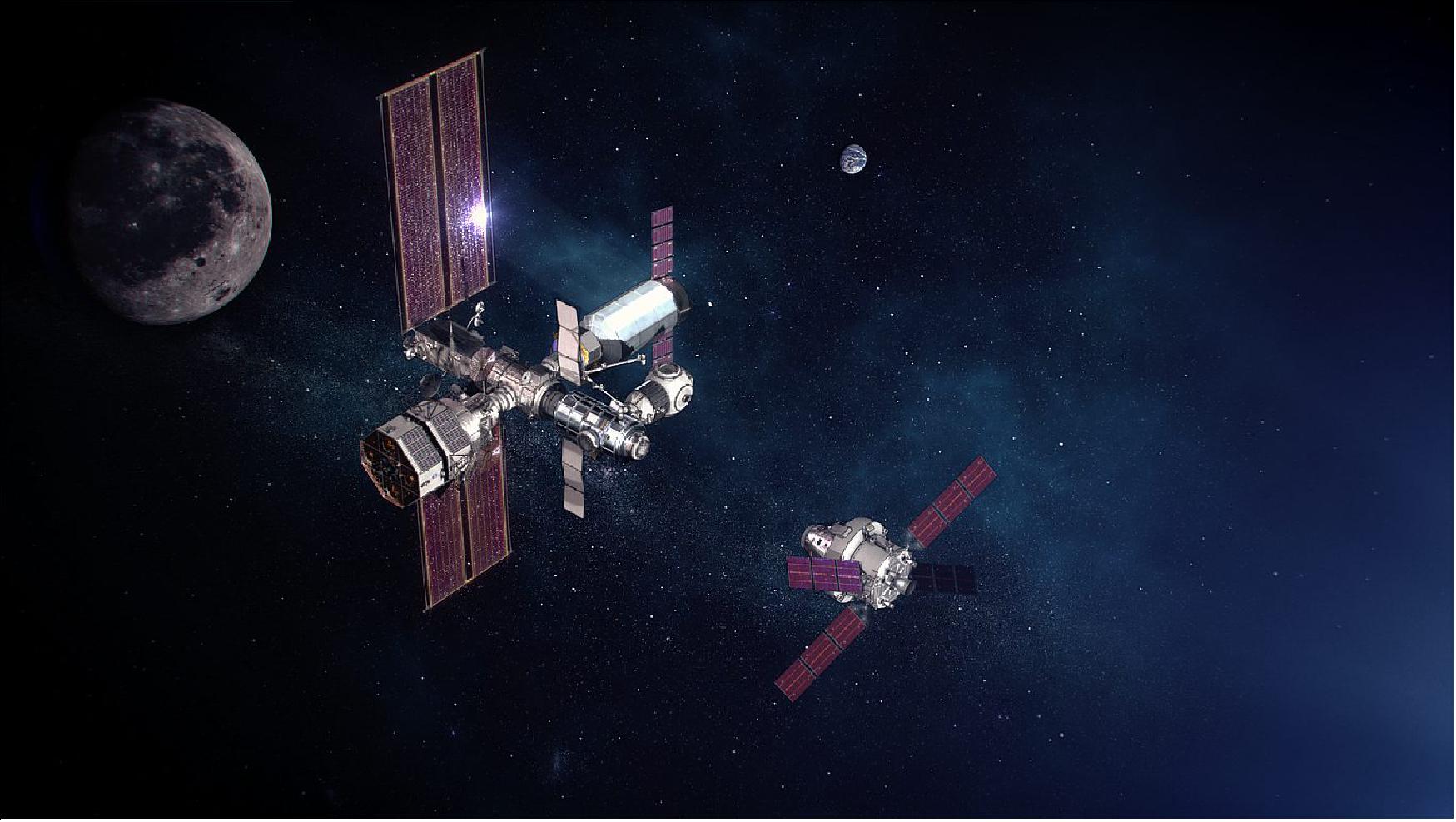

Proving Ground: Aboard NASA’s Orion spacecraft, astronauts will look down on Earth from a perspective never seen before. Far from the comparative hustle and bustle of the ISS- with the Earth speeding by the window, with 12-15 vehicle dockings per year, and with hundreds of government and commercial experiments running in constant communication with the ground- the Proving Ground will be a more secluded place. Beginning with missions of short duration and gradually building as experience is gained, the Proving Ground will allow NASA and its partners to practice with, innovate on, and demonstrate the technologies and capabilities needed to send humans to Mars, while remaining in a location near enough to Earth to allow for crew return (in a matter of days) and close monitoring of technology advancement. NASA recently issued a call for commercial industry to propose habitation concepts and solutions for the Proving Ground, continuing the partnership started in LEO.

Activities that have become what passes for routine in our industry- such as vehicle rendezvous and docking and EVA- will needed to be revalidated in cislunar space. The environmental, power, communications, and other systems that have been developed on ISS will be verified in the environment for which they were actually designed, far from regular resupply, and operating without the regularity of maintenance which they currently require.

Launching from the Kennedy Space Center in 2019, the first integrated flight of the SLS (Space Launch System) rocket and the Orion spacecraft, called EM-1 (Exploration Mission-1), will demonstrate NASA’s commitment and capability to extend human existence to deep space. The EM-1 mission will be flown without a crew. EM-1 is designed to stress the propulsion, navigation, communication, thermal, and Earth reentry systems. The mission will be the first mission flown to a distant retrograde orbit around the Moon, which is unique in that objects in this orbit will remain there without propulsive maneuvers. Testing the systems before the crew is flown is an important technique to reduce risks with the first crew missions to this remote location. The life support carbon dioxide removal system for Orion is being operated on ISS today.

The EM-1 milestone achievement will strengthen confidence in SLS and Orion as the right system design for the Journey to Mars strategy. The systems on Orion, and future deep space habitation systems, are designed to be Mars-class systems. EM-1 and subsequent missions will take these systems from Mars-class to “Mars Ready.” After a series of these missions, each increasing in duration and complexity, NASA will undertake a “shakedown cruise”- a long-duration mission using the “Mars-capable” systems, uninterrupted by outside assistance. This mission will validate the complete architecture needed to take humans to the Mars vicinity and return them to the Earth.

Earth Independent: Earth Independent systems and operations are NASA’s ultimate goal for Mars or any destination for humans beyond the Earth-Moon system. While true Earth Independence is many years away, NASA is laying the foundations for human exploration now. A fleet of robotic orbiters, landers, and rovers is on and around Mars, doing increasingly sophisticated analysis and exploration. Many of these missions have experiments explicitly dedicated to categorizing the environment humans will face; the Curiosity rover has a radiation detector that was also flown on ISS, and the upcoming Mars 2020 mission will have several more human health-related experiments. Robotic exploration is human exploration, albeit from a slightly removed distance, and both programs are tightly coordinated today. A safe human exploration of Mars cannot happen without a robust robotic foundation.

While the Earth Reliant and Proving Ground phases have been vigorously pursued and evaluated, the Earth Independent phase is less detailed. This is no accident. It will take an over a decade to get humans to Mars in a sustainable manner, and it is incumbent upon the current generation not to dictate or limit the manner that future generations will explore. While we can predict may of the needs of future explorers- radiation protection, food supply, environmental control, and so on- it is foolish to believe that our proposed technological solutions will be the ones most relevant to them. Instead, NASA is pursuing a capabilities-based approach, developing what we need as we can foresee the application. It is through this long-term view that we believe we can best serve our goal and destination of expanding the human presence in the solar system. We are developing an agile and sustainable approach to deep space exploration. Just as Apollo required a different approach to system engineering and hardware development, so too will the challenges associated with Mars-class missions require a different development approach and a new type of systems engineering. NASA and the U.S. alone cannot build all of the systems and perform all of the development needed for this adventure. NASA can orchestrate the plan, but will be dependent on the private sector and international partners for key components.

Today NASA is utilizing the ambitions of SpaceX to land a vehicle on Mars to obtain critical data on the technical considerations for using a propulsive landing capability in the Mars atmosphere. NASA is assisting SpaceX by providing deep space navigation capability and communication capability in exchange for access to SpaceX’s data on retro-propulsion Martian entry descent and landing data. NASA has also placed the European Space Agency in the critical path for all of its human deep space exploration capability by partnering with ESA to provide the Orion service module. The service module provides thermal control, power generation life support consumables storage and propulsion for Orion, allowing it to return to Earth from a distant retrograde orbit around the Moon. These functions are critical to keeping the crew safe on Orion.

A Marketplace Above: As NASA prepares to move beyond low Earth orbit, it is our goal to facilitate an orderly, timely, and profitable transition from government tenancy in LEO to the commercial sector. Through NASA’s commercial development programs, we have already demonstrated the ability of the private sector to deploy reliable launch and return vehicles for cargo to the ISS. In the near future, we are aiming to repeat that feat by using the world’s first commercially developed crew vehicles for ISS transportation. Earlier this year, with NASA’s assistance, the first commercially-developed expandable module was deployed onboard ISS.

Learning the benefits and issues with expandable modules directly in flight will provide criticality data for future planning. Rather than speculating on the properties of this new technology, direct on-orbit performance will be recorded. In ISS’s normal mode of operations, we see dozens of commercial payloads operating every day, from biological research to materials development to CubeSat deployment. The Center for the Advancement of Science (CASIS), NASA’s chosen operator for the U.S. National Laboratory portion of the ISS, is actively developing new markets and new opportunities for companies and even industries that have never previously considered spaceborne research. The goal is to expose the private sector directly to unique properties of space for their terrestrial based processes and let them see if there is a potential revenue generating opportunity in spaceborne research and manufacturing. These private sector companies can utilize to explore and test revenue generating concepts without a major investment in infrastructure. Transportation for both cargo and crew is already available from the private sector.

At the moment, the ISS is the only system in LEO. NASA and its international partners- Canada, Japan, and Russia- have committed to operating the ISS through at least 2024 (European confirmation of support is expected later this year). NASA does not intend to continue owning and operating a LEO platform. Through the research and development onboard ISS, we are trying to help create a new marketplace for both supply and demand in LEO- one where companies that require access to LEO for research or even production contract directly with companies that can provide transportation and logistics, without government involvement. We expect many of the approaches pioneered for commercial utilization of LEO will also have applications in NASA’s deep space activities. Commercialization of LEO (Low Earth Orbit) is the next frontier for private companies for both those that want to provide access and accommodations in space, and those that require the same.

The commercial LEO environment will likely be very different than ISS. It is unlikely that a facility as large and complex as the ISS will be built in LEO by the private sector. The facilities for the private sector are likely to be single purpose laboratories. The facilities could be crew tended and primarily ground operated. The facilities could also be extensions of current cargo vehicles or crew vehicles such as Cygnus, Dragon Lab or Dreamchaser. The facilities need to have low operating costs and reflect the revenue generation potential of the space research. The goal is a rich LEO research and manufacturing environment supported by a private sector transportation infrastructure.

Conclusion: It is a modern cliché to say that every generation believes they are living in a special time, with choices to be made that will positively or negatively affect the very future of humanity. It is true that the promise of Mars exploration and space commercialization has been made and broken- before, and it is tempting to believe that this time will be no different. However, we are at a point in space travel that is demonstrably unprecedented in human history. Privately developed and operated vehicles are delivering cargo to an international outpost that has been continually crewed for 15+ years, onboard which a commercial module is undergoing testing, and NASA has asked for concepts for the private sector to use the ISS to accelerate their development of revenue generation from space.

Private companies can now develop their own rockets and propulsion systems and sell them on the open market. Inside the ISS, experiments in nearly every scientific field are being conducted by commercial, industrial, and academic organizations, some of which are even looking to space as a production environment. We are also flying numerous pieces of terrestrial research equipment such as DNA sequencers. The private sector no longer needs to develop custom equipment but can fly their off-the-shelf research equipment to space. In the near future, commercial companies will begin ferrying astronauts to and from the ISS. And in public, in forums such as this, NASA is explicitly saying that not only is a commercial marketplace its desired and primary outcome for LEO, it is saying that a robust commercial space market is a fundamental building block for deep space human exploration.

Things are changing. As the Earth Reliant phase exits governmental control, NASA will take both its international and commercial partners to the Proving Ground, where we will learn to live and work farther from Earth than ever before in a sustainable manner. There is no set path for this journey to Mars- merely a set of frontiers that must be broken. There is no final frontier only the next one in front of us. We are beginning an exciting journey to move human presence off of the Earth and into the solar system.

Launch

Artemis I (former Orion EM-1) will launch uncrewed on the maiden test flight of NASA’s SLS (Space Launch System). NASA has reserved three days in late August and early September for the first launch of its Space Launch System rocket to send the Orion spacecraft to orbit around the moon and back. 7)

- At a July 20 briefing, NASA officials announced that they had target launch dates of Aug. 29, Sept. 2 and Sept. 5 for the Artemis 1 mission, an uncrewed test flight of the Orion spacecraft and the first launch of the SLS. Orion will spend up to six weeks in cislunar space before splashing down off the coast of San Diego.

- “We think we’re on a good path to get to attempts on those dates,” Jim Free, NASA associate administrator for exploration systems development, said on the call.

- Crews have been working on SLS and Orion since it returned to the Vehicle Assembly Building (VAB) July 2 after the fourth wet dress rehearsal test, where the rocket was loaded with liquid oxygen and liquid hydrogen propellants and put through a practice countdown. That included work to fix a liquid hydrogen leak on the core stage found during that test.

- During that work, technicians discovered a loose fitting, called a collet, where the liquid hydrogen umbilical connects to the rocket. That required going into the rocket’s engine section to tighten the fitting. “That actually gave us a little pause of wondering if we were going to be able to make a launch date on those three dates,” Free said. With those repairs complete, he said he was more confident about being ready for those dates.

- Free and other NASA officials on the call cautioned they still had work to perform on both SLS and Orion to get the vehicles ready for launch. If those preparations remain on schedule, the vehicle would roll back out to Launch Complex 39B around Aug. 18, although a final decision on proceeding with a launch attempt would come only after a flight readiness review about a week before launch.

- The three launch dates have different launch windows and mission durations:

a) The Aug. 29 launch window opens at 8:33 a.m. EDT for two hours, and would result in a 42-day mission ending with a splashdown Oct. 10.

b) The Sept. 2 launch window opens at 12:48 p.m. EDT for two hours, and would result in a 39-day mission splashing down Oct. 11.

c) The Sept. 5 launch window opens at 5:12 p.m. EDT for 90 minutes, and would result in a 42-day mission splashing down Oct. 17.

- All three are considered “long-class” missions by NASA, while launch opportunities on other days instead support shorter missions lasting about four weeks. “We don’t have a strong preference of whether it’s a short- or long-class mission,” said Mike Sarafin, NASA Artemis mission manager. Both support all the mission objectives of testing the launch vehicle and spacecraft, with a particular emphasis on demonstrating Orion’s heat shield on a reentry at lunar return velocities.

- One complication for launch planning is the batteries for the rocket’s flight termination system (FTS). That includes conducting a launch no more than 20 days after a final test of the system. “With our three attempts, we do have issues with that timing,” said Cliff Lanham, senior vehicle operations manager in NASA’s Exploration Ground Systems program. NASA is working with the Eastern Range to see if there are ways to address that issue.

- Another issue is that the FTS batteries are located on portions of the SLS not accessible at the pad. That means that, if the vehicle rolls out to the pad in August but does not launch by Sept. 5, it would have to return the VAB for additional testing and reset of the clock.

- That would make it difficult to have the vehicle ready for the next launch period, which runs from Sept. 20 to Oct. 4. “That would be a real challenge for us, to be honest with you,” Lanham said of launching during that timeframe. “But we would certainly give it our best shot.” The following launch period runs from Oct. 17 to 31.

• March 18, 2022: One of the many milestones in the leadup to the launch of Artemis is its rollout: this is when a crawler will carry the SLS rocket with Orion and ESM (European Service Module) from the Vehicle Assembly Building (VAB) to launchpad 39B. 8)

• February 10, 2022: The Orion spacecraft with European Service Module will fly farther from Earth than any human-rated vehicle has ever flown before. This video gives an overview of the first mission – without astronauts – for Artemis, focussing on ESA’s European Service Module that powers the spacecraft. 9)

- The total trip will take around 20 days, ending with a splashdown in the Pacific Ocean without the European Service Module – it separates and burns up harmlessly in the atmosphere.

- The second Artemis mission will have a similar flight plan but with astronauts. The third Artemis mission will see astronauts taken to the lunar surface.

- The European Service Module is ESA’s contribution to NASA’s Orion spacecraft that will send astronauts to the Moon and beyond. It provides electricity, water, oxygen and nitrogen as well as keeping the spacecraft at the right temperature and on course.

- The European Service Module has 33 thrusters, 11 km of electrical wiring, four propellant and two pressure tanks that all work together to supply propulsion and everything needed to keep astronauts alive far from Earth – there is no room for error.

• February 2, 2022: NASA is postponing the rollout of the first Space Launch System for a final prelaunch test by a month to give workers more time to complete vehicle preparations. 10)

- NASA announced Feb. 2 that it was delaying the rollout of the SLS from the Vehicle Assembly Building to Launch Complex 39B for a fueling test and practice countdown called a wet dress rehearsal. NASA officials said as recently as mid-January that they expected the vehicle to roll out to the pad in mid-February for that test.

- Instead, said Tom Whitmeyer, deputy associate administrator for exploration systems development at NASA Headquarters, that rollout will likely take place in mid-March. He said in a call with reporters it was too soon to give a more specific date for that rollout given the work still ahead for crews.

- Unlike in December, when a faulty engine controller, or computer that controls one of the SLS’s RS-25 engines, delayed a rollout then scheduled for the first half of January, there is no single issue causing this latest delay. “We just have a lot of things we need to close out,” Whitmeyer said. “It’s a big vehicle. There’s a lot of instrumentation that needs to be finished.”

- “There really isn’t a significant thing that we’re working,” added Mike Bolger, manager of NASA’s Exploration Ground Systems program. “It’s just the volume of work and it’s us being really meticulous and making sure that, when we roll, we’re ready.”

- Another factor has been the pandemic, including the recent surge in cases linked to the omicron variant. “I think that caught everybody off guard just by the sheer number of cases,” Bolger said. “It has slowed us down some.” He added, though, that the situation appeared to be improving as the number of new cases drops.

- That delay rules out a launch of the uncrewed Artemis 1 mission in March, as agency officials had previously been hoping for. Instead, NASA is looking at two-week windows from April 8 to 23 and from approximately May 7 to 21 as launch opportunities for Artemis 1. The windows are governed by the performance of the SLS and mission constraints, such as having the Orion spacecraft splash down in daylight conditions.

- That schedule will depend on the vehicle’s performance during the wet dress rehearsal. Bolger said it should take about two weeks to complete the full series of tests on the pad, from checks of vehicle interfaces on the pad through the full tanking test and practice countdown.

- That time frame is approximate, though. “We do have some first-time uncertainties, but then some standard uncertainties,” said Mike Sarafin, Artemis 1 mission manager. The first-time uncertainties involve activities not done before, such as rolling the full SLS out to the pad and linking it to pad infrastructure. Standard uncertainties, he said, involve issues like weather that could delay the rollout and testing.

- As in the past, agency officials said they don’t plan to set a launch date for Artemis 1 until after the wet dress rehearsal is complete. “We really don’t know until we do the wet dress rehearsal how much additional time it will take to get ready for launch,” Whitmeyer said. “We hope it won’t be a significant amount of time.”

- Engineers are also continuing to study the engine controller problem that caused the delay in December. “We think we’ve isolated the cause of the problem,” he said, with an update on the issue expected in a couple of weeks. The issue needs to be cleared before launch, but would not delay the wet dress rehearsal.

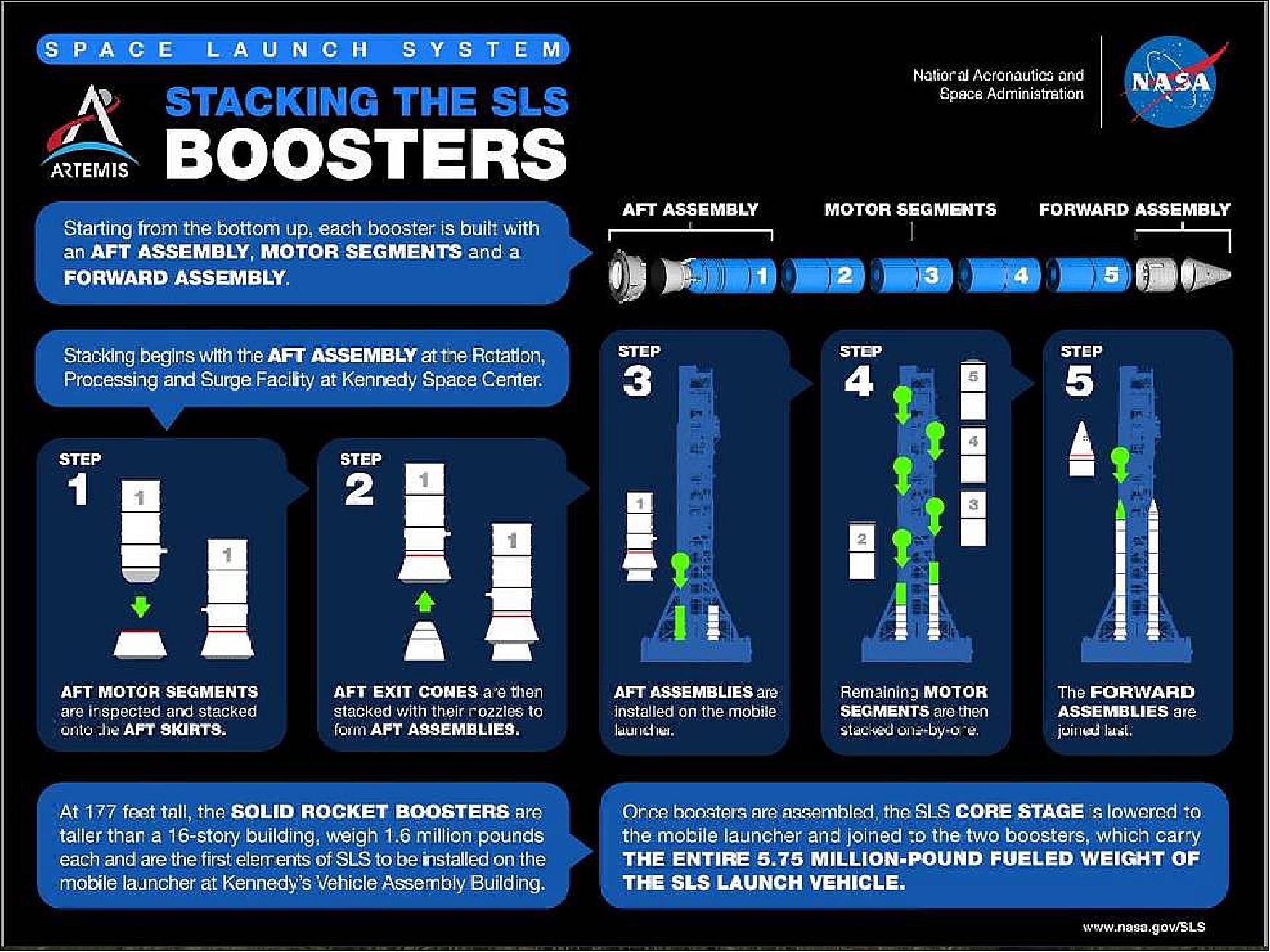

- Delays in the launch should not pose an issue for the SLS’s two five-segment solid rocket boosters. When NASA started stacking the boosters a year ago, agency officials said the boosters were certified for 12 months, but that testing could extend that limit.

- “We would run into this problem periodically with the shuttle as well,” Whitmeyer said. Testing and data analysis, he said, allows them to extend the life of the boosters in their stacked configuration. “Right now on the boosters, we don’t really see this as a risk, even if we proceed on further into the year. We think we’re in OK shape.”

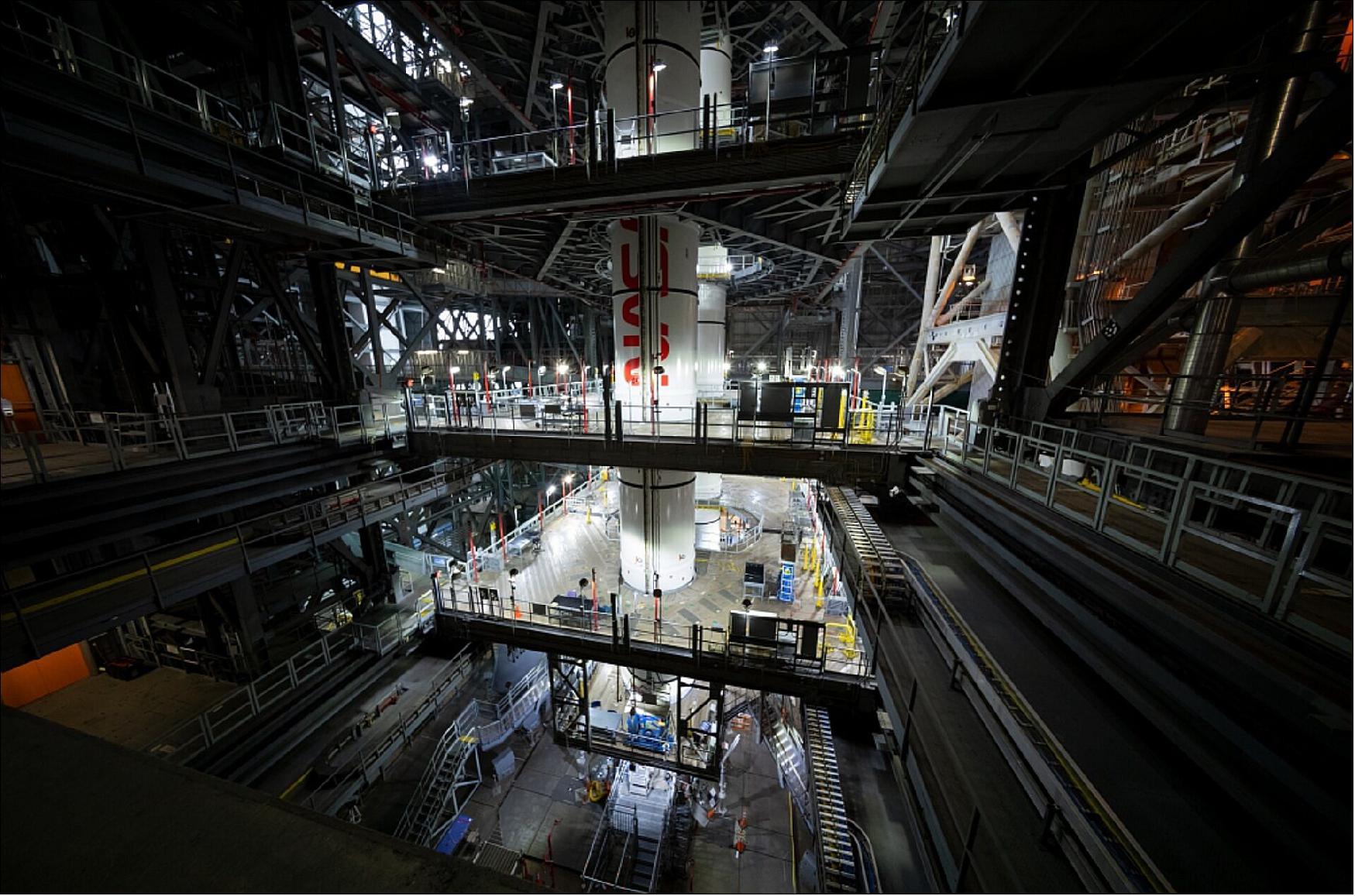

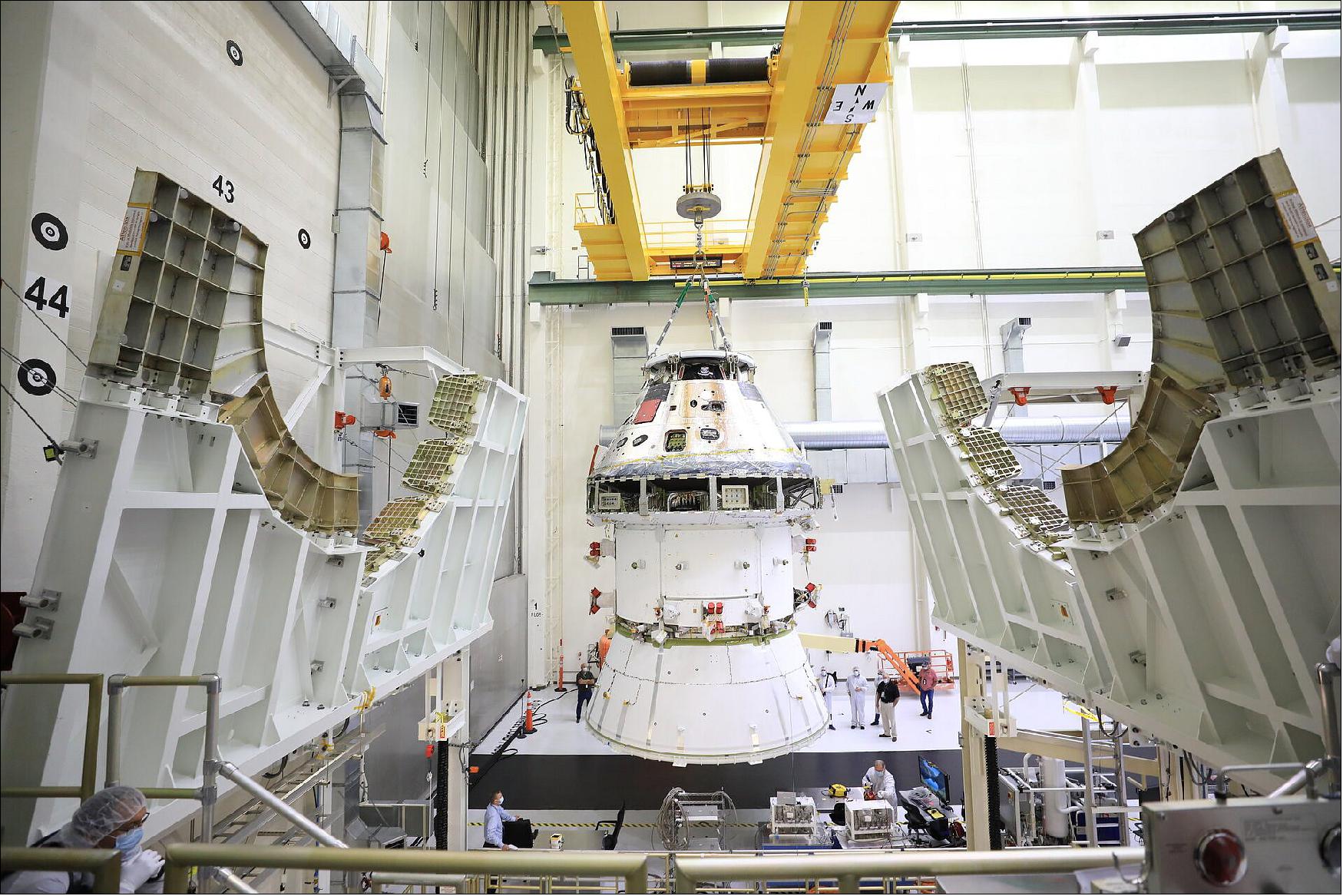

• October 27, 2021: Integration of the Orion spacecraft on top of the Space Launch System (SLS) rocket at NASA’s Kennedy Space Center in Florida. 11)

- Artemis I is the first in a series of increasingly complex missions for human deep space exploration. The European Service Module will power Orion's crew module around the Moon and back with over 30 engines. The European Service Module provides electricity, water, oxygen and nitrogen as well as keeping the spacecraft at the right temperature and on course.

• In a call with reporters Oct. 22, 2021, agency officials said they had completed the installation of the Orion spacecraft on top of the Space Launch System’s upper stage, wrapping up the assembly of the vehicle for the Artemis 1 launch. The spacecraft had been moved over the Vehicle Assembly Building (VAB) at the Kennedy Space Center Oct. 19. 12)

- “Completing stacking is a really important milestone. It shows that we’re in the home stretch towards the mission,” said Mike Sarafin, Artemis 1 mission manager at NASA Headquarters.

- The completed vehicle will undergo tests inside the VAB before being rolled out to Launch Complex 39B late this year, said Tom Whitmeyer, NASA deputy associate administrator for exploration systems development. A wet dress rehearsal, where the SLS core stage is fueled and goes through a practice countdown that stops just short of ignition of its four RS-25 engines, is expected in early January. The vehicle will then go back to the VAB for final preparations before going back to the pad for launch.

- “We’re looking at a period of time within February” for the launch, he said. “We’re very excited. We think this is really tremendous progress.”

- Sarafin said the launch period for Artemis 1 runs from Feb. 12 to 27. A launch on Feb. 12, the first possible opportunity, would take place at 5:56 p.m. EST at the start of a 21-minute window. Additional launch opportunities run from March 12 to 27 and from April 8 to 23.

- The launch windows are governed by the performance of the SLS. “It really has to do with the three-body system that we’re dealing with” involving the vehicle, Earth and moon, including constraints on a daylight splashdown of Orion. “With the Interim Cryogenic Propulsion Stage, we, at certain points in that lunar cycle, are performance constrained.”

- Originally, NASA projected just a one-week launch period per month. However, he said mission planners found a way to double the length of the period by changing parameters of the mission. If the launch takes place in the first half of the period, the mission will last six weeks, versus four weeks for launches in the second half. The difference, he said, is taking an extra lap in Orion’s distant retrograde orbit around the moon, which sets up the desired landing conditions.

- The briefing was the first formal confirmation by NASA that Artemis 1 will not launch this year. NASA had been holding on to a launch late this year in public statements, although in recent weeks agency leaders had acknowledged that a slip to early next year was increasingly likely.

- While Feb. 12 is the earliest possible launch date for Artemis 1, officials stopped short to committing to that day. Whitmeyer said NASA will wait until after the wet dress rehearsal before setting a formal launch date. “We really want to see the results of that test, see how we’re doing, see if there’s anything we need to do before we get ready to launch,” he said.

- Once on the pad, there will be other limitations on the launch. “We are limited by the amount of liquid hydrogen that we have,” said Sarafin, which dictates the amount of time the vehicle can stay fueled on the pad on any given launch attempt as well as the timing between launch attempts.

- Mike Bolger, Exploration Ground Systems program manager at KSC (Kennedy Space Center), said if the first launch attempt is scrubbed, there would be a 48-hour turnaround before the second attempt. A third launch attempt would come 72 hours after that.

• March 8, 2018: Exploration Mission-1 (EM-1) will be the first integrated test of NASA’s deep space exploration systems: the Orion spacecraft, Space Launch System (SLS) rocket and the ground systems at Kennedy Space Center in Cape Canaveral, Florida. The first in a series of increasingly complex missions, EM-1 will be an uncrewed flight test that will provide a foundation for human deep space exploration, and demonstrate our commitment and capability to extend human existence to the Moon and beyond. 13)

- During this flight, the spacecraft will launch on the most powerful rocket in the world and fly farther than any spacecraft built for humans has ever flown. It will travel 280,000 miles from Earth, thousands of miles beyond the Moon over the course of about a three-week mission. Orion will stay in space longer than any ship for astronauts has done without docking to a space station and return home faster and hotter than ever before.

- “This is a mission that truly will do what hasn’t been done and learn what isn’t known,” said Mike Sarafin, EM-1 mission manager at NASA Headquarters in Washington. “It will blaze a trail that people will follow on the next Orion flight, pushing the edges of the envelope to prepare for that mission.”

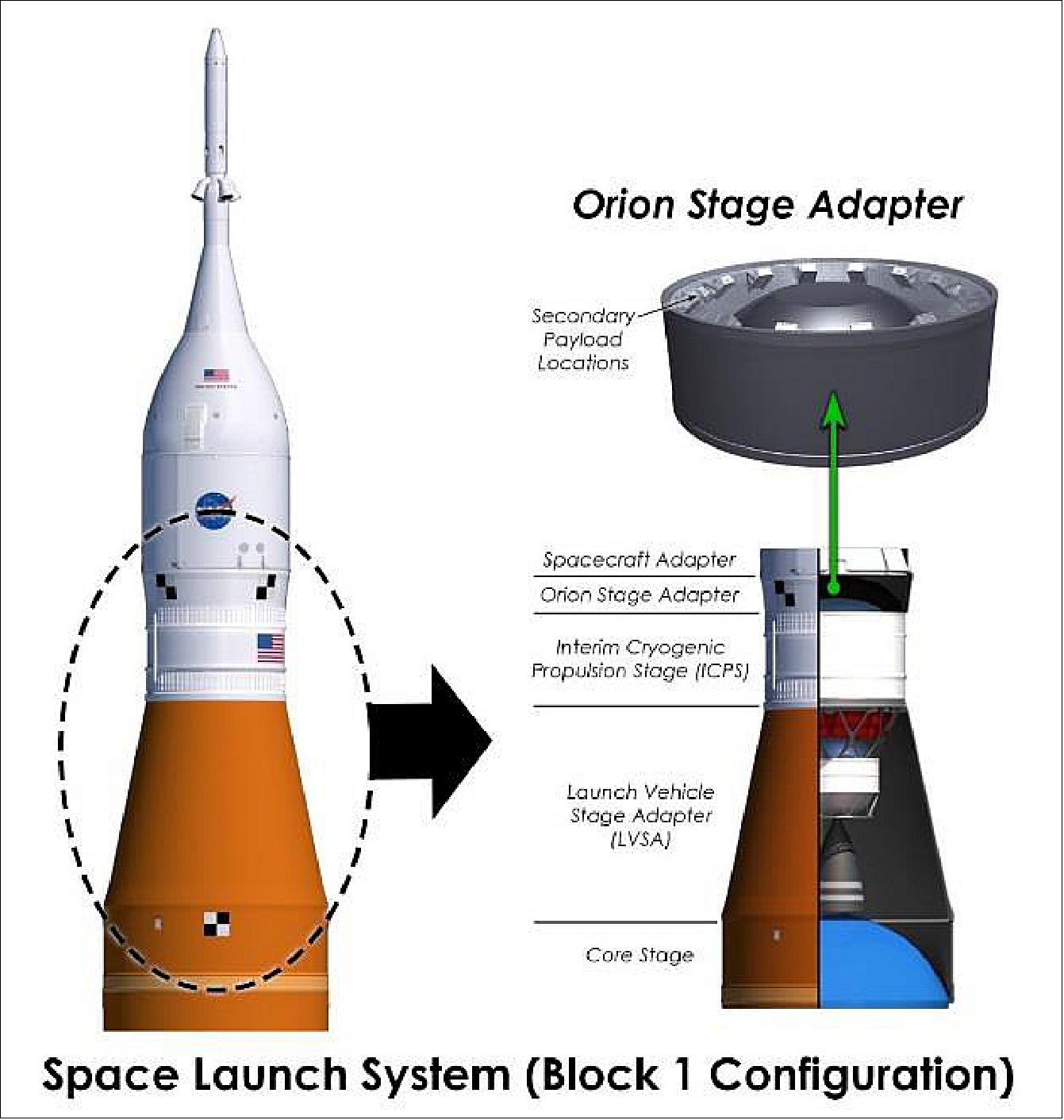

- Leaving Earth: SLS and Orion will blast off from Launch Complex 39B at NASA’s modernized spaceport at Kennedy Space Center in Florida. The SLS rocket is designed for missions beyond low-Earth orbit carrying crew or cargo to the Moon and beyond, and will produce 8.8 million pounds of thrust during liftoff and ascent to loft a vehicle weighing nearly six million pounds to orbit. Propelled by a pair of five segment boosters and four RS-25 engines, the rocket will reach the period of greatest atmospheric force within ninety seconds. After jettisoning the boosters, service module panels, and launch abort system, the core stage engines will shut down and the core stage will separate from the spacecraft.

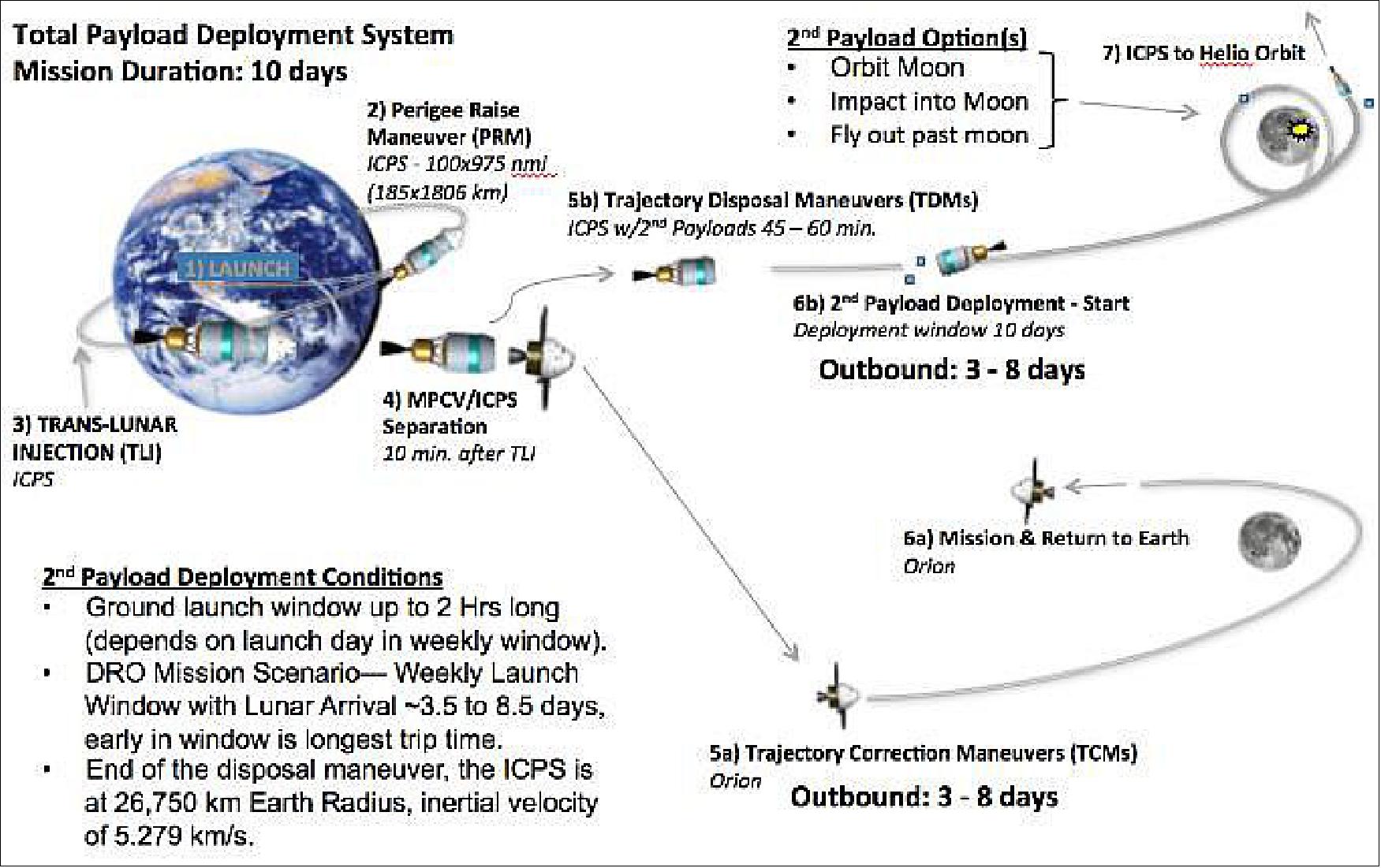

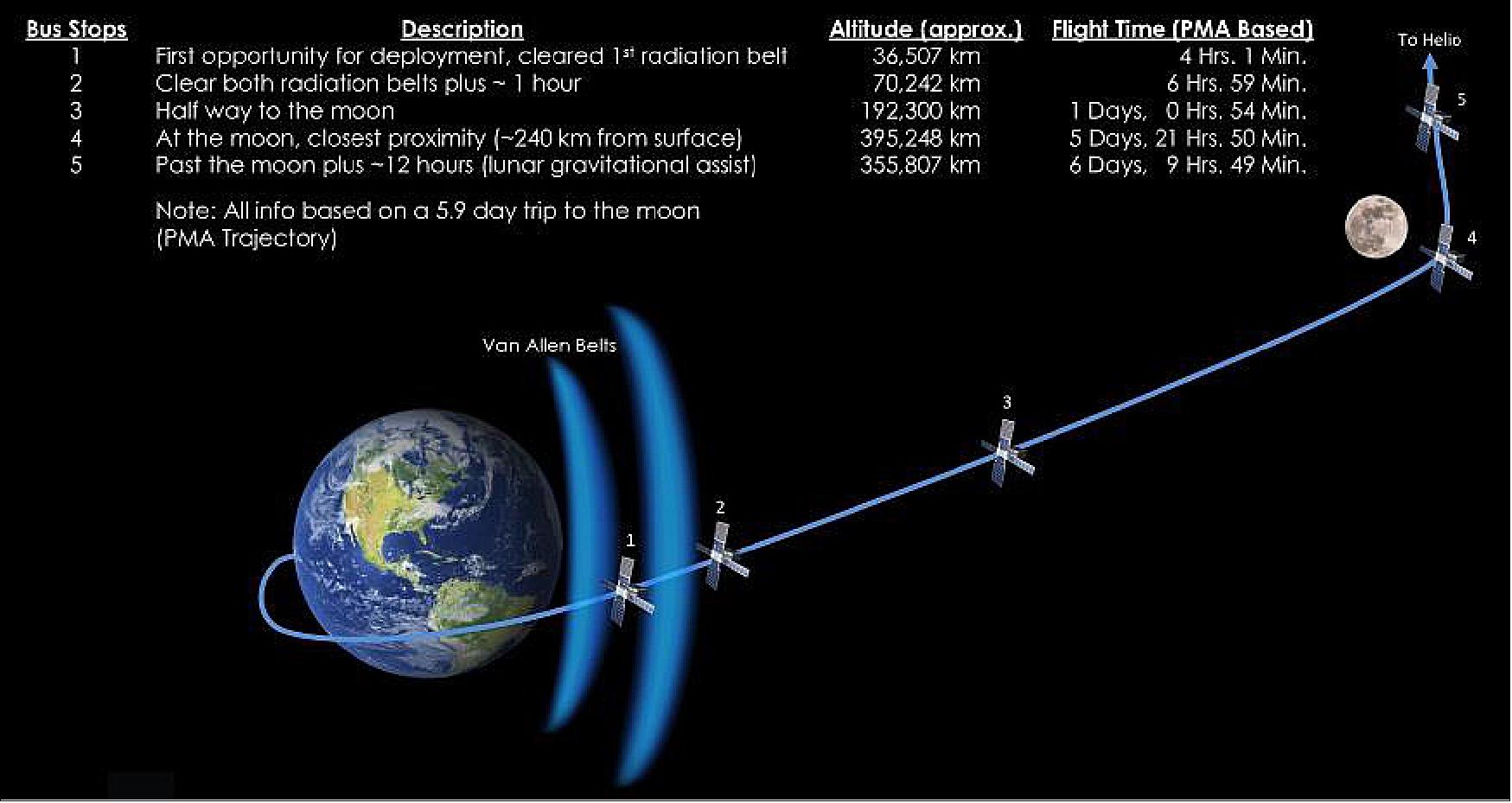

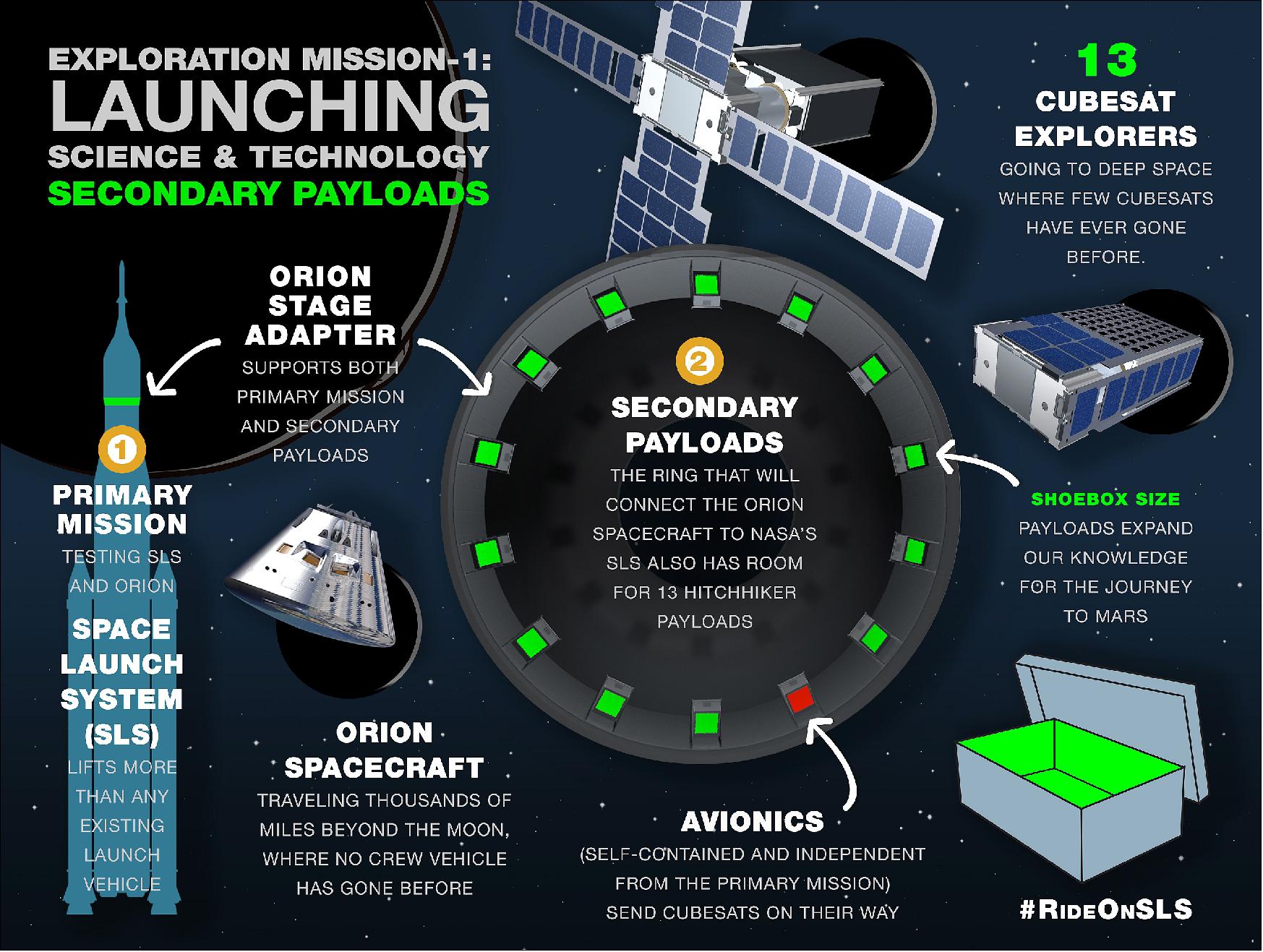

- As the spacecraft makes an orbit of Earth, it will deploy its solar arrays and the ICPS (Interim Cryogenic Propulsion Stage) will give Orion the big push needed to leave Earth’s orbit and travel toward the Moon. From there, Orion will separate from the ICPS within about two hours after launch. The ICPS will then deploy a number of small satellites, known as CubeSats, to perform several experiments and technology demonstrations.

- On to the Moon: As Orion continues on its path from Earth orbit to the Moon, it will be propelled by a service module provided by the European Space Agency, which will supply the spacecraft’s main propulsion system and power (as well as house air and water for astronauts on future missions). Orion will pass through the Van Allen radiation belts, fly past the Global Positioning System (GPS) satellite constellation and above communication satellites in Earth orbit. To talk with mission control in Houston, Orion will switch from NASA’s Tracking and Data Relay Satellites system and communicate through the Deep Space Network. From here, Orion will continue to demonstrate its unique design to navigate, communicate, and operate in a deep space environment.

- The outbound trip to the Moon will take several days, during which time engineers will evaluate the spacecraft’s systems and, as needed, correct its trajectory. Orion will fly about 62 miles (100 km) above the surface of the Moon, and then use the Moon’s gravitational force to propel Orion into a new deep retrograde, or opposite, orbit about 70,000 km from the Moon.

- The spacecraft will stay in that orbit for approximately six days to collect data and allow mission controllers to assess the performance of the spacecraft. During this period, Orion will travel in a direction around the Moon retrograde from the direction the Moon travels around Earth.

- Return and Reentry: For its return trip to Earth, Orion will do another close flyby that takes the spacecraft within about 60 miles of the Moon’s surface, the spacecraft will use another precisely timed engine firing of the European-provided service module in conjunction with the Moon’s gravity to accelerate back toward Earth. This maneuver will set the spacecraft on its trajectory back toward Earth to enter our planet’s atmosphere traveling at 25,000 mph (11 kilometers per second), producing temperatures of approximately 5,000 degrees Fahrenheit (2,760 degrees Celsius) – faster and hotter than Orion experienced during its 2014 flight test.

- After about three weeks and a total distance traveled exceeding 1.3 million miles, the mission will end with a test of Orion’s capability to return safely to the Earth as the spacecraft makes a precision landing within eyesight of the recovery ship off the coast of Baja, California. Following splashdown, Orion will remain powered for a period of time as divers from the U.S. Navy and operations teams from NASA’s Exploration Ground Systems approach in small boats from the waiting recovery ship. The divers will briefly inspect the spacecraft for hazards and hook up tending and tow lines, and then engineers will tow the capsule into the well-deck of the recovery ship to bring the spacecraft home.

- Future Missions: With this first exploration mission, NASA is leading the next steps of human exploration into deep space where astronauts will build and begin testing the systems near the Moon needed for lunar surface missions and exploration to other destinations farther from Earth, including Mars. The SLS rocket will evolve from an initial configuration capable of sending more than 26 metric tons to the Moon, to a final configuration that can send at least 45 metric tons. The second flight will take crew on a different trajectory using a powerful exploration upper stage and test Orion’s critical systems with humans aboard. Together, Orion, SLS and the ground systems at Kennedy will be able to meet the most challenging crew and cargo mission needs in deep space.

- Future exploration missions with crew aboard Orion will dock with a Lunar Orbital Platform-Gateway. NASA and its partners will use the gateway for deep-space operations including missions to and on the Moon with decreasing reliance on the Earth. Using lunar orbit, we will gain the experience necessary to extend human exploration farther into the solar system than ever before.

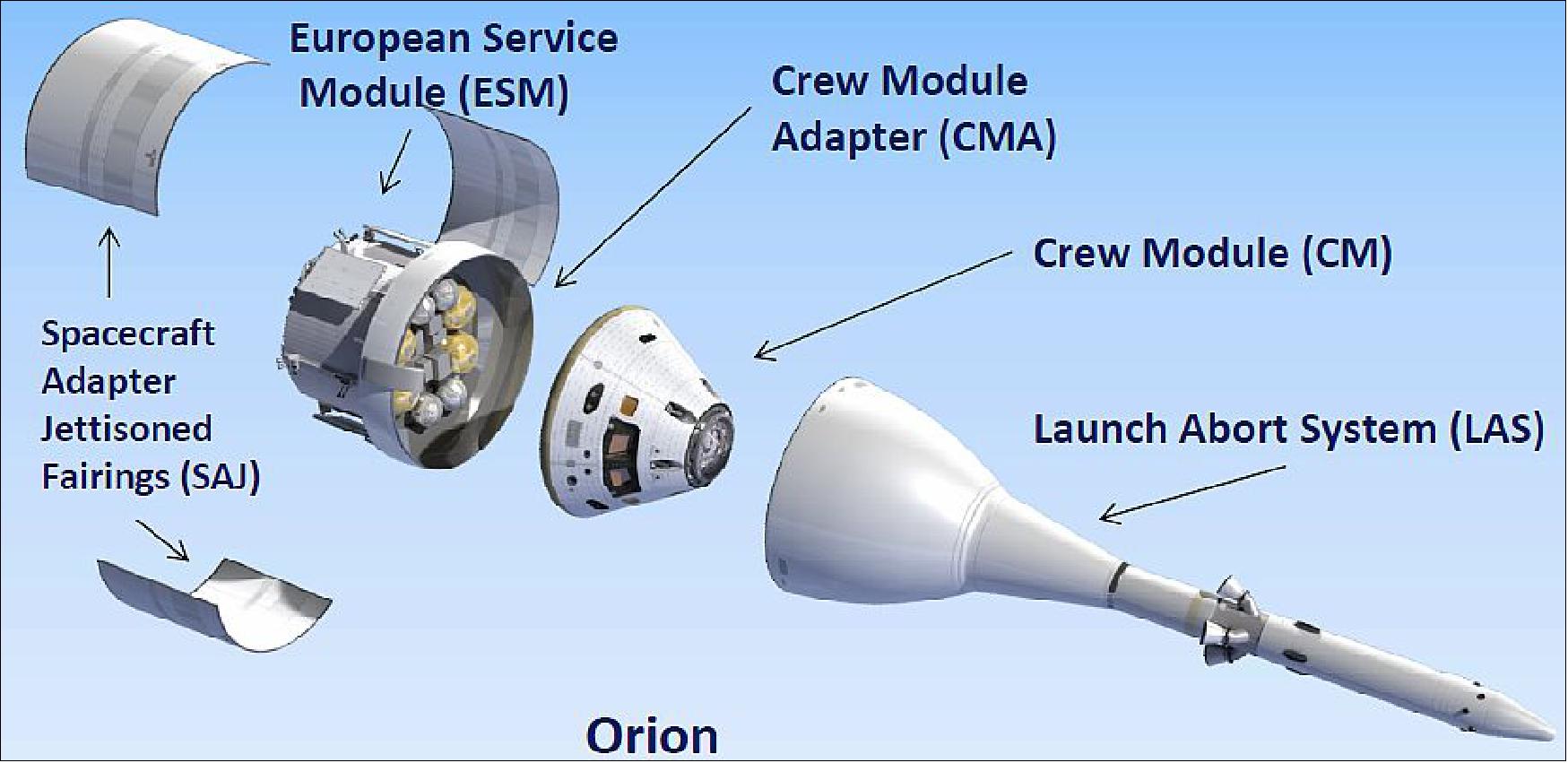

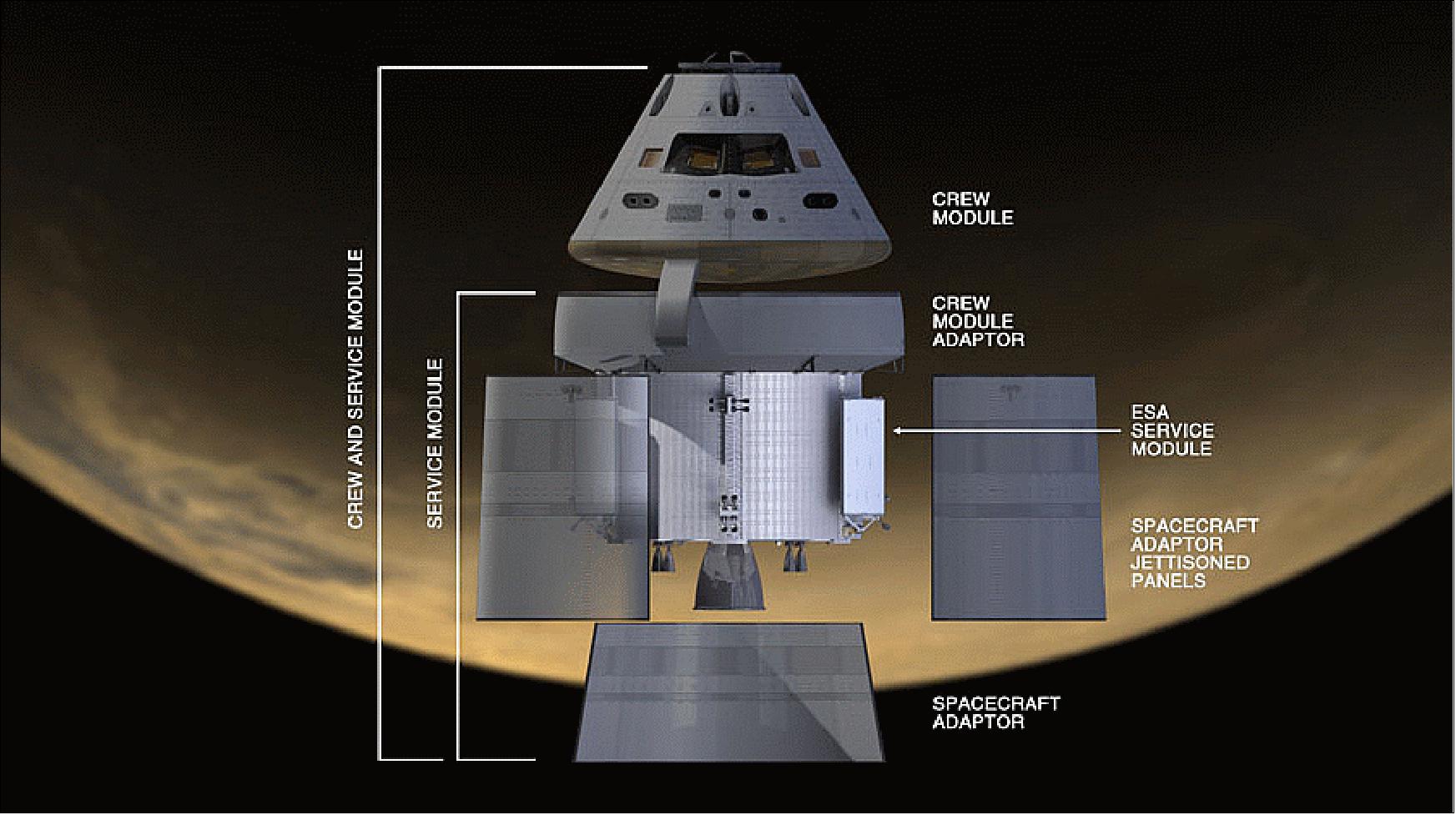

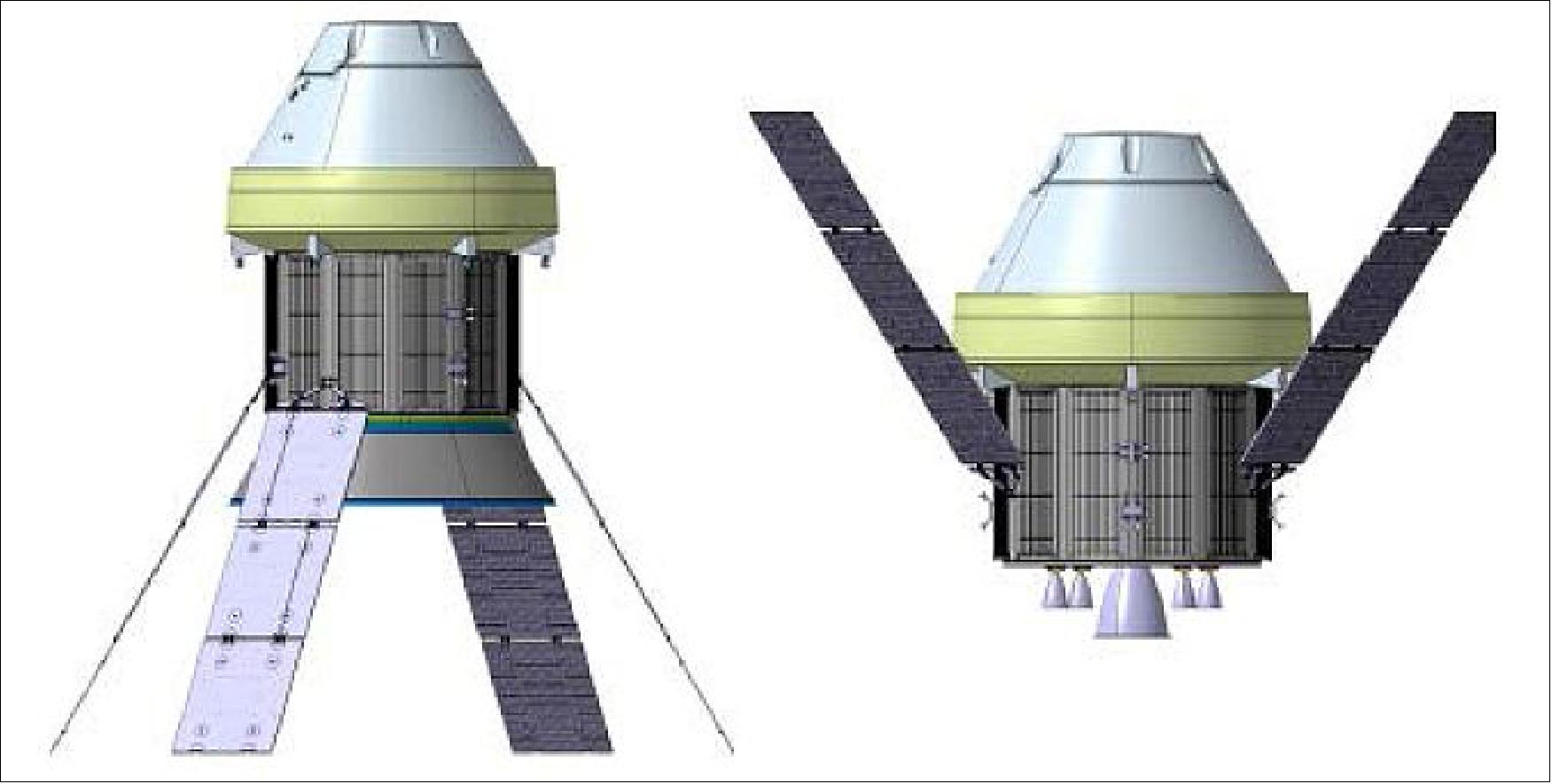

The Orion Vehicle

The Orion architecture configuration consists of the following modules: (Figures 8 and 9, Ref. 2)

• CM (Crew Module)

• ESM (European Service Module)

• CMA (Crew Module Adapter)

• SA (Spacecraft Adapter)

• SAJ (Spacecraft Adapter Jettisoned Fairings)

• LAS (Launch Abort System)

The Service Module (SM) refers to the combined CMA + ESM + SA + SAJ.

The Crew Module and ESM (European Service Module), also referred to as SM, are physically interfacing via an interface ring called the CMA (Crew Module Adapter). The ESM is attached to the CMA for the duration of the mission. Just prior to the Earth’s orbit entry, the CMA separates from the CM for CMA/ESM disposal and the CM performs final reentry and landing operations.

NASA is responsible for development of the CM, CMA, SA, SAJ, and LAS elements of the Orion spacecraft. The CMA provides the structural, mechanical, electrical, and fluid interface between the CM and ESM. In addition, the CMA houses communication equipment, sublimators for thermal heat rejection, and power and data control/interface electronics. The SM is enclosed by three spacecraft adapter fairing panels (SAJ) which provide a partial load path from the CMA to SA but also protect the solar arrays, radiators, and thrusters from launch and ascent loads. The fairings will be jettisoned during the ascent phase or following main engine cut-off of the launch vehicle.

The SA (Spacecraft Adapter) provides the interface to the launch vehicle during launch. During launch and ascent, the ESM and SA will be enclosed by the SAJ. The SA attaches to the aft end of the ESM to the Launch Vehicle and includes the structural interface, separation mechanisms, and umbilical connectors for communication between the launch vehicle and the Orion Spacecraft. At launch vehicle burnout, the Orion Spacecraft separates from the SA at the ESM/SA separation plane.

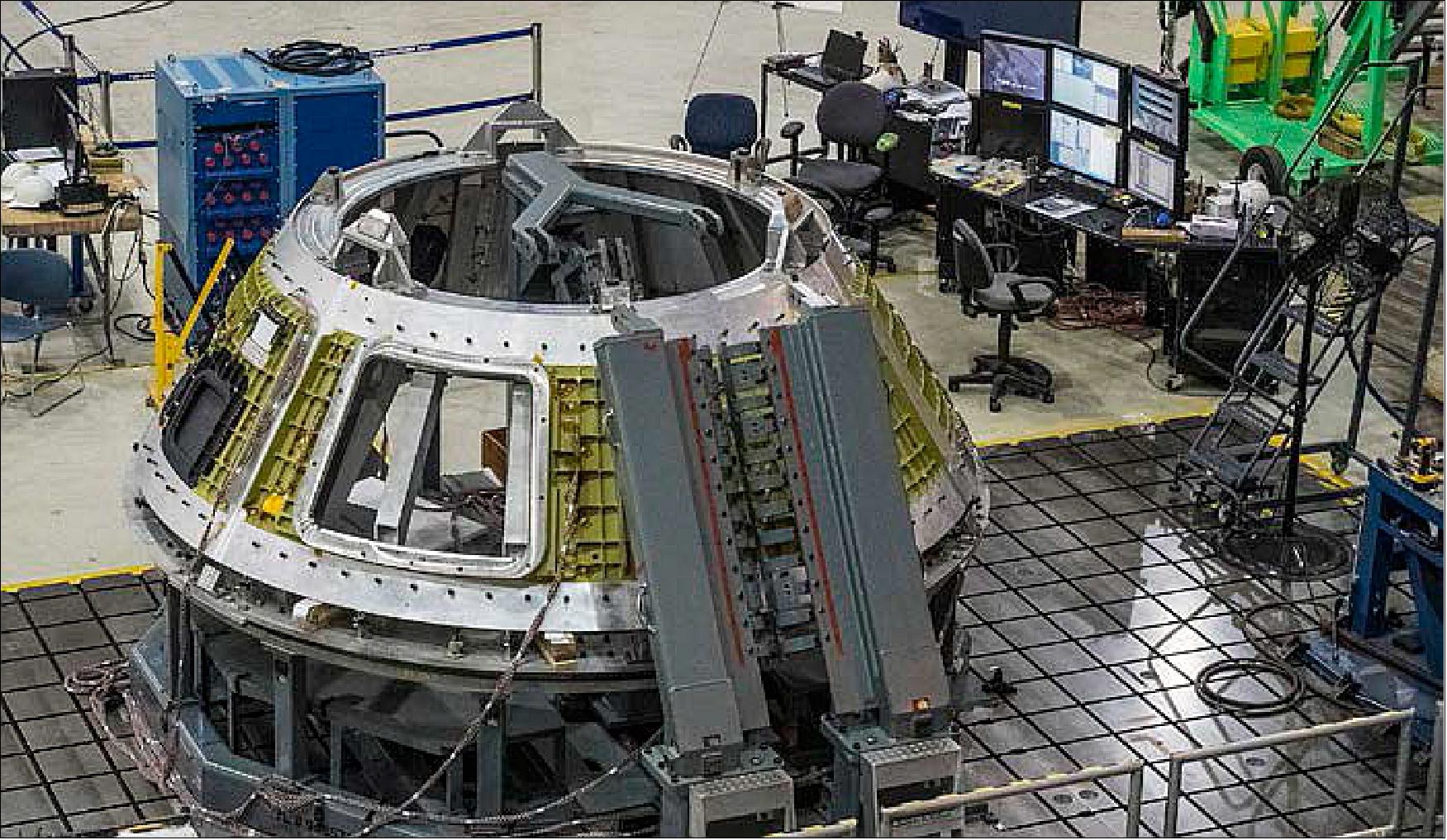

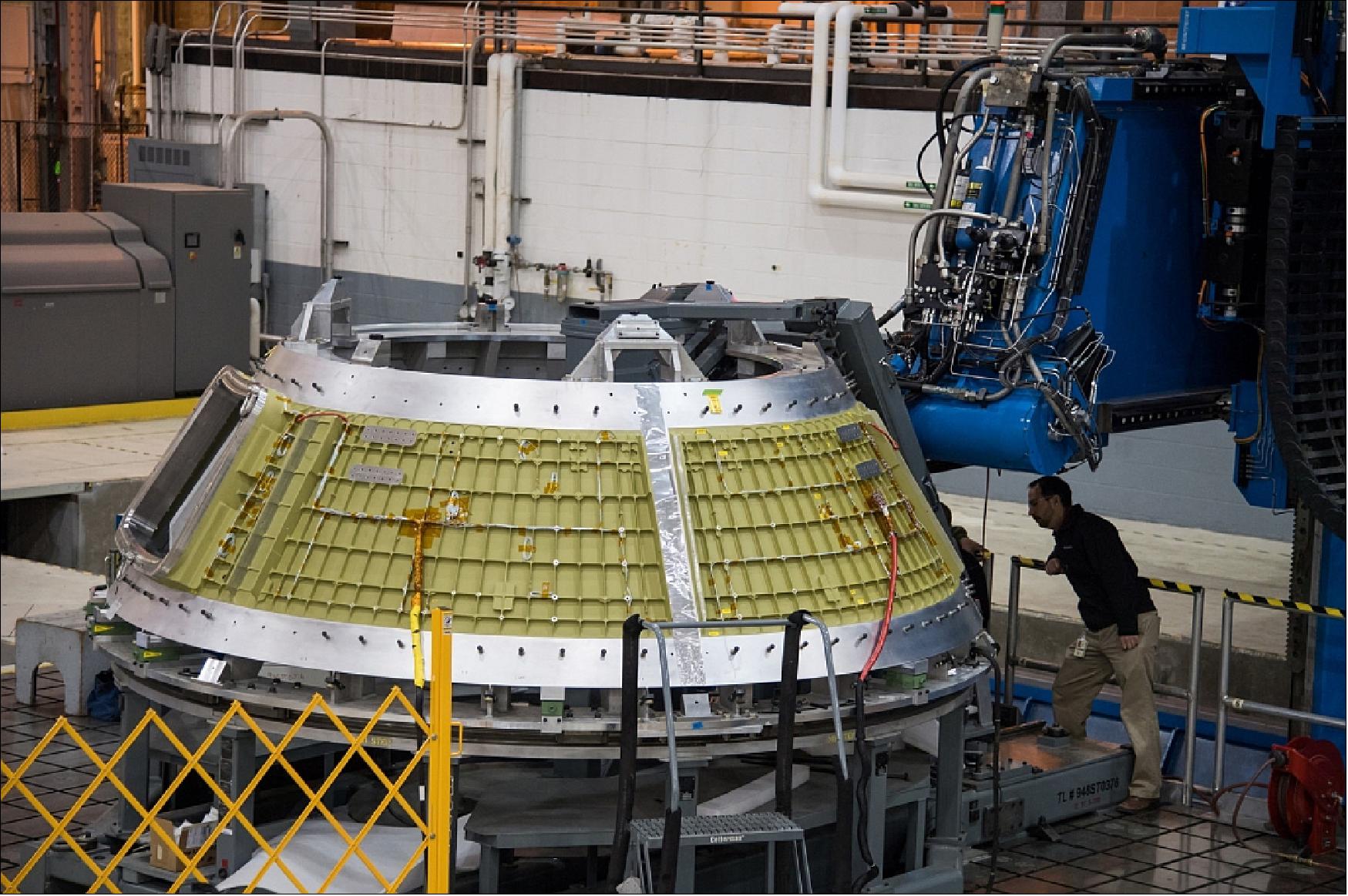

Crew Module

The milestones for the Orion EM-1 mirror the path taken by the Orion EFT-1 (Exploration Flight Test-1) spacecraft. However, the Orion EM-1 will sport a number of improvements based on the experiences of the December 2014 test flight. NASA is beefing up the critical TPS (Thermal Protection System) that will protect astronauts from the searing heats experienced during reentry as the human rated vehicle plunges through the Earth’s atmosphere after returning from ambitious expeditions to the Moon and beyond.

Based in part on lessons learned from EFT-1, engineers are refining Orion’s heat shield to enhance the design, ease manufacturing procedures and significantly strengthen is heat resistant capabilities for the far more challenging space environments and missions that lie ahead later this decade and planned further out in the future as part of NASA’s agency-wide ‘Journey to Mars’ initiative to send humans to the Red Planet in the 2030s.

On all future flights starting with EM-1 (Exploration Mission-1), the Orion crew module must withstand the higher temperatures and speeds experienced during return from more distant destinations such as the Moon, near-Earth Asteroids and Mars. Orion's TPS is comprised of the 5 m diameter main heat shield covering the rounded base of the capsule as well as the grid of back shell tiles bonded around the vehicle from top to bottom. 15)

Starting with EM-1, engineers will bond Orion’s thermal protection system back shell tiles with a silver, metallic-based thermal control coating. The coating is designed to keep Orion’s back shell in a temperature range from approximately -65 to 290ºC prior to entry and afford protection against electrical surface charges in space and during reentry.

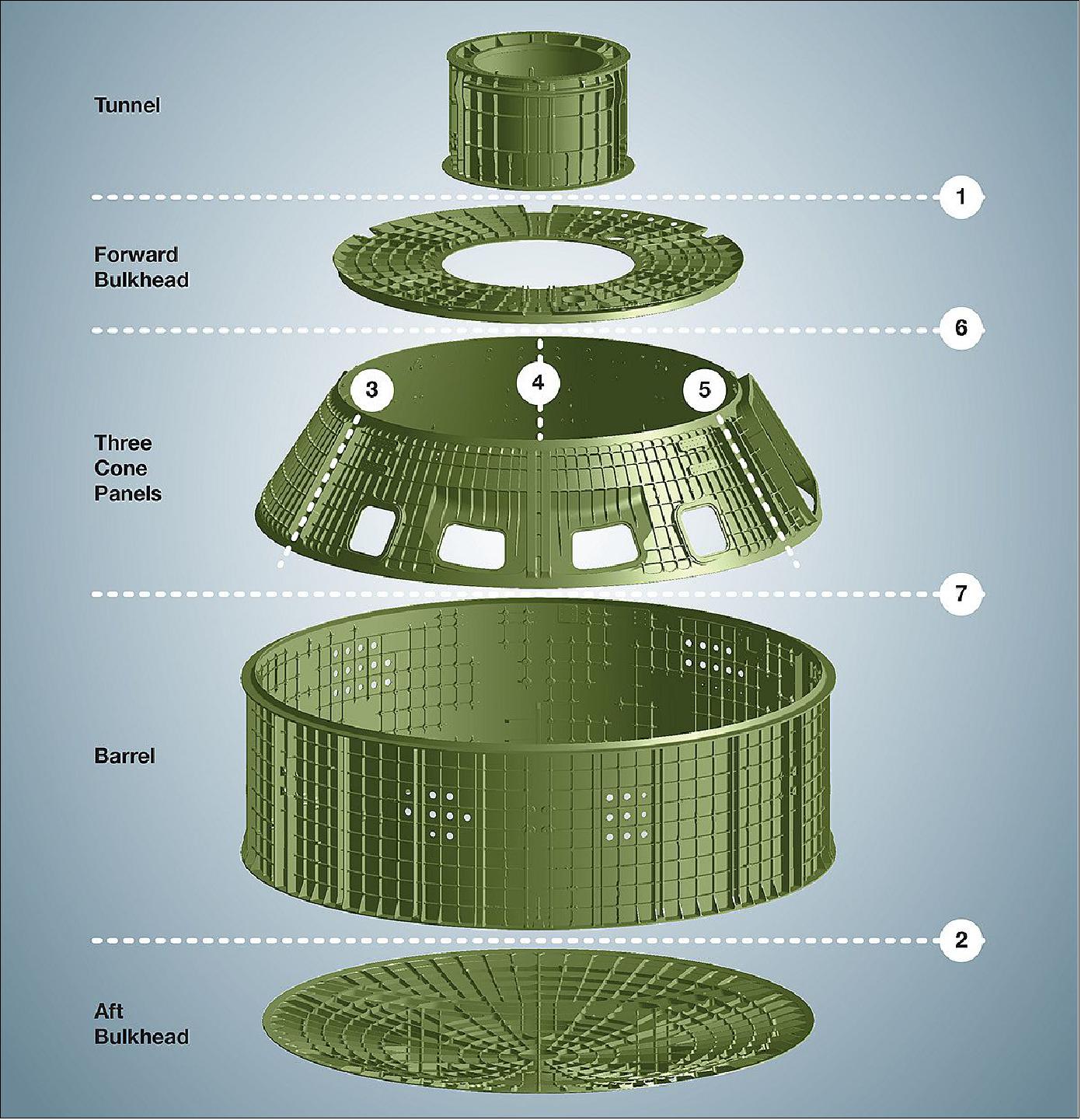

The pressure vessel is the primary structure of Orion’s crew module and is made of seven large aluminum pieces that must be welded together in detailed fashion. The first weld connected the tunnel to the forward bulkhead, which is at the top of the spacecraft and houses many of Orion’s critical systems, such as the parachutes that deploy during reentry. Orion’s tunnel, with a docking hatch, will allow crews to move between the crew module and other spacecraft. 16)

Orion’s pressure vessel is composed of seven large pieces of aluminum, three of which are the cone panels. The pressure vessel holds the atmosphere astronauts will breathe against the vacuum of deep space, forming the crew compartment. The three panels together form the angled mid-section around the crew module where the windows and hatch are located. While technicians have been joining other elements of the structure together since early September, the cone panels have presented a unique challenge for NASA and Lockheed Martin, the agency’s prime contractor for Orion. Engineers who have sought to reduce the crew module’s overall weight have encountered and overcome technical challenges. 17)

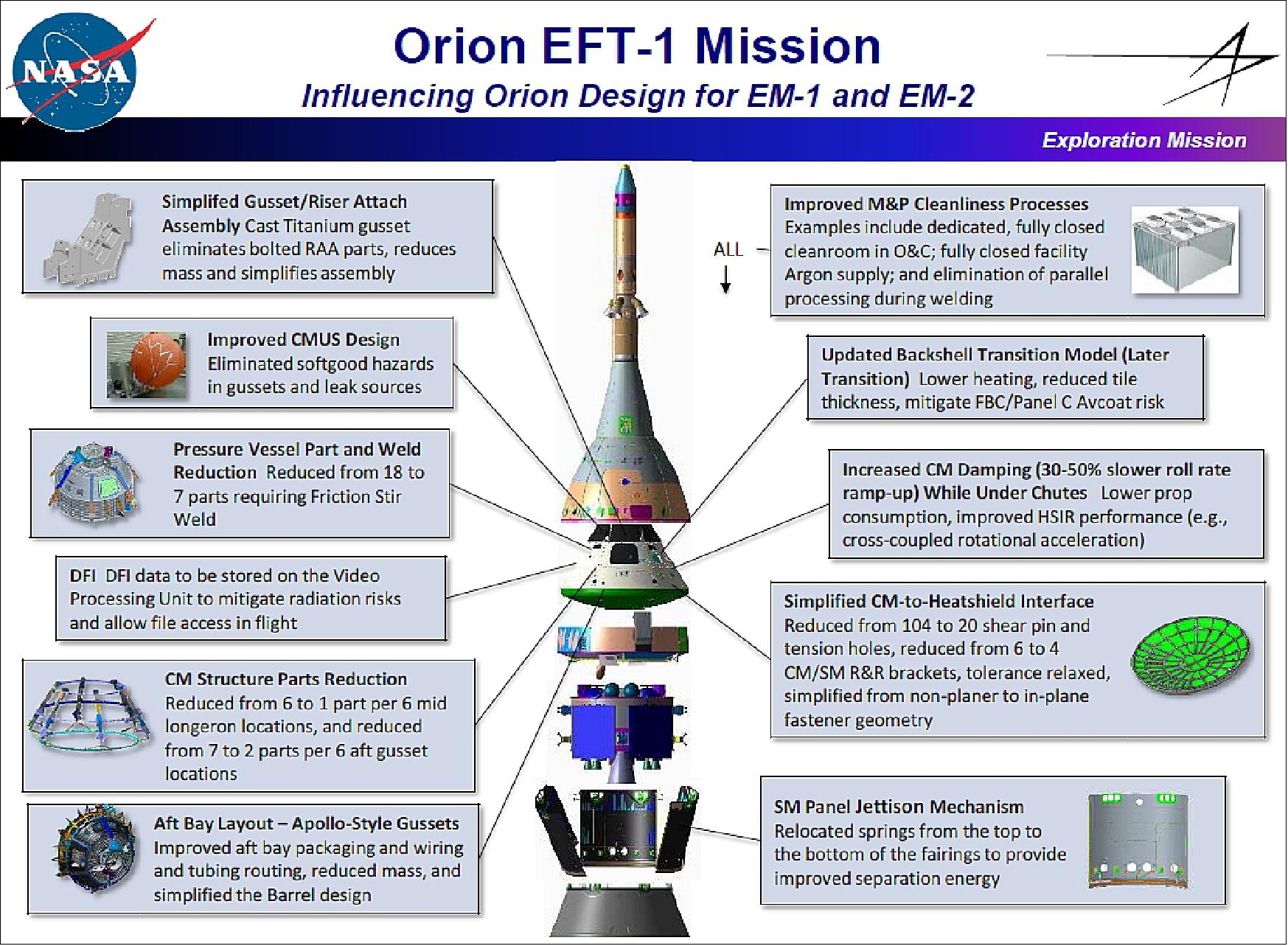

The lessons learned from the EFT-1 mission are being applied to the EM-1 (Exploration Mission-1) and EM-2 flight test configurations to optimize a system design that can smoothly transition into production.

Ten of the most important lessons from EFT-1 focused on the ability to evaluate the design with actual flight performance. This was critical for the remaining design process as NASA continues to develop the most advanced Human rated spacecraft ever built. The following are the top ten lessons learned from this test flight: 18)

1) Some deep space designs are classic for a reason: Every aspect of Orion’s design is driven by crew safety. Over 50 years of NASA’s investment learning the ins and outs of human spaceflight has provided direction for meeting deep space requirements. An example is LAS (Launch Abort System). About 6 minutes into launch, the LAS is jettisoned to save mass for the journey to deep space destinations. While other system configurations exist, design trade studies repeatedly highlighted the advantage of not carrying extra weight past the time it is needed. So because the Orion LAS supports missions to deep space, mass is king and any extra weight is an extreme hindrance to those missions. By shedding the Orion LAS early, this mass isn’t a burden to the vehicle for the entire mission, and other Orion systems are able to provide the abort function for the remainder of ascent to orbit.

2) Crew safety is built in, not bolted on: The EFT-1 tested and verified systems that are built “into the bones” of the spacecraft from the very beginning. This means not just the heat shield or the flight computers are designed for the rigors of deep space, but everything included in the fundamental systems and structure of the spacecraft are designed and built to specifications set forth by NASA. Every system design has a deep space requirement it is being built to right now: Orion’s seats are being designed to help prevent loss of consciousness as astronauts experience up to 5 G’s during high-velocity re-entries, the cooling system keeps the crew cabin about 25ºC despite its heat shield being heated to 2,200ºC during reentry, the built in stowage lockers are designed to double as a safe-haven during dangerous solar activity, the life support system allows for exercise since deep space missions require much longer stays in zero gravity, computers and avionics are designed to self-correct in case there is a failure and you’re months from home, and the crew module tiles are designed to protect from multiple micro-meteoroid strikes since the number of strikes will increase during missions that last months instead of days.

3) Reusability must be tied to reality: Part of flying for the first time in space is being able to make informed decisions about what we can realistically reuse following a deep space mission. After evaluating areas of water intrusion and corrosion, we’ve come to expect that many components in the crew module, especially inside the pressurized volume, or the hull where the crew sits, can be reused for later flights—components such as the computers, avionics and electrical distribution for example. The structure itself is more difficult to predict for reuse base on the unpredictable landing loads it might experience from a long journey from deep space with unpredictable landing sea conditions. The program is looking at options for reuse based on actual landing load data provided.

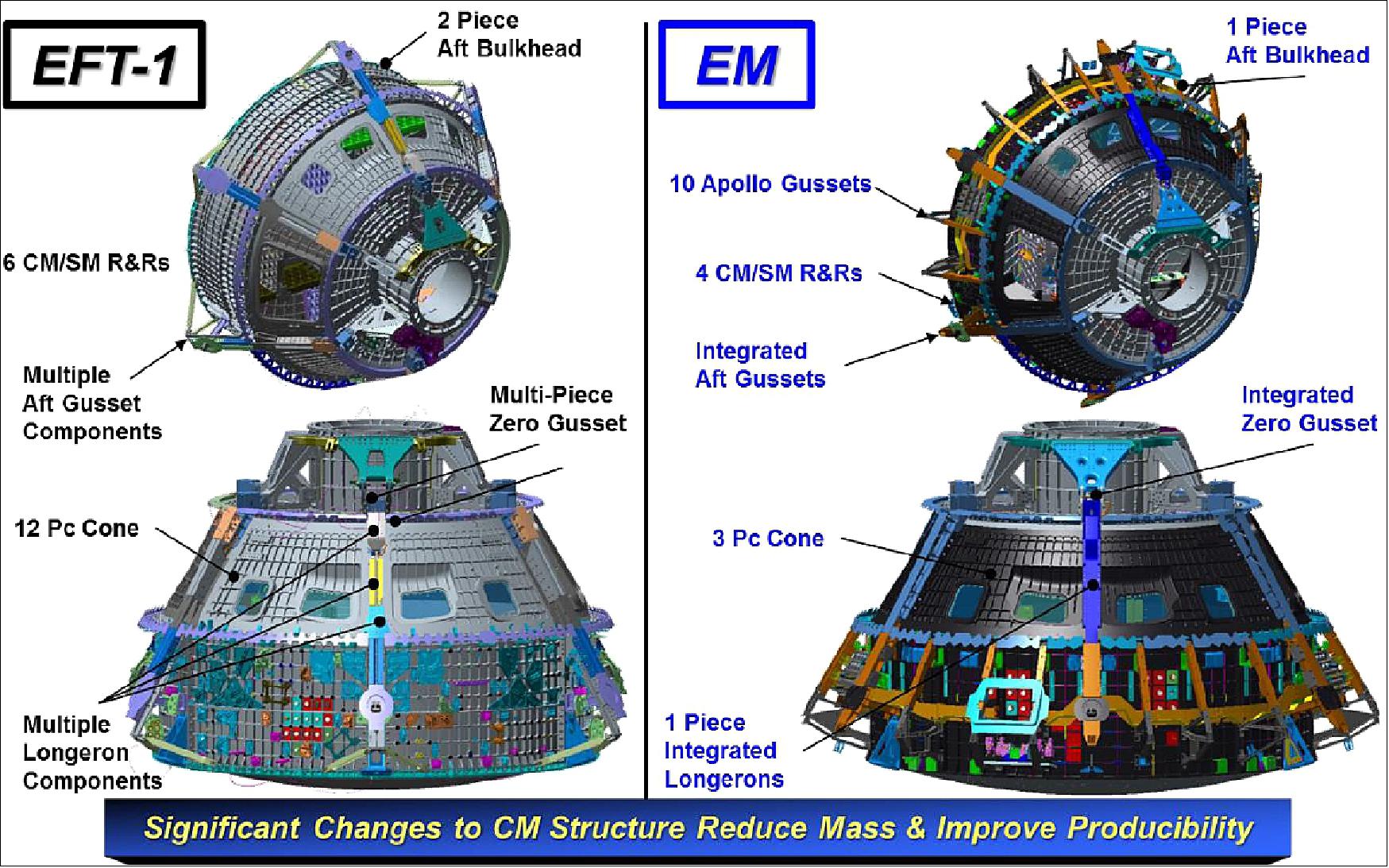

4) Designs mature as we learn: Significant design changes are being made to optimize the EM vehicles. Thefuture design and analysis efforts will be simplified (Figure 10), overall mass has gone down, and recurring costs for production will be lowered. Establishing a common design philosophy has prevented a large number of engineering revisions and hardware changes. The Orion design is now incorporating lessons from EFT-1 and updated requirements for the crewed EM-2 mission.

5) Test like you fly to ensure success: After extensive testing on the ground in “Flight Like” scenarios EFT-1 successfully tested Orion in real flight environments, which could not be duplicated in ground simulations. The systems were subjected to the most critical crew safety requirement with the same rigors they will see when carrying humans. Systems verified included: thermal protection system, hardware separation events and the parachute system. This was a 100% mission success. 87 EFT-1 flight test objectives were identified in the early phases of the test development program. These objectives included verification of Orion’s subsystems ability to launch, control its trajectory with OFI (Operational Flight Instrumentation), complete all separation events, reenter the Earth’s atmosphere at 32, 200 km/hr and 2200ºC, land accurately in the Pacific Ocean and be recovered without damage. 81 of the 87 FTOs (Flight Test Objectives) were fully satisfied with six being partially met. Four of the seven FTO's were related to suspect DFI (Developmental Flight Instrumentation) performance. Two FTO’s related to the Crew Module Up-righting System were partially met, and one FTO related to structural measurements was partially met.

6) Organize for focus: Organizationally, Lockheed Martin and NASA agreed assigning a “mission director” to each test flight would allow program focus on the near term test milestones while maintaining a parallel program focus on the remaining DDT&E (Design, Development, Test, and Evaluation) efforts. EFT-1 was the first mission where this was implemented and proved to ensure the test was completed on time and within budget. This effort also saved over one year of development time for EM-1 by performing this in parallel versus chronologically.

7) Processes and reviews tailored: Since its inception the Orion program has spent significant time focusing on defining an efficient set of requirements to enable the design of Orion as well as optimize the concept of operations for a recurring program rhythm. In an effort to remain flexible the program continues to evolve the requirements based on lessons learned. On EFT-1 the program used a consolidated requirements document approach that was successful in limiting the number of requirements, individual requirements documents, and tiers of requirements documents. The team is using the success of this approach to streamline the EM requirements where possible. Requirements verifications were completed later than planned, partly because the verification work did not carry the same urgency as other launch campaign tasks. The team is looking at a more structured “waterfall” approach to prevent lower level verifications from conflicting with launch campaign activities.

8) Flexibility to accommodate change: Several program planning improvements were accomplished during the course of the program leading up to EFT-1. Improving the Orion IMS ( Integrated Master Schedule) by integrating the NASA “non-Prime” elements improved the continuity of the entire schedule past vehicle delivery. Through Monthly Orion Program Performance Review meetings, the assessments team continued to monitor the contractor performance. Data input for these reviews consisted of Integrated Master Schedule updates, CPRs (Cost Performance Reports), Financial Management Reports (533 inputs), contractor supplemental financial and schedule data, and through participation in the subsystem IPT (Integrated Product Team) meetings. The assessments team integrated these data each month to update the assessment and forecast for the EFT-1 launch date and financial position enabling program management to make rapid decisions.

9) Partnerships ensure Communication: After the President’s proposed cancellation of the Constellation program, NASA and Lockheed Martin recognized reductions needed to occur both on the government side and within Industry to keep the program intact. NASA identified all work within their scope as “Non-Prime” and all work within Industry as “Prime”. NASA and Industry were challenged with a $738.9 M reduction in funding in 2010 and needed to re-plan the entire program in anticipation of this reduction. The cost reduction initiatives they initiated have come to be known as “The streamlining of Orion” and have been used as examples of how NASA and Industry can work together to become more efficient and affordable. The continued emphasis on meeting program objectives within the government’s affordability range have resulted in a refined program plan that accomplishes all of its goals within the annual budget and without jeopardizing mission success. One example of this was the reduction of test flights from seven to four while maintaining the same requirements verifications.

10) Supply Chain must remain healthy: EFT-1 provided the Orion team the ability to exercise 80% of the supply chain that will be utilized for future production vehicles. This includes subcontractors currently spread across 42 states with 60,000 parts being received by NASA or its prime subcontractor in 3 major integration facilities. Throughout this endeavor the processes were validated, enhancements were made and opportunities for improvement identified. EFT-1 helped establish 6 key principles needed to ensure effective supply chain management:

• Centralized supply chain ownership/management offers advantages over IPT ownership

• Need for timely actionable information, including stable engineering design documentation, is mandatory

• Consistent, effective and constant communication is mandatory

• Management of the supplier certification and work load

• Manage with the tools, don’t expect the tools to manage

• Work within the system.

In summary, NASA and Lockheed Martin are taking what we have learned from EFT-1 and years of government investments to make improvements, fly again, making improvements again, and developing a spacecraft that we can proudly stand behind and say we are confident in its abilities to take humans into deep space and bring them safely home.

Design Changes

The Orion design for future Exploration Missions experienced many design optimizations as a result of the EFT-1 flight results. The following section highlights several changes to exemplify optimizations that was realized. Note: (For more information, the reader is referred to Ref. 18).

Structures: Reduced parts and weld assemblies required on the pressure vessel include:

- Reduction from 6 to 3 cone panels, and reduction of cone section welds from 12 to 3.

- Reduction from a 3 piece welded aft bulkhead design to a single spun-formed design.

- Change to an “Apollo-gusset” design in the aft-bay to help reduce the number of separable-parts, and combine structural elements (reduced thruster pod support structures and harness support structures, etc.).

Propulsion: Tubing subassemblies on EFT-1 were custom fit for propulsion system integration (e.g. fit-up tube assembly, cut, face, install heaters / temp sensors, reinstall, repeat as required). On EM-1 no trim to fit will be required on the vehicle. Tubing subassemblies will be delivered in their net shape and subassembly welds will be proof & leak tested prior to delivery.

PCAs (Pressure Control Assemblies) on EFT-1 required a custom fit for propulsion system integration (similar to Tubing subassemblies). On EM-1 there will be improved packaging and attachment methods including PCA welds proof & leak checked prior to delivery.

Propellant and Pressurant Tanks on EFT-1 were difficult to integrate and perform welding operations. The EM-1 design created a new inlet / outlet orientation to ease integration and welding operations.

RCS (Reaction Control System) thrusters on EFT-1 had support struts that have been simplified to a Pod design and attachment method eliminating all struts.

TPS (Thermal Protection Systems): The Heatshield Avcoat design improvement included changing from a monolithic, individual cell injection process to a “Block Avcoat” design where the heat shield blocks could be automated in production while increasing material properties performance. The use of thermal tape that was used on the EFT-1 heatshield (and similar to Apollo) was changed to use on all backshell and heatshield surfaces for all future Exploration Missions.

Micrometeoroid and Orbital Debris Performance: There are a number of lessons learned in the realm of MMOD (Micrometeoroid and Orbital Debris) environments and analyses, which are being examined and used to influence change for the EM and beyond missions. Chief among these lessons learned is that time spent in the high orbital debris flux altitude band, approximately 650 km to 1200 km, should be minimized. The MMOD analysis performed on EFT-1 was the first such analysis of a human-rated spacecraft above ISS ( International Space Station) altitudes since man-made orbital debris has become an issue, and found the risk at these altitudes (600 km – 1600 km) to be much higher than anticipated; Apollo was too early in spaceflight history for much OD (Orbital Debris) to have accumulated yet. Post-flight inspection of the EFT-1 capsule indicated that actual MMOD exposure may have been even higher than the analyses had assessed. Based on this lesson learned, the parking orbit of EM-1 has been reduced from 3.5 hours in a high-MMOD-risk orbit (2 orbits), to half that time (limited to 1 orbit) to reduce MMOD risk. And as EM-2 trajectory trades and analysis is ongoing, avoiding these altitudes has been accepted as a prerequisite in the EM-2 trajectories. Largely anchored on this finding, other lesson learned recommendations include: increasing MMOD protection in upper-stage and other critical hardware, re-assessing window damage cause and remediation, and continued post-flight inspections and MMOD environment recommended updates based on EM flights.

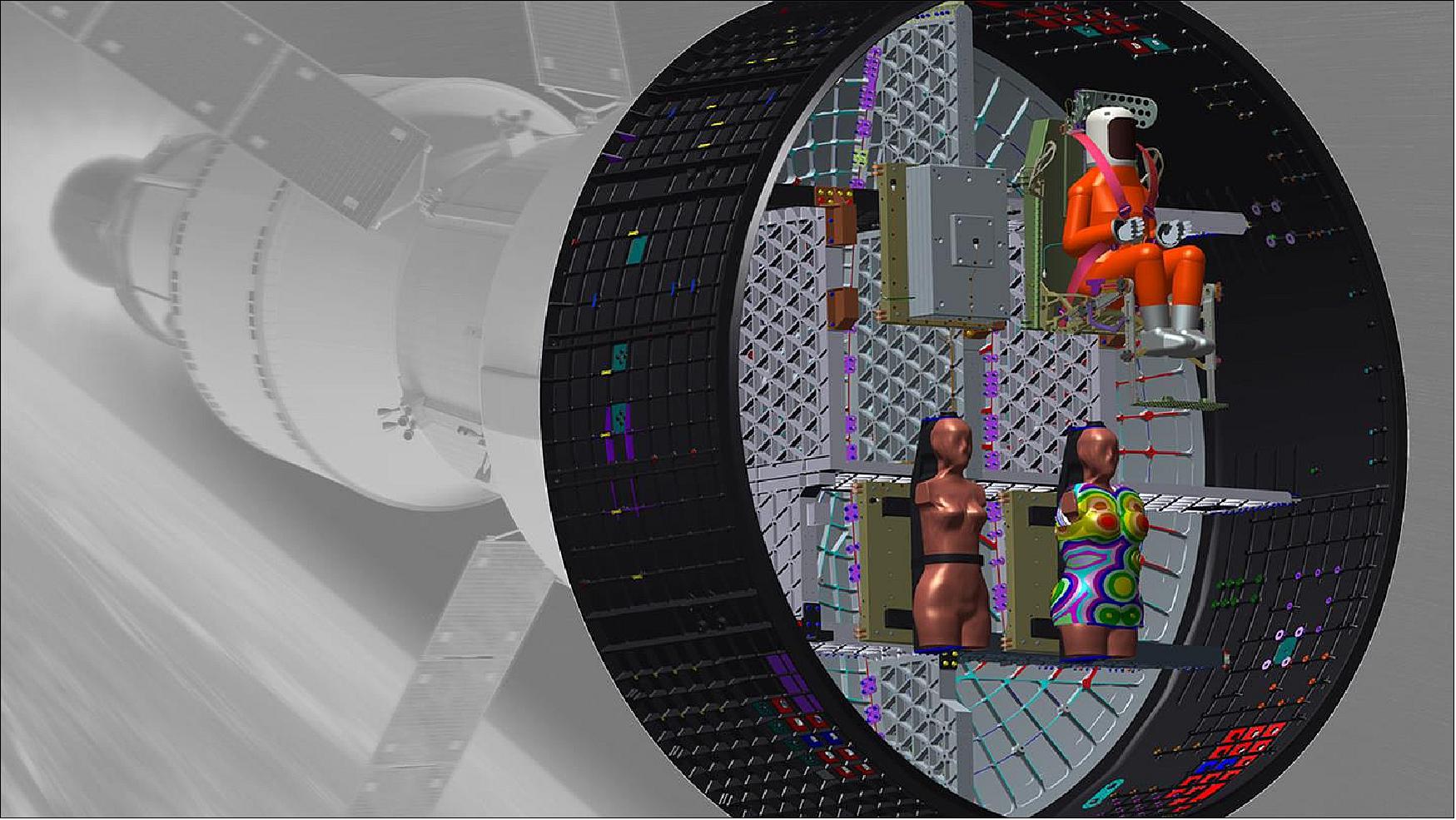

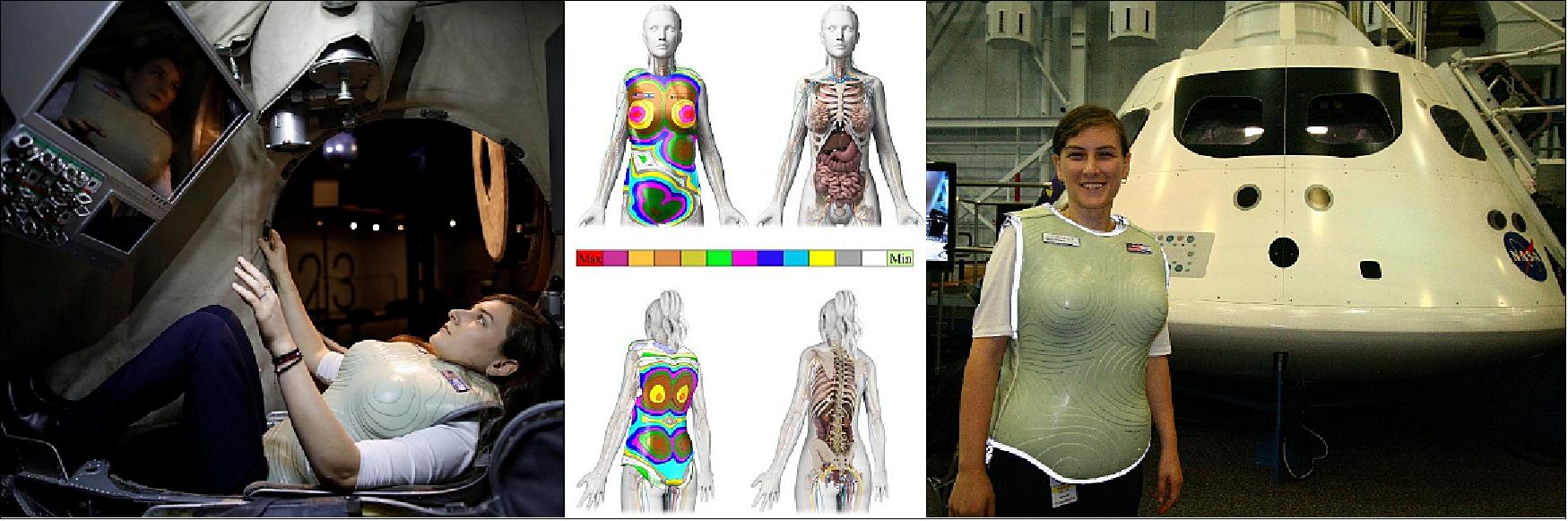

Radiation Summary: Orion is the first spacecraft that addresses crew radiation protection as an integral part of the vehicle design. We are using a state-of-the-art radiation analysis process to analyze the shielding provided by the vehicle and quantify the internal radiation environment. This analysis is based on the full fidelity Orion CAD model and space radiation environment models. Due to the EFT-1 trajectory passing through the very core of the van Allen proton belts, intravehicular radiation environment was equivalent to 4-6 weeks inside ISS (in terms of cumulative exposure). Thus EFT-1 presented a valuable opportunity to validate our analysis procedure and ultimately improve crew radiation protection for future manned missions. This opportunity was materialized by flying six RAMs (Radiation Area Monitors) on EFT-1. Radiation measurements were in very good agreement with pre-flight predictions, confirming the validity of the radiation analysis approach and providing confidence in our efforts to maintain crew radiation exposure ALARA (As Low as Reasonably Achievable) consistent with NASA requirements.

An important lesson learned for electronic components radiation hardening refers to the importance of considering time variability of the environments in the Single Event Effect rate calculations. The EFT-1 proton environment varied dramatically throughout the mission. Accounting for this time variation was an essential component in selecting the appropriate level of redundancy in critical systems such as the VMC/FCMs (Vehicle Management Computer / Flight Control Modules). This lesson continues to apply to Exploration Missions. Stochastically occurringSPEs ( Solar Particle Events) may cause significant temporary increase in the radiation environment, and critical systems need to design appropriately. A related lesson learned reflects the importance of assessing timing of critical mission events with respect to the radiation environment. Environment assessments performed for EFT-1 drove modification of the mission timeline such that Avionics intensive mission events be executed outside of the core of the van Allen belts. This too is a lesson learned relevant for future missions especially in off-nominal conditions that may expose the spacecraft to high radiation environments.

EM-2 (Exploration Mission-2): EM-2 will be a Crewed High Lunar Orbit test flight that will be launched on an SLS and enter lunar orbit in 2022 to verify the capability of Orion to successfully launch, perform a crewed mission, and return them safely to Earth. It is planned to spend several days in lunar orbit before performing a TEI (Trans-Earth Injection) burn to begin the return to Earth. The total mission duration is expected to be 14 days maximum (4 at destination). Figure 2 depicts one option for a lunar mission. The EM-2 configuration will consist of:

• A fully functional launch abort system

• A fully functional Crew Module that includes a crew of up to four and all Cis-Lunar life support systems

• A fully functional Service Module.

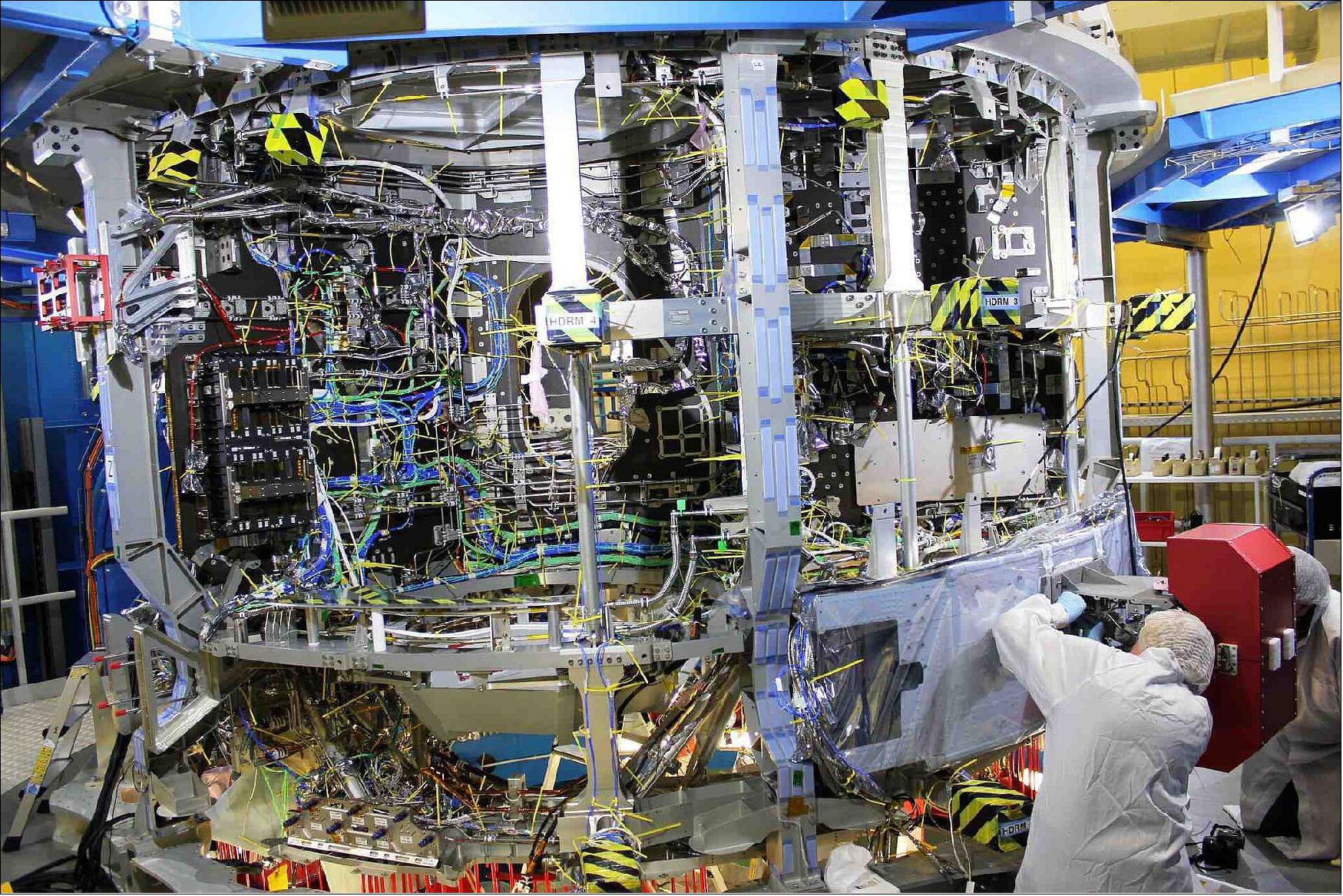

ESM (European Service Module)

The ESM implements four major system functions to Orion (Ref. 2):

• provides thrust for orbital maneuvers and attitude control after upper stage/launch vehicle separation

• generates electrical power and distributes it to the ESM users and to the CM/CMA

• regulates heat for the life support and avionics equipment during the orbital phases of the mission

• stores and provides to the CMA/CM potable water, oxygen, and nitrogen.

Mission | Purpose | Duration |

EM-1 - Lunar (DRO (Distant Retrograde Orbit) mission | - Qualification (uncrewed) | 25 days (6 at destination) |

EM-2 - Crewed High Lunar Orbit mission | - Qualification (crewed) | 14 days (4 at destination) |

Lunar Sortie mission | - Land crew of four on the surface of the Moon | 26 days (7 uncrewed in LLO) |

ISS Backup Crew Delivery mission | - Backup crew and cargo delivery to the ISS | 216 days (210 quiescent) |

In addition, it ensures structural spacecraft integrity during launch and in-orbit maneuvers. The ESM can also provide additional volume and other resources on select missions for accommodating science, engineering demonstrations, development test objectives, and deployment of lunar infrastructure equipment during the cruise and lunar orbit phases of lunar missions. This volume provides electrical power distribution, network access for command and control interfaces, and structures and mechanisms.

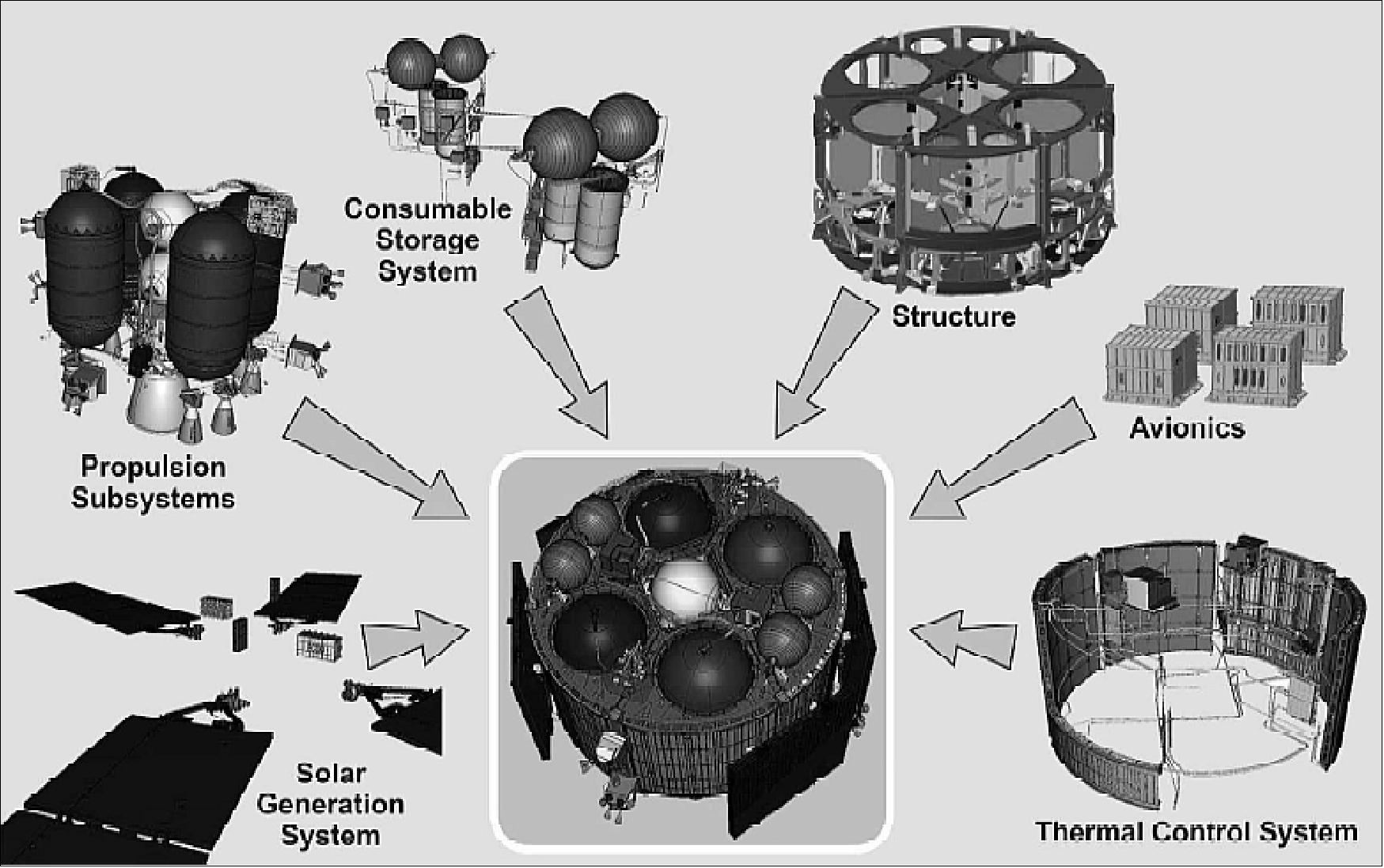

The architecture of the module has been developed based on the ATV spacecraft concept (five successful missions to the ISS),modified to cope with the different mission requirements and the man-rating approach for beyond LEO missions. 19)

The resulting ESM architecture is depicted in Figure 16, for comparison. The architecture of the system and subsystems hereafter proposed is the reference design for the Lunar Sortie Mission. Changes in the architecture are expected for the other missions to tailor the configuration to mission needs, to remove unnecessary HW and to optimize the launch mass.

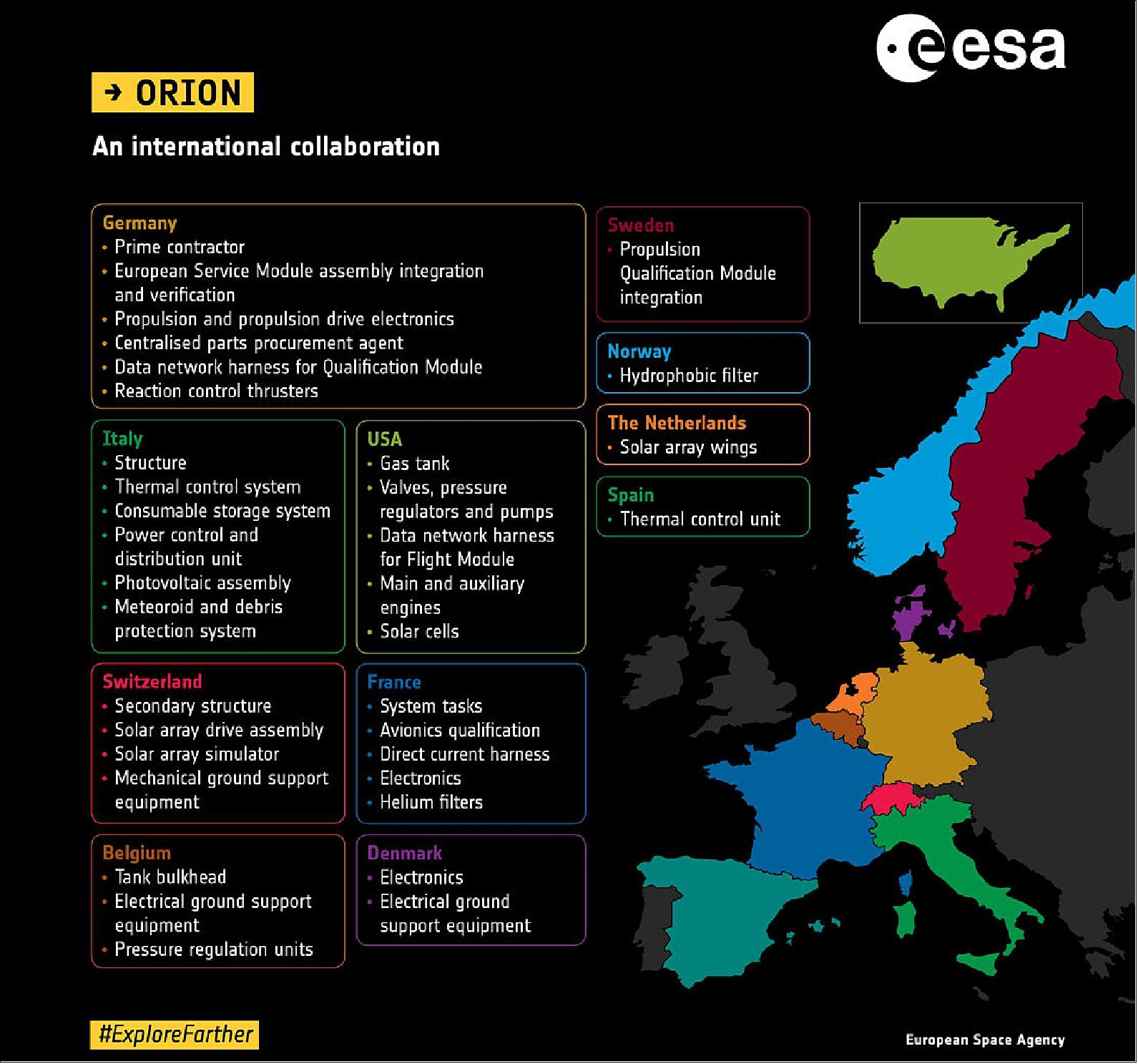

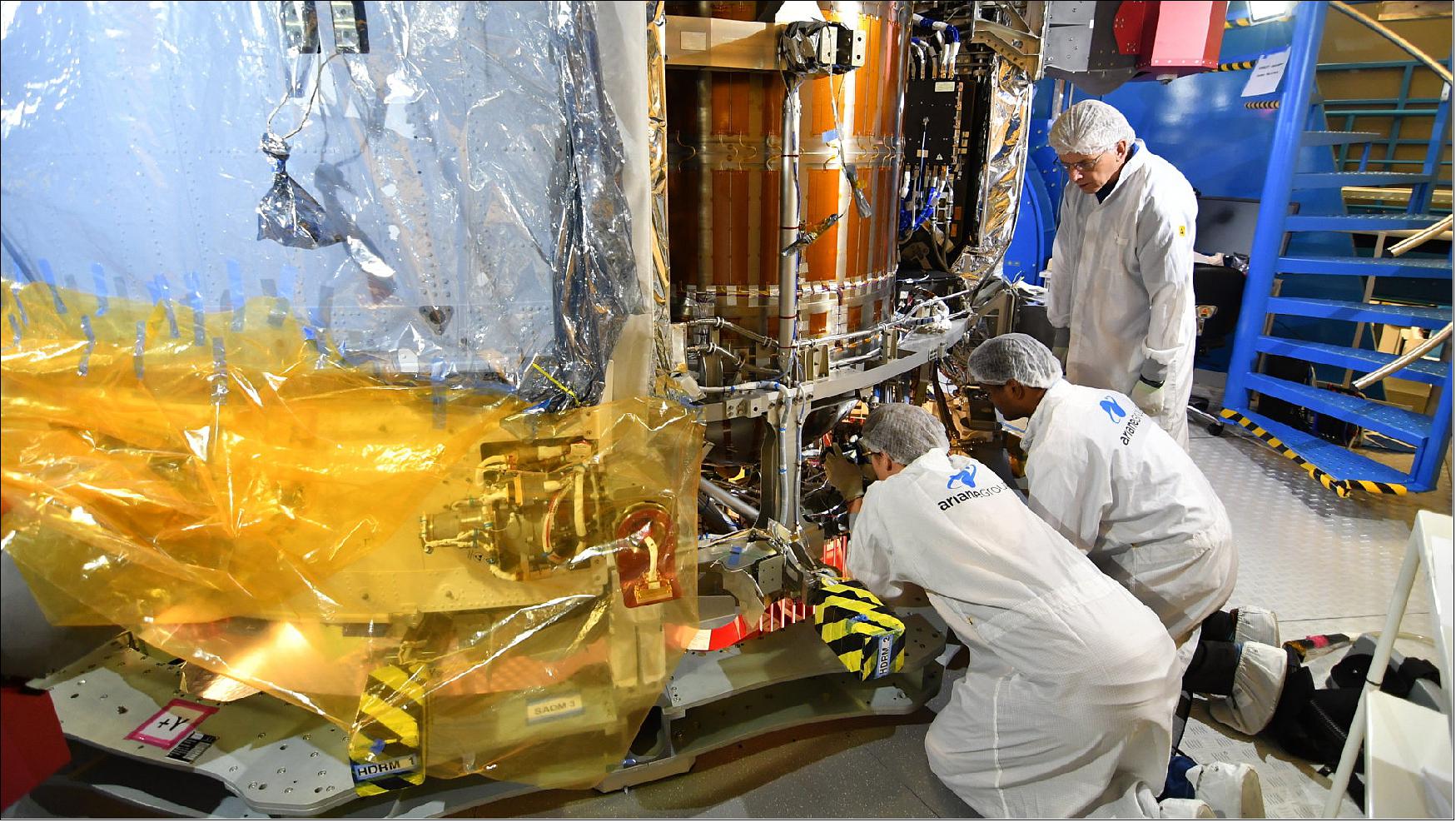

European Industrial Consortium: ESA entrusted the development of the ESM (European Service Module) to a consortium of European industries led by Airbus Defence and Space. The consortium of companies was selected to reuse the experience and industrial heritage of the very successful ATV (Automated Transfer Vehicle). Airbus Defence DS Germany as the Prime Contractor is responsible for all system-related work. This includes: 20)

- The overall Management of the contract

- The overall System Engineering activities

- The Management of the procurement activities

- The System Product Assurance and Safety activities

- The liaison with Lockheed-Martin (NASA prime contractor of the Orion vehicle).

Airbus DS, France is responsible for part of the system engineering, ground software, Helium pressurant tanks and simulation facility.

On Subsystem level, Airbus DS, Germany is responsible for the System Engineering, the Propulsion, Power and Avionics Subsystem Engineering as well as for GSE and AIT activities. The responsibility for the development of the other sub-systems or equipment has been distributed among European companies as follows:

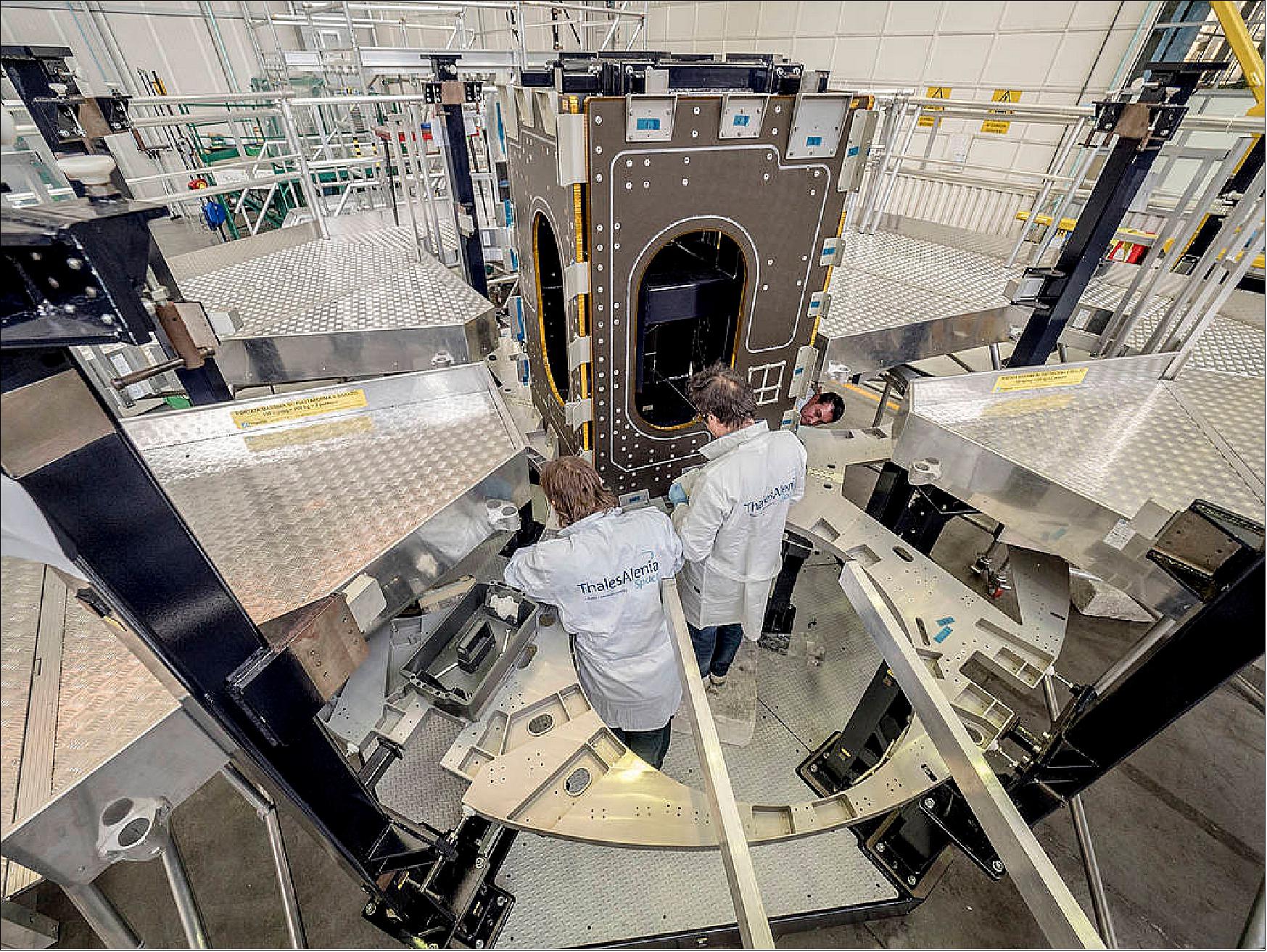

TAS (Thales Alenia Space) Italy: the Structure, Thermal and Consumable Storage Subsystems, supported by the following level-2 subcontractors:

- RUAG, Switzerland: secondary structures

- SONACA, Belgium: tank bulkhead

- APCO, Switzerland: MDPS (Meteoroid and Debris Protection System)

- CRISA, Spain, TCU (Thermal Control Unit)

- Prototech, Norway: nitrogen filters

- MEWASA, Switzerland, Water tank bellows.

Dutch Space, The Netherlands: the SAW (Solar Array Wings), supported by the following level-2 subcontractors:

- SELEX SE, Italy for the Photo Voltaic Assemblies

- RUAG, Switzerland: deployment dampers.

Airbus DS, Germany: the propellant tanks, Propulsion Drive Electronic and reaction control thrusters.

RUAG, Switzerland: the SADA (Solar Array Drive Assembly) composed of the mechanism and electronic unit.

SELEX SE, Italy: the PCDU (Power Conditioning and Distribution Unit)

Thales Alenia Space, Belgium: PRU (Pressure Regulation Unit)

Antwerp Space, Belgium: the Electrical Ground Support Equipment Front Ends, supported by the following level-2 subcontractors :

- Clemessy, France

- Rovsing, Denmark.

APCO, Switzerland: Mechanical Ground Support Equipment.

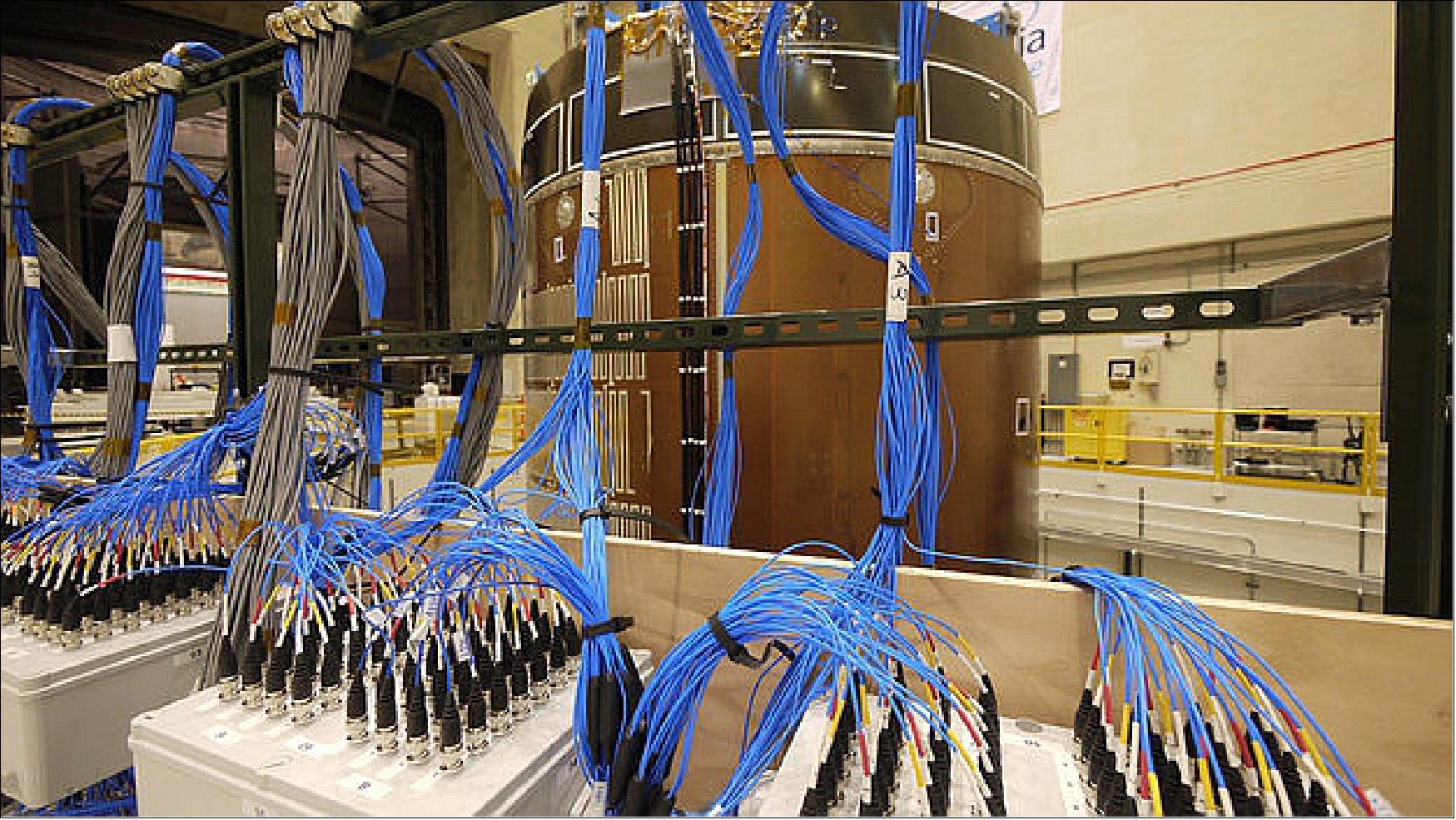

Latelec, France: avionics and power harness

TESAT Germany and Alter, Spain: CPP (Centralized Parts Procurement) scheme for EEE (Electrical, Electronic and Electromechanical)-parts.

Equipment suppliers encompasses Vacco (US), Moog (US), Sofrance (F), Cobham (US), Vivace (US).

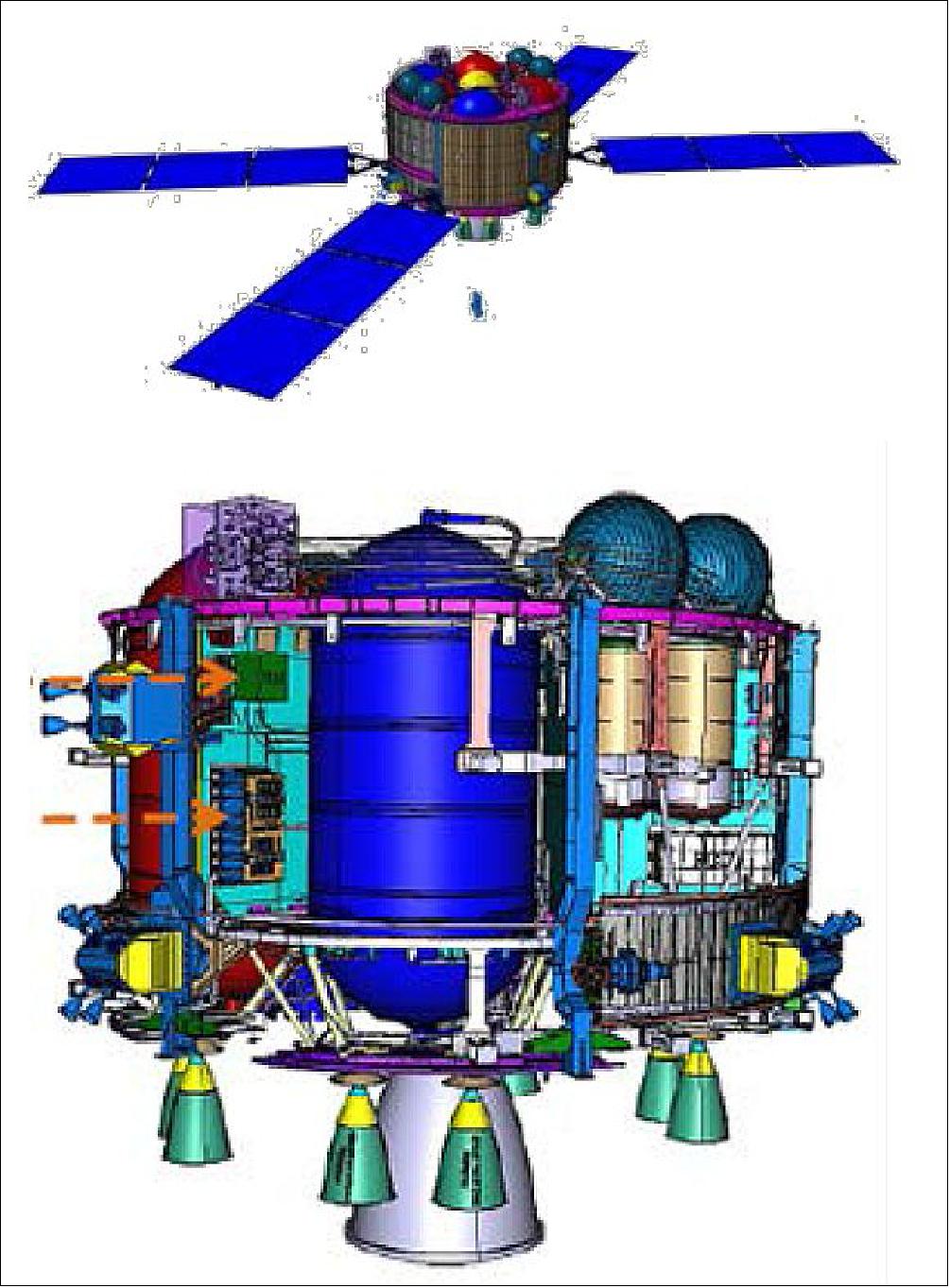

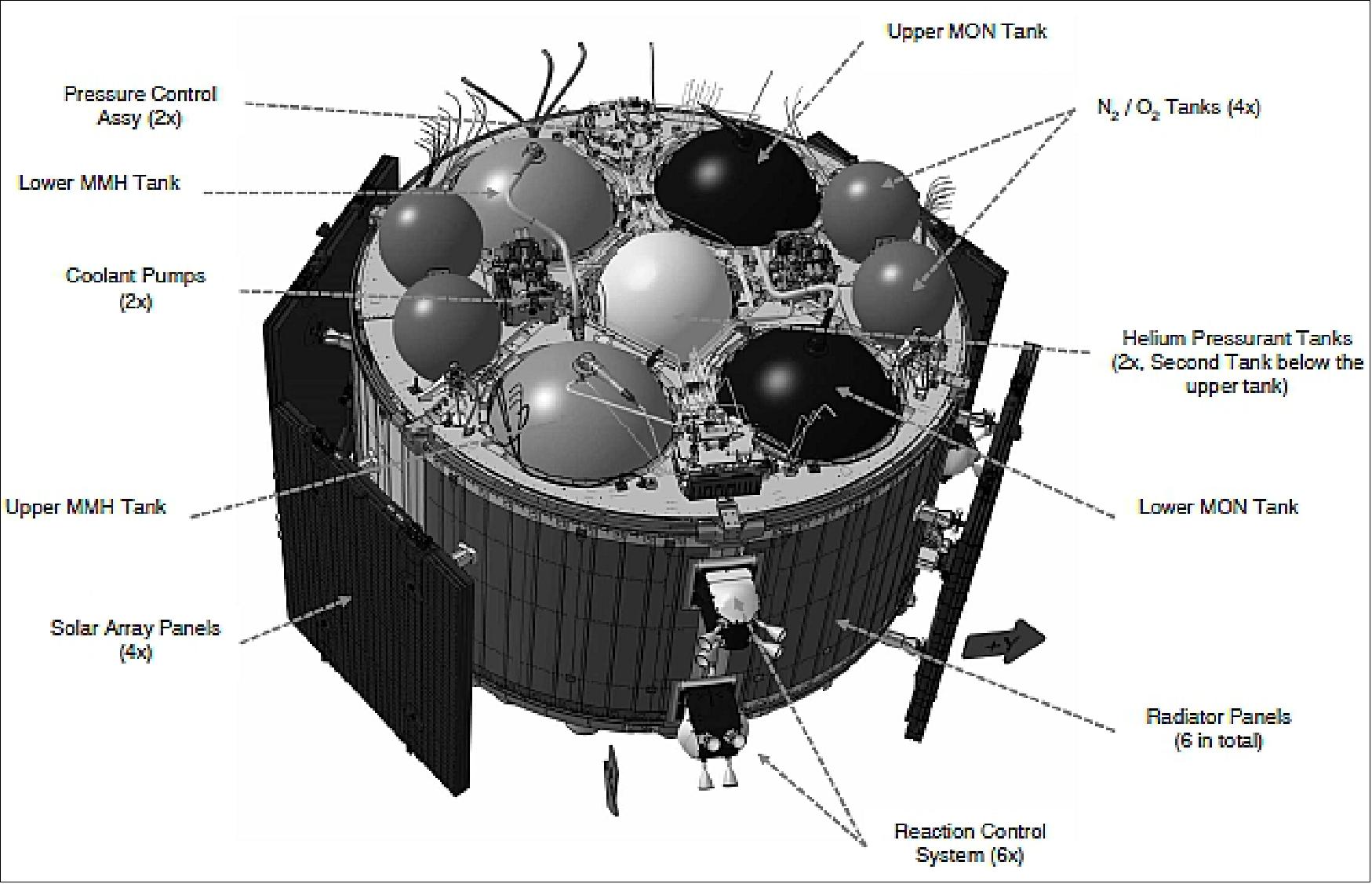

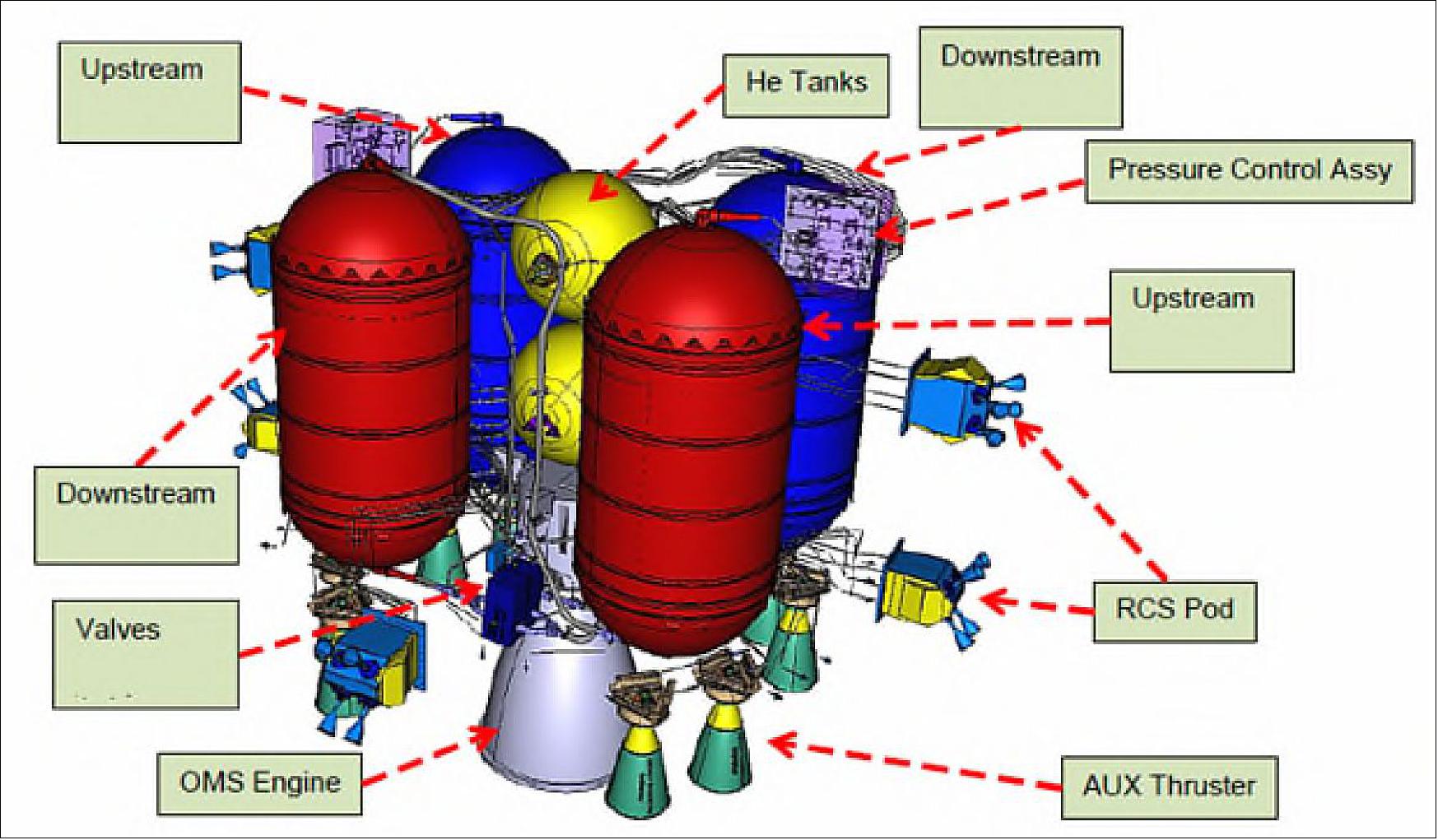

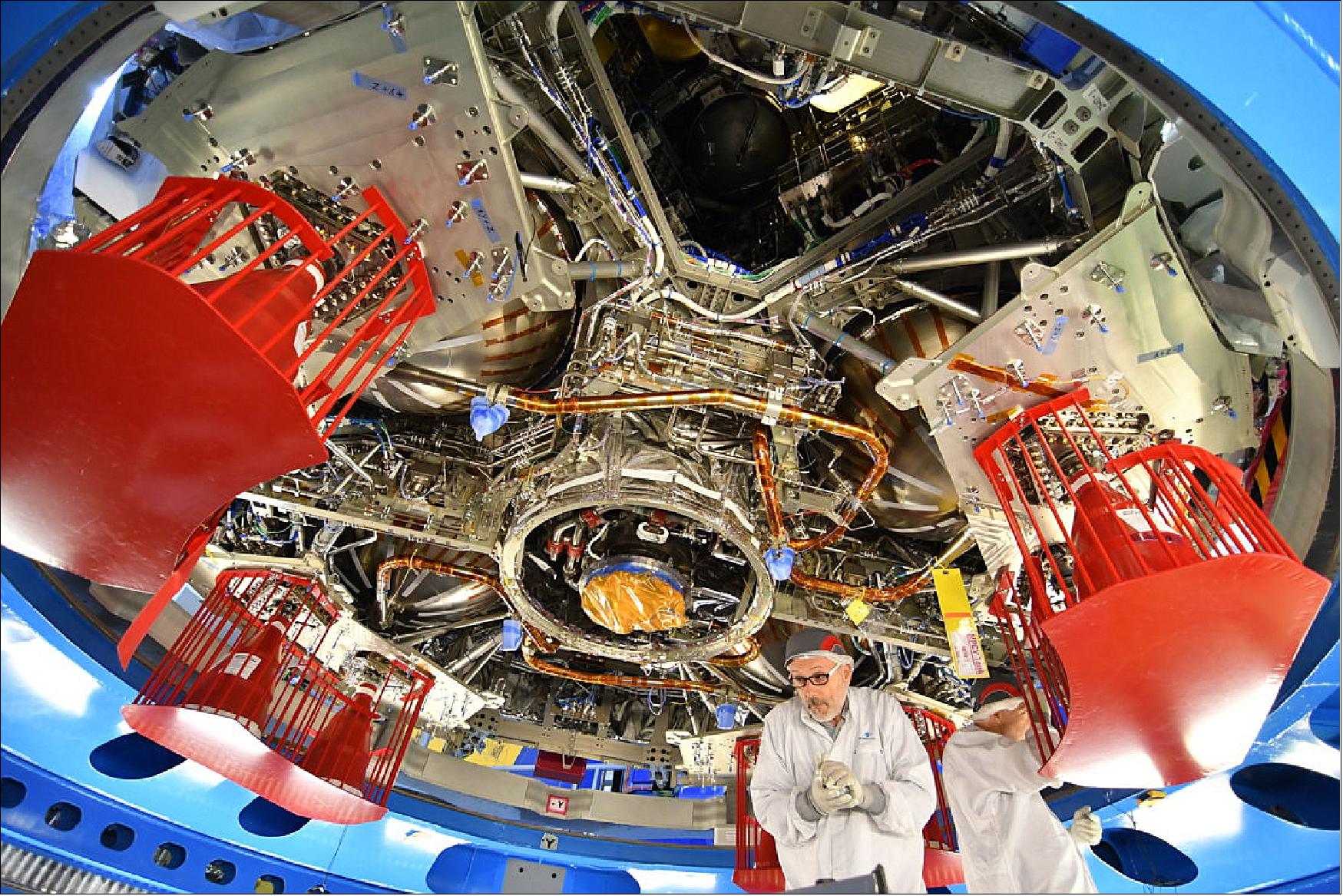

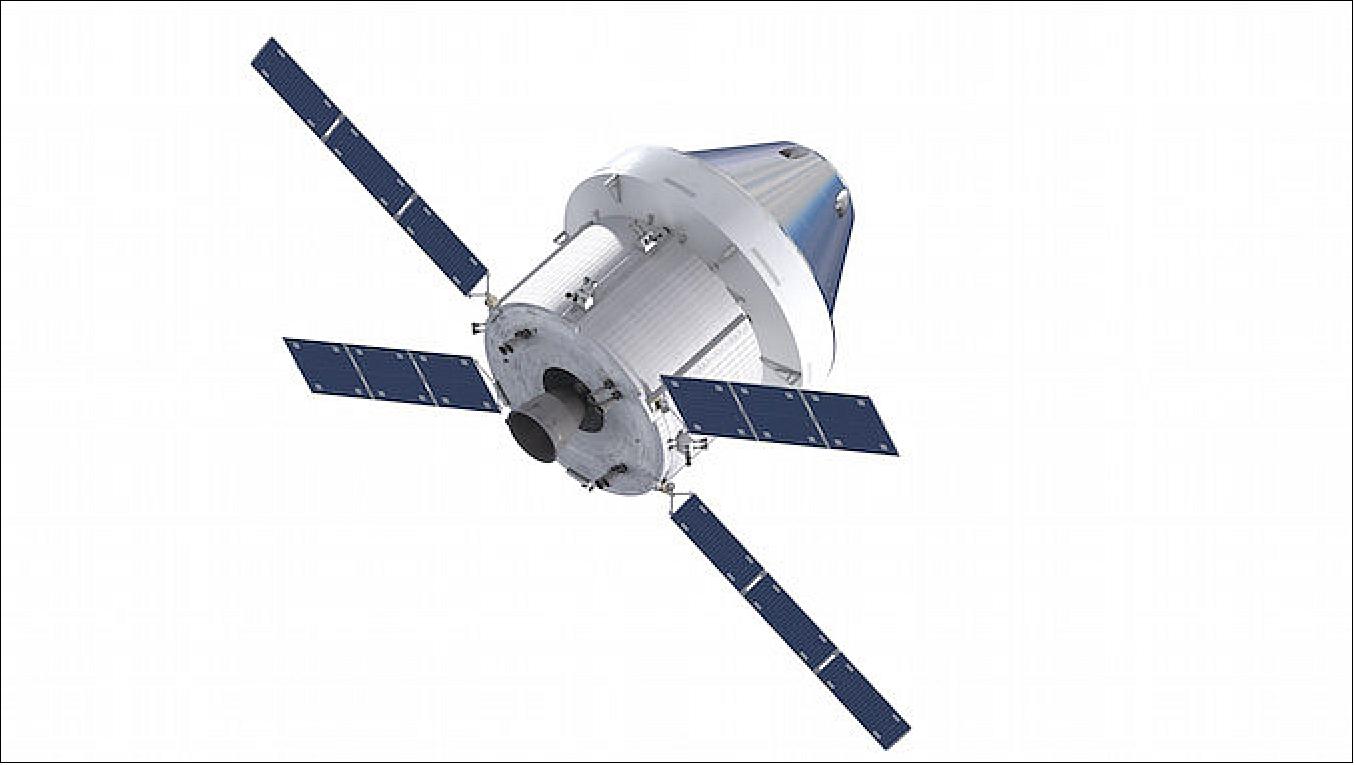

Physical architecture: The ESM is a cylindrical unpressurized module which interfaces at its bottom to the SA and at its top to the CMA. The OMS-E (Orbital Maneuvering System -Engine), i.e. the main engine, protrudes into the SA. Equipment on the tank platform is also allowed to protrude into the CMA. The total height of the ESM is 4.0 m.

The cylindrical shape is defined by the external radiators which enclose the body of the ESM. The function of the radiators is twofold, i.e. to radiate heat, and to serve as the first barrier of the MDPS (Micrometeoroid and Debris Protection Subsystem ). Mounted to the back side of the radiators are Nextel and Kevlar blankets which serve as the second barrier. The externally mounted RCS (Reaction Control System) pods and SAWs (Solar Array Wings) must be designed such that these respect the Orion SAJ allowable envelope.

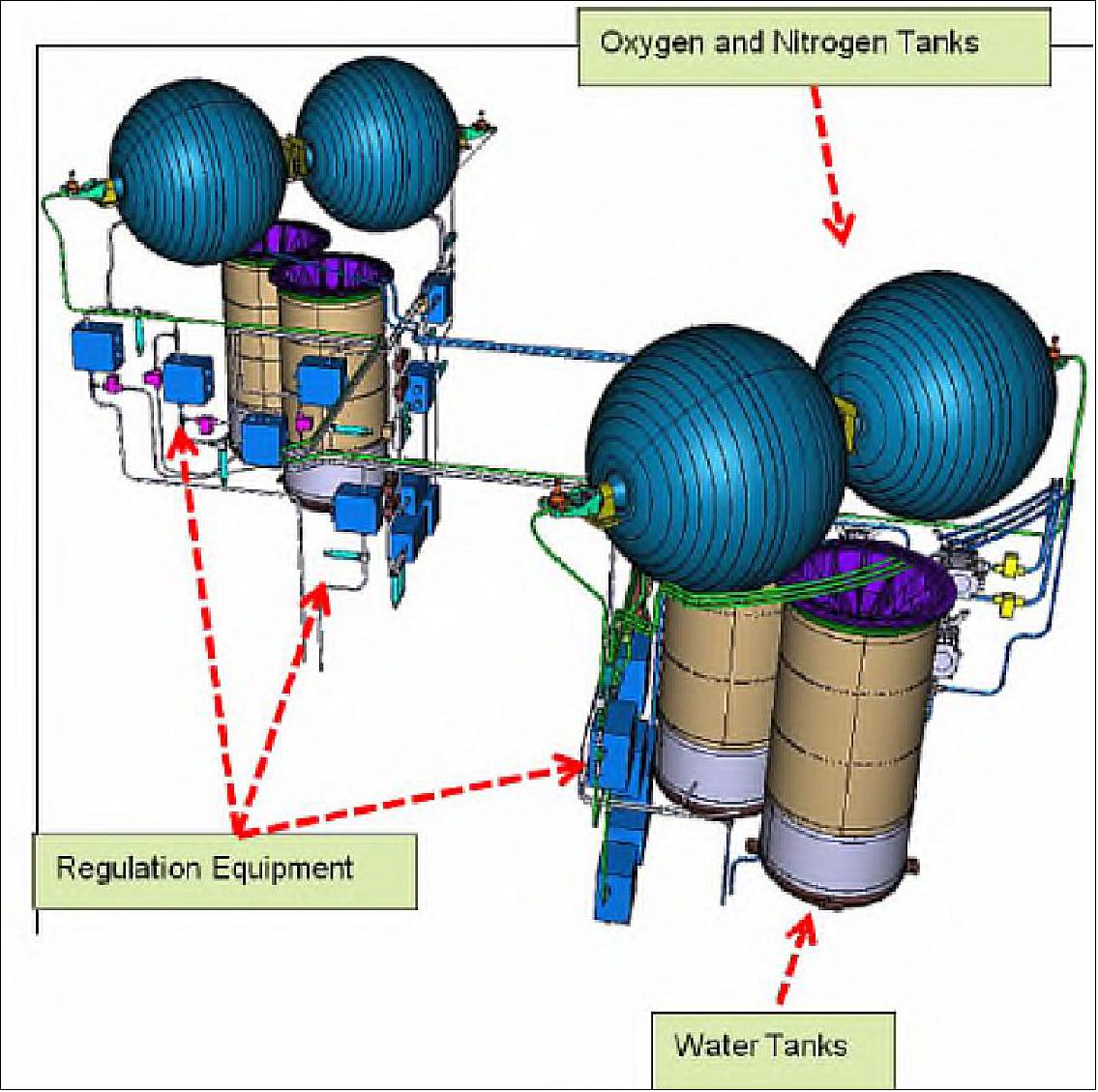

The internal accommodation of the ESM subsystem equipment is highly dependent to the primary structure architecture, based on seven separate bays for accommodation, six located circumferentially about the central bay. The pressurant tanks are accommodated in the center bay. The four largest bays are used for the accommodation of the propellant tanks which dominate the available volume. The remaining volume provides accommodation to the avionics equipment, CSS (Consumable Storage Subsystem) water tanks, harnessing and tubing.

The top surface of the ESM is dominated by the protruding tank domes for the propellant subsystems, one of the helium pressure tanks, the four tanks for Oxygen and Nitrogen, and the Flow Control Assembly for the active cooling subsystem. These elements protrude into the CMA, while maintaining a specific minimum distance to the CM Heat Shield. For these elements above the tank platform, the CMA provides the MDPS protection.

The lower surface is dominated by the OMS-E, which serves as the main engine of the ESM, and the eight auxiliary thrusters. Within the lower platform, a panel is incorporated through which the UPC (Unpressurized Cargo) is installed, and optionally ejected.

Total launch mass | 13,500 kg for Lunar Mission, including 8600 kg of usable propellant, 240 kg of potable water, 30 kg of N2 and 90 kg of O2 |

Dimensions | - ∅=5.2 m (with solar wings stored), L=4 m, deployed solar array span: 19 m |

Cargo | 380 kg (max), maximum volume of 0.57 m3 |

Solar array power | 11.2 kW |

Propulsion | - 1 main engine, ca. 30 kN |

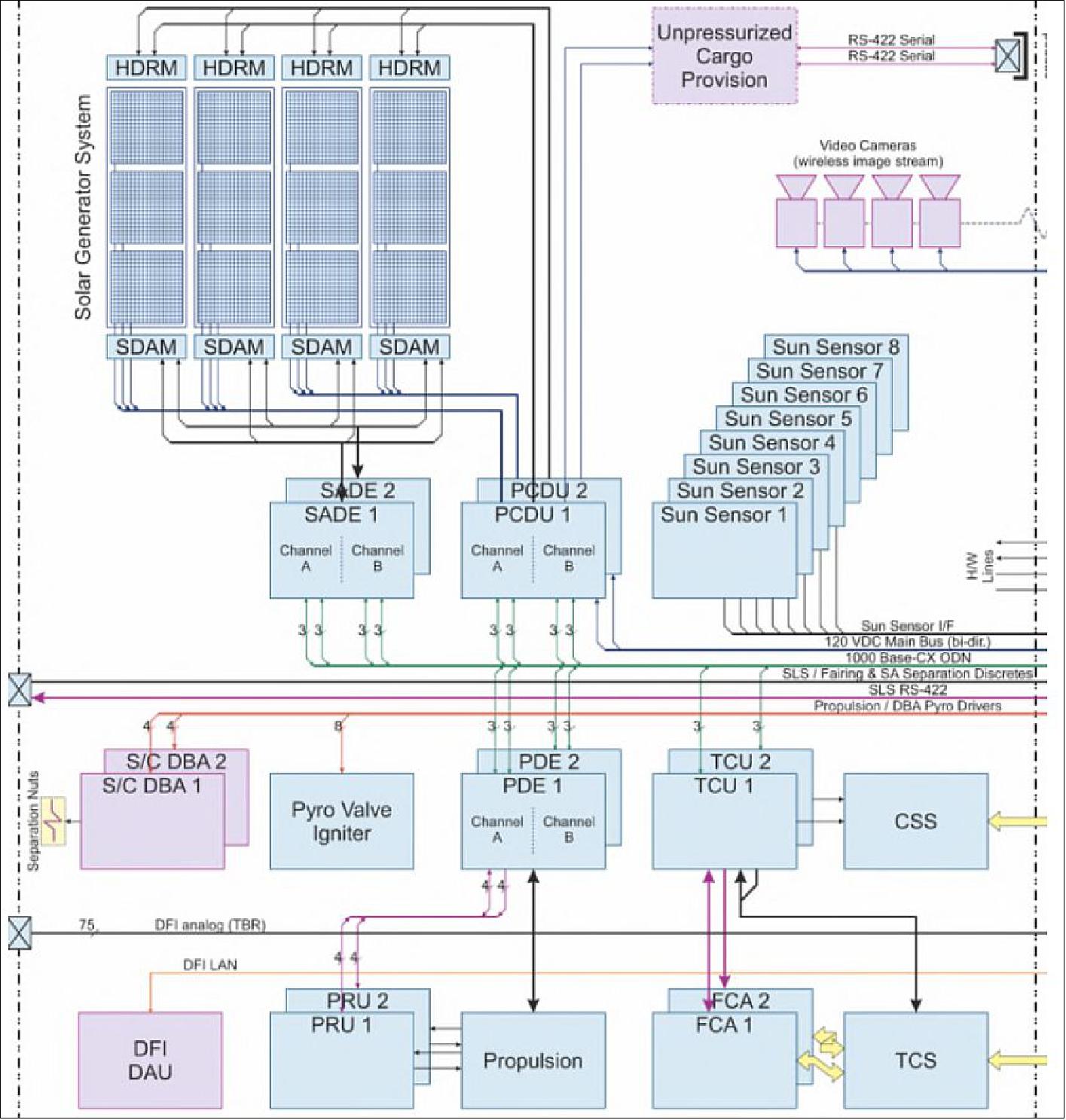

Functional architecture: Orion functionalities are generally shared between ESM and CMA/CM. Functional Chains gather equipment of the ESM which participate to a same service provided by Orion for the accomplishment of its mission.

Figure 17 depicts the overall avionics subsystem architecture and interfaces. The interface to the SLS launcher is depicted on the left side of the drawing, and the CM and CMA (labeled as SM-CM I/F Adapter) are on the right side. The main link with Orion CM on-board computers is the ODN (On-board Data Network), based on a time-triggered Ethernet solution. This interface ensures the connection of all ESM avionics to the on-board computers and allows the ESM to receive commands and to deliver monitors.

Few discrete lines ensure the independent command of ESM power subsystem electronics, allow to acquire signals from 8 sun sensors used as back-up AOCS sensors and allow the transfer of data acquired from the development flight instrumentation.

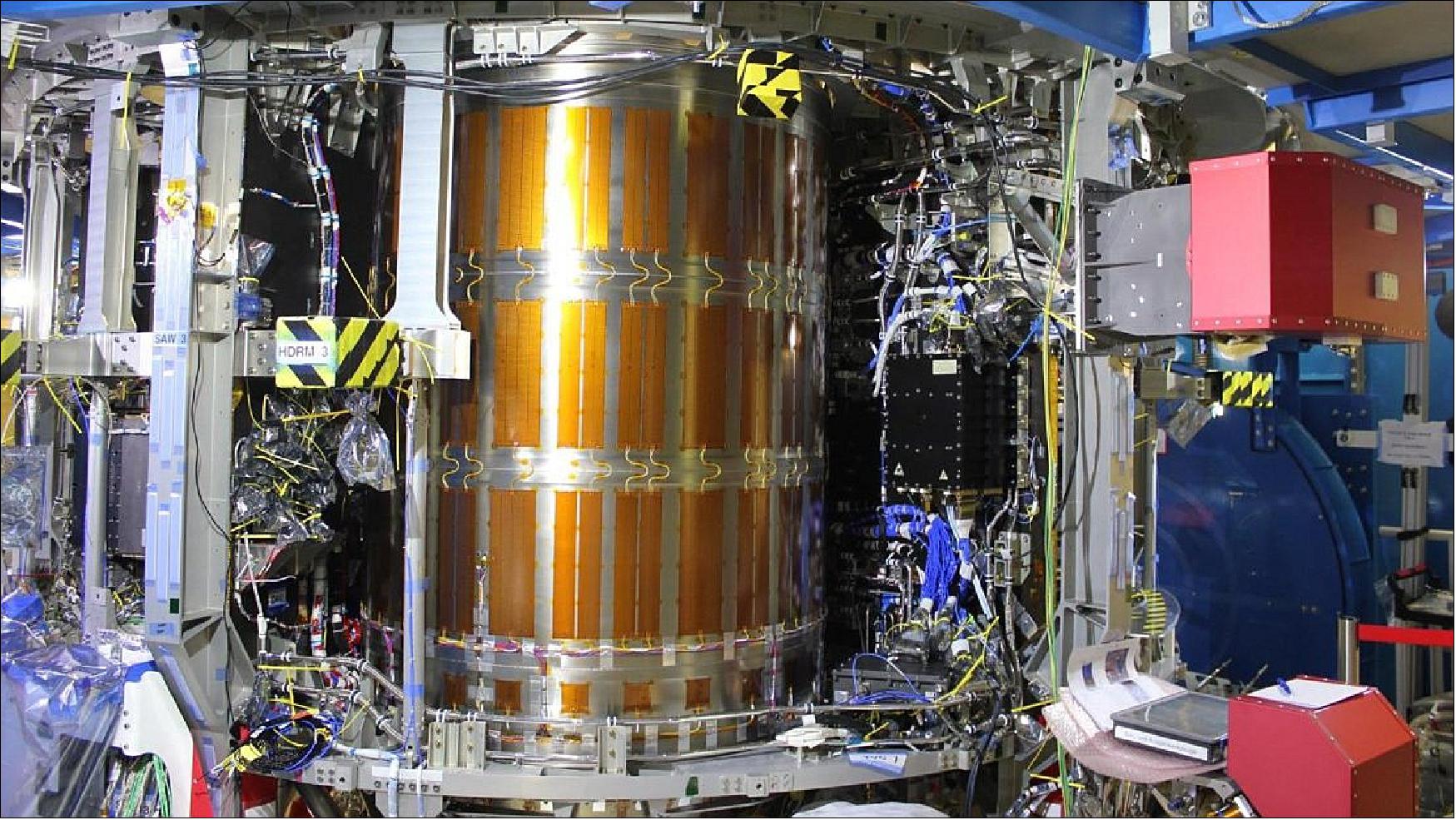

The four SAWs (Solar Array Wings) ensure a maximum electrical power production of 11.2 kW, to cope with a CMA/CM power demand of maximum 7.3 kW to be respected with one wing failed.

Four power buses allow powering to / from the CMA/CM depending on mission phases. Additional and independent power lines are provided for the wireless cameras installed on top of SAWs.

Finally, a dedicated pass-through harness connects the CMA to the SA/SAJ and launcher to allow transfer of monitoring data and separation commands.

ESM Layout

The ESM provides translational and 3-axis attitude control for the spacecraft, stores consumables for the crew module and provides power via the solar arrays. The ESM is also being designed to carry cargo. The main subsystems of the ESM are: 21)

• Structure Subsystem

• TCS (Thermal Control Subsystem)

• CSS (Consumable Storage Subsystem)

• PSS (Propulsion Subsystem)

• EPS (Electrical Power Subsystem)

• Avionics Subsystem

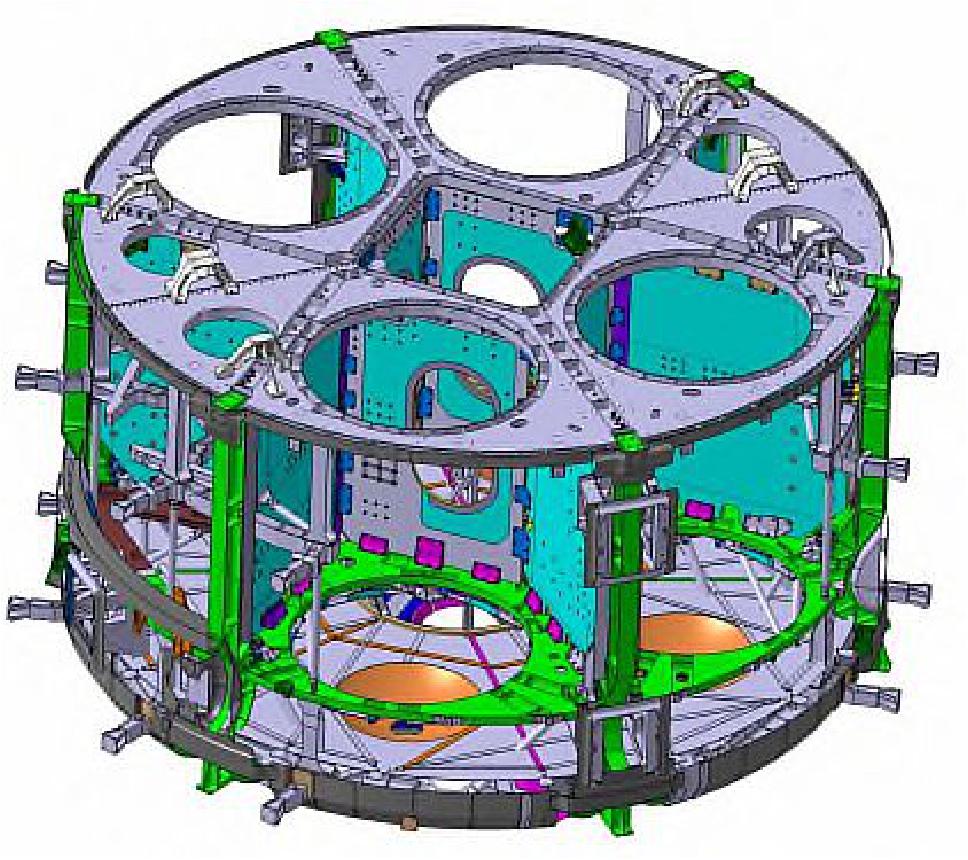

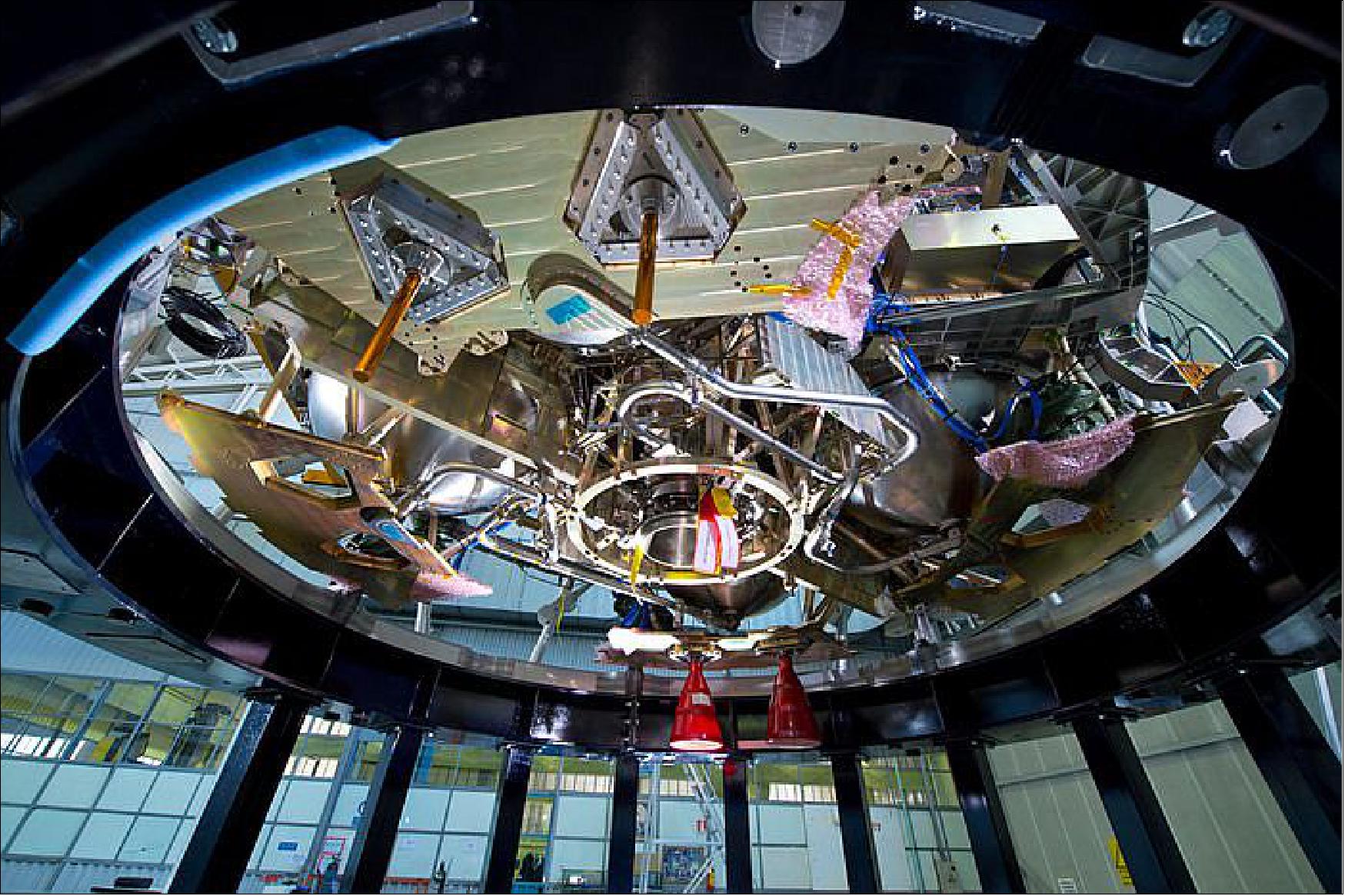

Structure subsystem: The ESM astructure consists of the following major elements:

• Primary structure

• Secondary structure

• MDPS (Meteoroid and Debris Protection).

The primary structure transmits the SLS launch loads to the upper composite composed of the CMA, the CM, and the LAS, then supports the upper composite aerodynamic and inertial loads as well as the ESM inertial loads generated by the ESM internal equipment. The design is based on a shared load path between the ESM and the external SAJ fairings. The objective is to minimize the loads applied on the ESM mechanical structure in order to optimize its mass which is propelled all along the mission, whilst the SAJ capability is sized to the extent possible by the main launch phase, since the SAJ mass is jettisoned early during the launch. The primary structure is composed of:

• 6 longerons (machined aluminum) linked to the CMA frame and six pyronuts that separate the ESM from the Spacecraft Adapter

• Tank bulkhead (machined aluminum) supporting the four propellant tanks, as well as the gas delivery CSS tanks, ensuring the main link between the CMA lower interface ring and the rest of ESM structure.

• "Radial" shear webs and internal "square" webs assembly (composite sandwich panels), housing most of the ESM equipment, including water tanks and SAW support frames and propulsion high pressure system. It forms the ESM core attached to the tank bulkhead, longerons and lower closeout panels. The main engine is attached to the central square tube panels via struts transmitting the thrust.

• Lower Platform (machined aluminum) on which the equipment is connected: OMS-E main engine, auxiliary thrusters supports, RCS pods supports, SAD (Solar Array Drive) mechanism, and PIE (Propulsion Isolation Equipment).

• MDPS covers and aft closure panels to protect the ESM from the MMOD (Micrometeoroid and Orbital Debris) environment.

The secondary structures support the ESM equipment carrying the inertial and dynamic loads of the equipment during launch and transmitting in-orbit thrust and inertial loads.

The MDPS is partly metallic and partly composed of Nextel reinforced MLI (Multi-Layered Insulation). Debris and meteoroid particles with velocities up to 24 km/s hit the outer wall, forming a cloud of lower energy particles which are then contained by the inner wall, preventing any penetration of the ESM.

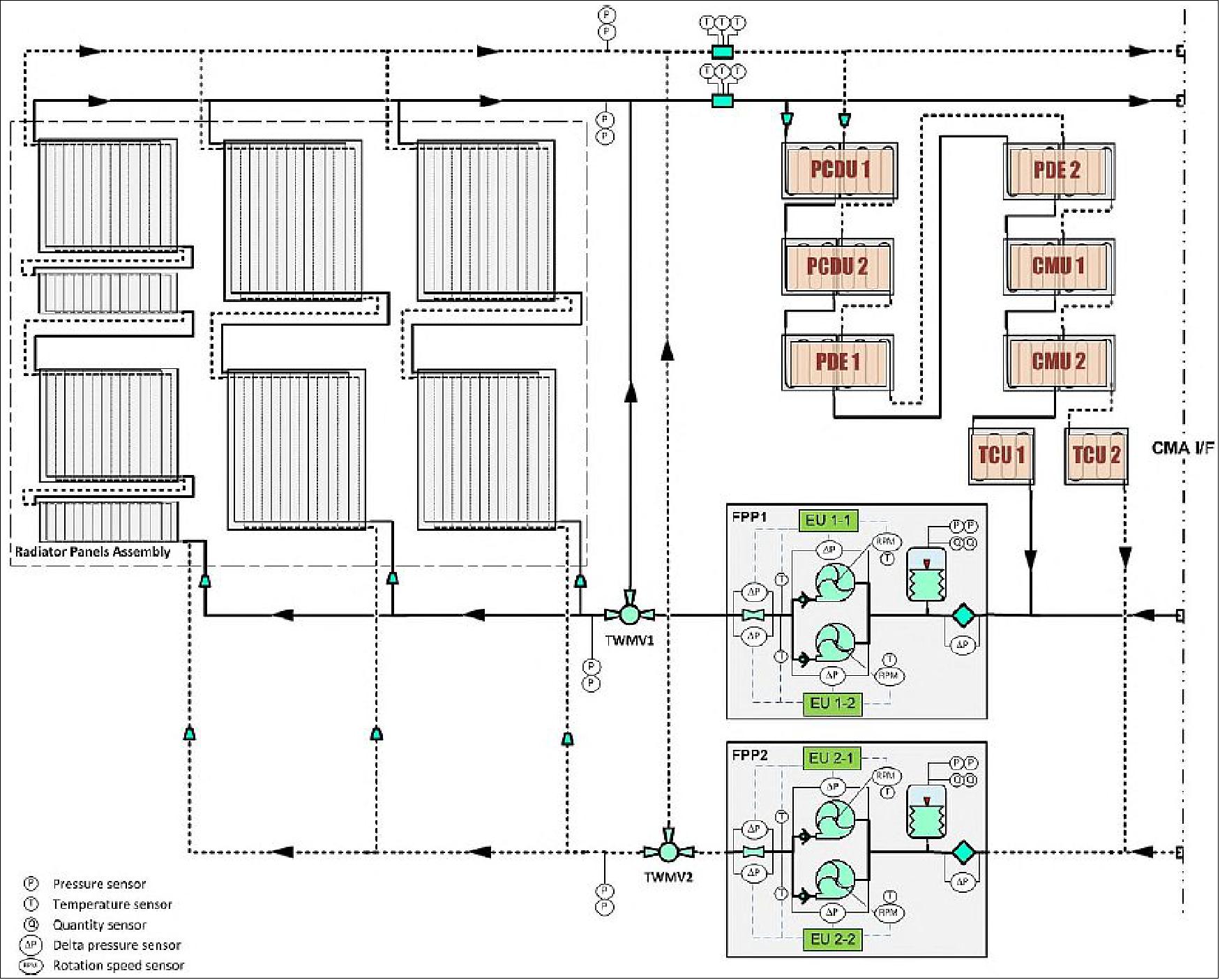

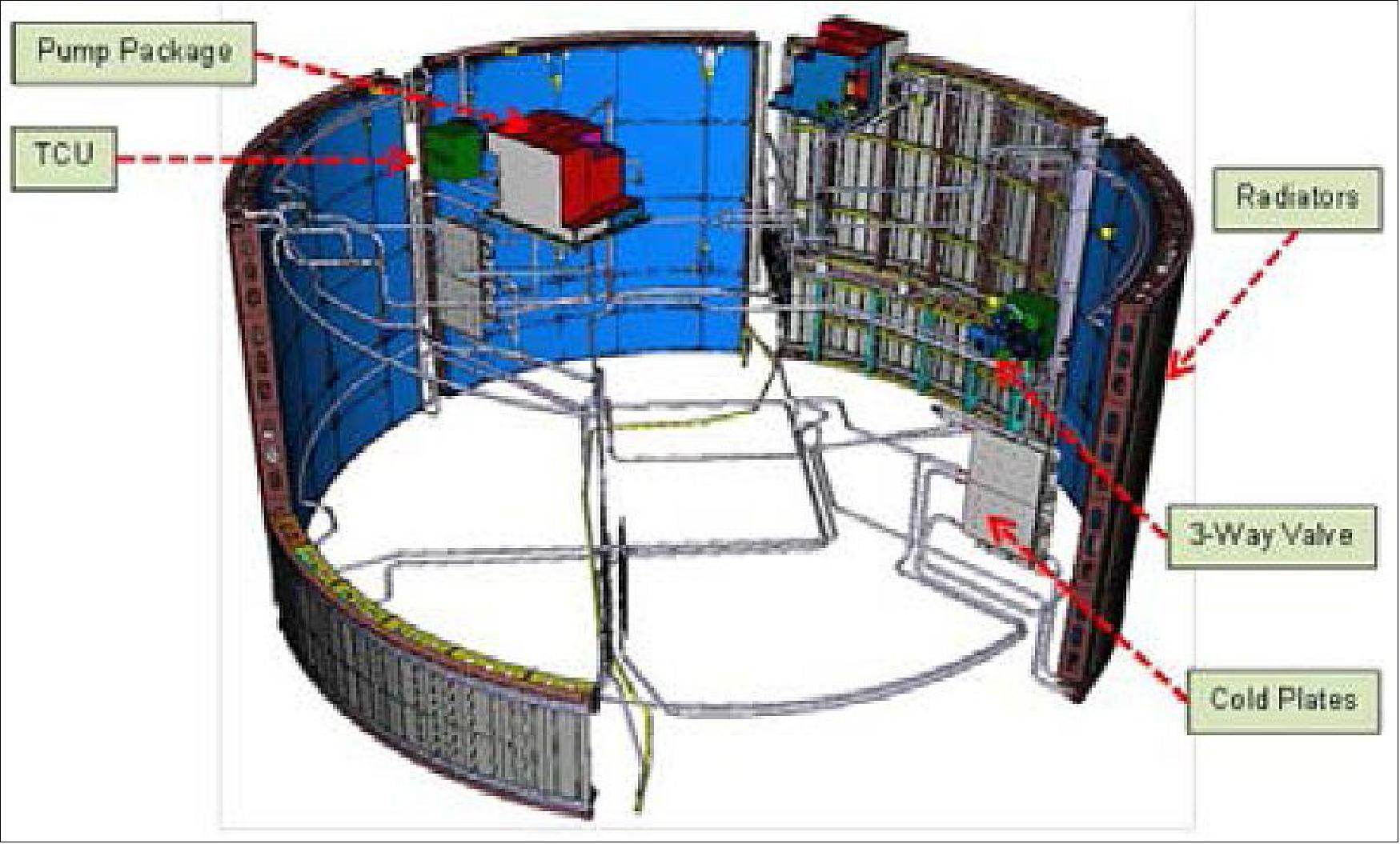

TCS (Thermal Control Subsystem): The TCS includes an ATCS (Active Thermal Control Subystem), a PTCS (Passive thermal control Subsystem) and the TCU (Thermal Control Unit).

11) ATCS (Active Thermal Control Subystem): The ATCS is designed to collect the thermal loads from the CM and from the ESM powered equipment and to reject them toward the space radiative sink. The ATCS architecture is based on a Single-phase Fluid Loop Architecture using the HFE-7200 coolant to collect and to transfer the heat loads from both ESM avionics (via cold plates) and CM (via Inter-Loop Heat Exchanger) and to reject them through specific body mounted radiators. The ATCS is composed of two fully independent loops working simultaneously (hot redundancy approach). The schematic of the ATCS architecture is presented in Figure 21.

Each ATCS loop is composed by the following main components:

• 1 Radiator Assembly commonly used for both loops and composed of 4 full height radiators and 2 split radiators (with lower part not removable) mounted in serial configuration

• 1 CP (Cold Plate)

• 2 online APSBs (Absolute Pressure Sensor Blocks)

• 1 wet on-line TSB (Temperature Sensor Block)

• 1 FCA (Fluid Control Assembly) including redundant pumps with relevant passive accumulator and a TWMV (Three-Ways Modulating Valve)

• Hard/flex hoses, tees, couplings and restrictors.

The FCA is controlled by the TCU to provide constant mass flow rate inside the loop. In particular two flow rate set points are foreseen, one for nominal operation and one for contingency (with only one loop operative). The FCA also includes the TWMV, controlling the temperature at the ESM-CMA interface.

The external surface of the radiator panels is coated with a specific paint characterized by the following thermal-optical characteristics:

• Alpha (α) = 0.2

• Emissivity (ε) = 0.8.

The Cold Plates are devoted to collect the entire thermal load from the ESM avionics boxes. Their design is constituted by a stainless steel channelling enclosed in an aluminum casting acting as a plate in direct contact with the thermally active unit. Different Cold plate sizes, to satisfy the different configuration needs, are foreseen.

12) PTCS (Passive Thermal Control Subsystem): The PTCS provides the thermal control of ESM hardware (propulsion, CSS, power and avionic items) and reduces the temperature gradients and minimize heat flows through the internal elements. The PTCS has two main components, heaters (with thermistors and wire heater) and insulation (MLI thermal blankets, including some specific high temperature MLI blankets, for thrusters and engine nozzle thermal impingement protection).

The MLI protects the internal parts against the external environment and heater lines compensate the heat leaks toward space. Different MLI typologies, in terms of composition, have been identified for the different applications on the ESM. The MLI composition mainly depends on exposure or not to the space, geometry & fixation interfaces and exposure to thrusters plume flux and nozzle radiation.

Two cold redundant heater lines managed by the TCU assure thermal control and temperature uniformity in the Orion internals and for the local thermal control of specific items. In addition, heater lines managed by thermostats and powered by the PCDU (Power Control and Distribution Unit) provide a further redundancy to the environmental control function.

13) TCU (Thermal Control Unit): The TCU is designed to ensure the management of the TCS and of the CSS.

For the ATCS, the TCU acquires the various parameters from the ATCS sensors, monitors and commands the ATCS valves, and issues commands to the FCA (Flow Control Assembly).

For the PTCS, the TCU commands the heater chains and monitors the thermistors. It operates according to activation and de-activation thresholds defined and modified by the CM on-board computers, while ensuring bus interface and power supply logic.

For the CSS (Consumables Storage Subsystem), the TCU commands the valves and monitors their position. It also monitors the pressure and temperature parameters in the subsystem to support the system FDIR (Failure Detection, Isolation and Recovery).