Ariane 6: ESA Space Transportation Program

Launchers and Propulsion

ESA Space Transportation Program (Ariane 6, Vega, Prometheus)

Next Generation Launcher Development Status Ariane ConceptFuture Launchers Preparatory Program Launch Opportunities

Prometheus Engine Demonstrator Program References

It is more than 50 years since a group of European governments decided that Europe needed guaranteed and autonomous access to space, and that it made sense to combine their efforts to achieve this goal. 1)

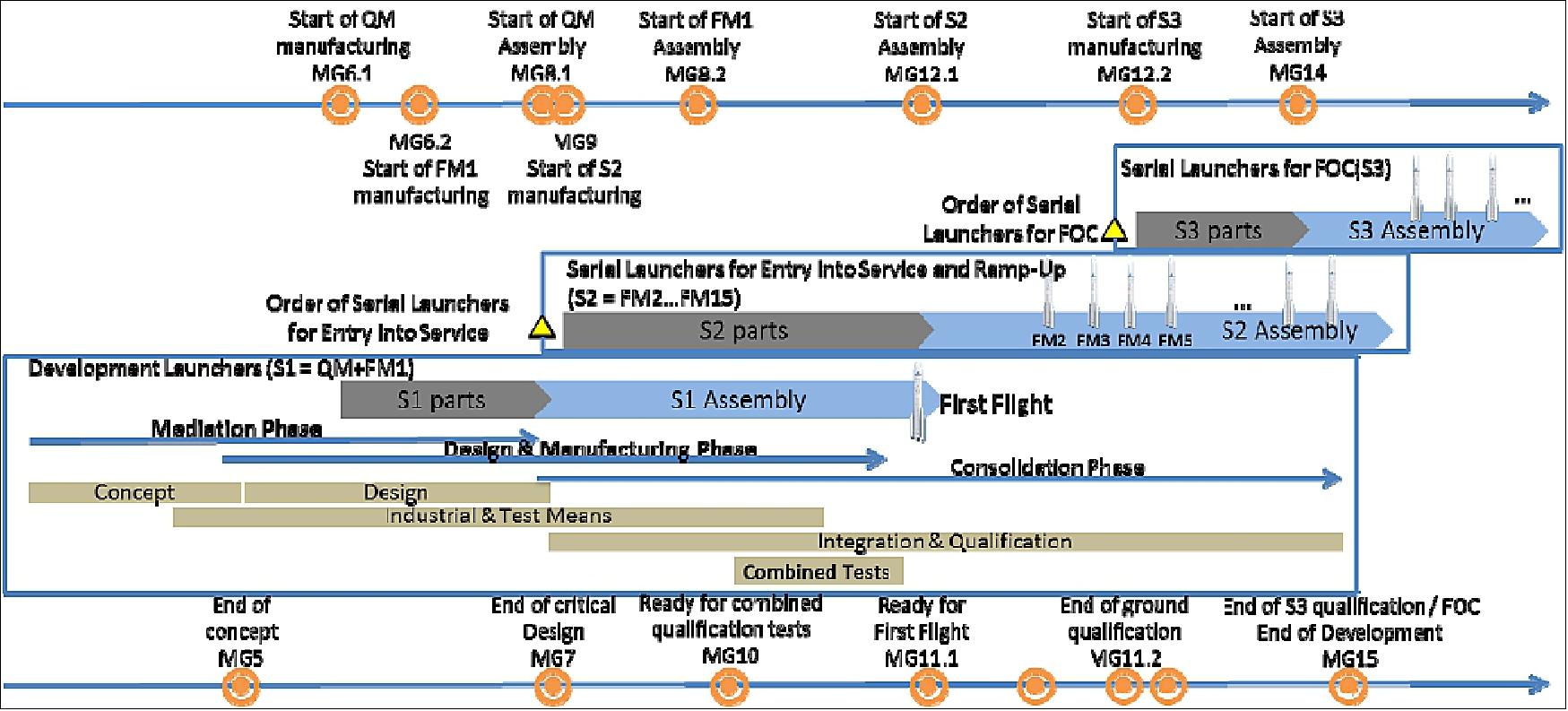

Thanks to their foresight, Europe has developed a range of launchers and its own base in French Guiana for European launches. To have access to space is the first enabling element in the utilization of space and the many benefits this brings.

Space utilization and exploration yields greater knowledge of our Solar System, enables better navigation and telecommunication systems, and provides the data to monitor our environment. All this is only possible because we have the launchers capable of placing satellites accurately into space.

The benefits of space exploration have expanded in ways that could not have been envisaged even 30 years ago. Space applications will continue to grow, which is why guaranteed access to space now, and in the future, is so important.

The EU (European Union) and ESA recognize the growing importance of space and signed a joint declaration on 26 October 2016 on their "Shared Vision and Goals for the Future of Europe in Space".

This demonstrates the importance both institutions attribute to close and integrated cooperation with the shared ambition that Europe remains a world-class actor in space and a partner of choice internationally.

One enduring goal is to ensure European autonomy in accessing and using space in a safe and secure environment, by consolidating and protecting its infrastructures.

Europe offers a range of launchers to meet institutional and commercial needs, and ensures that Europe’s Spaceport remains a byword for excellence and reliability.

Building for the future: ESA is able to build on its years of experience to:

• ensure availability and foster the competitiveness and reliability of Ariane, Vega and Soyuz from Europe’s Spaceport;

• maintain the ground infrastructure needed for launches;

• foster a European institutional market for Ariane and Vega;

• ensure that Europe can respond to evolving market demands by developing Ariane 6 and Vega C and their ground infrastructures;

• support European industry, technology and research capabilities by improving industrial competitiveness and promoting innovation;

• create employment;

• prepare a future for Europe to better serve institutional and commercial markets by focusing on innovative technologies, investigating future launcher evolutions, demonstrating technical capabilities and preparing routine access to and return from space.

Ariane 6: A Next-Generation Launcher for Europe

ESA (European Space Agency) and European industry are currently developing a new-generation launcher: Ariane 6. This follows the decision taken at the ESA Council meeting at Ministerial level in December 2014, to maintain Europe’s leadership in the fast-changing commercial launch service market while responding to the needs of European institutional missions. 2)

This move is associated with a change in the governance of the European launcher sector, based on a sharing of responsibility, cost and risk by ESA and industry. The participating states are: Austria, Belgium, Czech Republic, France, Germany, Ireland, Italy, Netherlands, Norway, Romania, Spain, Sweden and Switzerland.

Objectives

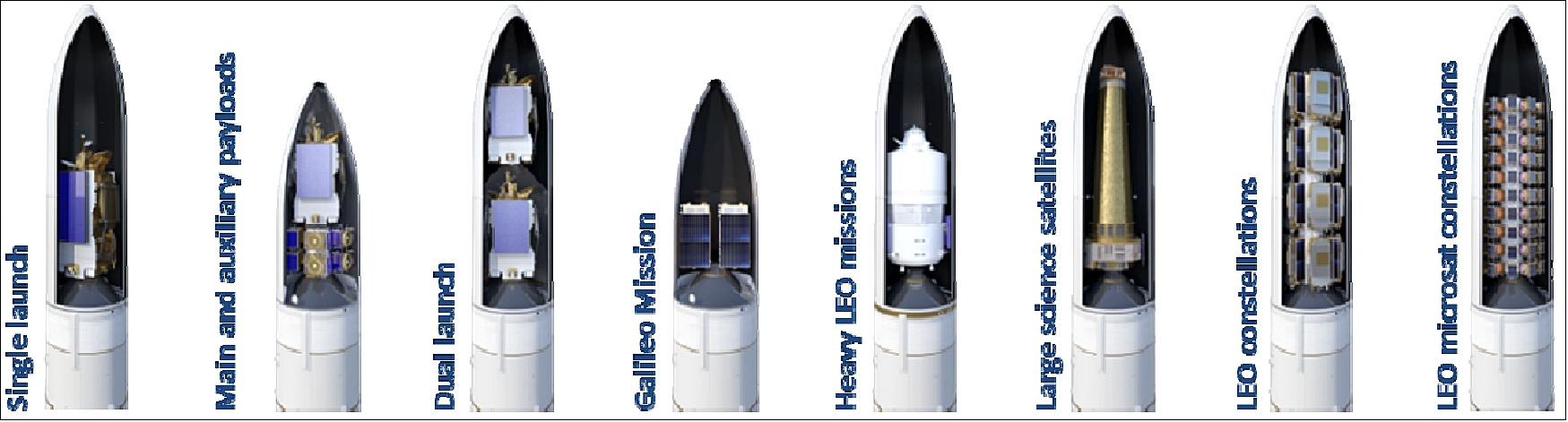

The overarching aim of Ariane 6 is to provide guaranteed access to space for Europe at a competitive price without requiring public sector support for exploitation. Different concepts have been examined for Ariane 6 such as single- and dual-payloads, solid or cryogenic propulsion for the main stage, and the number of stages (three or more), all to cover a wide range of missions:

• GEO, either directly or through intermediate orbits, in particular GTO and LEO,

• Polar/SSO (Sun Synchronous Orbit),

• MEO (Medium Earth Orbit) or MTO (Mars Transfer Orbit),

• other.

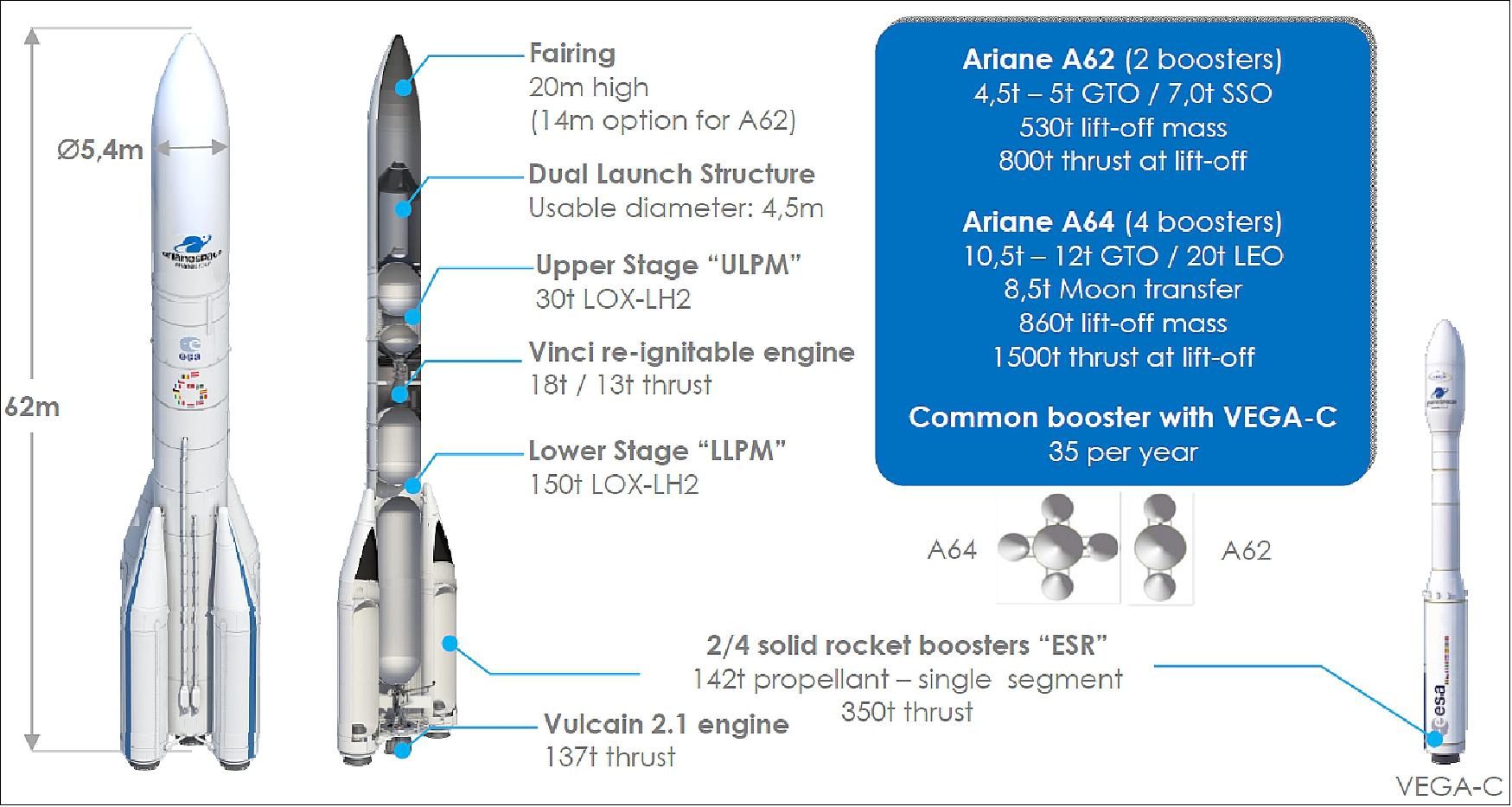

The targeted payload performance of Ariane 6 is over 4.5 t for polar/Sun-synchronous orbit missions at 800 km altitude and the injection of two first-generation Galileo satellites. Ariane 6 can loft a payload mass of 4.5–10.5 tonnes in equivalent geostationary transfer orbit.

The exploitation cost of the Ariane 6 launch system is its key driver. Launch service costs will be halved, while maintaining reliability by reusing the trusted engines of Ariane 5. The first flight is scheduled for 2020.

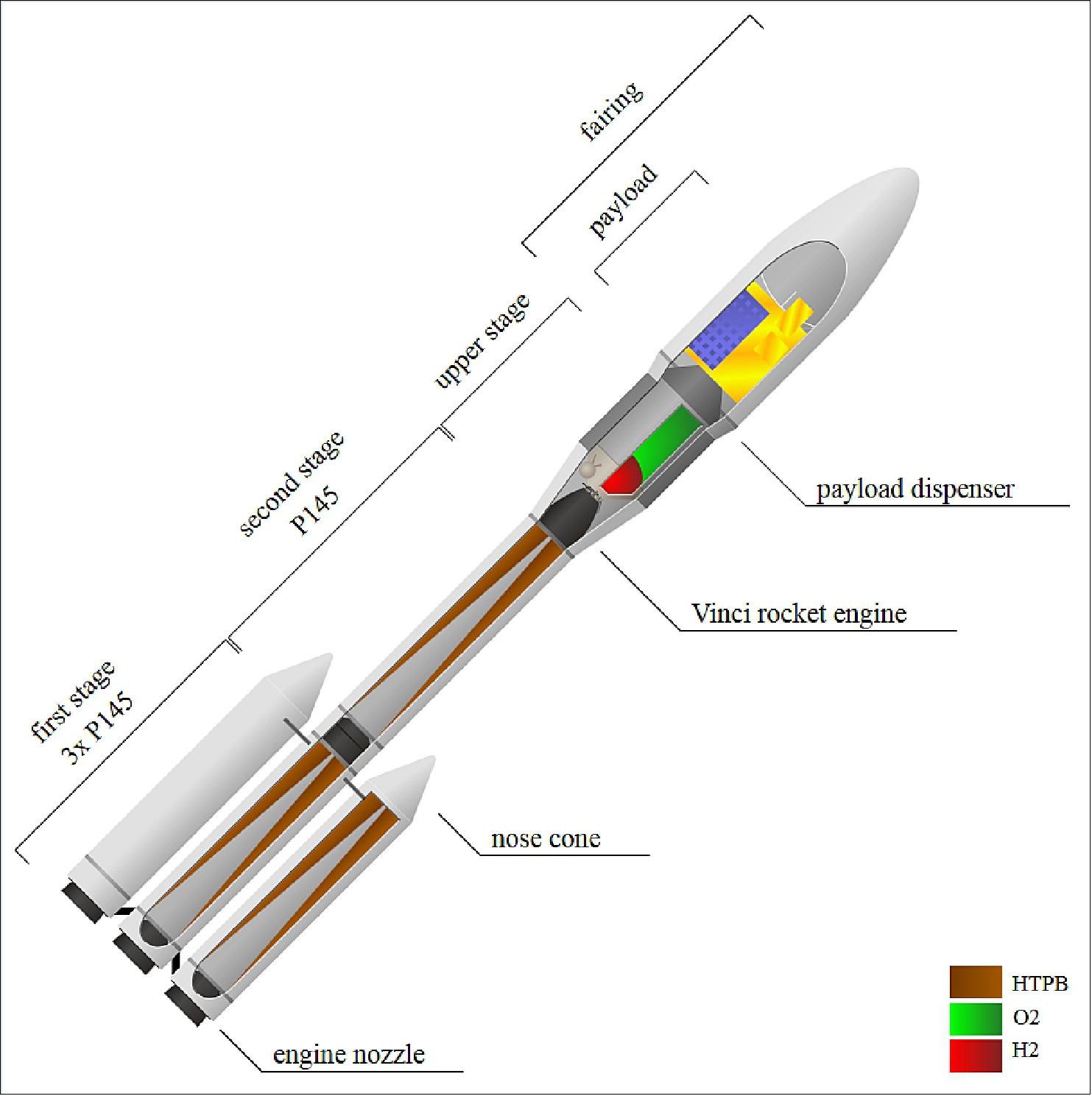

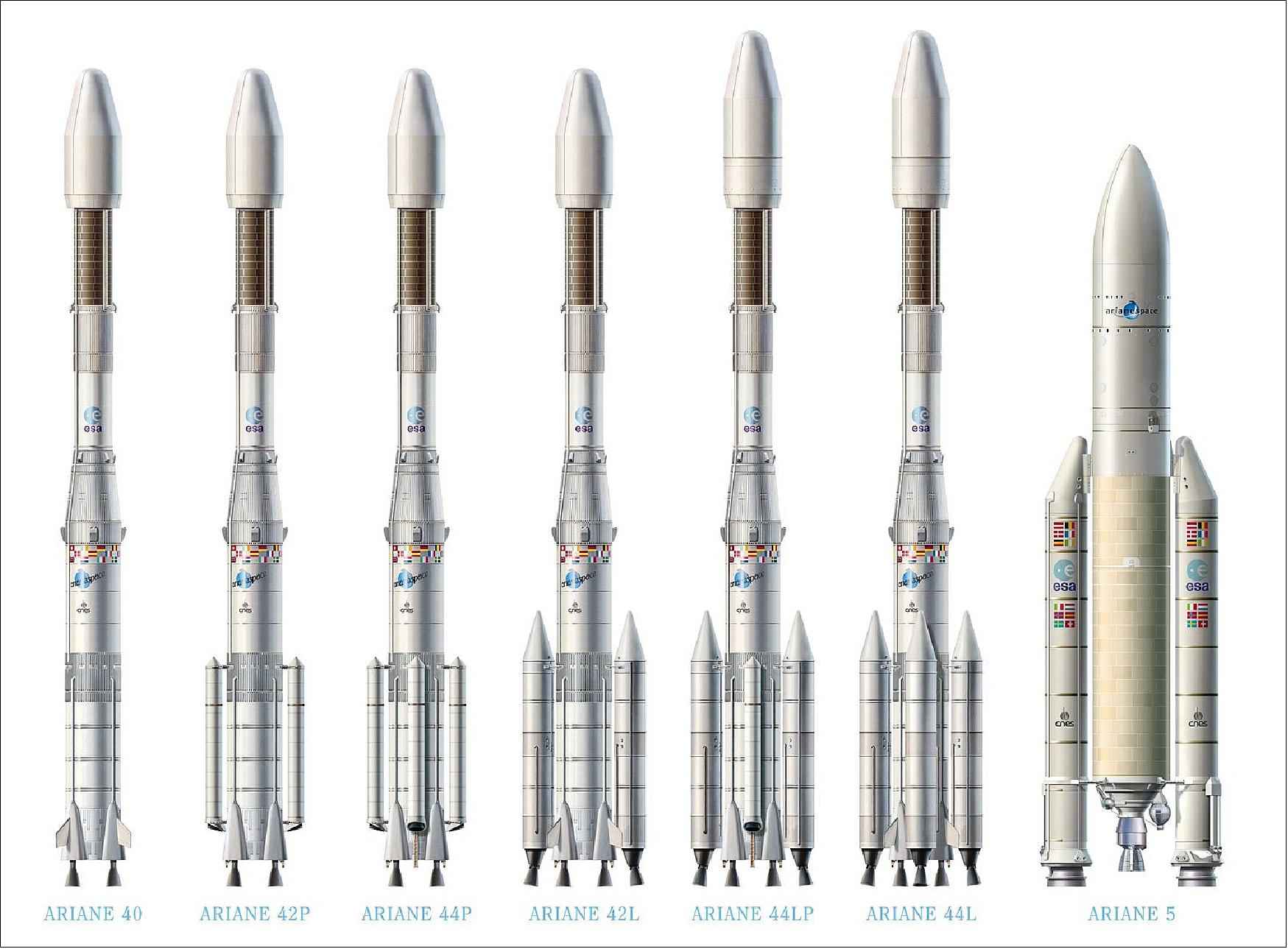

Ariane 6 has a ‘PHH’ configuration, indicating the sequence of stages: a first stage using strap-on boosters based on solid propulsion (P) and a second and third stage using cryogenic liquid oxygen and hydrogen propulsion (H).

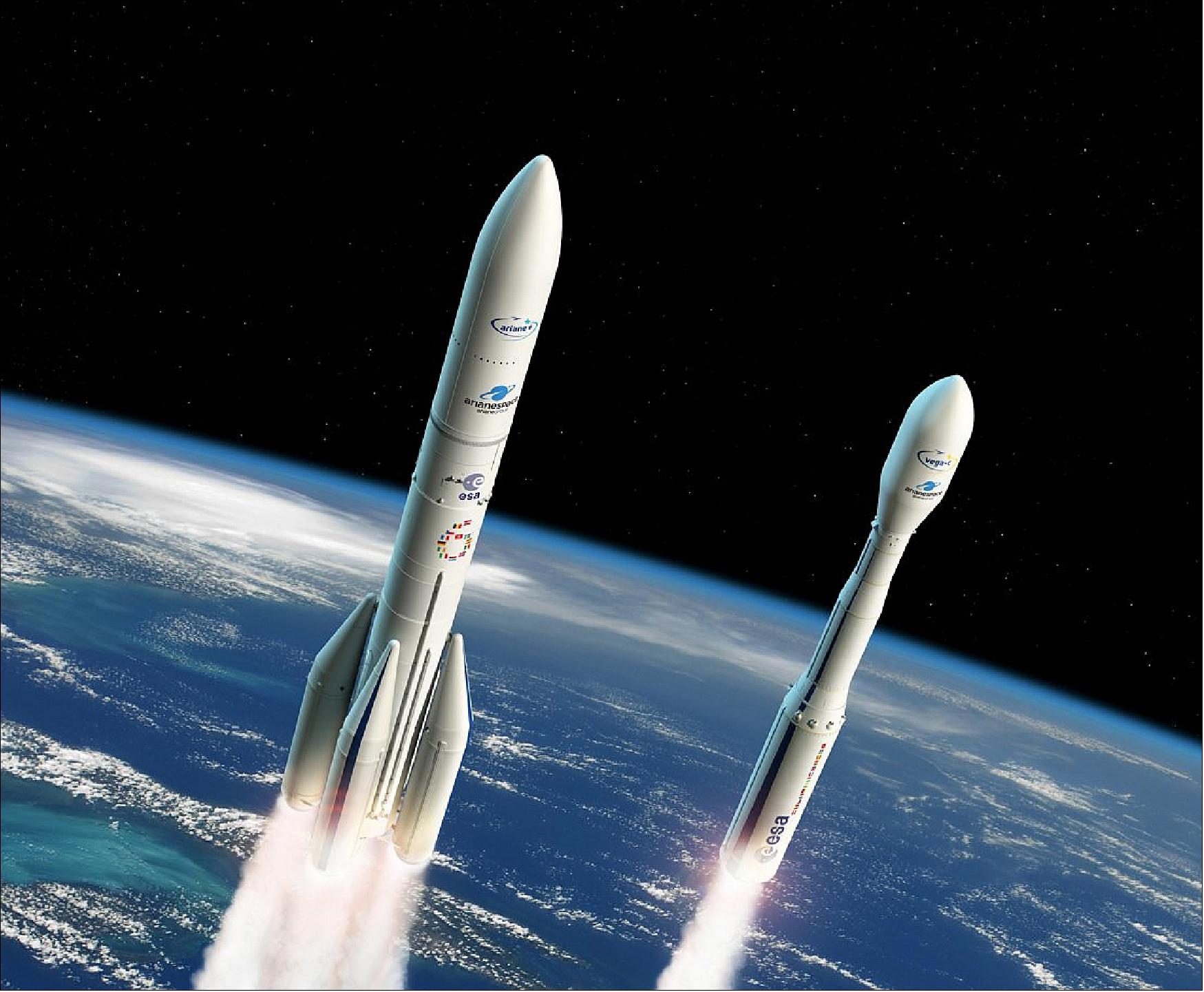

Ariane 6 provides a modular architecture using either two boosters (Ariane 62) or four boosters (Ariane 64), depending on the required performance. Two or four P120 solid-propellant boosters will be common with Vega-C, an evolution of the current Vega launcher.

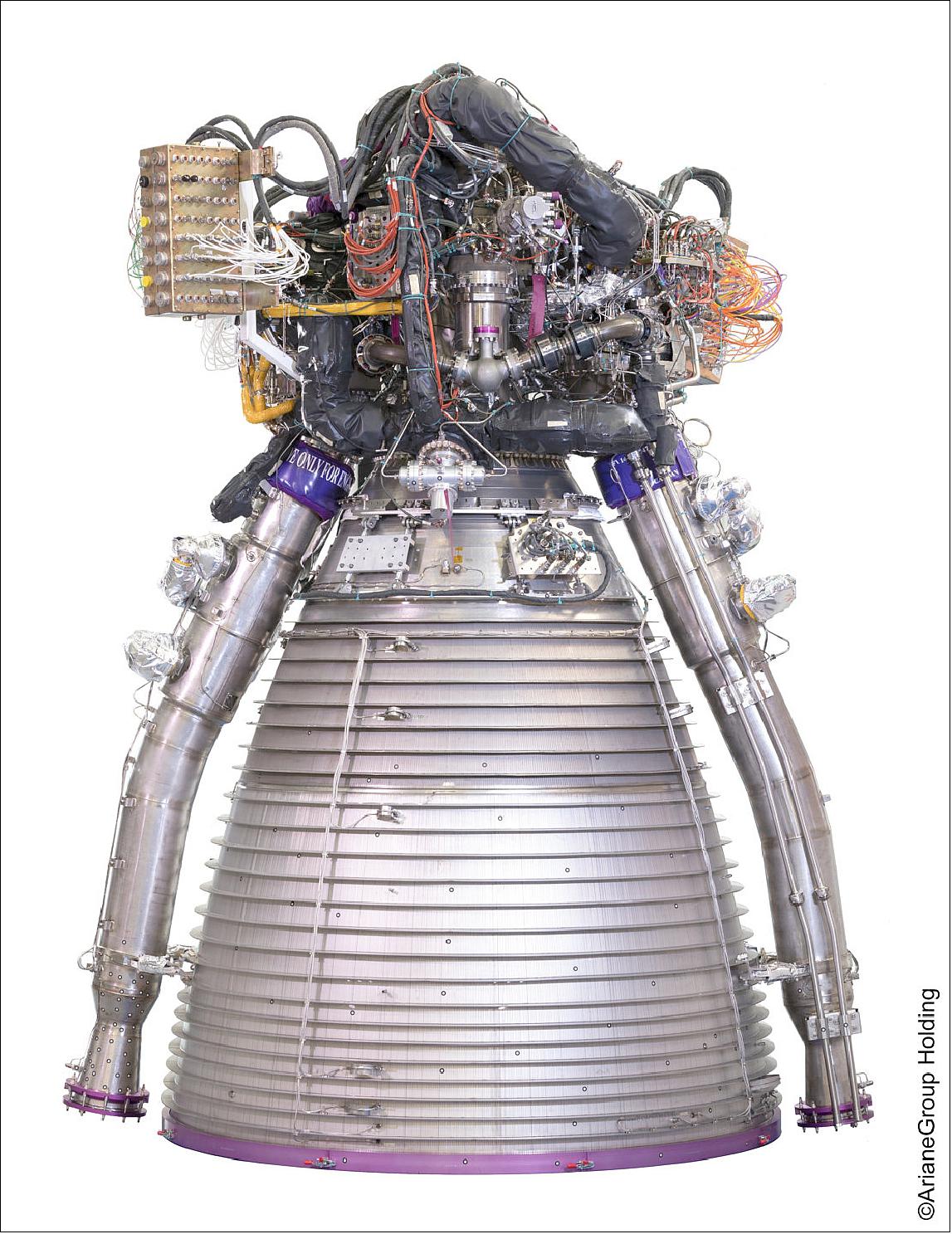

The main stage containing liquid oxygen and hydrogen is based around the Vulcain 2 engine of Ariane 5. The upper stage of Ariane 6 builds on developments for the Adapted Ariane 5 ME, and cryogenic propulsion using the Vinci engine. It will be restartable and have direct deorbiting features to mitigate space debris.

The main characteristics of the Ariane 6 concept are:

• The total length of the vehicle is about 62 m,

• The cryogenic main stage holds about 150 tons of propellants, the upper stage holds about 30 t,

• The external diameter of the cryogenic main stage and upper stages including the part that connects the fairing is about 5.4 m.

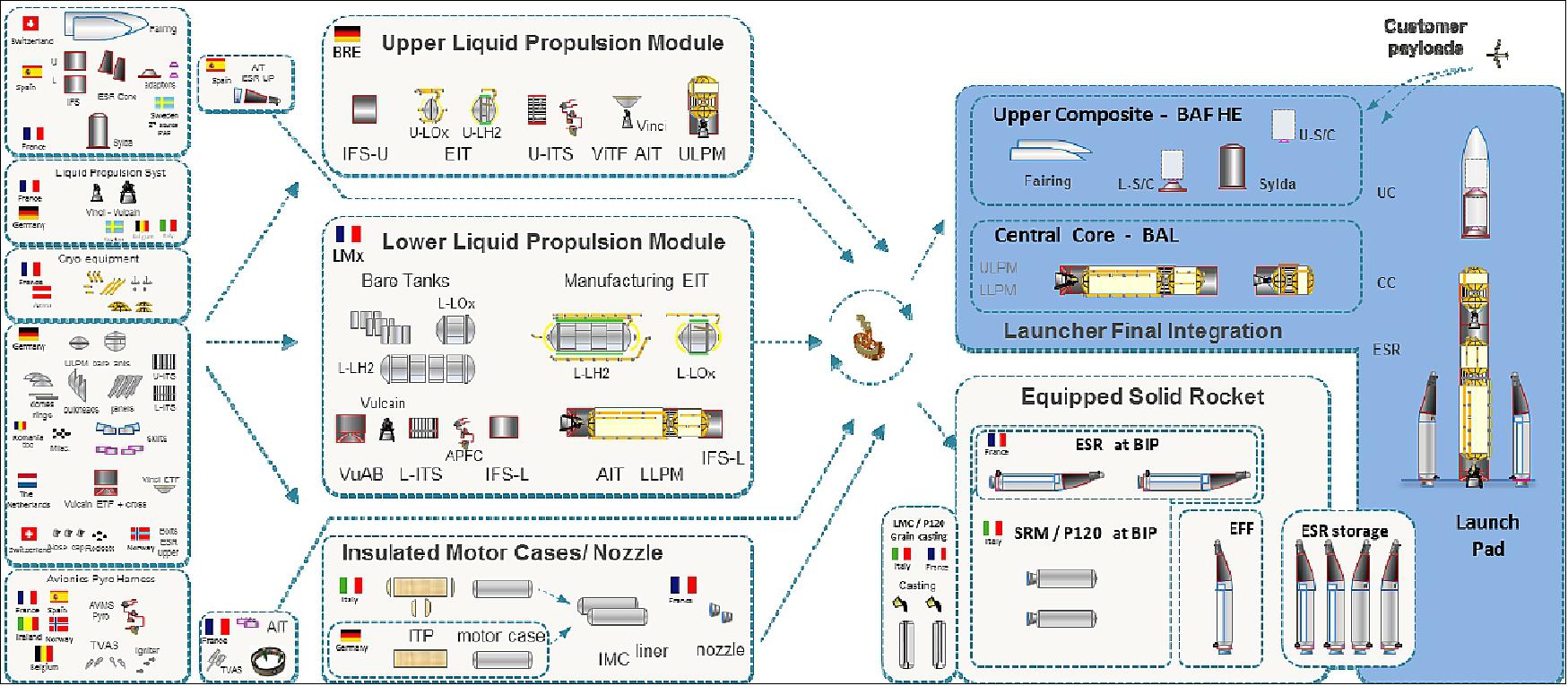

ESA is overseeing procurement and the architecture of the overall launch system, industry is building the rocket with ArianeGroup as prime contractor and design authority. An industrial cooperation agreement has been signed between ArianeGroup and Avio for the P120C solid motor.

The industrial prime contractors, CNES and ArianeGroup, who are responsible for the launch base and launcher respectively, have jointly agreed on developing a common family of test and control systems that will be used in Europe and French Guiana during the build, verification, integration and launch of Ariane 6.

The Ariane 6 launcher will provide Arianespace with new levels of efficiency and flexibility to meet customers’ launch services needs across a full range of commercial and institutional missions. To ensure Arianespace’s continued competitiveness, this next-generation launcher has been conceived for reduced production costs and design-to-build lead times, all while maintaining the quality and reliability that have made Ariane 5 an industry leader. 3)

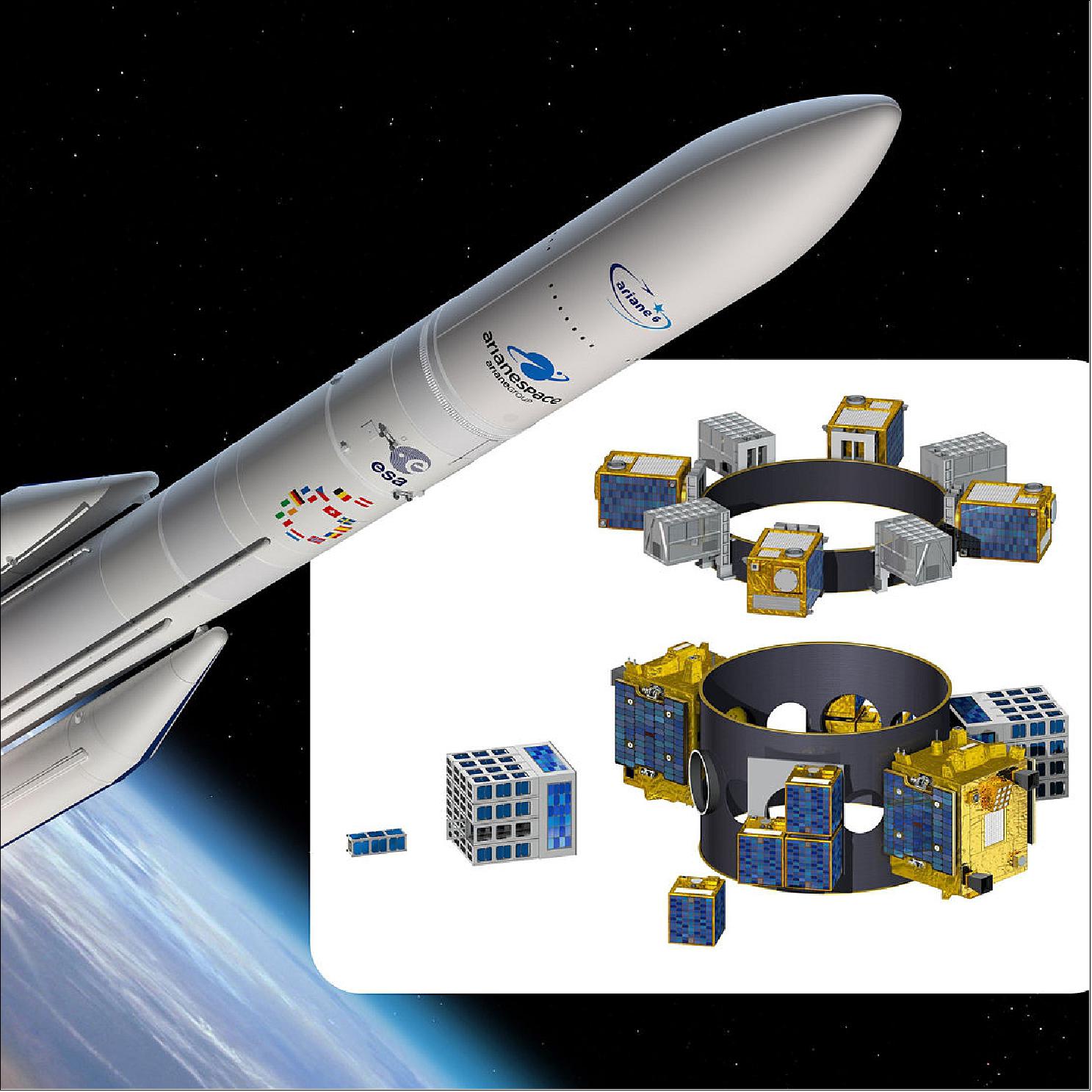

Ariane 6 features a modular configuration based on core stages powered by lower and upper liquid propellant modules, which that are supplemented by either two or four strap-on solid rocket motors. Enhancing Ariane 6’s competitiveness is the series production of its rocket engines and a technology-sharing approach with Arianespace’s Vega C – particularly this lightweight launcher’s P120 engine that also will be used in Ariane 6’s solid rocket motors.

ArianeGroup, formerly Airbus Safran Launchers, is prime contractor and design authority for Ariane 6, while ESA oversees procurement and architecture of the overall launch system. On 12 August 2015, ESA appointed Airbus Safran Launchers as principal contractor with the new development of the Ariane 6. On 1 July 2017, Airbus Safran Launchers changed its corporate name to ArianeGroup.

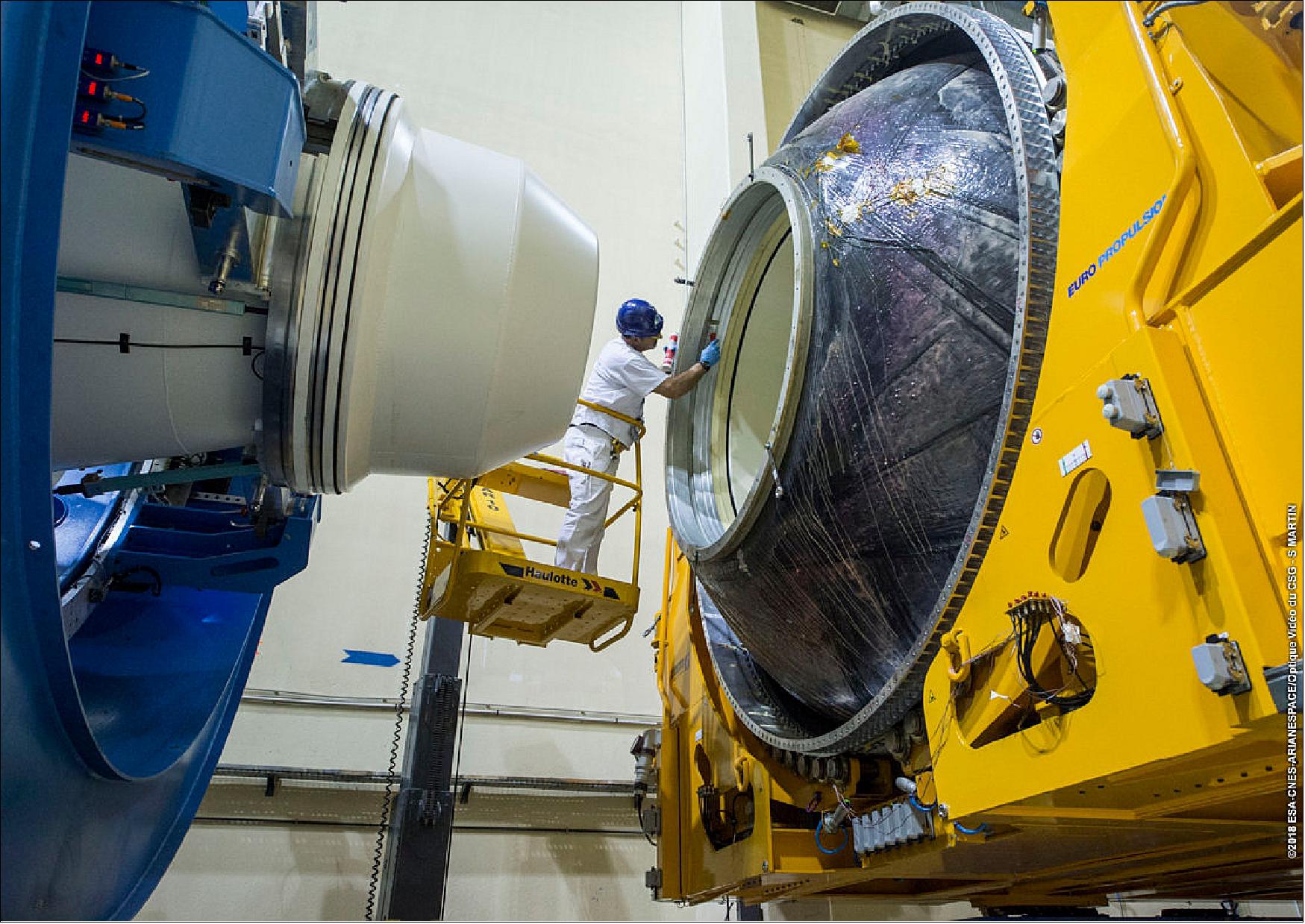

The industrial organization put into place for building Ariane 6 aims for maximum efficiency throughout the production cycle, up to delivery to the launch pad where, for greater flexibility, the payload is assembled on the launcher. The creation of European clusters of excellence allows to work with industrial partners via an extended enterprise approach, in order to standardise launcher methods and tools. The contribution of new industrial processes and innovative manufacturing technologies (3D printing, friction-stir welding, laser surface treatment, etc.), combined with a product lifecycle management system that meets the latest standards, helps optimize industrial level production. 4)

The overall goal is to achieve production costs 40 to 50% lower than those of Ariane 5 in order to be competitive in the face of new market demands. With the aim of ensuring continuity of independent European access to space, Ariane 6 should be making its first launch in 2020 and will be fully operational as of 2023, offering a level of reliability equivalent to that of Ariane 5.

Development Status

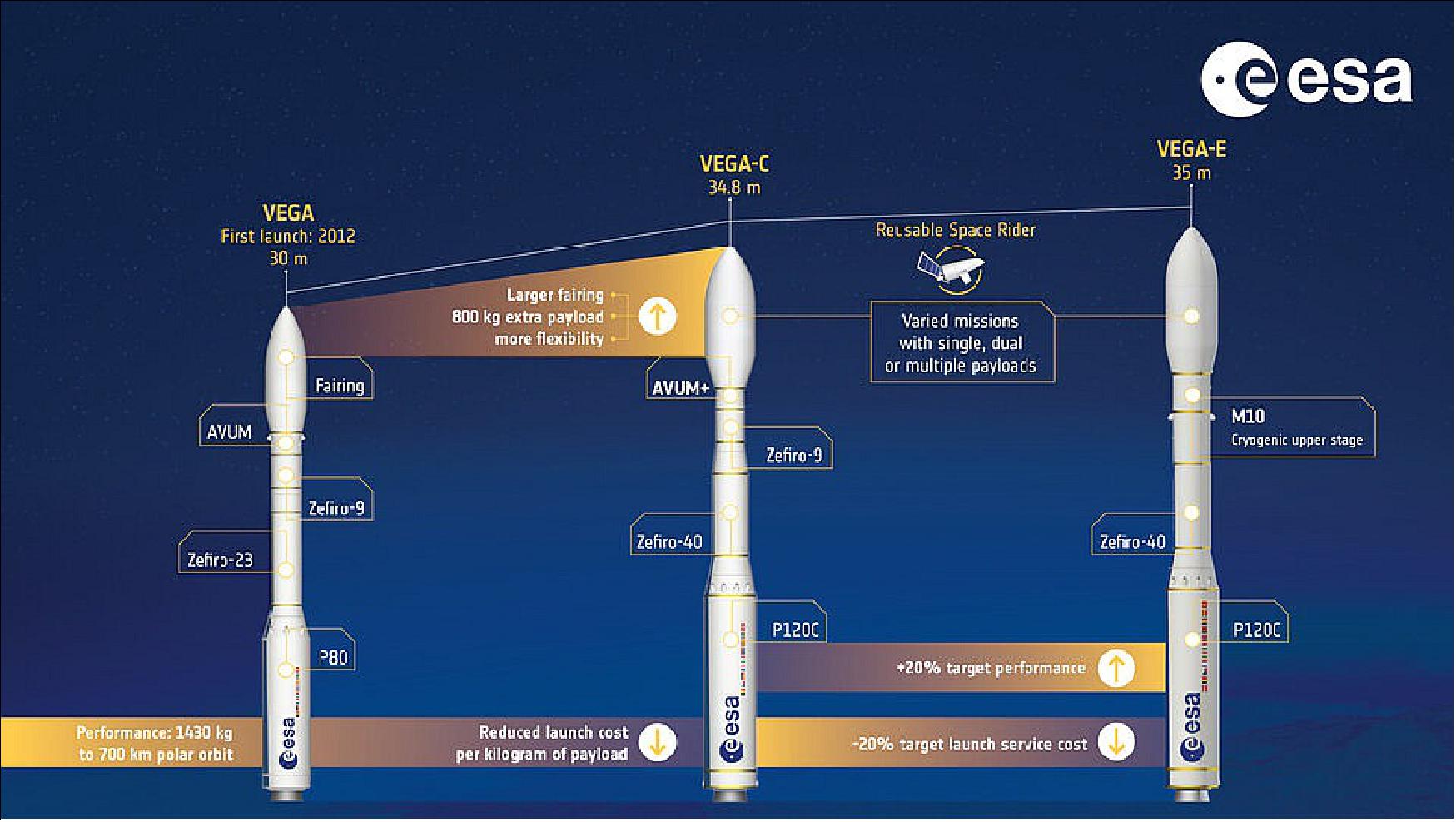

• July 13, 2022: ESA’s new Vega-C rocket has completed its inaugural flight, placing main payload LARES-2 – a scientific mission of the Italian Space Agency ASI – into its planned orbit. Six research CubeSats from France, Italy and Slovenia flew as secondary payloads. The launch caps a multi-year effort by ESA, prime contractor Avio and industrial partners in 13 ESA member states to build on the heritage of its predecessor, Vega. 5)

- Flight VV21 lifted off from Europe’s Spaceport in French Guiana at 15:13 CEST (13:13 UTC) on 13 July 2022 (10:13 local time). This mission lasted about 2 hours and 15 minutes from lift-off to release of final payload and final burn of the AVUM+ upper stage engine.

- Total payload mass at liftoff was approximately 474kg: 296 kg for LARES-2, with the remainder being the six CubeSats, payload adapters and carrying structures.

- Vega-C represents a dramatic capability boost compared to Vega, which has flown since 2012. With new first and second stages and an uprated fourth stage, Vega-C increases performance from Vega’s 1.5 t to about 2.3 t in a reference 700 km polar orbit.

- Overseeing launch operations from mission control at the Spaceport, ESA Director of Space Transportation Daniel Neuenschwander remarked: “Today we open a new era of European launch solutions, starting with Vega-C and to be complemented by Ariane 6.”

• July 12, 2022: The Ariane 6 launch pad at Europe’s Spaceport in French Guiana now hosts the first example of ESA’s new heavy-lift rocket. This Ariane 6 combined tests model will be used to validate the entire launch system during its ground phase in readiness for the inaugural launch of Ariane 6. 6)

- The combined tests include filling tanks, and draining them in case of launch abort, count-down automated sequence, and cryogenic arms disconnection and retraction at a simulated lift-off.

- These tests will be carried out under ESA’s authority by an integrated team from ESA, ArianeGroup and French space agency CNES.

- The Ariane 6 combined tests model is highly representative of the flight model. It consists of the core stage and the upper stage, which make up the central core, as well as three pylons shaped like the rocket’s solid boosters and a fully representative but inert mockup of the fourth booster.

- The Ariane 6 combined tests model central core was precisely mated in the purpose-built launcher assembly building, where this task is carried out horizontally. Automated guidance vehicles then brought the assembled core to the launch and, working with the crane at the mobile gantry, raised it to its vertical position.

- “This key milestone is a cornerstone of the validation of the Ariane 6 integration concept which was imagined at the very beginning of this wonderful adventure. Achieving it is a source of great pride and a terrific motivator for Ariane 6 teams”, says Jérôme Crubilhé, ESA Mechanical Engineer.

- Before receiving the central core, launch pad systems underwent a battery of tests to check the “cryogenic connection system” of umbilical cords carrying hydrogen and oxygen fuel – liquified at -253C and -183C respectively – that will keep the rocket topped up in the critical moments before liftoff. The system must also deliver helium and nitrogen used for flushing and purging.

- Critically, these systems are designed to remain connected to the rocket until nearly the moment of liftoff. The method demands careful choreography of large mechanical systems but brings several advantages by improving reliability and availability while eliminating some equipment that is not needed in flight. The net result is to reduce the rocket’s dry mass and recurring costs.

- Also, last-moment decoupling does away with some purging lines needed by Ariane 5, to reduce recurring costs and the dry mass of the rocket.

- Daniel Neuenschwander, ESA’s Director of Space Transportation, said: “I am delighted to see solid progress towards first flight. Ariane 6 marks a new era in reliable, competitive and autonomous European spaceflight.

- “Ariane 6 is also the foundation for a series of developments which will maintain Europe’s gateway to space into the 2030s.”

- Ariane 6 is a modular launch vehicle using either two or four P120C strap-on boosters, depending on mission requirements. The P120C engine does double duty, also serving as the first stage of ESA’s new Vega-C rocket.

- The reignitable Vinci engine which powers the upper stage allows Ariane 6 to deliver multiple payloads to different orbits on a single launch. After payload separation a final engine burn deorbits the upper stage so that it does not become a debris threat in space.

- Ariane 6 development is project-managed and funded by ESA, which also acts as launch system architect. ArianeGroup is design authority and industrial prime contractor for the launcher system and CNES is prime contractor for the Ariane 6 launch base at Europe’s Spaceport. Arianespace is the launch service provider of Ariane 6.

• July 8, 2022: The Vega-C Payload Assembly Composite (PAC) with LARES-2 has been rolled out to the Vega Launch Zone (ZLV) and hoisted onto the Vega-C launch Vehicle on 7 July 2022 at Europe's Space Port in Kourou, French Guiana. 7)

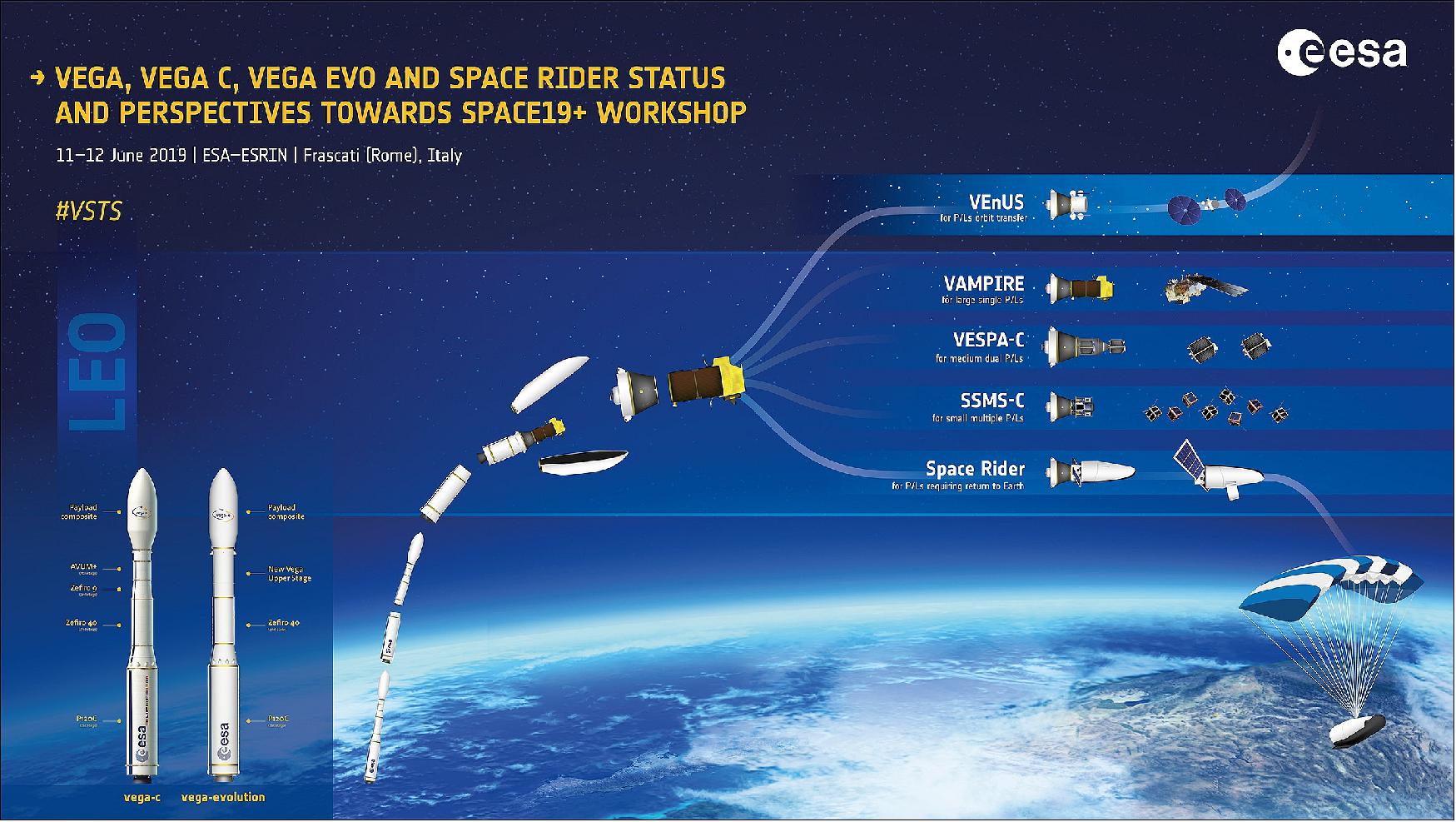

- On the wave of Vega’s success, Member States at the ESA Ministerial meeting in December 2014 agreed to develop the more powerful Vega-C to respond to an evolving market and to long-term institutional needs.

- Vega-C increases performance from Vega’s current 1.5 t to about 2.2 t in a reference 700 km polar orbit, covering identified European institutional users’ mission needs, with no increase in launch service and operating costs.

- The participating states in this development are: Austria, Belgium, the Czech Republic, France, Germany, Ireland, Italy, the Netherlands, Norway, Romania, Spain, Sweden and Switzerland.

• June 16, 2022: As the European Space Agency prepares to begin operations of its next-generation Vega-C and Ariane 6 launch systems complemented by the reusable Space Rider orbital transportation system, work is underway to define the future of European space transportation capabilities for the coming decade and beyond. 8)

- ESA, together with partners, is elaborating a vision of the future of space transportation in Europe. The objective is to identify the activities required to unleash Europe’s technological potential as a global competitor, with an industrial landscape that fosters innovation and drives cost reduction.

- Identifying critical technologies is a key feature of this approach.

- Work has been underway since summer 2021 to identify features of a future European space transportation infrastructure. The next phase will be to define a technology roadmap that allows ESA, Europe’s national space agencies and institutions, and both established and start-up space companies to match the intense technical and commercial competition coming from the USA, China, Russia and India.

- More than 100 representatives of Europe’s space sector are preparing to gather on 28 June in Palermo, Sicily for an intensive series of roundtable discussions.

- Giorgio Tumino, ESA’s Chief Technical Advisor for Space Transportation, is leading the elaboration of this vision and organising the Palermo gathering, called “Shared Vision for the Future of Space Transportation in Europe”.

- Critically, he says, concepts for a “Vision 2030+” must be discussed independently of the needs and constraints of existing programmatic frameworks. “We need to think about the future without being held back by the parameters of today,” he says.

- Encouragingly, he adds, work done so far has been supported by technical experts from institutions of ESA’s Member States: “There are elements for a vision of the future from the technical and technological perspective.”

- One key focus of the Palermo meeting is to share ESA’s Vision 2030+ with industry and consolidate a technology development strategy, because it is important to define coordinated actions by Europe’s institutions and companies. 2030, he notes, is coming soon – it is the “next step, not the step after the next”.

- Following the Space Summit held in Toulouse in February 2022, another focus is to share the steps ESA is taking to prepare an informed decision on human exploration, including human space transportation capabilities in Europe, as these may become an additional dimension of Vision 2030+. At Palermo, discussions will grapple with the question of competition versus cooperation between institutional and private-sector actors spread across many European countries.

- ESA, its national partners and other European institutions which rely on space services may also need to redefine their roles. Going from being project leaders – the traditional role of a space agency – to project enablers means learning to work with private sector actors and their objectives, rather than hiring them to fulfil a specified mission.

- That new role may see agencies work to de-risk ambitious technology development efforts to smooth the path from concept to reality. Agencies may also need to act as “anchor customers” to ensure a coordinated European procurement of end-services by, for example, guaranteeing a minimum yearly order.

- In that context, Tumino says, an important objective of the Palermo gathering will be to identify where to focus resources for the best return on investment.

- Daniel Neuenschwander, ESA’s Director of Space Transportation, says the event in Palermo will be a unique opportunity to share objectives and work with European stakeholders to further elaborate Vision 2030+ in preparation for November’s ESA Council at Ministerial Level. “Our objective is to identify the paths we need to follow to unleash European technological potential and position Europe as a key space power in a competitive global space sector,” he says.

- The final event programme and list of roundtable participants is now available at: https://www.roundtable-spacetransportation.com/. Interested participants should register to attend by 19 June 2022.

• June 16, 2022: ESA’s new medium-lift Vega-C rocket is nearly ready for its inaugural flight, with its four fully-stacked stages now ready for payload integration, final checks and launch from Europe’s Spaceport in French Guiana. 9)

- Flight VV21 will lift off as soon as 7 July, pending suitable conditions for launch.

- Vega-C represents a dramatic capability boost compared to its predecessor, Vega, which has flown since 2012. With new first and second stages and an uprated fourth stage, Vega-C increases performance from Vega’s 1.5 t to about 2.2 t in a reference 700 km polar orbit.

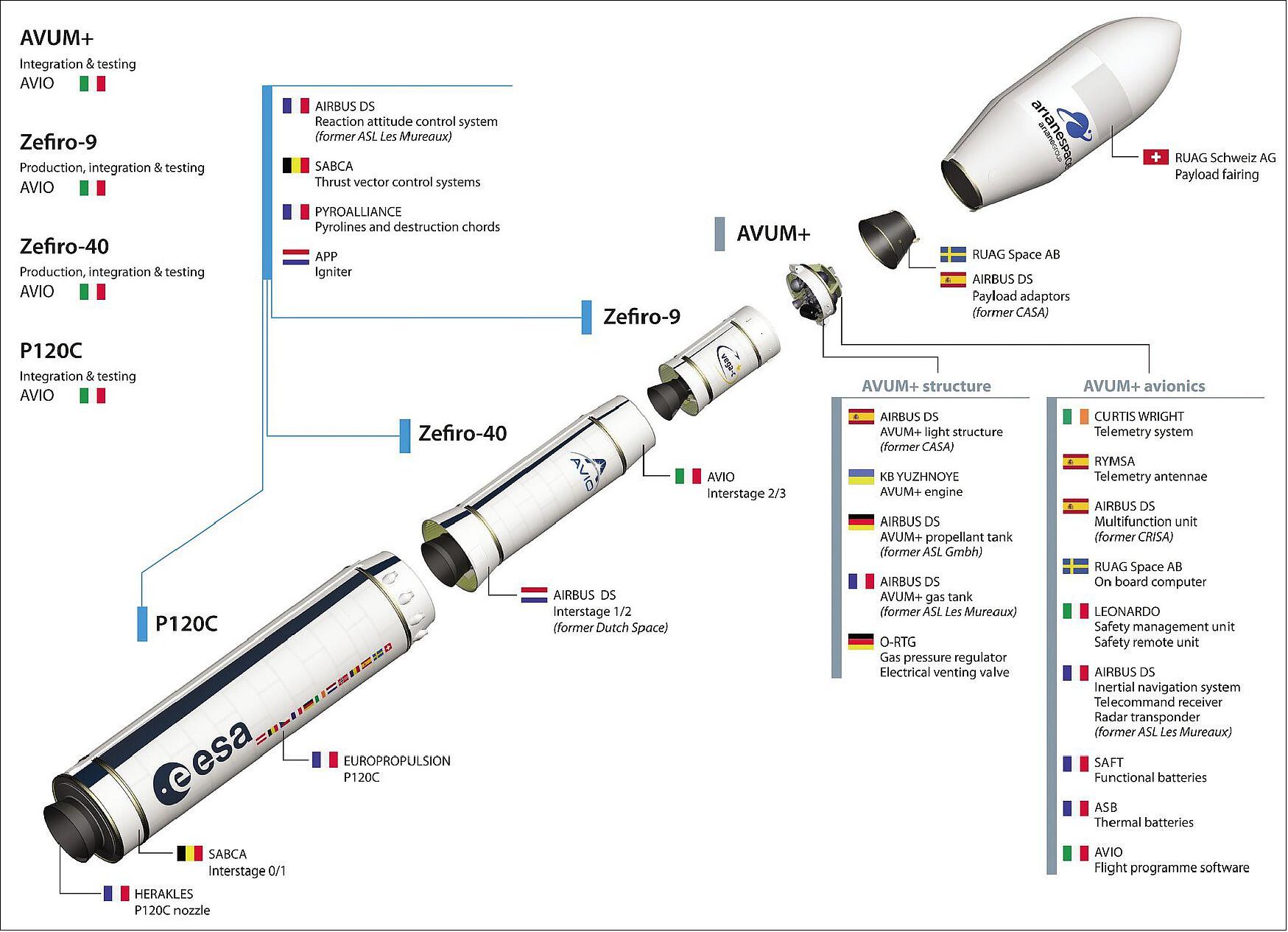

- Vega-C features a new, more powerful first stage, P120C, based on Vega’s P80. Atop that is a new second stage, Zefiro-40, and then the same Zefiro-9 third stage as used on Vega.

- The re-ignitable upper stage is also improved. AVUM+ has increased liquid propellant capacity, to deliver payloads to multiple orbits depending on mission requirements and to allow for longer operational time in space, to enable extended missions.

- The P120C motor will do double service, with either two or four units acting as strap-on boosters for Ariane 6. Sharing this component streamlines industrial efficiency and improves cost-effectiveness of both launchers.

- With its larger main stages and bigger fairing – which doubles the payload volume compared to Vega – Vega-C measures 34.8 m high, nearly 5 m taller than Vega.

- The new launcher configuration delivers a significant improvement in launch system flexibility. Vega-C can orbit larger satellites, two main payloads or can accommodate various arrangements for rideshare missions. ESA’s upcoming Space Rider return-to-Earth vehicle will be launched to orbit on Vega-C.

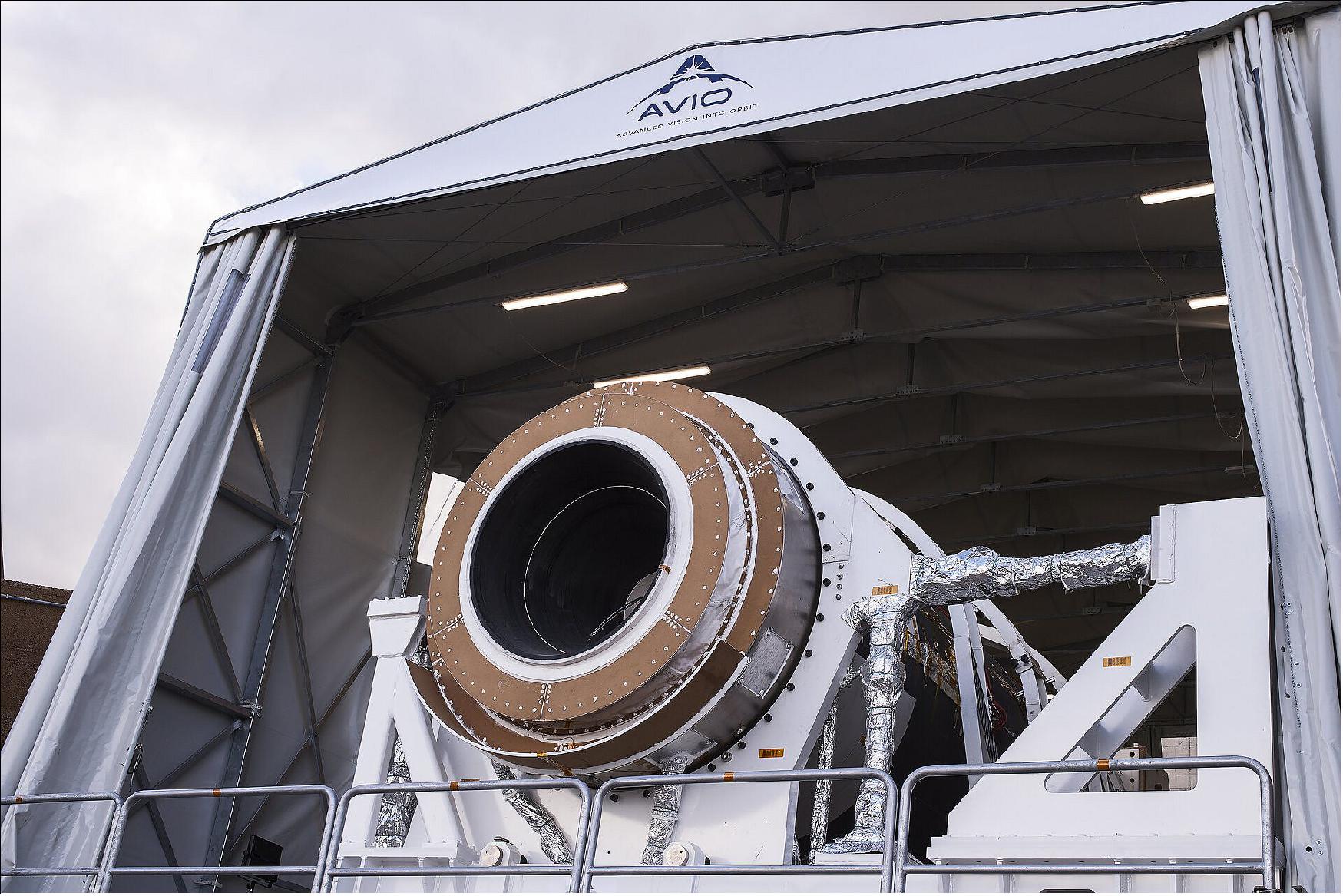

• April 26, 2022: Launcher integration for the inaugural flight of Vega-C began with the P120C solid-fuel first stage being delivered to the Vega Launch Zone (Zone de Lancement Vega, or ZLV) at Europe's Spaceport in Kourou, French Guiana on 15 April 2022. P120C will also fly on Ariane 6, with two or four units serving as boosters depending on mission requirements. 10)

- The interstage segment to join the P120C first stage with the Z40 second stage followed on the 22nd.

- For flight VV21, the principal payload will be LARES-2 (Laser Relativity Satellite-2), a scientific mission of the Italian Space Agency (ASI). Also onboard will be six European research CubeSats.

- Following Vega’s success, Member States at the ESA Ministerial meeting in December 2014 agreed to develop the more powerful Vega-C to respond to an evolving market and long-term institutional needs.

- Vega-C increases performance from Vega’s 1.5 t to about 2.2 t in a reference 700 km polar orbit and increases the available payload volume, covering identified European institutional users’ mission needs with no increase in launch service and operating costs.

- The participating states in this development are: Austria, Belgium, the Czech Republic, France, Germany, Ireland, Italy, the Netherlands, Norway, Romania, Spain, Sweden and Switzerland.

• April 5, 2022: Arianespace and Amazon sign agreement for 18 Ariane 6 launches, the largest ever both for Arianespace. — The highest performing version of Ariane 6, Ariane 64, will be used over three years to orbit satellites of the Project Kuiper broadband constellation. 11)

- Arianespace and Amazon (NASDAQ: AMZN) announced an unprecedented launch service contract during the International Space Symposium in Colorado Springs, USA, on April 5. Under the terms of the contract, Arianespace will perform 18 Ariane 6 launches for Amazon’s Project Kuiper over a period of three years from Europe’s Spaceport in French Guiana. Among the 18 launches planned for the deployment of the Project Kuiper, 16 will be carried out with an advanced version of the Ariane 64.

- Stéphane Israël, CEO of Arianespace, declared: “This contract, the largest we’ve ever signed, is a great moment in Arianespace’s history. We are honored to be given a significant role to play in the deployment of Amazon’s Project Kuiper, which aims to connect tens of millions of people to the internet. It will build on the European innovative spirit, industrial might, and years of experience of the Ariane partners. That Amazon has chosen the Ariane 6 to do the job is a matter of tremendous pride for us and a great vote of confidence for our new launch vehicle. This day marks a decisive success for the Ariane 6 Program and all its value chain in Europe.”

- Arianespace is renowned for its competence in deploying institutional and commercial satellite constellations. For this contract, Arianespace will rely on the Ariane 64 vehicle, the highest performing European launcher which is perfectly tailored for the demanding work of deploying constellations. Ariane 6 will enter service and replace the Ariane 5 as Arianespace’s heavy lift workhorse.

- The versatility, high capability, and expected reliability of the Ariane 6 played a key role in securing this agreement with Amazon for the Project Kuiper. Ariane 6 has been designed from the outset to be scalable and able to integrate, during its life and on a regular basis, new technologies. Out of the 18 A64 launches, 16 A64 will benefit from an increase in the power of the P120C solid boosters (called “P120C+” version). Ariane 6’s incremental development is intended to regularly improve the performance of the launch solutions offered by Arianespace and always better fulfil the needs of both institutional and commercial customers. These developments are funded and managed by the European Space Agency (ESA) and implemented by Ariane 6’s launcher system prime contractor ArianeGroup.

- Amazon’s Project Kuiper aims to connect the unconnected, providing high-speed, low-latency broadband to unserved and underserved communities across the globe at affordable rates. Homes, schools, hospitals, businesses, governments, and institutions that lack access to connectivity could soon have it through Project Kuiper.

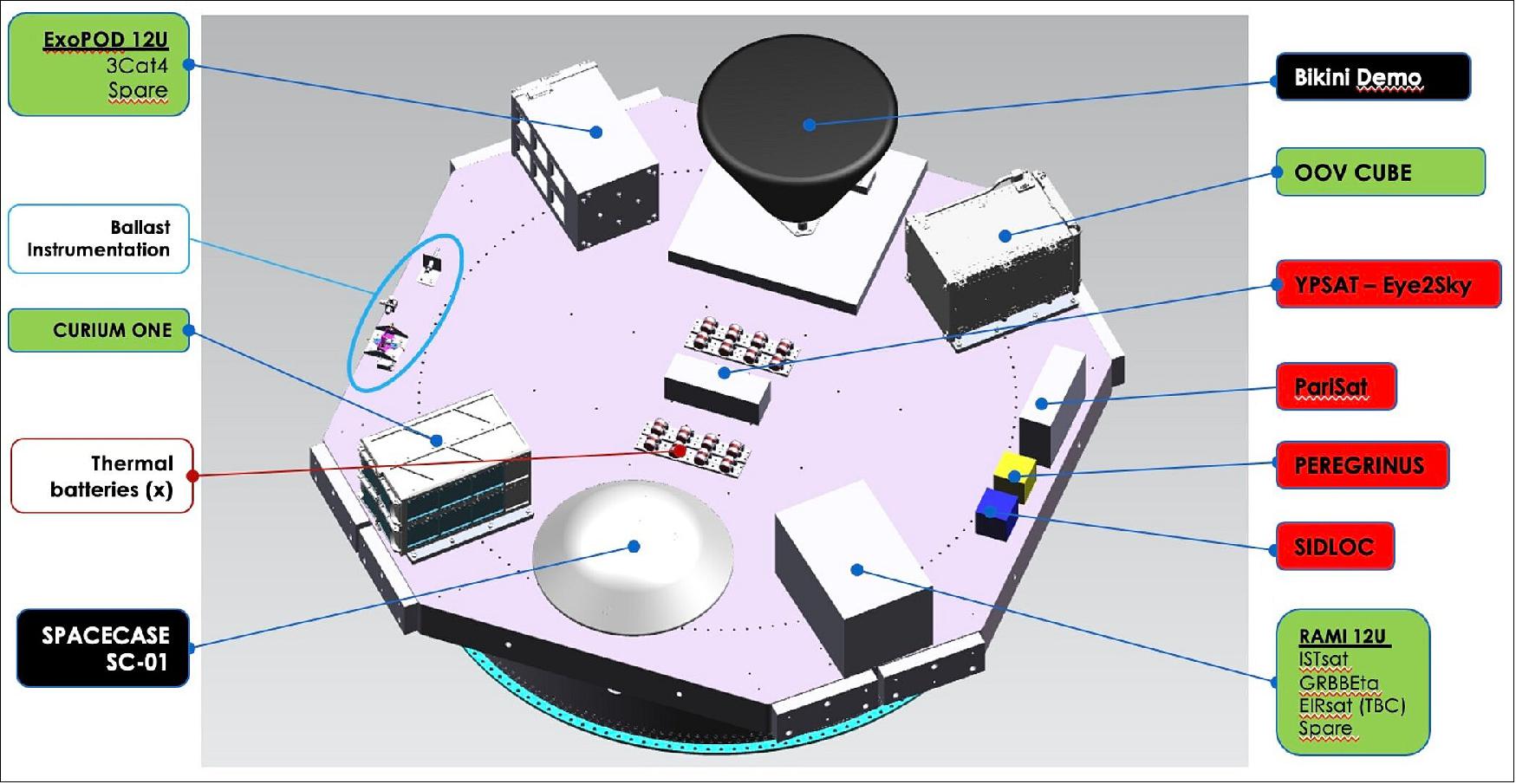

• February 11, 2022: ESA in close collaboration with ArianeGroup and Arianespace has selected payloads which best fit the profile of the first mission of its new generation Ariane 6 launch vehicle from Europe’s Spaceport in French Guiana. 14)

This selection follows ESA’s announcement of opportunity in November 2021, which offered a launch to low Earth orbit for experiments up to a total mass of 80 kg and release of payloads with a combined mass of up to 800 kg. They will be hosted on a ‘mass dummy’ featuring a large platform, inside the 14 m long version of the fairing on an Ariane 6 fitted with two strap-on boosters (A62 version).

This demonstration flight will contribute to the qualification of the Ariane 6 launch system as part of the transition from its highly reliable and successful predecessor, Ariane 5. This launch is an important step in the preparation for future institutional missions planned for Ariane 6, such as Galileo.

For this flight, ESA is responsible for operations from the launch campaign to the payload separation, and then disposal of the upper stage through burn-up during reentry.

“I’m glad that ESA can use the very first Ariane 6 flight as a platform for launching these fantastic payloads, some of which will enable European start-ups to validate their systems and provide future commercial services. The Ariane 6 inaugural launch is a key step towards full qualification of the Ariane 6 launch system,” said Daniel Neuenschwander, ESA Director of Space Transportation.

Experiments Onboard

Organisation | Country | Payload | Description | Mass (kg) |

Garef Aerospatial | France | PariSat | Thermal equilibrium of an array to confirm | ≤12 |

Sint-Pieterscollege | Belgium | Peregrinus | Dual sensor magnetic field | ≤ 0.5 |

Libre Space | Greece | SIDLOC | In-orbit demonstrator Radio Frequency beacon | ≤ 0.15 |

ESA | - | ESA YPSat – Eye2Sky | Photo and video footage | <3 |

Organisation | Country | Payload | Description | Mass (kg) |

PTS | Germany | CuriumOne | with a duplicate ASTRIS Engineering Qualification | ≤24.5 (AstroFein |

TU Berlin | Germany | OOV-Cube | Microsatellite – IoT agriculture use case demo | ≤17( AstroFein |

ESA Education Office | Spain | 3Cat4 | 1U CubeSat – Techno demo Flexible | 1.3 |

ESA Education Office/ | Portugal | ISTSAT | 1U CubeSat – Characterisation of aircraft’s ‘cone | 1.3 |

Spacemanic | Slovakia | GRBBeta | 1U CubeSat – Gamma Ray Burst detection | 1.3 |

ArianeGroup | France | SpaceCase SC-X01 | Test platform for reentry technologies such as new-generation | ≤43, (separated: 40) |

The Exploration Company | France, Germany | Bikini Demo | First passive, small-scale demonstrator of a reentry capsule | ≤26 (separated: 20) |

Deployers

Two deployers will be arranged on board and will accommodate CubeSats. The RAMI deployer is built by Spain’s UARX Space, and the ExoPOD is built by ExoLaunch, Berlin, Germany.

With some spaces for CubeSats still available, ESA may add to this collection closer to launch.

Ariane 6 is a modular launch vehicle using two or four P120C strap-on boosters to achieve the required performance. The reignitable Vinci engine powers the upper stage which allows Ariane 6 to reach a range of orbits to deliver more payloads on a single launch. The upper stage engine will typically burn one, two or more times to reach the required orbits. After payload separation a final burn deorbits the upper stage to mitigate space debris.

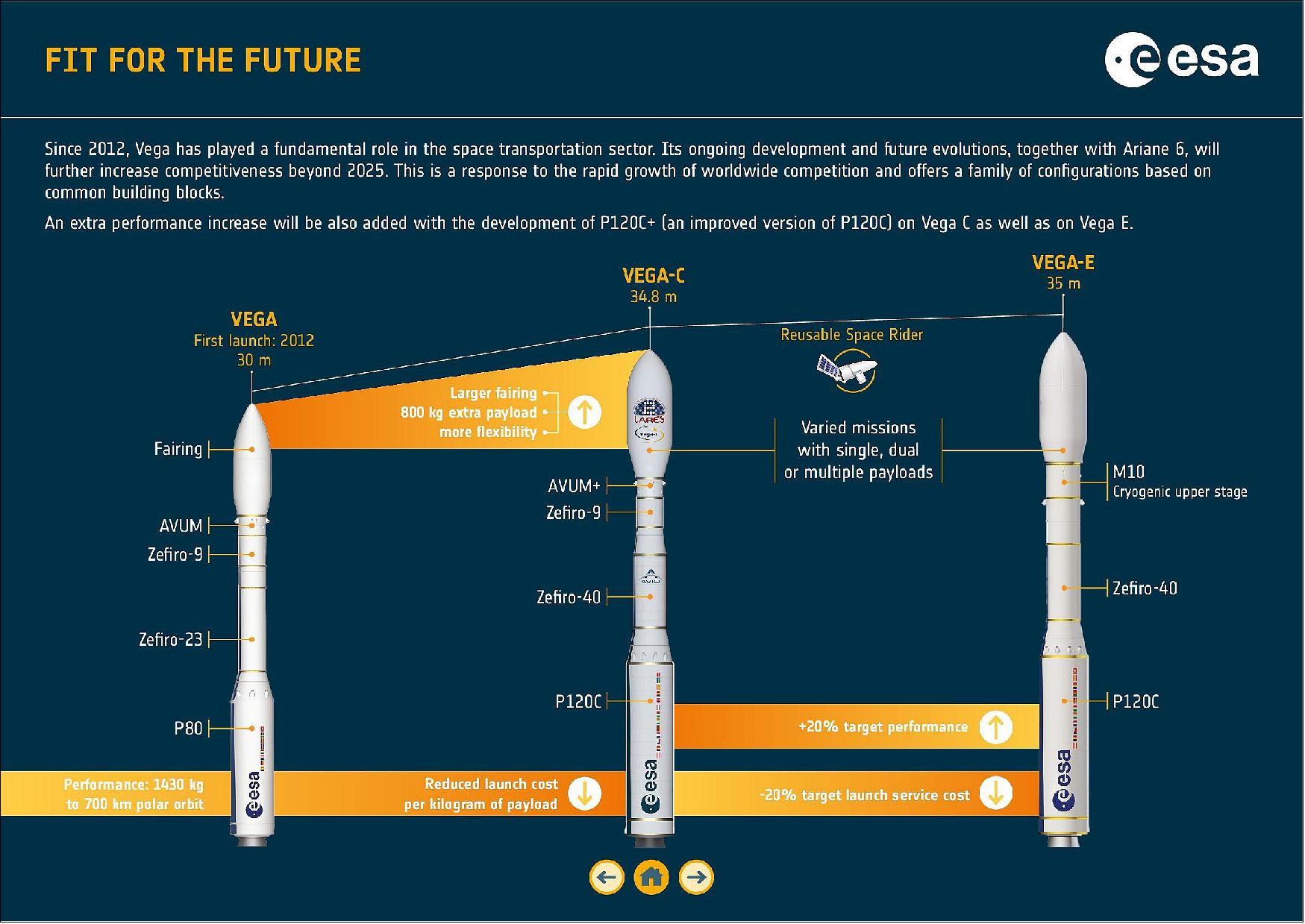

• February 11, 2022: Ten years ago this week, 13 February 2012, ESA opened a new era of independent access to space with the flawless inaugural flight of its small launcher Vega. Flying from Europe’s Spaceport in French Guiana, Vega has gone on to earn a reputation for precision and versatility in anticipation of a more capable version, Vega-C. 15)

- Placing medium-sized satellites into the low Earth polar orbits that are ideal for scientific and Earth observation missions – about 1430 kg to 700 km – is Vega’s trademark capability. But the vehicle has also delivered an ESA science mission to deep space – the gravitational wave detector demonstration mission, LISA Pathfinder – and followed the equatorial flight path needed for an experimental IXV ‘lifting body’ payload that paved the way for a European launchpad-to-runway space transportation service, with ESA’s uncrewed Space Rider vehicle.

- Vega has also mastered ‘ride sharing’, to cost-effectively put multiple satellites into orbit on a single flight. This launch vehicle has set the stage for the imminent first flight of a bigger, more capable variant, Vega-C – delivering more payload and greater flexibility for the same cost. And, with its industrial partners, ESA is developing a further evolution, Vega-E, to reduce programme costs while boosting performance.

- For Vega’s inaugural flight, VV01, the Italian space agency, ASI, supplied the principal payload, LARES (LAser RElativity Satellite).

- VV01 capped more than a decade of work on a small vehicle to complement ESA’s heavy lifter, Ariane 5, and the upcoming Ariane 6. ESA and Arianespace partly filled that gap by bringing the medium-lift Soyuz rocket to French Guiana from 2011.

- But the breakthrough was Vega which became an ESA programme in 2000. Seven Member States contributed: Belgium, France, Italy, the Netherlands, Spain, Sweden and Switzerland. ESA, with the technical support of the Italian and French space agencies, and about 40 industrial companies coordinated by the prime contractor Avio, made this enormous challenge a reality.

- About 1000 individuals were involved in the Vega development. “Vega is above all a human adventure built on a great European team, built on competence and cooperation, relying on outstanding dedication and effort,’’ said Stefano Bianchi, Head of Flight Programmes. “For all the engineers and operators who worked so hard to prepare the launch, the 13 February 2012 is a day that will always remain deeply rooted in their memories, as it is in mine.’’

- Vega combines three solid-fuel stages with a fourth, liquid-fuelled stage. Solid fuel motors cannot be throttled, stopped or restarted – after ignition they burn at full-power until the fuel runs out – but they provide exceptional liftoff thrust without the tanks, fuel pumps and fuel handling infrastructure needed for liquid propellants. These economical motors can be manufactured and fuelled in advance to be safely stored until needed for launch.

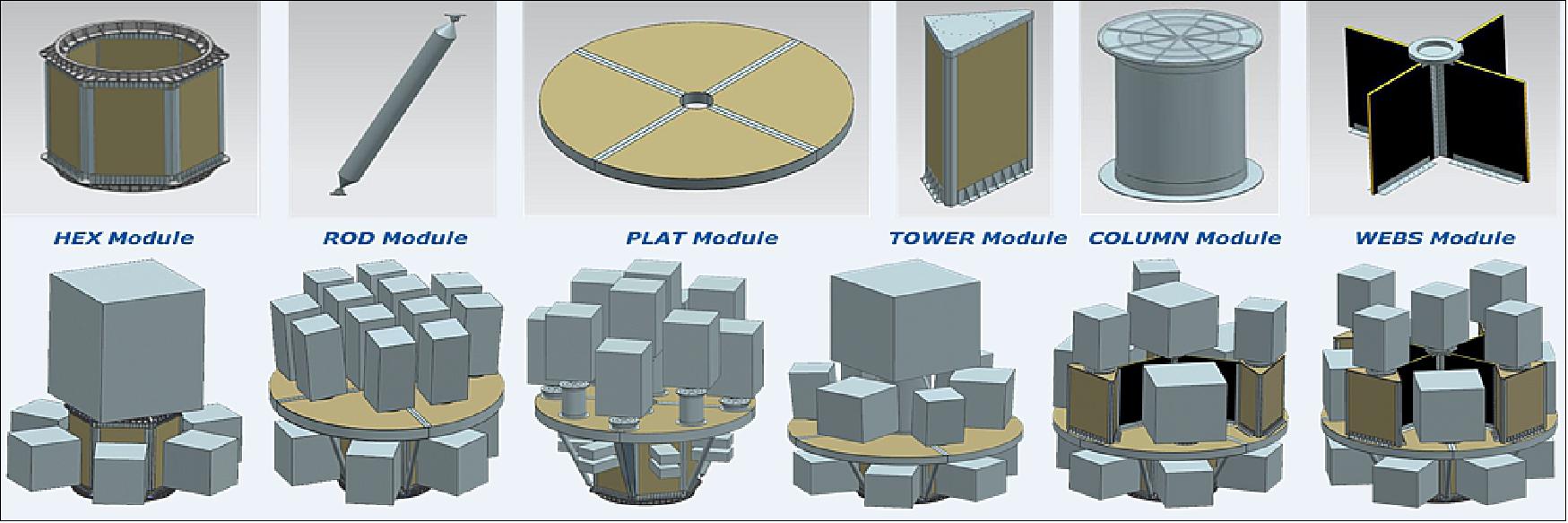

- The liquid-fuelled fourth stage provides fine control of position thanks to its stop-start-throttle capabilities, so Vega can accurately deliver single or multiple payloads to different orbits on one launch. This flexibility was demonstrated on flight VV16 in September 2020, when Vega first carried its Small Spacecraft Mission Service (SSMS) dispenser for light satellites. The ride share mission orbited seven microsatellites and 46 cubesats.

Continuous Development

- Since 2012, Vega has played a fundamental role in the space transportation sector and its ongoing development and future evolutions, together with Ariane, will further increase competitiveness beyond 2025. This is a response to the rapid growth of worldwide competition and offers a family of configurations based on common building blocks.

- While Vega team members will surely take a moment today to reflect on a memorable decade, their focus is on the future – and the inaugural flight of Vega-C.

- “Vega-C is now in the last phase of its qualification – a crucial step towards its inaugural flight,’’ commented Renato Lafranconi, Vega Programmes Manager. “Its development is driven by the rapidly growing worldwide competition in the Space Transportation sector which requires the continuous improvement of the Vega launch system versatility and competitiveness to ensure its sustainability.’’

- Like Vega, Vega-C features three solid-fuel stages and a liquid-fuelled fourth stage. But Vega-C brings two great improvements. One is an extra 800 kg payload capacity – an increase of more than a third, to about 2.2 tonnes – but for a similar launch cost.

- Vega-C features a new, more powerful first stage, P120C, based on Vega’s P80. Atop that is a new second stage, Zefiro-40, and then the same Zefiro-9 third stage as used on Vega. The new AVUM+ fourth stage can remain operational in space for longer than Vega’s AVUM, to enable extended missions.

- With its larger main stages and bigger fairing, Vega-C measures 34.8 m high, nearly 5 m taller than Vega.

- Equally important is another Vega-C innovation. Its P120C first stage will do double service, with either two or four of these acting as strap-on boosters for Ariane 6. By coordinating Vega-C and Ariane 6 development, ESA and its partners are realising a strategy of continuous, agile development. Vega-E, for example, is being readied to add another 20% payload capability while reducing costs, from as soon as 2025.

- ESA’s Director of Space Transportation Daniel Neuenschwander observes, “Major ongoing development programmes with Ariane 6 and Vega-C will allow Europe to maintain its independent access to space, which is a strategic priority in a world where technology, business and politics move very quickly.”

- “We have to keep pushing forward, to make sure Europe is ready for the future.”

• January 28, 2022: The lower stage of ESA’s next-generation Ariane 6 launch vehicle has been installed on the assembly line at Europe’s Spaceport behind the upper stage. It is now time to join the two horizontally to create the central core of Ariane 6 in readiness for the first combined tests on the launch pad. 16)

- The arrival from Europe of Ariane 6’s central core in French Guiana is a major milestone and an exciting step forward in the path to first flight as it allows combined tests to start. From arrival to hot-firing tests on the launch pad, operational procedures will mimic an Ariane 6 launch campaign.

- The lower stage is from ArianeGroup’s Les Mureaux site in France. Fitted with an additional two or four solid rocket boosters it is designed to power Ariane 6 in the first 10 minutes of flight to about 200 km, delivering about 135 tonnes of thrust in vacuum. The core stage is powered by the liquid-fuelled Vulcain 2.1 – an upgraded engine derived from Ariane 5’s Vulcain 2.

- The Ariane 6 upper stage, built in ArianeGroup’s Bremen factory in Germany, allows Ariane 6 to reach a range of orbits on a single mission to deliver more payloads.

- The upcoming tests verify all the interfaces and functions between the Ariane 6 launch vehicle and ground facilities of the new Ariane 6 launch complex at the spaceport. Reaching this phase of activities is the result of intense preparation by ESA and its partners in Europe and at Europe’s Spaceport.

• January 21, 2022: The central core of ESA’s new generation Ariane 6 launch vehicle arrived at Europe’s Spaceport on 18 January and is now inside the launch vehicle assembly building. 17)

- Ariane 6’s central core comprises a lower stage and upper stage. The lower stage is from ArianeGroup’s Les Mureaux site in France; the upper stage is from ArianeGroup’s Bremen factory in Germany.

- Upon arrival by boat at Pariacabo harbour, two containers were transported by road to the new Ariane 6 launch vehicle assembly building – part of the Ariane 6 launch complex at Europe’s Spaceport. Here, the rocket stages were unpacked and installed on the assembly line machinery for horizontal integration, to form the Ariane 6 central core. After this, they will be used in ‘combined’ tests which will verify all the interfaces and functions between the Ariane 6 launch vehicle and ground facilities at the spaceport.

- From arrival to hot-firing tests on the launch pad, operational procedures will follow as closely as possible those for any Ariane 6 launch campaign.

• January 18, 2022: The central core of ESA’s new generation Ariane 6 launch vehicle has arrived in French Guiana from Europe. This enables combined tests at Europe’s Spaceport where Ariane 6 parts will come together on the launch pad for the first time. 18)

- “To have Ariane 6 at Europe’s Spaceport is tremendously exciting. This is a major milestone, the culmination of intense preparation by ESA and partners in Europe and at Europe’s Spaceport, and an important step towards proving Ariane 6 is ready for flight,” commented Daniel Neuenschwander, ESA Director of Space Transportation.

- Ariane 6 will be capable of carrying out all types of missions to all orbits thanks to its multiple reignition capability and modular design. Using two or four boosters to suit the required performance, this new launch vehicle further extends and secures Europe’s independent access to space.

- Ariane 6’s central core comprises a lower stage and upper stage. The lower stage is from ArianeGroup’s Les Mureaux site in France; the upper stage is from ArianeGroup’s Bremen factory in Germany. They will be used in ‘combined’ tests which will verify all the interfaces and functions between the Ariane 6 launch vehicle and ground facilities at the spaceport.

- Upon arrival by boat at Pariacabo harbour, the two containers were transported by road to the new Ariane 6 launch vehicle assembly building – part of the Ariane 6 launch complex at Europe’s Spaceport. Here, the rocket stages will be unpacked and installed on the assembly line machinery for integration, to form the Ariane 6 central core.

Combined Tests

- From arrival to hot-firing tests on the launch pad, operational procedures will follow as closely as possible those for any Ariane 6 launch campaign.

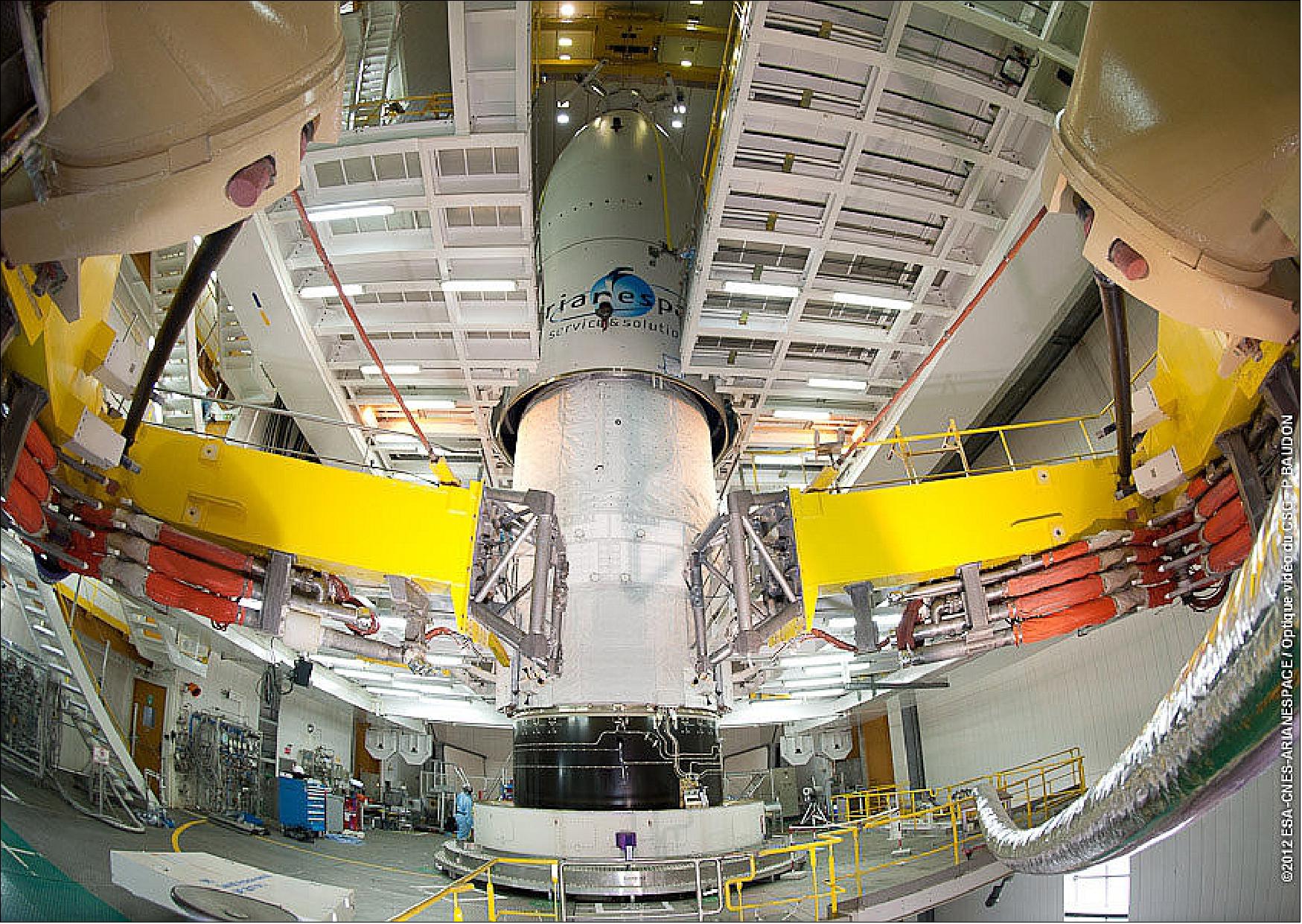

- First, the central core will be integrated horizontally inside the Ariane 6 launch vehicle assembly building then taken to the launch pad and raised vertical inside the mobile gantry. This is a major difference with respect to the current Ariane 5 launch campaign.

- The mobile gantry has moveable platforms so that engineers can access the whole vehicle for integration.

- Four mock-up solid rocket boosters will be strapped to the lower stage. These are the same weight and dimensions as the real boosters and enable engineers to practise the procedures and test the equipment.

- The hot firing test of the Ariane 6’s lower stage Vulcain 2.1 engine will follow a special set of operations on the Ariane 6 launch pad which has been adapted for use as a test bench. Ariane 6’s lower stage Vulcain 2.1 engine will be ignited several times, but Ariane will not lift off during tests.

- The flight software and tank filling and draining operations will be tested too. These are vital to ensure a safe launch sequence, whether it is nominal or interrupted.

- While some elements of the launch pad infrastructure are unfinished, the risky and complex tests of the ground systems have been previously completed and the new Ariane 6 launch complex was inaugurated last year.

Tests in Mainland Europe

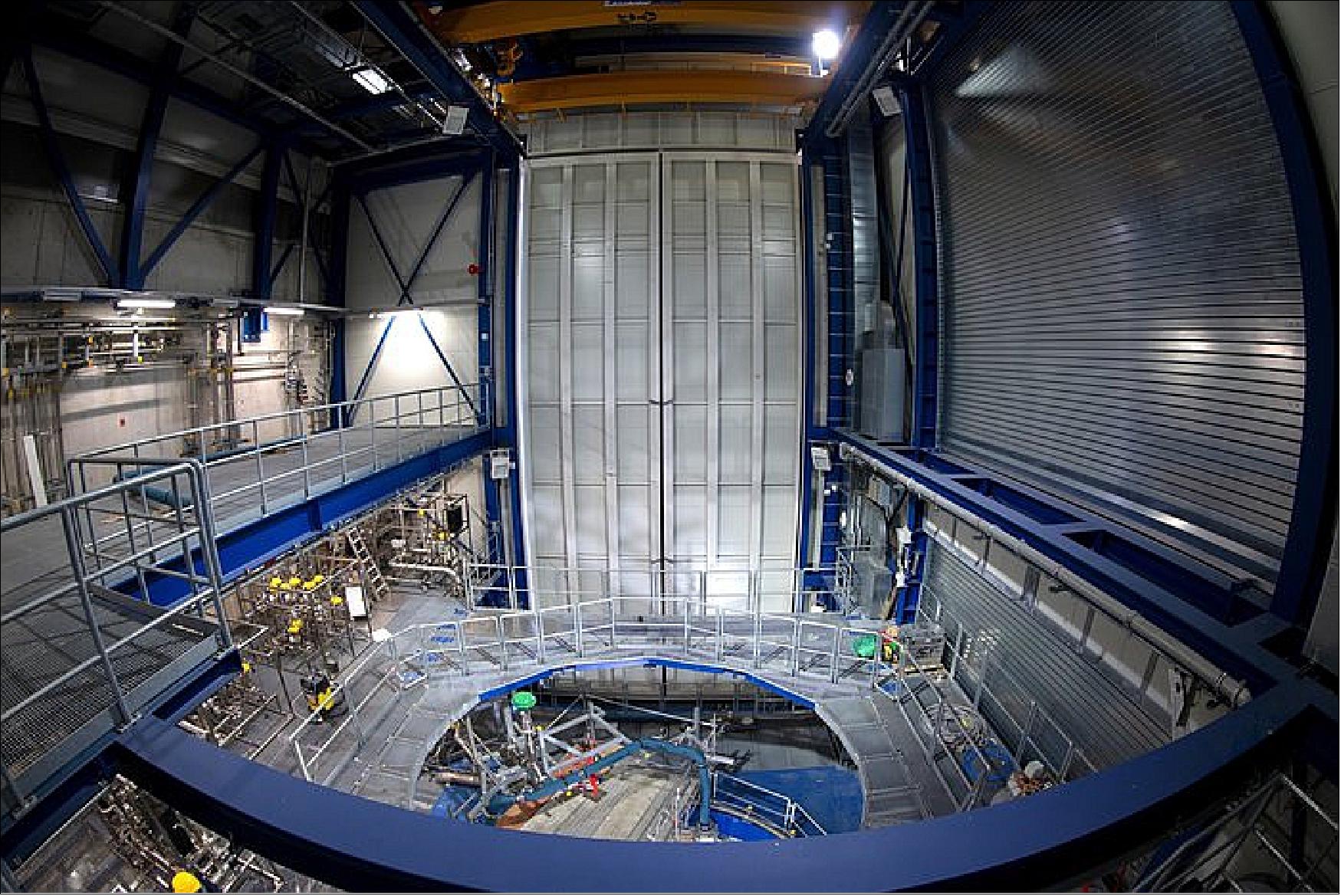

- Meanwhile, a further complete Ariane 6 upper stage is being prepared for hot-fire tests at the DLR German Aerospace Center in Lampoldshausen, Germany. Tests inside a special facility will mimic the conditions of space and verify the innovative systems which enhance the versatility of Ariane 6.

- Further tests at ESA’s Technical Centre in the Netherlands, ESTEC, will include separation tests of the lower and upper stage.

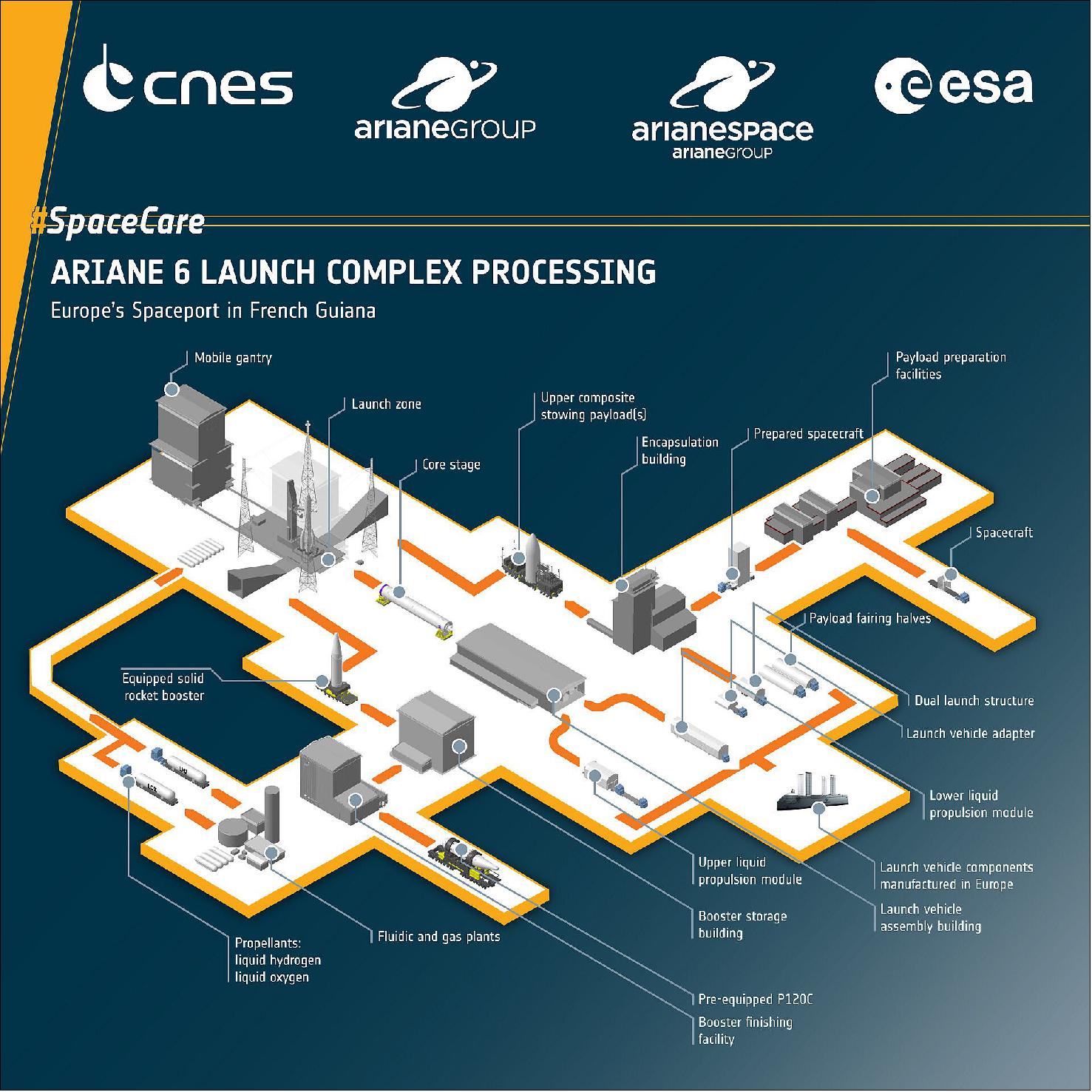

• January 7, 2022: Tour the new launch complex for Ariane 6 at Europe's Spaceport in French Guiana. 19)

- First, enter the launch vehicle assembly building which is 20 m tall, 112 m long, and 41 m wide, located a kilometer away from the launch zone. It is used for horizontal integration and preparation of the central core of Ariane 6 – its main stage and upper stage – before it is rolled out to the launch zone.

- The hydrogen and oxygen storage facilities connect to the launch pad via underground pipes as part of the launch support systems.

- The 8200 ton 90 meter-high mobile gantry rolls on rails. Its platforms enable engineers to access the vehicle for integration of the boosters around the core stage and for mounting the fairing containing the payload on top of the upper stage. This steel mobile gantry protects Ariane 6 before launch and is rolled back prior to liftoff.

- At the entrance of the gantry is a mockup Ariane 6 P120C rocket booster. This is representative of one of the real boosters, having the same size and mass but filled with water instead of solid propellant and used in mechanical tests.

- Four lightning protection masts, and a water tower for the deluge system are also part of the launch pad.

• December 16, 2021: ESA’s Vega-C launch vehicle will fly in the second quarter of 2022 offering more performance to all orbits and extended mission flexibility at a similar cost to the current Vega. A new contract aims to widen these mission capabilities to capture new opportunities and satisfy emerging market needs to 2027. 20)

- The ESA–Avio contract is worth €51 million over two and a half years. The signature event in Paris on 15 December was attended by Daniel Neuenschwander, ESA’s Director of Space Transportation, and Maurizio Cutroni, Avio’s CCO, on behalf of Guilio Ranzo, CEO at Avio.

- “ESA reaches forwards to strengthen future access to space for Europe. This contract for Vega-C contributes to enhance flexibility of the services to the customer and ensures increased competitiveness of our developments,” said Daniel Neuenschwander, Director of Space Transportation at ESA.

- Under this contract, Avio as prime contractor to ESA for the Vega and Vega-C launcher systems will work with industrial partners to put into action a series of improvements intended to enable Vega-C to meet a wider range of market needs.

- These developments will also reduce launch service costs and comply with the payload allocation policy approved by the ESA Council, through the achievement, in the short term, of three major high-level objectives.

- The activities are intended to reduce the main production and operation tasks thereby decreasing the launcher system cost by 10% and therefore the Vega-C launch service cost. In particular, it is planned to cut manufacturing costs for mechanical subsystems and components as well as optimise mission preparation and the launch campaign duration.

- A wider range of missions will be possible by increasing the launch system performance margins giving higher mission flexibility, still complementary to the Ariane 6 launch system, to cope with specific missions needs and constraints.

- Increasing versatility of the Vega-C launch system services is expected by offering ad-hoc launch services solutions based on a portfolio of available products, including small spacecraft mission services and dual-launch services.

- “Avio and ESA have identified and consolidated areas to further increase Vega-C competitiveness during the lead up to commercial exploitation. I thank supporting Member States, the Italian Space Agency and our partners for their trust in Avio,” said Maurizio Cutroni, Chief Commercial Officer at Avio.

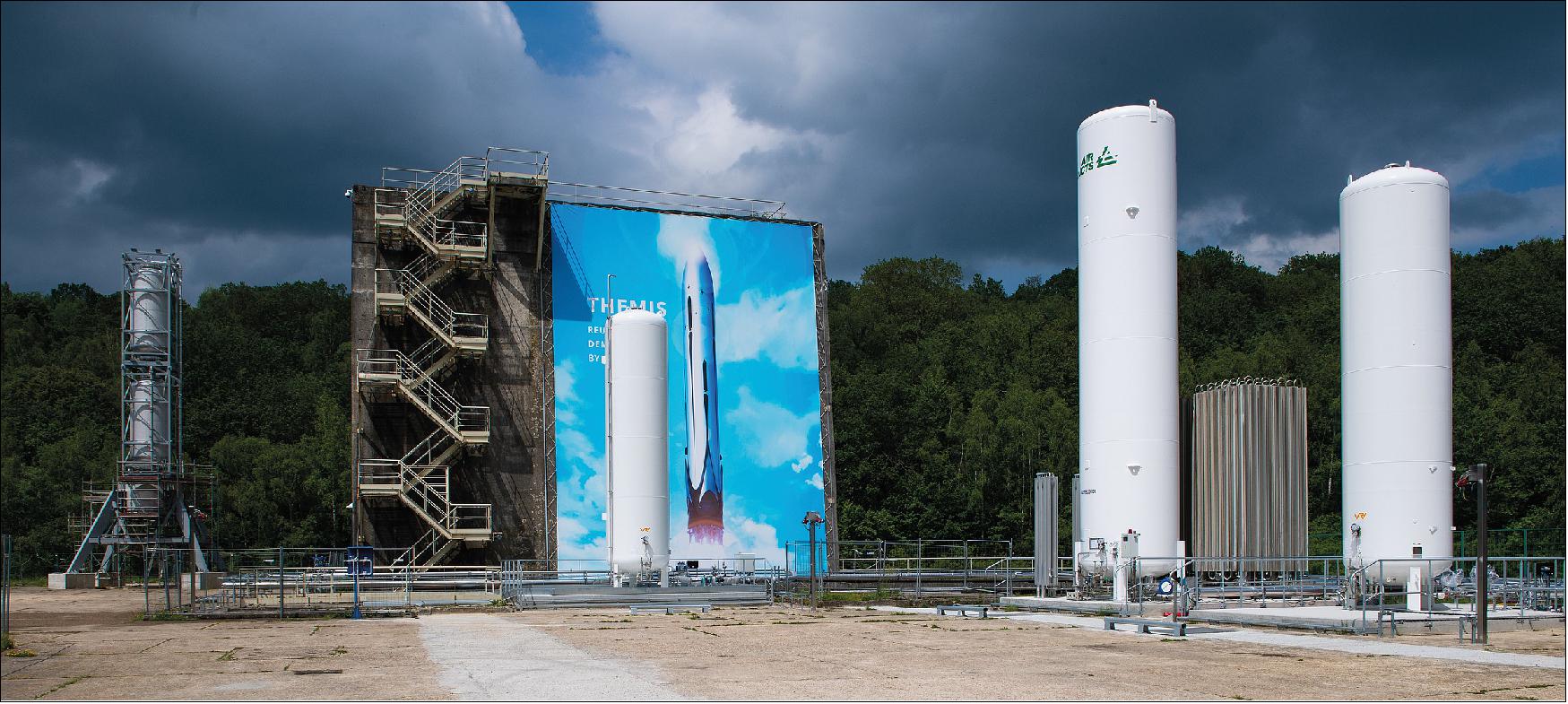

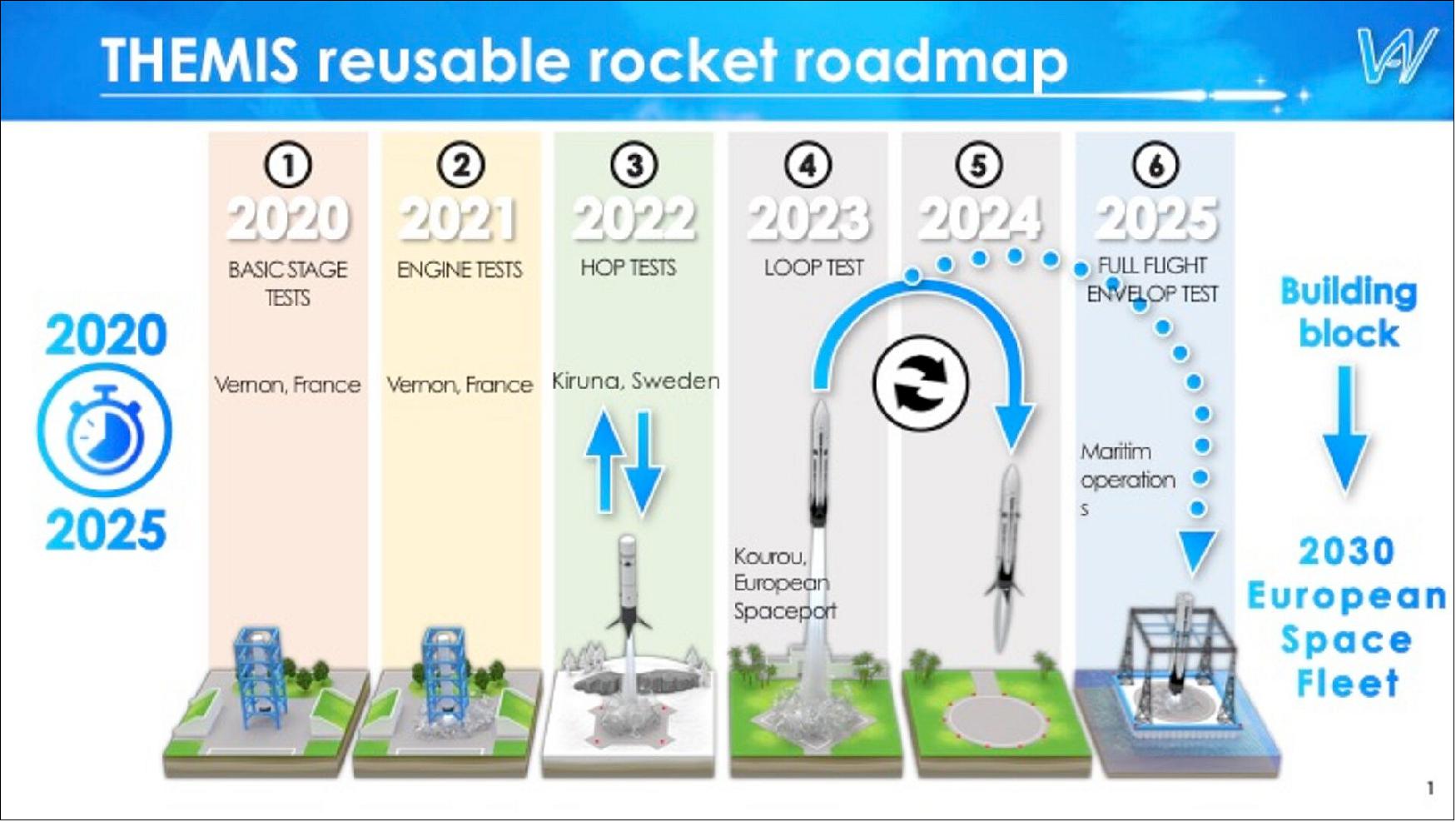

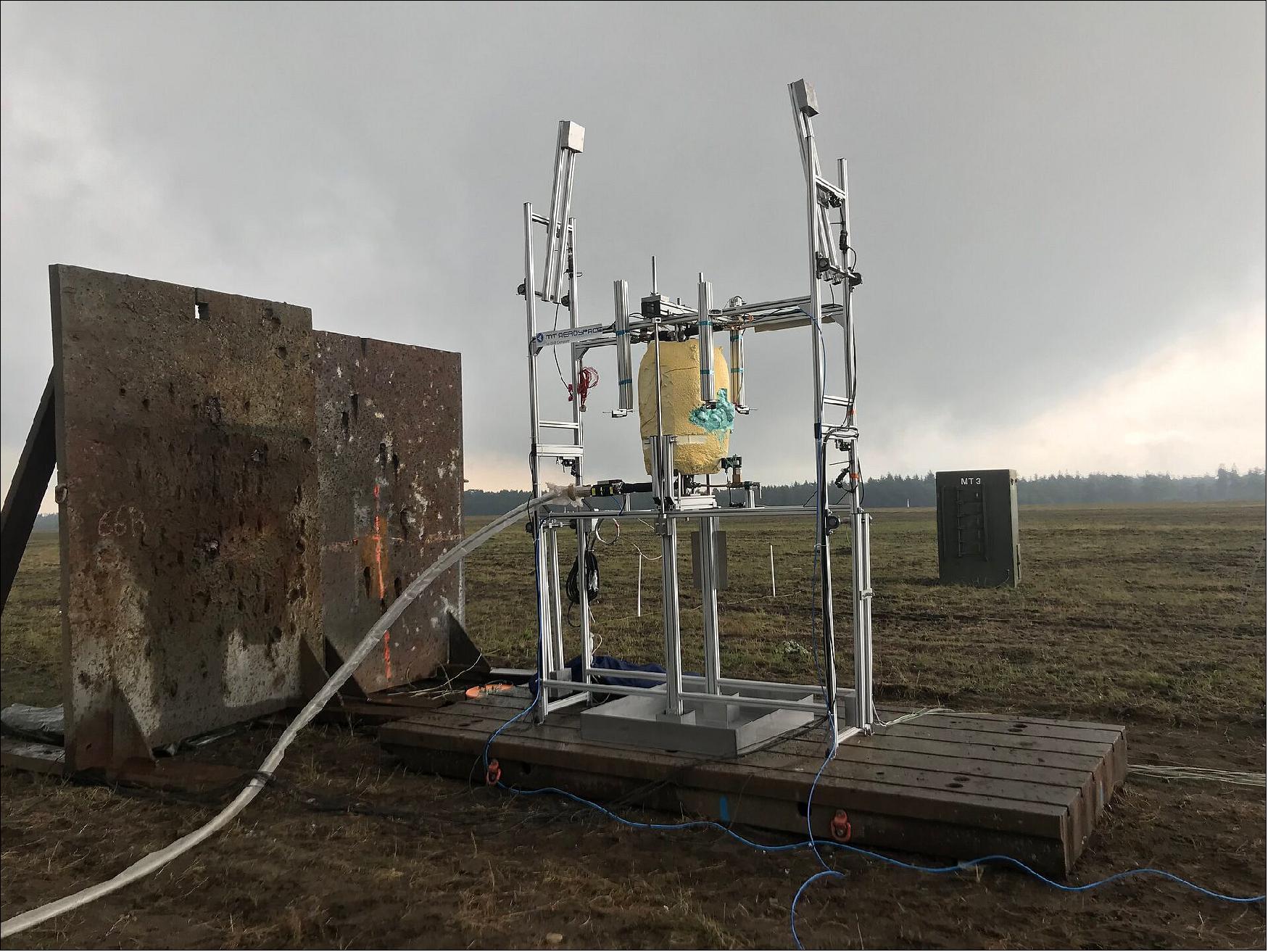

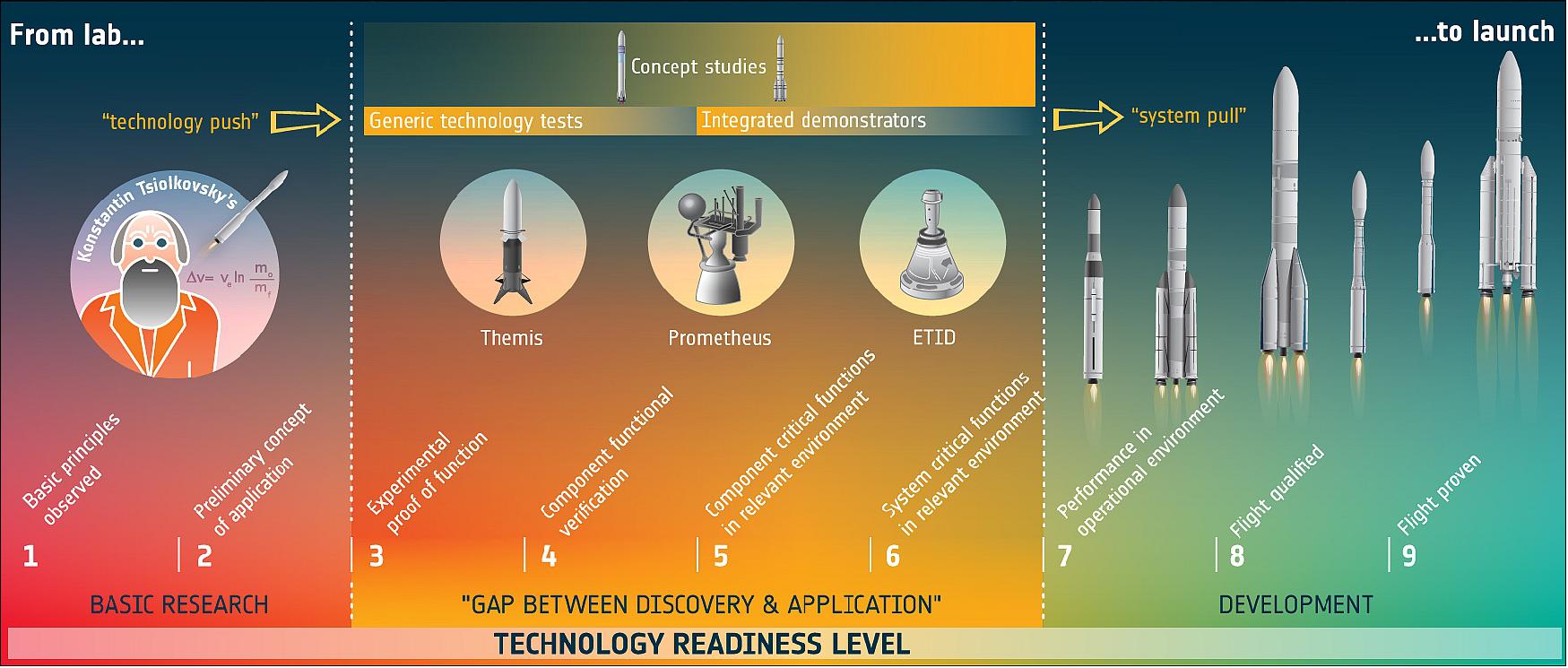

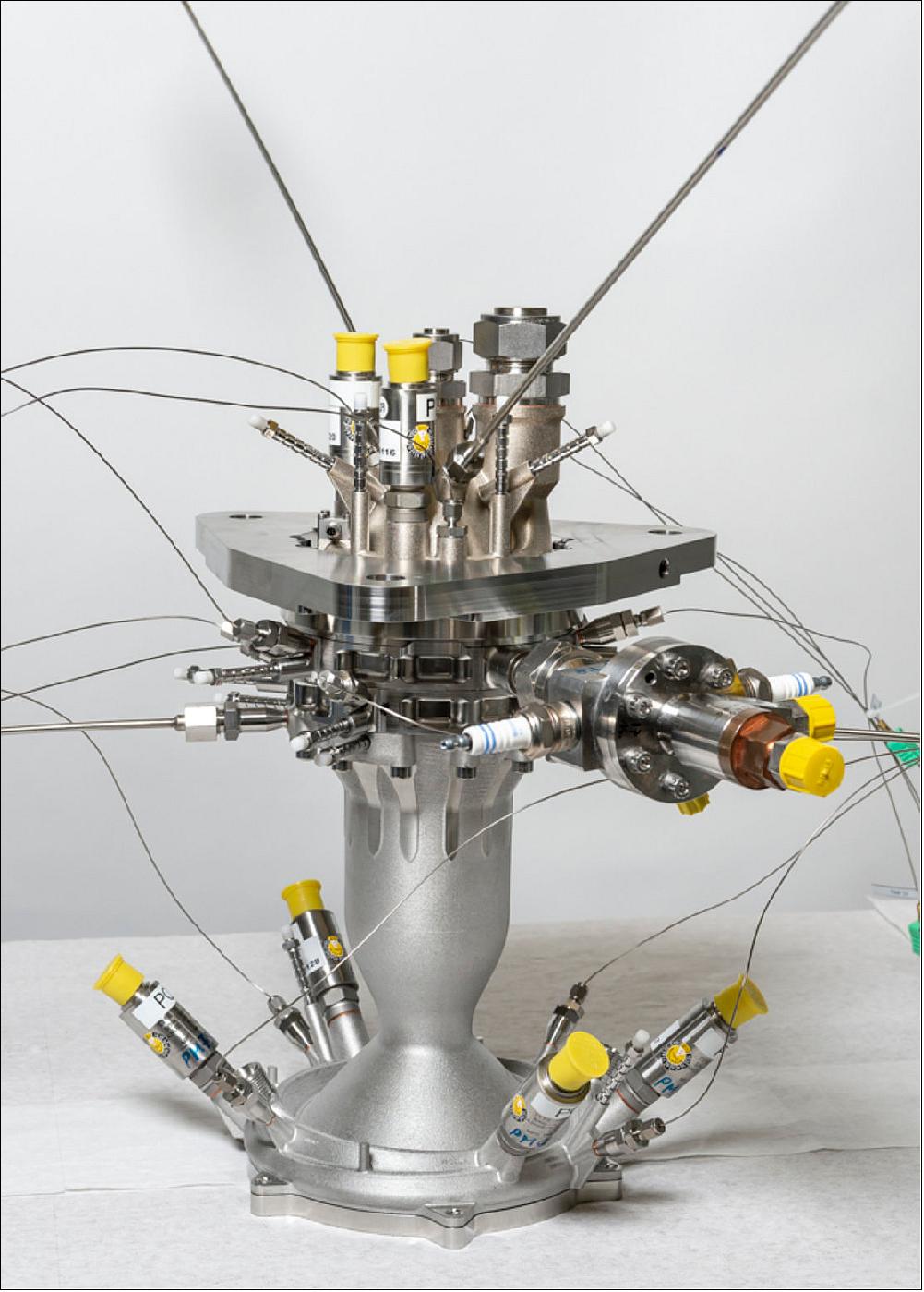

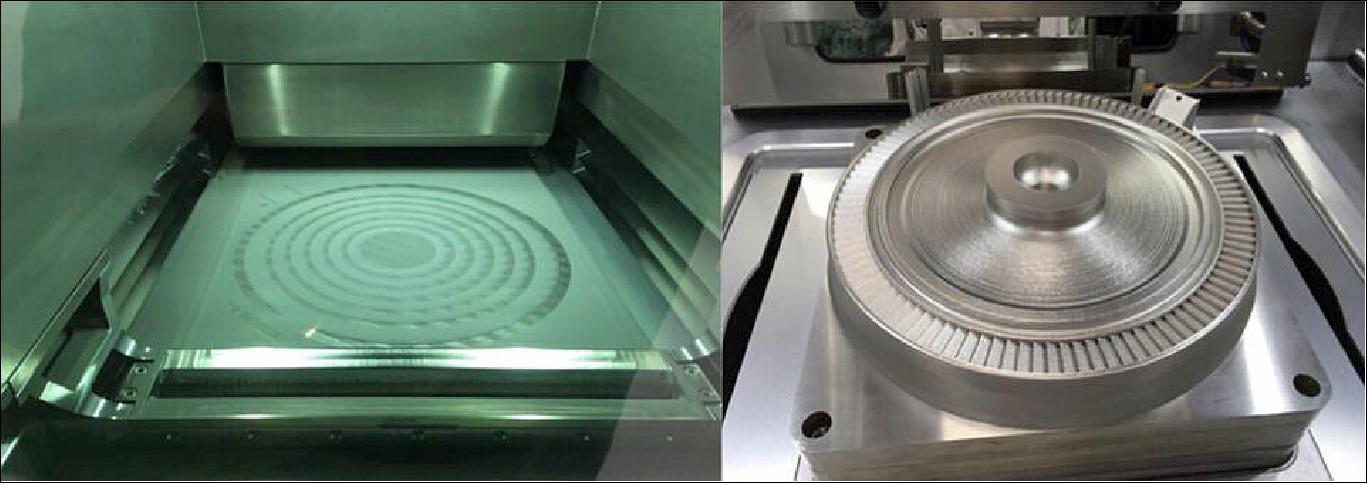

• December 1, 2021: Recently completed tests of two propellant tanks set a first technological milestone in the ESA reusability roadmap towards the demonstration of a reusable first stage vehicle called Themis. 21)

- Through the Themis program, ESA aims to assess the economic value of reusability for Europe while investing in new technologies for potential use in ESA’s future fleet of launch vehicles.

- The Themis experimental approach promotes learning by hardware testing. This Agile methodology focuses on activities of greatest value and works to short timescales.

- To accelerate development, technologies are being tested early in the development cycle. As part of this, prime contractor ArianeGroup recently performed six tests in Vernon, France, to validate the fluidic and electrical processes and sequences for the correct operation of two test propellant tanks. During these tests the tanks were filled then drained of cryogenic propellants.

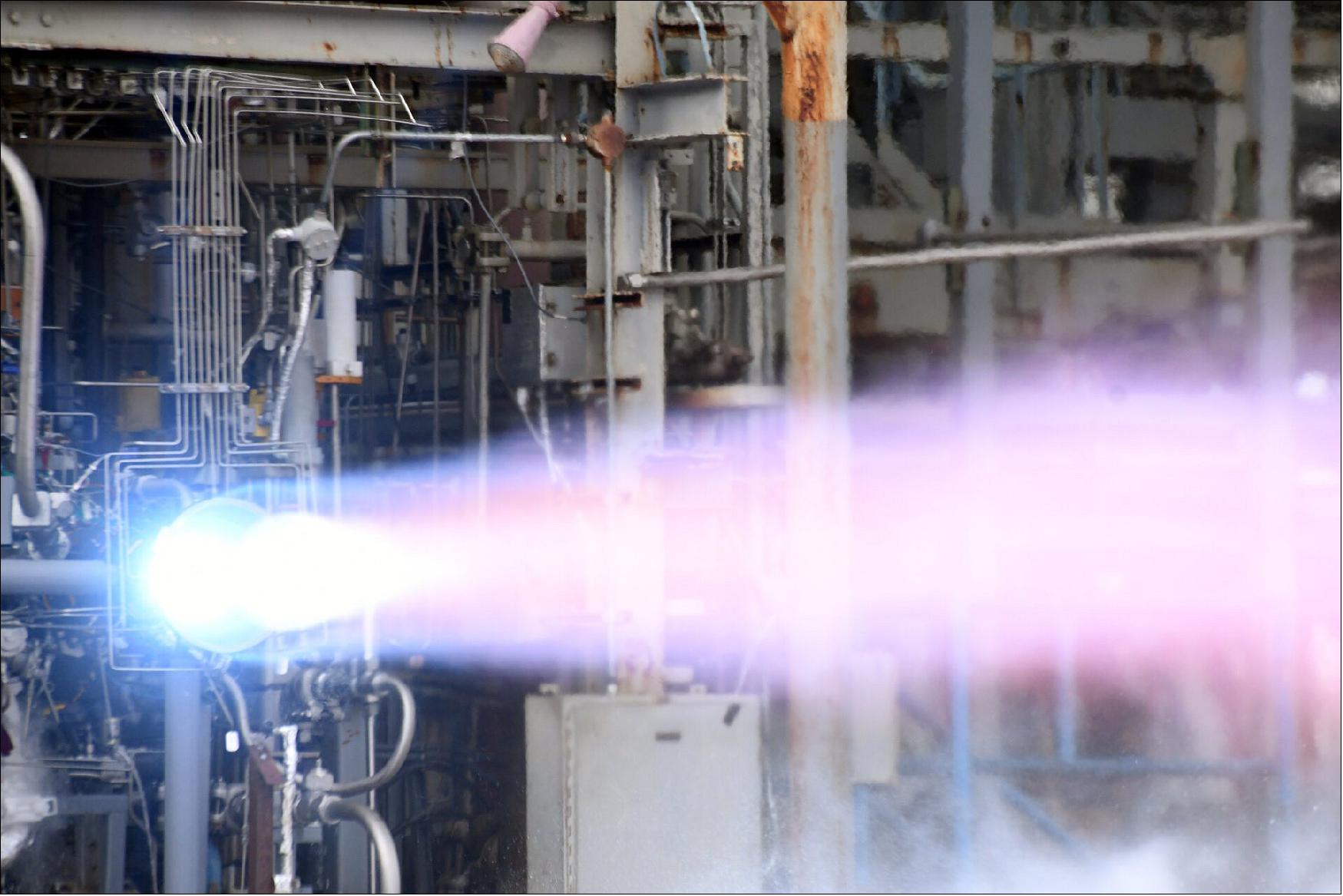

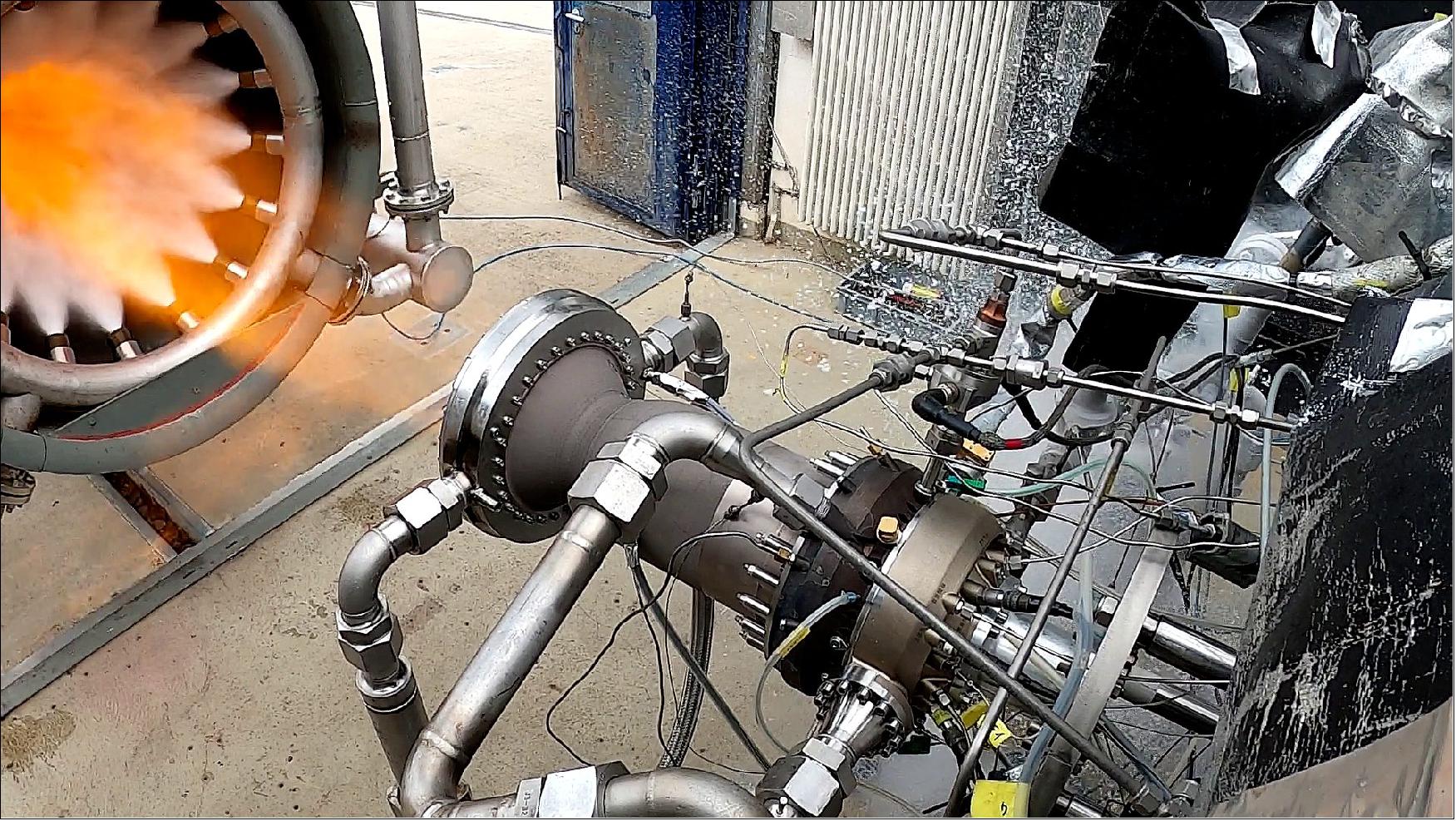

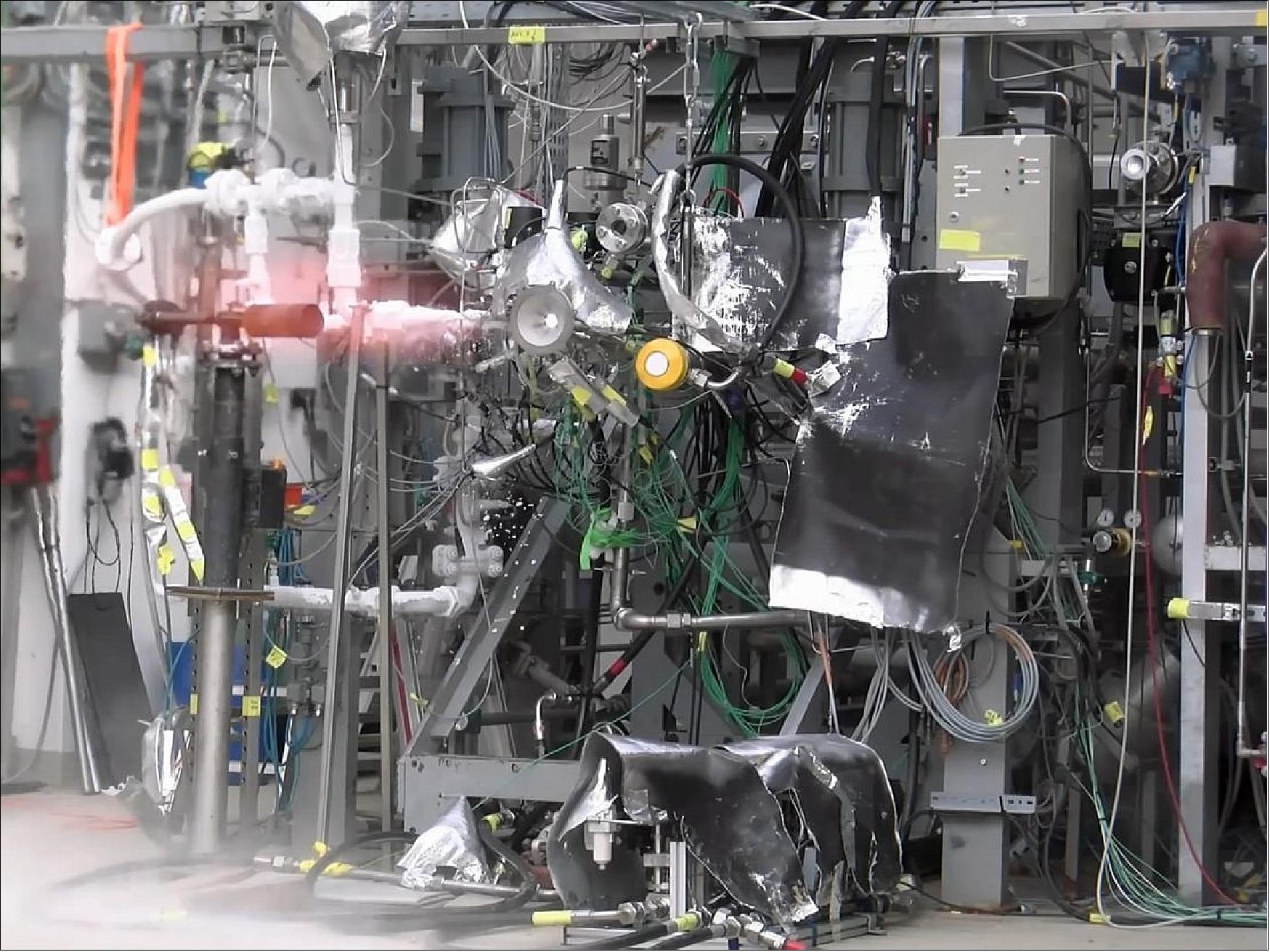

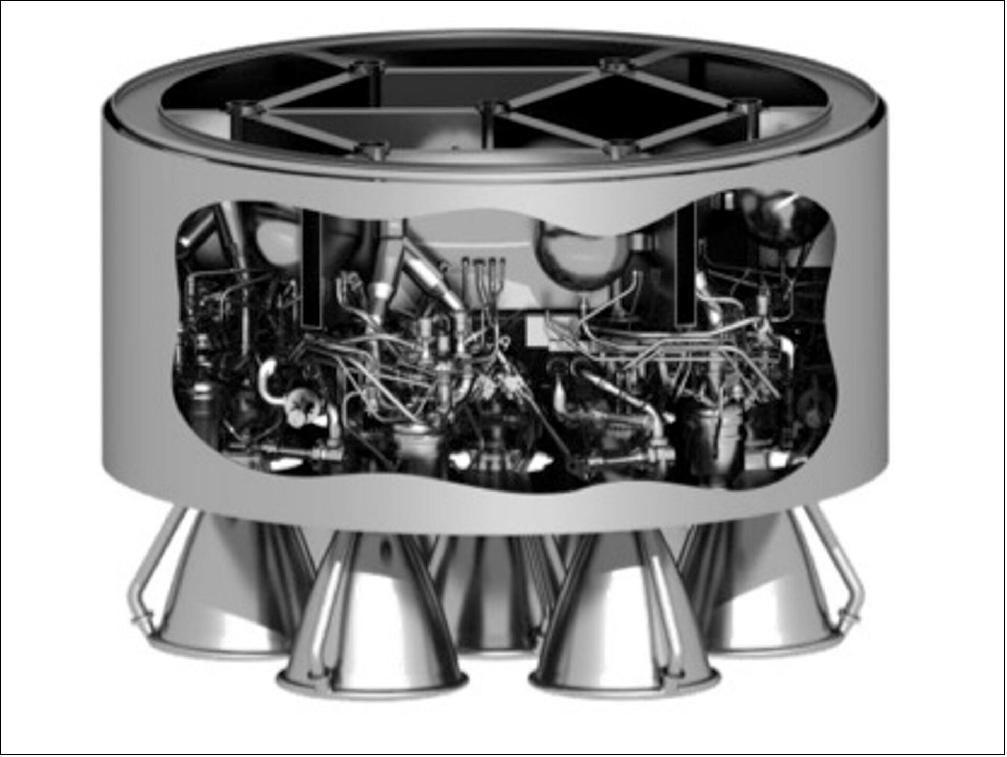

- This initial phase of the Themis project involves the preparation of the flight vehicle technologies alongside firing demonstrations of its reusable Prometheus engine. It also includes the preparation of the ground segment at the Esrange Space Center in Kiruna, Sweden, for the first hop-test flights and any associated refurbishment of the vehicle between flights.

- The fluidic and electrical operations of these test cryogenic tanks and ground equipment have been validated ahead of time to de-risk hot firing tests with the Prometheus engine under integration on the same test bench.

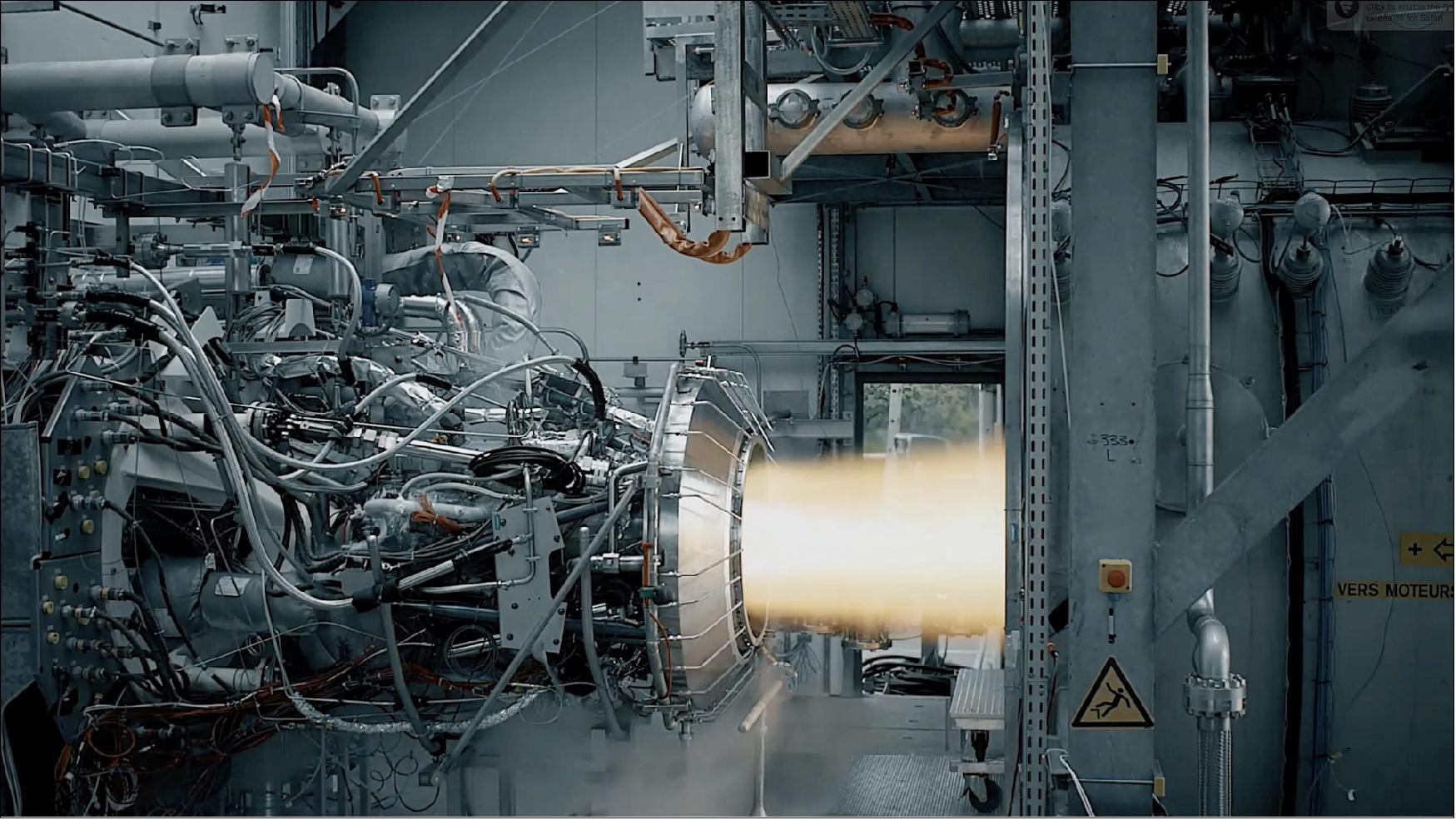

- “This is an exciting time. In the next step for Themis, we will combine two key building blocks for the future of space transportation systems in Europe. Both are developed within ESA’s Future Launchers Preparatory Program. Themis, ESA’s flagship reusable first stage vehicle and Prometheus, its next-generation low-cost reusable engine,” said Yann Tincelin, Space Transportation Systems Project Engineer at ESA.

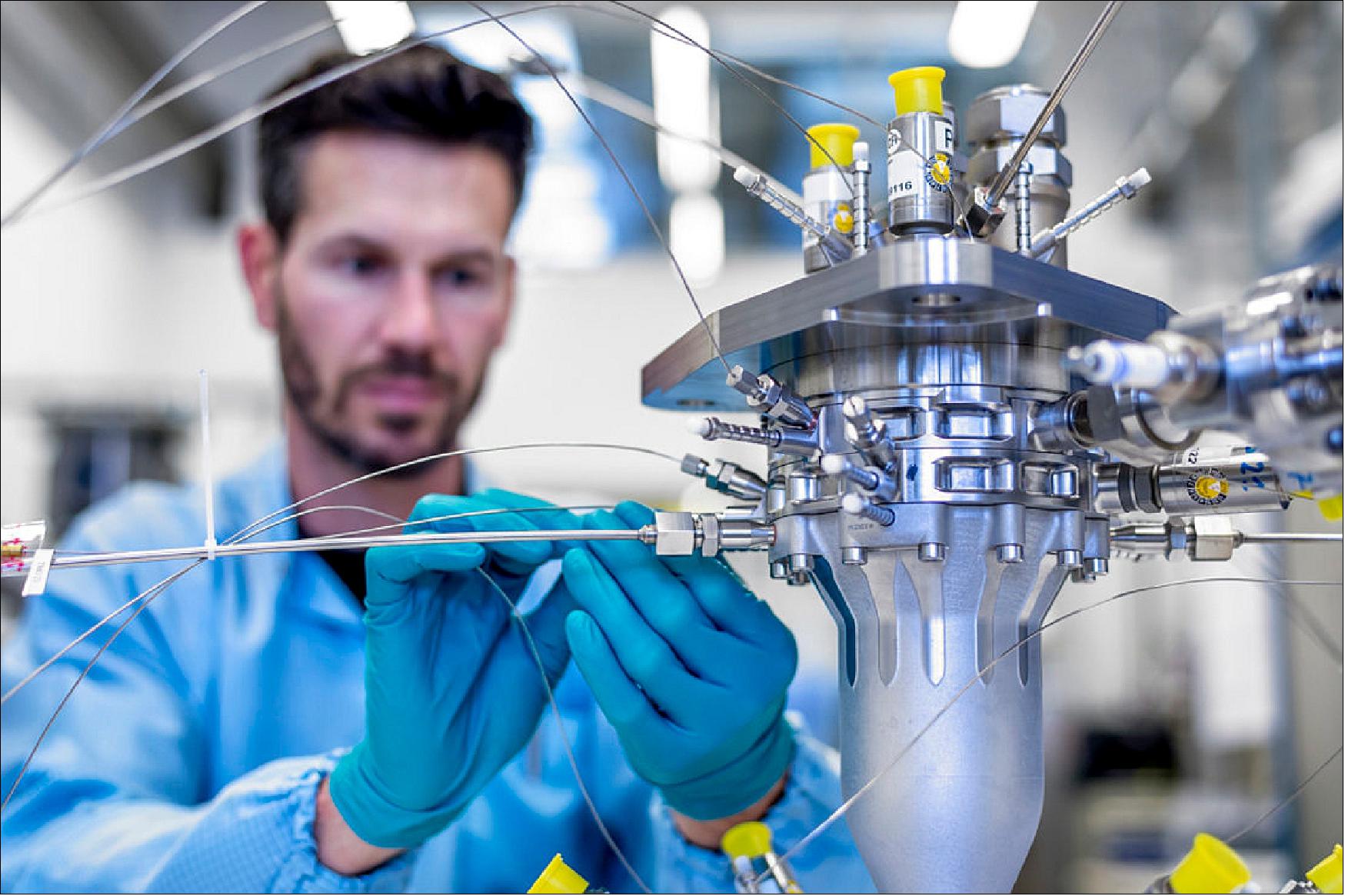

- Prometheus is an ultra-low-cost engine built extensively through additive layer manufacturing. This has reduced the estimated cost of production by a factor of ten compared to Ariane 5’s core stage Vulcain engine. It features variable thrust and multiple ignitions and is therefore suitable for core and upper rocket stages.

- The fuel used for Prometheus is liquid oxygen–methane which is highly efficient, allows standardization and operational simplicity. Methane propellant is also widely available and easy to handle which will minimize ground operations before and after flight.

- Prometheus technologies are likely to be incorporated in improvements made to rocket engines currently in operation.

European Industry

- In parallel to the ongoing activities for ground hot firing tests, Themis flight demonstrators are also under preparation. A European ecosystem of industry partners is forging ahead to develop and manufacture components.

- Flight version steel cryogenic tanks are being manufactured. Low-cost optimized thrust vector actuation systems for Prometheus are being designed. The landing legs system has entered its final design stage before manufacture. All these enabling building blocks will come together for integration on the Themis flight demonstrator for low-altitude hop-tests in Kiruna, Sweden.

- Meanwhile, the final design of ‘Launch complex 3’ at Kiruna Esrange Space Center has been reviewed by the Swedish Space Center and ArianeGroup, to prepare for the first Themis hop-tests in Sweden in 2023.

- This incremental progress is built on early evaluation at each intermediate step with focus first on technical de-risking of Prometheus integration into a fully operational stage, then on flights increasingly representative of operational launch vehicles.

- The final steps will be flights from Europe’s Spaceport in French Guiana in 2025 to demonstrate ascent to high altitude, reentry, landing, refurbishment and reuse, with an integrated Themis demonstrator equipped with three Prometheus engines and all the required subsystems for enabling stage recovery.

• November 5, 2021: ESA offers an opportunity for payloads and experiments to ride on board the first flight of Ariane 6 planned in 2022. Notice of interest should reach ESA by 15 November. 22)

- For its first flight, Ariane 6 will be in the two-booster configuration with a short fairing. ESA will use a payload carrier able to host experiments totalling 80 kg and release payloads with an aggregated mass of 800 kg.

- Under the responsibility of ESA, this launch will serve to qualify the overall Ariane 6 system, including the vehicle, the ground infrastructure and operations from the launch campaign to the payload separation and then disposal of the upper module through reentry, minimizing space debris.

- This Announcement of Opportunity is open in priority, but not exclusively, to any European commercial and institutional candidate mission. Applications from ESA Member States participating in the Ariane 6 program will be given priority: Austria, Belgium, Czech Republic, France, Germany, Ireland, Italy, Netherlands, Norway, Romania, Spain, Sweden and Switzerland.

- Ariane 6 is a project managed and funded by the European Space Agency. ArianeGroup is design authority and industrial prime contractor for the launcher system. The French space agency CNES is prime contractor for the development of the Ariane 6 launch base at Europe’s Spaceport in French Guiana. Arianespace commercializes Ariane 6.

• October 13, 2021: Europe’s Spaceport in French Guiana is preparing for the arrival of Ariane 6, ESA’s new heavy-lift rocket. This involves the final preparations of the new Ariane 6 launch complex and all the systems necessary for a launch. 23)

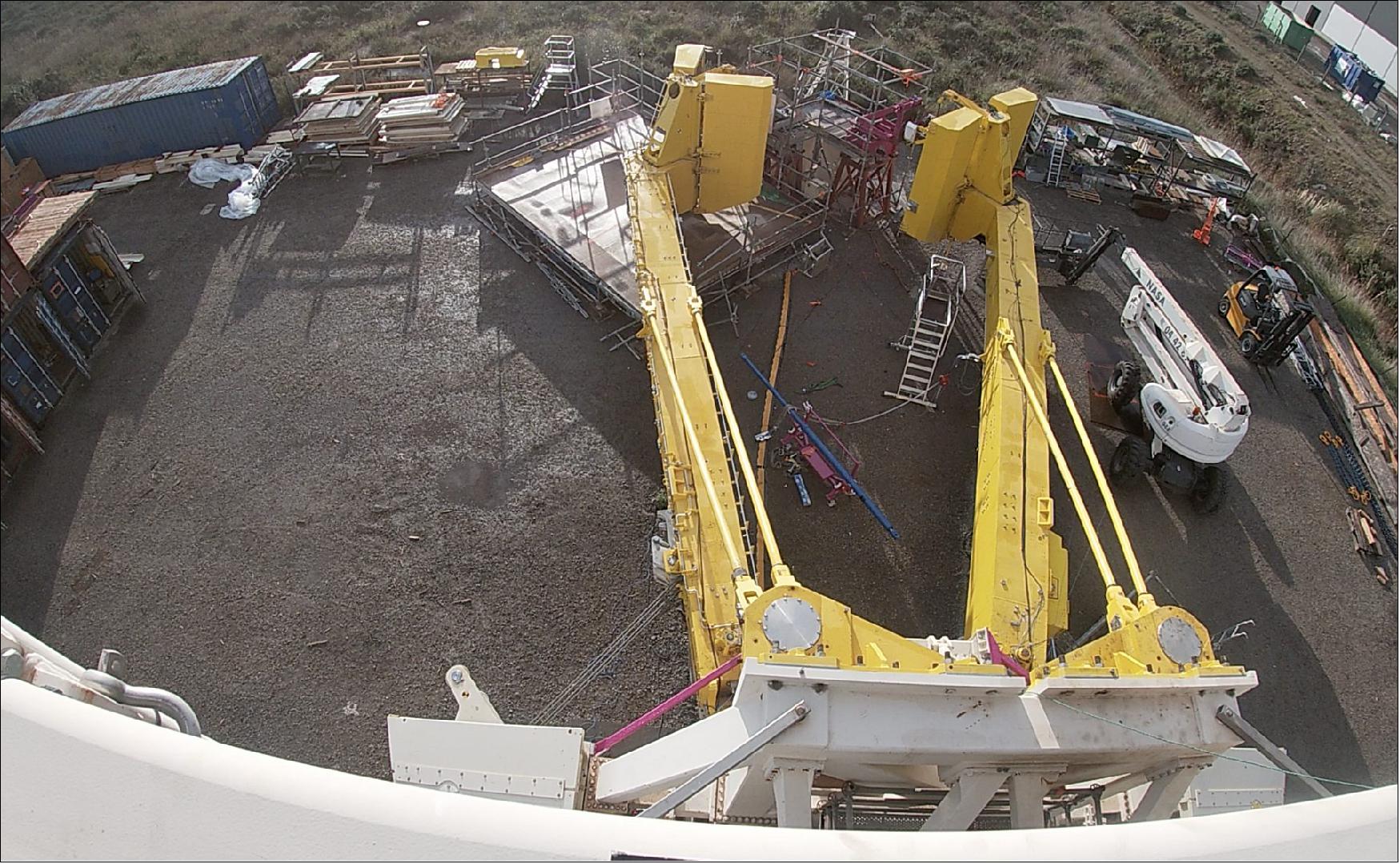

- On the launch pad, two ‘cryo-arms’ made and tested in France have been attached to the upper end of the mast. They are part of the fluidic connection system which connects to the Ariane 6 upper stage.

- These ‘cryo arms’ support the upper umbilicals which supply the Ariane 6 upper stage with cryogenic top-up fuel, maintain the correct pressurization of the upper stage tanks, cool the engines before ignition and generally keep the upper stage in an optimal condition right up to the point of liftoff. The same umbilicals allow the fuel to be drained safely if a launch is aborted.

- Each arm is 13 m long and weighs 20 tons. One arm supplies liquid hydrogen at -250ºC, the other supplies liquid oxygen at -180ºC. When Ariane 6 lifts off, these arms will disconnect from the rocket and then pivot away quickly in just 2.6 seconds to avoid interfering with the rocket's ascent.

- This maneuver requires great precision in order, almost simultaneously, to disconnect the arms, protect the supply hoses from gas ejections from the boosters and allow the launch vehicle to pass while avoiding any contact with it. A 50-tonne counterweight inside the mast – as heavy as a humpback whale – speeds up the retraction of the arms. A smart damping system allows the arms to brake before the end of their swing backwards in order to preserve the mechanical links with the mast.

- Keeping the fluidic supplies connected with the rocket until the moment of liftoff guarantees the best availability and simplification of the interface with the launch vehicle.

- The disconnect time for Ariane 6 is much faster than for Ariane 5, which is six seconds before liftoff. This means that the sequence for Ariane 6 can be triggered at the latest possible moment in the countdown reducing the chance of unnecessary disconnects on an aborted launch.

- These articulated structures will now be tested with the mobile gantry fully retracted – as for a launch. They will repeat the tests performed in Fos-sur-Mer, France, but this time attached to the mast.

• September 28, 2021: The new launch complex built for Europe’s upcoming Ariane 6 rocket is inaugurated at Europe’s Spaceport in French Guiana. 24)

- With this, ESA celebrates another important milestone in the Ariane 6 roadmap as it forges ahead with combined tests between launch vehicle and launch base and preparations towards the first launch campaign.

- Clearly visible from space, the facilities feature remarkable complex structures above and below ground specially designed to support Ariane 6 launches into the next decade. It is the proud achievement of the French space agency, CNES – prime contractor to ESA for the development of the launch base, and its European industry partners.

- The Ariane 6 program is funded and developed by ESA. This new launch vehicle will replace Europe’s heavy-lift Ariane 5. Available in two versions, with either two or four boosters, Ariane 6 will offer more performance and flexibility than its predecessor. This opens new opportunities and guarantees continued access to space for ESA Member States.

- The Ariane 6 launch complex is a marvel of engineering, designed to optimize the launch system performance and operations workflow. Its design benefits from lessons learned in the construction and operation of the existing Ariane, Vega and Soyuz launch complexes at the spaceport.

- The main elements include the launch pad with two exhaust ducts, the mobile gantry and the launch vehicle assembly building.

- The launch pad is 28.5 m deep and 200 m wide. Its basic structure was poured in concrete the volume of 67 Olympic-sized swimming pools. At its center is the launch table which weighs 700 tons and is 4 m high, 20 m long, and 18 m wide. This structure was built in Europe by MT Aerospace in Germany and shipped to Kourou for integration on the launch pad. Below ground it protects a host of support systems and will bear the weight of Ariane 6.

- Ariane 6’s final integration will take place inside a mobile gantry, just like Soyuz and Vega. The mobile gantry was manufactured in Europe by Eiffage Metal in Germany and was assembled at the spaceport. It will protect Ariane 6 on the launch table during each launch campaign.

- This 90 m-high by 50 m-wide gantry weighs 8200 t – more than a thousand tons heavier than France's Eiffel Tower. Work platforms will enable engineers to access the vehicle levels to vertically position Ariane 6’s central core directly on the launch table, add two or four boosters depending on the launch configuration, and integrate the fairing that houses the payload. The gantry retracts 140 m on rails before launch. If the launch is delayed the gantry can be rolled back in place to allow access to Ariane 6 before its next launch attempt.

- The Ariane 6 core and upper stages will be integrated horizontally inside the launch vehicle assembly building and prepared for rollout to the launch zone. The building is 20 m tall, 112 m long and 41 m wide, some 1 km from the launch zone.

- Horizontal integration lowers the cost of facilities and launcher integration while offering a higher level of flexibility and growth potential and allowing easier access to the whole rocket. Overall, the improved Ariane 6 approach to integration and operations will reduce the duration of a launch campaign from months to weeks.

- ESA’s contract with CNES for the launch base development worth €600 million was signed in 2015. CNES allocated a third of this funding to infrastructure with notable involvement of local industry for construction, materials and equipment, and the remainder to contracts in mainland Europe.

- The systems that are part of the main launch complex structures are being qualified. For example, the deluge system which will protect Ariane 6 and ground installations from the acoustic energy created at liftoff was tested. The disconnection of the fluidic systems for Ariane 6 on the launch pad, tested in France, are now being tested on the launch pad. A central core mockup was used to test ground equipment and practise the maneuvers involved in a launch campaign. France’s space agency (CNES) and ArianeGroup teams jointly performed these tests under the responsibility of ESA.

- “The Ariane 6 launch complex is a remarkable achievement and an icon of European cooperation and advancement. It represents a vital part of a program of intense activity at Europe’s Spaceport to prepare for the first flight of ESA’s next generation launch vehicle,” commented Daniel Neuenschwander, ESA Director of Space Transportation.

- The inauguration was held in the presence of Sébastien Lecornu, French Minister of the Overseas, Philippe Baptiste, President Director General of CNES, and Daniel Neuenschwander, ESA Director of Space Transportation. Also present were industry partners André-Hubert Roussel, CEO of ArianeGroup, Stéphane Israël, CEO of Arianespace, and Gabriel Serville, President of the Territorial Collectivity of French Guiana.

• September 3, 2021: ESA Member States have agreed upon the boundary conditions for Europe’s upcoming exploitation of Ariane 6 and Vega-C and request ESA to propose a roadmap for new and innovative space transportation solutions for the next decade and a framework for associated short cycle demonstrations. 25)

- The Resolution agreed upon by ESA Member States mid-August sets the conditions for the first three years of stabilized exploitation of Europe’s new launch vehicles, Ariane 6 and Vega-C at Europe’s Spaceport in French Guiana.

- Driven by the launch needs of European institutions and taking stock of the volatile context of the worldwide launch services market, Member States have converged on a stable and secure basis for the exploitation of these new launch vehicles to provide guaranteed access to space for Europe in the coming years.

- The revised stabilized exploitation model is based on a European institutional launch service demand of four Ariane 6 vehicles (three Ariane 62 with two boosters and one Ariane 64 with four boosters, or two positions on a dual payload launch on Ariane 64) and two Vega-C per year on average. Price conditions for the associated standard launch service have also been agreed upon.

- Member States have also established a basis for maintaining strategic industrial capabilities through options to serve either additional institutional launches or a higher commercial demand. Corresponding financial decisions by Member States are planned to be taken at the occasion of the Council Meeting at Ministerial Level at the end of 2022. European institutional customers of launch services will also need to commit to launch on ESA-developed launchers.

- In addition, the ESA Council also requested the ESA Director General to agree with the European Union on a European flight ticket initiative to regularly demonstrate and validate in orbit missions of less than 200 kg on launch services with proven capabilities to be selected on a competitive basis.

- To prepare for the future, ESA Member States have further tasked ESA to propose the next generation of European space transportation solutions required for the next decade. To that end, ESA is asked to create a frame for short-cycle demonstration of such space transportation solutions for approval at the occasion of the upcoming Council Meeting at Ministerial Level. Preparation is under way including through ESA’s New European Space Transportation Solutions initiative (NESTS) initial studies.

- “Considering the continuously changing space transportation market, the agreed boundary conditions ensure a stable reference for the successful exploitation of Ariane 6 and Vega-C to serve European institutional needs and the commercial market.

- “At the same time, Member States have given ESA the important mandate to propose a roadmap for new and innovative European space transportation solutions for the next decade and beyond. In addition, we will work, together with the European Union to foster regular opportunities for small missions to be launched on flight-proven European launch vehicles, selected on a competitive basis,” commented Daniel Neuenschwander, ESA Director of Space Transportation.

• July 28, 2021: Future rockets could fly with tanks made of lightweight carbon fibre reinforced plastic thanks to ground-breaking research carried out within ESA’s Future Launchers Preparatory Program. 26)

- Building on earlier studies, MT Aerospace in Germany has demonstrated a novel design of a small scale tank made of a unique carbon-fibre reinforced plastic (CFRP) that is not only leak-proof with liquid hydrogen, but also compatible with liquid oxygen, without the use of a metal liner.

- A tank made solely of CFRP is much lighter than metal, requires fewer parts and is therefore faster and cheaper to manufacture.

- This is a milestone achievement as normally, storage of cryogenic propellants such as these which are cooled to -253ºC requires tanks with metallic liners to make them leak-proof, with or without a composite overwrap.

- “Fuel tanks are safety-critical elements in any propulsion system,” explained Hans Steininger, CEO at MT Aerospace. “We have provided proof that a high-performance pressure tank made of CFRP can withstand cryogenic stress. In the future, the use of CFRP high-performance tanks should not only enable safe rocket launches, it can also exploit the advantage of significantly lower mass compared to metallic tanks.”

- “This is a tremendous step forward. We have found a very specific carbon composite and processing method that will allow us to consider new architectures and combinations of functions for rocket upper stages which are not possible using metal,” added Kate Underhill, Upper stage and propulsion demonstrators project manager in the Future Launchers Preparatory Program at ESA.

- “Metal is leak-tight. To recreate the same property with carbon composite required a complex weave of black carbon fibre and a special resin. The material resisted cryogenic temperatures, pressure cycles and reactive substances over a number of separate tests.”

- Following these ‘bottle’ tests, small-scale tank demonstrators with integrated thermal protection will soon be built for further tests. Data collected will feed into development of a full-scale demonstrator of a future highly-optimized upper stage, called Phoebus (Figure 99).

- Phoebus will have 3.5m diameter hydrogen and oxygen tanks, thermal protection, structural assembly elements and feature new technologies in avionics, structures and propulsion equipment. CFRP will be applied in the tanks, the interface structure between the two tanks and the outside cylinder representative of the upper stage outer skin.

- The Phoebus demonstrator will be tested with cryogenic fluids in 2023 to confirm the functional performance of the technologies and new cost-efficient production methods as part of a new contract to advance the development of highly optimized upper stages.

- “Here is an excellent example of how ESA’s support to mature cutting-edge technologies leads to major breakthroughs. This new lightweight carbon-based material would allow the manufacture of an Ariane 6 upper stage that is two tonnes lighter – mass made free for payloads,” said Daniel Neuenschwander, ESA Director of Space Transportation.

- The Phoebus project is a joint initiative by MT Aerospace and ArianeGroup in Germany to validate key technologies developed with support from ESA since May 2019.

• July 21, 2021: ESA will further increase the competitiveness and environmental sustainability of Europe’s Vega launch system beyond 2025 through a contract signed with Avio in Italy. 27)

- Vega operates from Europe’s Spaceport in French Guiana to launch light satellites to one or multiple orbits in a single launch. This contract takes Vega a step further and marks the start of a new phase in preparation of a new Vega launch vehicle called Vega-E, which will make extensive use of Vega-C building blocks.

- The objective with Vega-E is to further increase the competitiveness and performance of Vega-C – which is planned to have its first flight in 2022. This will increase its flexibility in terms of payload mass and volume and reduce the launch service cost and globally the cost of launch per kilo offered in the market.

- The key for achieving these objectives is the use of new technologies for a completely new upper stage, featuring a new low-cost liquid-fuelled engine.

- “This contract takes Vega a step further having at its heart the new M10 liquid oxygen–methane cryogenic engine, which will further increase its competitiveness, performance and sustainability,” said Daniel Neuenschwander, ESA Director of Space Transportation.

- Vega-E will have three stages unlike Vega-C which has four. Two stages will be derived from Vega-C: the first stage P120C solid rocket motor which provides the thrust at liftoff and the second stage solid rocket Zefiro-40 motor. The new third stage is the liquid oxygen–methane cryogenic upper stage which is the core of the Vega-E preparation.

- “Vega-E’s upper stage will replace the third stage Zefiro 9 solid-propellant motor and the fourth stage upper AVUM of the current Vega configuration. This will have a beneficial effect on performance and cost,” explained Renato Lafranconi, Vega programs manager at ESA.

- Vega-E’s upper stage will improve mission flexibility through its new M10 expander cycle engine with multiple reignition capability. The fullscale 3D-printed thrust chamber assembly of the M10 passed its first series of hot firing tests last year which also qualified new efficient manufacturing methods.

- “The reduction of emissions and combustion waste makes the introduction of the M10 engine a further improvement in environmental sustainability which is a driver for the future of Vega,” added Adriana Sirbi, Vega Evolution Preparation Manager at ESA.

- Industries and universities from eleven countries are involved in the preparation of the Vega-E launch system, and will contribute to the success of this European rocket. Prime contractor, Avio, with partners will further define the launcher system and its subsystems as well as the preliminary design of the Vega-E launch pad and the associated infrastructure at Europe’s Spaceport in French Guiana.

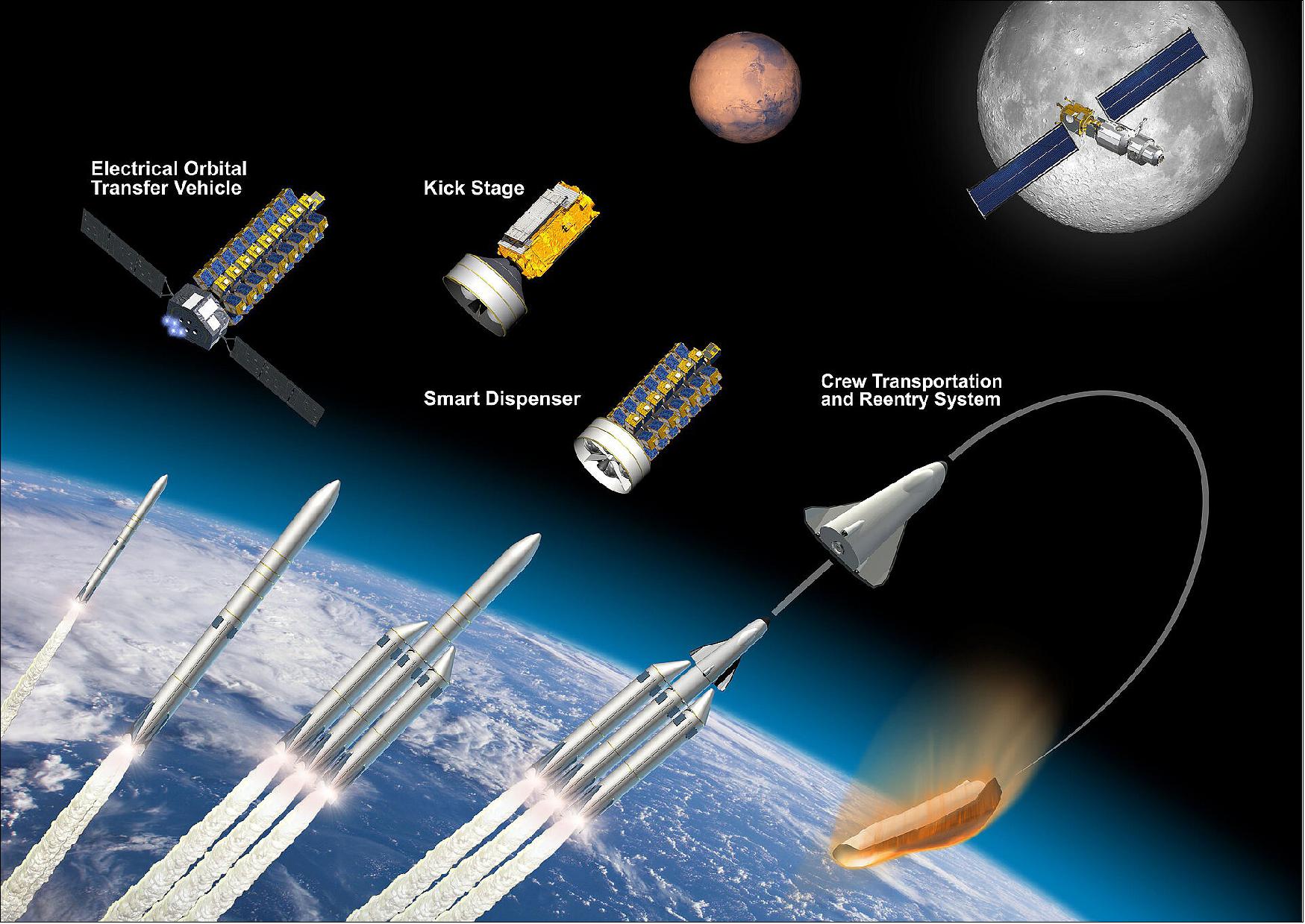

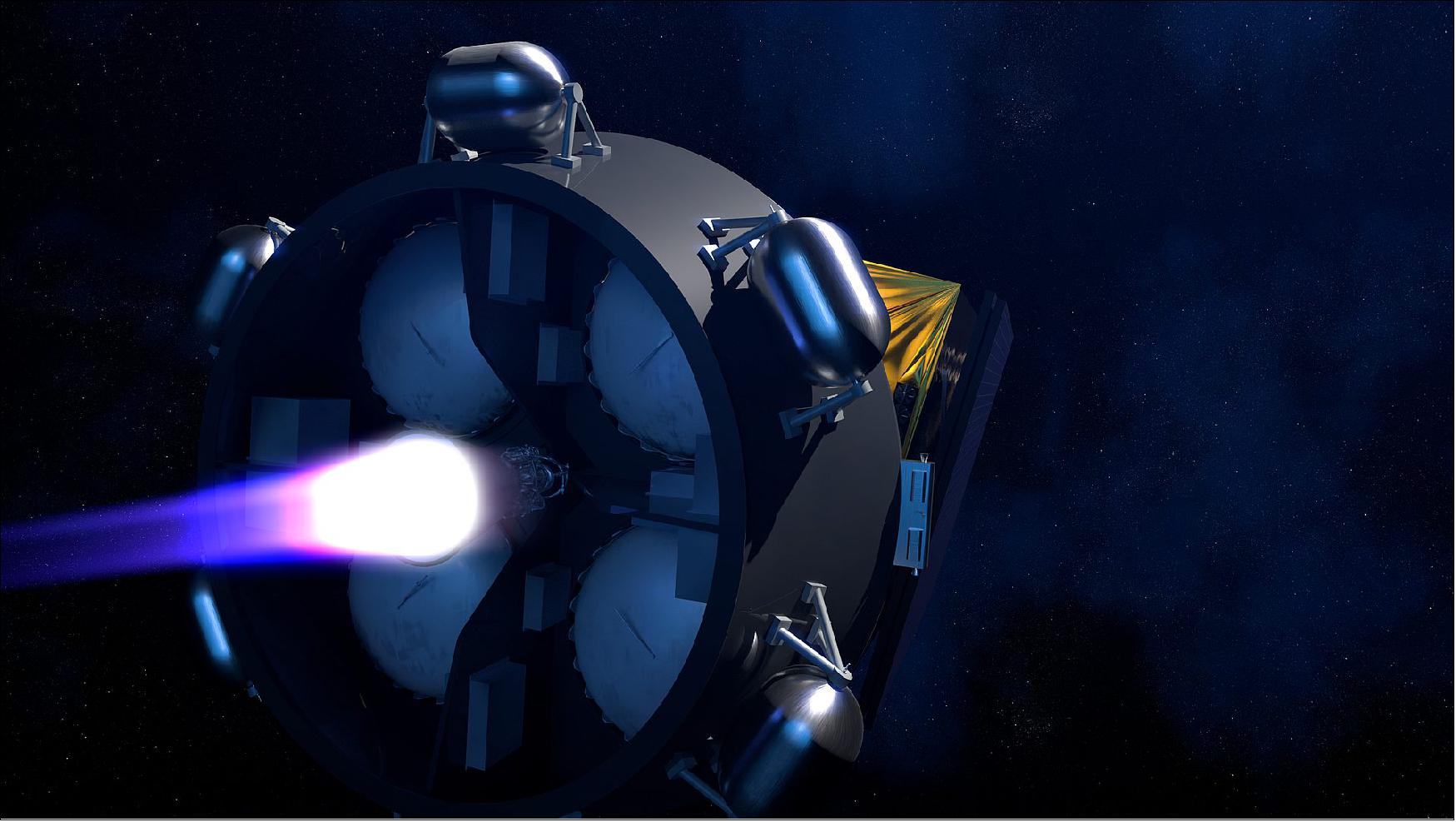

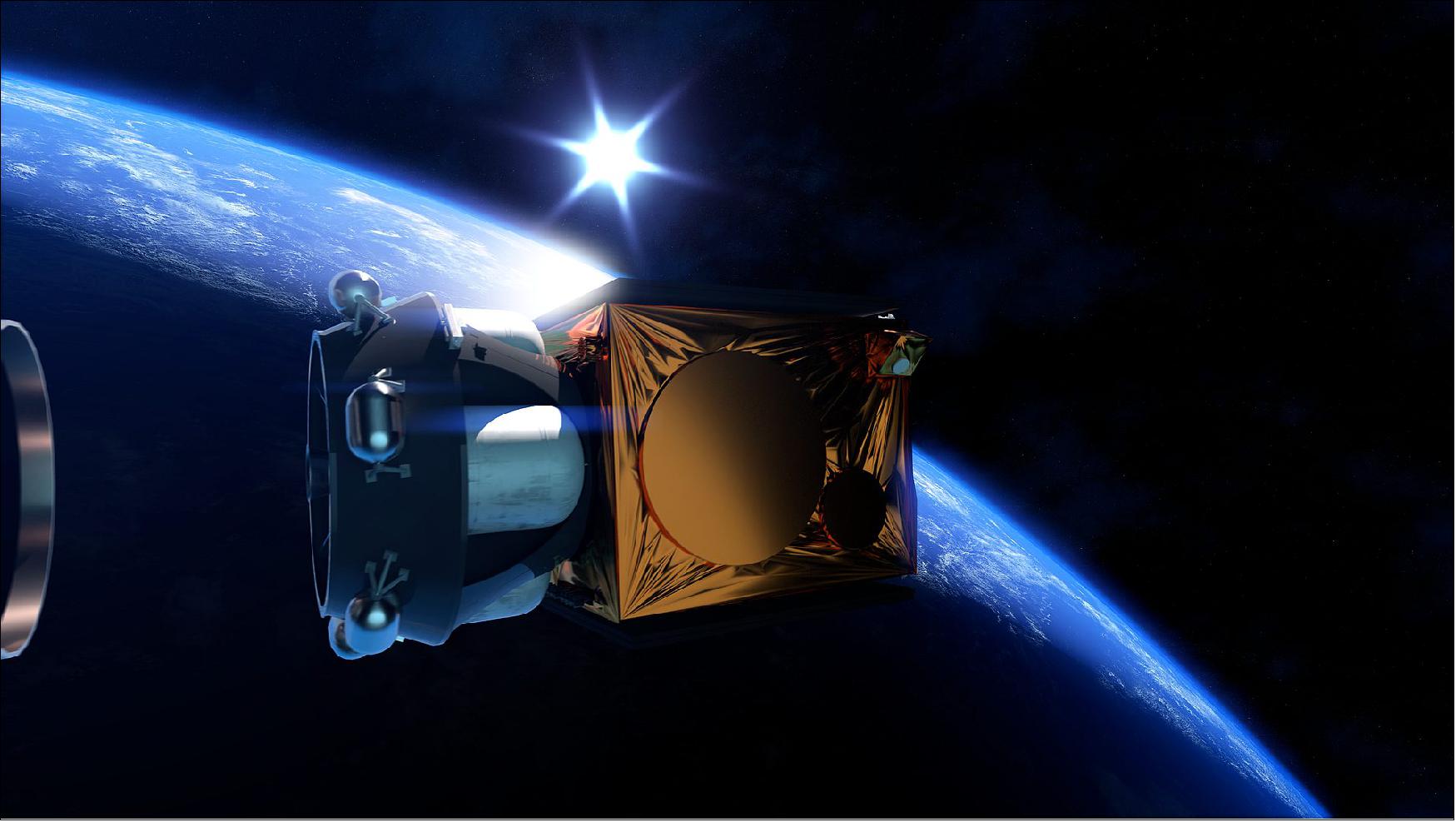

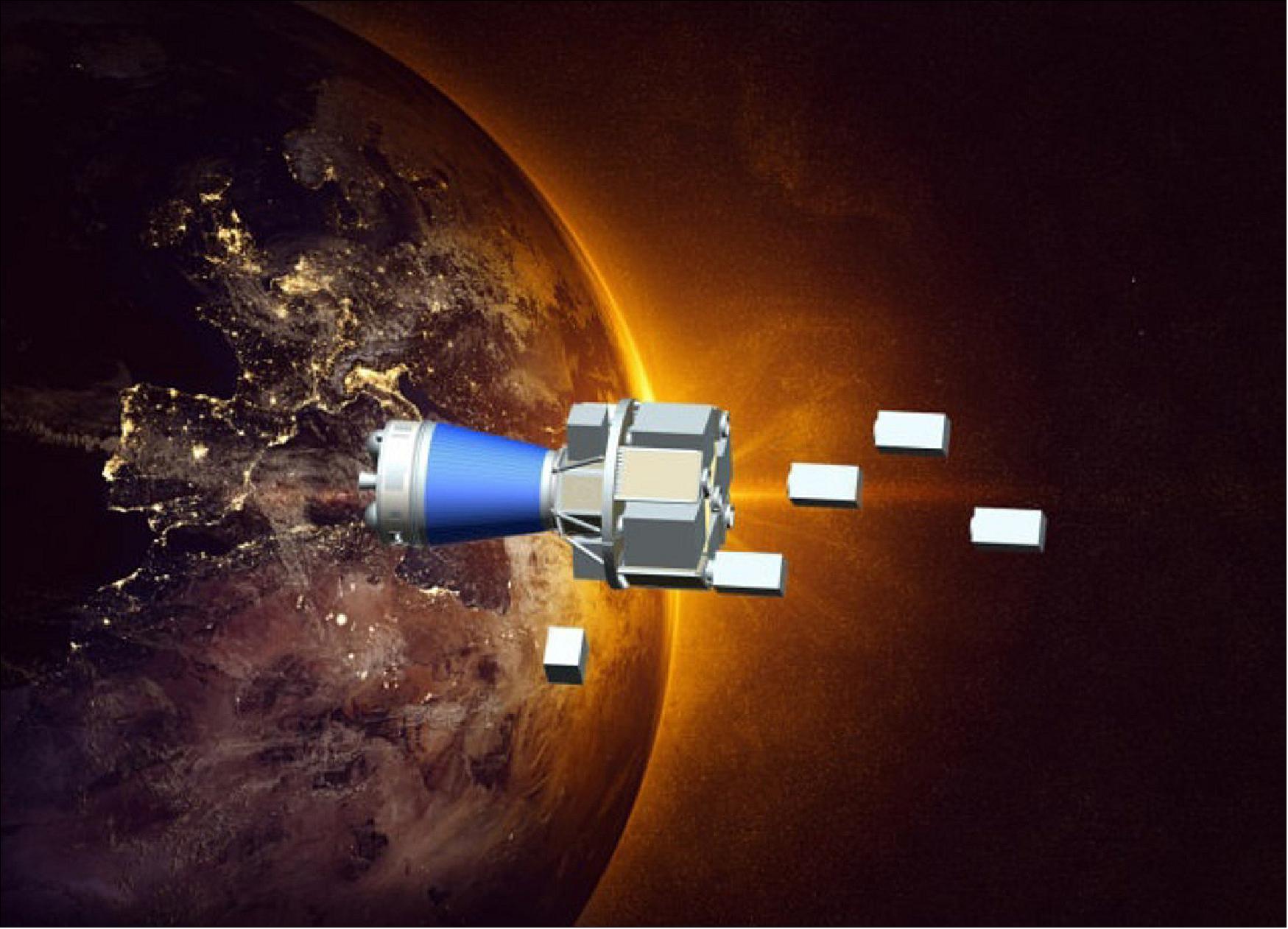

• July 13, 2021: ESA will enhance the versatility of Europe’s Ariane 6 rocket with a kick stage called Astris in a €90 m development contract with prime contractor, ArianeGroup. This is part of ESA’s strategy to extend Ariane 6’s capabilities to serve a wider range of space transportation requirements. 28)

- Astris is planned to fly by mid 2024 as an optional add-on to Ariane 6’s upper stage and will interface directly with the payload. This will enable Ariane 6 to offer a range of new space transportation services by allowing complex orbital transfers.

- Astris will simplify missions by taking over some of the required built-in propulsion capabilities of payloads to move themselves to their final position in orbit. This will reduce the burden on satellite manufacturers to factor this into their design.

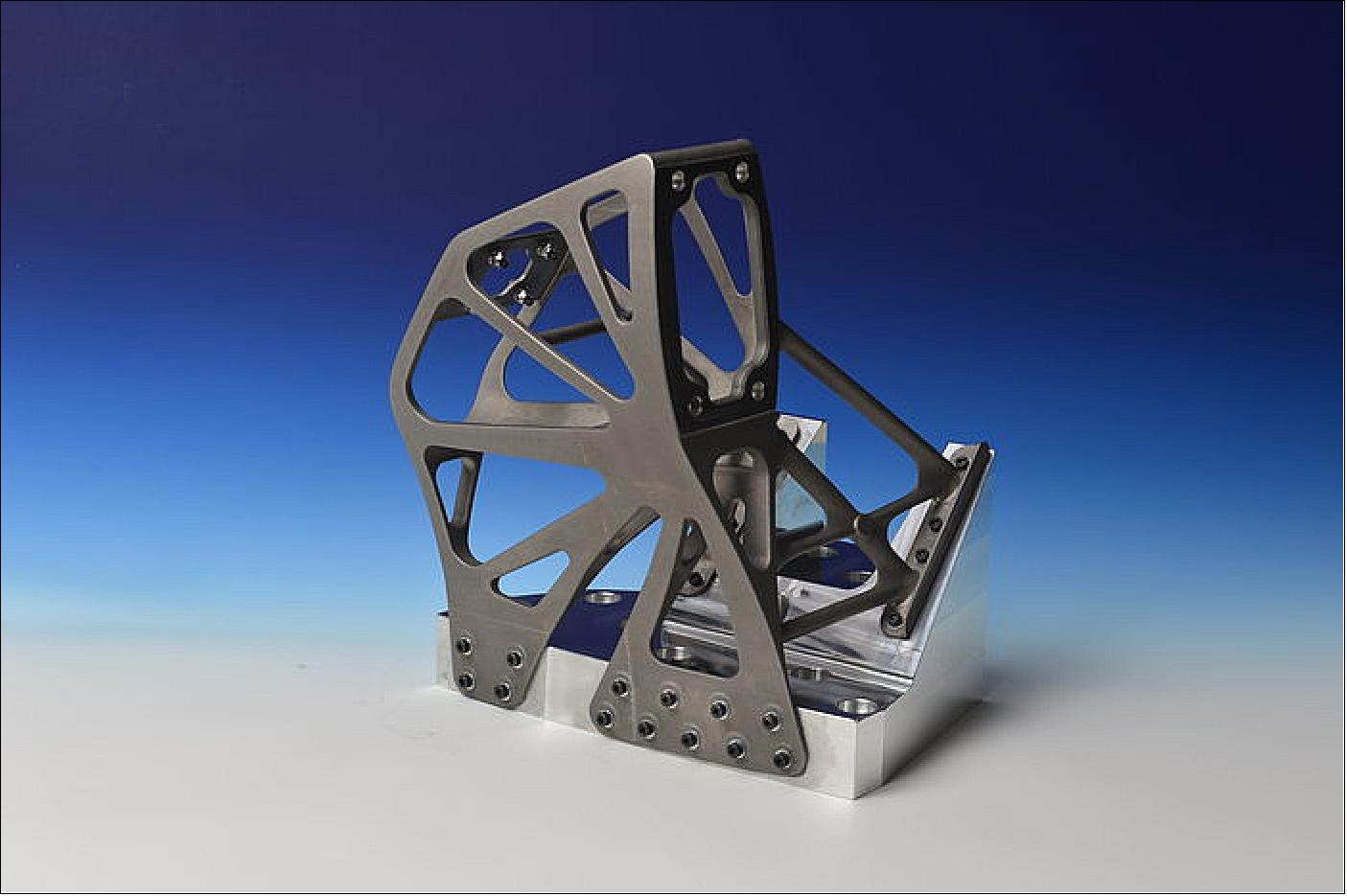

- The modular architecture of Astris makes it versatile, giving potential for even more capabilities. Structures will include a flight proven family of propellant tanks. This approach makes it possible to develop mission specific kits that offer a tailored solution to each customer.

- Future space missions, especially for telecommunications applications and space exploration, could use Astris to reduce mission cost and risk. ESA’s Hera spacecraft, a planetary defence mission to the Didymos asteroid system, is set to be the first to benefit.

- “ESA’s Astris kick stage is a major development to ensure that Ariane 6 can serve the widest possible range of present and future space transportation requirements. It is an important element to enable flexible in-space transportation services, such as space logistics, in-orbit servicing and specific exploration missions,” commented Daniel Neuenschwander, ESA Director of Space Transportation.

- “From the beginning of the Ariane 6 program, the launcher was designed to be scalable and incorporate innovations throughout its operating cycle. This contract rewards the expertise and innovation capacity of our Bremen site in the field of launcher upper stages, while our teams near Munich are currently developing the new Berta engine. By pooling our skills, this project further strengthens Germany’s role in the new European launcher, Ariane 6,” added Pierre Godart, CEO at ArianeGroup in Germany.

- Through Astris, Ariane 6 could enable deep space exploration for ridesharing payloads with destinations such as asteroids, the Moon and Mars. The Astris concept will make objects in the Solar System more accessible to a wider range of payloads.

- Closer to Earth, Astris will augment Ariane 6’s ability to deploy multiple payloads into separate low Earth orbits on a single launch.

- Alternatively, Ariane 6 could place one payload in a transfer orbit then Astris would separate from the upper stage to take a second payload directly into its final position in geostationary orbit.

- The Berta engine, a mid-size storable propellant propulsion system for Astris is in development and qualification at ArianeGroup in Ottobrunn, Germany, carried out within ESA’s Future Launchers Preparatory Program (FLPP). This type of engine can be reliably reignited several times, making it particularly suitable for extended missions or for transport to different orbits.

- Activities for the Astris kick stage are carried out within ESA’s Ariane 6 Competitiveness Improvement Program. It anticipates future space transportation needs and works with industry to create solutions to ensure Europe remains competitive in the global market.

• May 6, 2021: Europe’s Spaceport in French Guiana is carrying out combined tests to prepare for the arrival of Ariane 6, Europe’s next generation heavy-lift launch vehicle. 29)

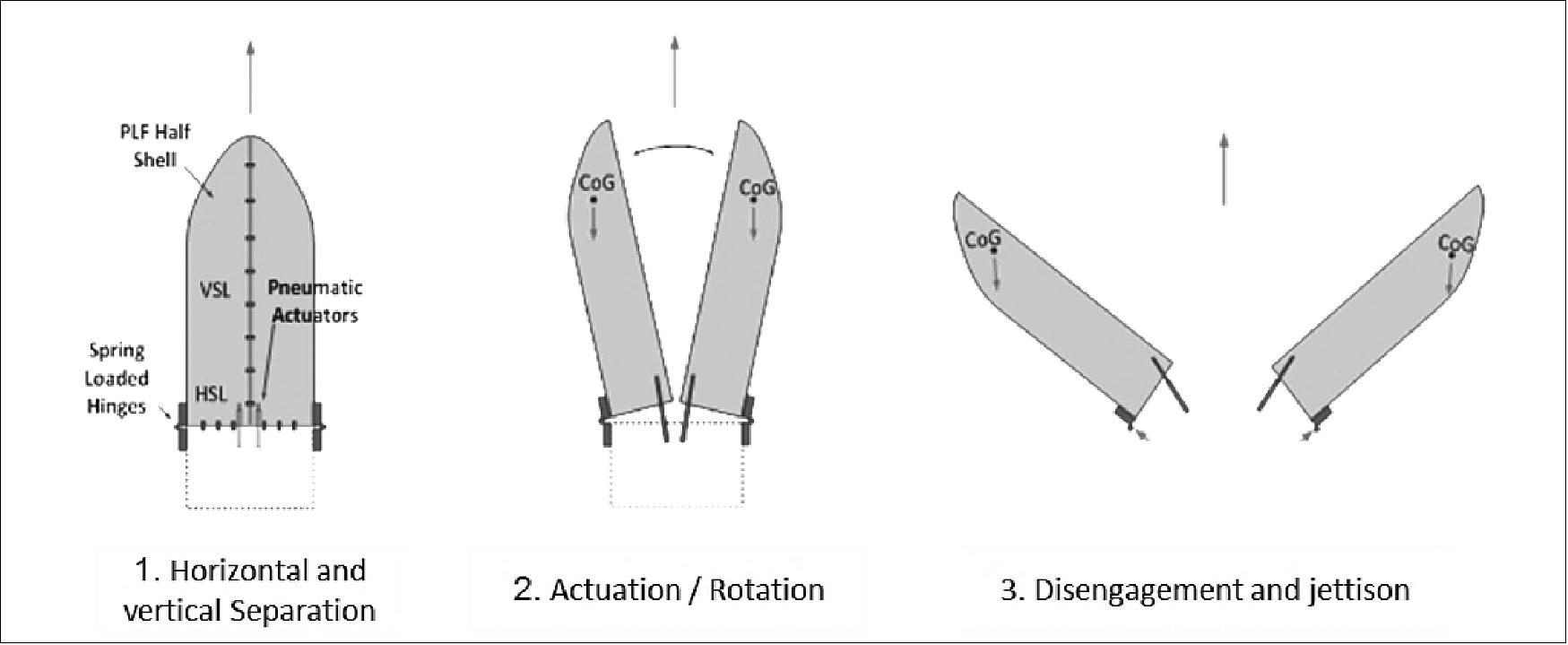

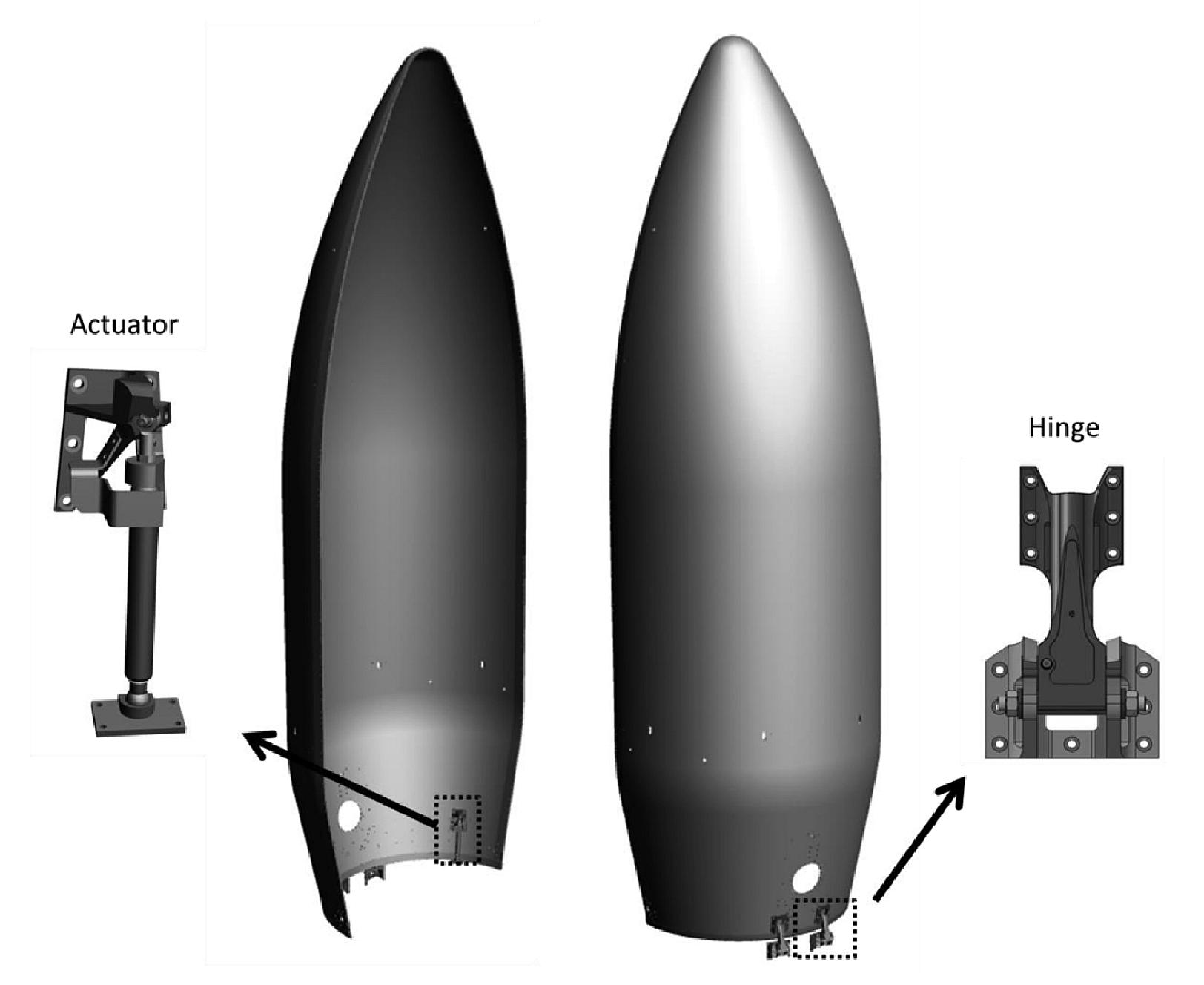

- The first Ariane 6 fairing has already arrived at the Spaceport from Europe. It is 20 m high and 5.4 m in diameter and is being integrated with a mockup payload to test equipment and procedures inside the assembly building.

- RUAG Space in Emmen, Switzerland manufactures each entire large half-shell in one piece from carbon-fibre composite which is ‘cured’ in an industrial oven. This reduces cost and speeds up production. Fewer parts allow horizontal as well as vertical assembly of the closed fairing and the launch vehicle, which is particularly important for Ariane 6.

- A blue metal scaffold on the right of the picture, called the ‘strongback’, encases the fairing. There is one for each half-shell to hold each steady and to maintain the shape of the fairing while it is being raised vertical, and during assembly.

- Before this combined test, the French space agency, CNES, updated the existing Ariane 5 assembly building with a new integration dock, composed of a large white frame, with two mobile platforms adjustable to any level and accessible by fixed stairs and platforms.

This assembly building has two halls: one for integration of the fairing on the Ariane 5 rocket, and an encapsulation hall where the payload is stowed in the fairing. This encapsulation hall is a spacious clean room for Ariane 6.

- A new door 26 m high has been installed at the entrance of the building to make room for the integrated fairing, payload and adapter to move on its trailer to the Ariane 6 launch zone.

- This activity is one of many extensive ‘combined tests’ which are being carried out in a team effort at the Spaceport by ESA, CNES, ArianeGroup, Avio and other industry partners. These tests will prove the systems and procedures that will prepare Europe's new Ariane 6 launch vehicle for flight.

• May 3, 2021: Europe’s new launch vehicle, Vega-C, is near completion. Elements will soon be shipped to Kourou for assembly and preparation for Vega-C’s inaugural flight. 30)

• April 6, 2021: Ariane 6 early combined tests at Latesys in Fos-sur-Mer, in France, have simulated the moment of liftoff when the umbilicals separate from the launch vehicle. 31)

- These tests are part of the critical path towards the first flight of Europe’s new Ariane 6 launch vehicle. They validate the interfaces and mechanical behavior during separation of this complex cryogenic connection system. More extensive combined tests will be carried out at Europe’s Spaceport in Kourou, French Guiana which will include the fluidic supplies.

- The cryogenic connection system sustains the launch vehicle on the launch pad during the countdown to launch.

- Umbilicals supported by ‘cryo-arms’ on the main mast, supply Ariane 6 with top-up fuel, maintain the correct pressurization of Ariane 6’s tanks, cool the engines before ignition and generally keep the launch vehicle in an optimal condition right up to the point of liftoff. The same umbilicals allow the fuel to be drained safely if a launch is aborted.

- “At the moment of liftoff, it is paramount that the connections between launch vehicle and launch base are disconnected and pulled away quickly and safely,” explained Luis Escudero, ESA’s Core Future Launch Preparation Program Manager.

- “Pyrotechnic actuators detonate to burst hinges open allowing the umbilicals to safely separate from Ariane 6. The supporting cryo-arms that hold the upper umbilicals then move out horizontally away from the launch vehicle. A 50-ton counterweight inside the mast – as heavy as a humpback whale – speeds up this maneuver.

- “At the same time, steel doors slam shut on the mini-masts at the base of Ariane 6 on the launch pad to shield the connectors from the rocket exhaust.

- “This all happens in split seconds in a highly precise, synchronized sequence.”

- The launch base design is improved for Ariane 6. The disconnect time is now faster than it is for Ariane 5. This means the sequence can be triggered at the latest possible moment in the countdown reducing the chance of unnecessary disconnects on an aborted launch.

- Over the last few months, Latesys under CNES responsibility and with the support of ArianeGroup, have performed tests to validate the disconnection and retraction functions of the launch pad mechanical systems and the mounts between launch base and rocket, and verified mechanical loads.

- These tests involved the cryo-arms which connect to the Ariane 6 upper stage; mini-masts fixed to the launch table connected by umbilicals to the lower stage; and other Ariane 6 connections.

- ESA has overseen these tests and analyzed the results to verify and validate the cryogenic connection system.

- Following these tests, the components were dismantled and will be shipped to Kourou for integration on the launch pad. Here they will be reassembled and further tested in combination with the cryogenic systems that will supply liquid oxygen and liquid hydrogen to the launch vehicle.

- A launch base technical qualification followed by combined tests at the Spaceport lasting several months will prepare for the launch system technical qualification and debut flight of Ariane 6.

- “These tests were a vital link in a chain of test campaigns that move us forward to further combined tests in French Guiana. This is a very positive step forward for Ariane 6,” commented Pier Domenico Resta, ESA’s Ariane 6 Launch System Engineering Manager.

• March 19, 2021: During the recent meeting in Rome between Bruno Le Maire, French Minister of the Economy, Finance and Recovery, and Giancarlo Giorgetti, Italian Minister of Economic Development, Arianespace announced the signature of an agreement with Avio to start production of 10 new Vega C launch vehicles. 32)

- his agreement kicks off the procurement of long lead-time items and the initial activities for the production of 10 new launchers, to be delivered from 2023.

- Arianespace, the European launch services company, announced today the signature of an agreement with Avio, industrial prime contractor for the Vega and Vega C launchers, to start production of a batch of ten new Vega C rockets, to be launched as from 2023.

- “Arianespace is delighted to have signed this agreement with our long-standing partner Avio, confirming the ramp-up of Vega C, in particular to meet European government requirements,” said Stéphane Israël, Chief Executive Officer of Arianespace. “Through this long-term supply, Arianespace kicks off its order for a fourth batch of Vega launchers, the first comprising only upgraded Vega C launchers. A number of European Earth observation and science programs, most notably Copernicus, will fully benefit from the greater competitiveness of Vega C. More than ever, Vega is establishing its role as the second pillar of Europe’s space access capabilities, along with Ariane.”

- Giulio Ranzo, Chief Executive Officer of Avio, commented: “We are delighted to receive a new batch order for Vega C, which confirms Arianespace’s customers’ interest and trust in the new launcher product, which is the result of an effective cooperation among several European industries under Avio’s leadership”.

- The agreement was signed in Rome on March 19, 2021 by Stéphane Israël, CEO of Arianespace, and Giulio Ranzo, CEO of Avio, during a meeting between Bruno Le Maire, French Minister of the Economy, Finance and Recovery, and Giancarlo Giorgetti, Italian Minister of Economic Development.

- Vega C launchers produced within Batch 4 will serve institutional and commercial missions from 2023 onwards; in particular, they will contribute to the fulfillment of strategic objectives selected by European institutions, either collectively through ESA and the European Commission, or for national purposes. Thus, 2021 will see the contracting by Arianespace of launch services for the next nine Copernicus satellites within the Multiannual Financial Framework 2021-2027 of the European Commission.

- Vega C is a new-generation light launcher, perfectly suited to the launch of both commercial and government payloads. Because of its high performance and versatility, Arianespace provides the best possible solution to orbit small and medium spacecraft into a wide range of orbits (Sun- synchronous, ballistic, transfer to the Lagrange point L1, etc.), for Earth observation, science, education, defense and other applications. With Vega C, Arianespace will offer enhanced performance and greater payload volume for future customers at the same price as for launches by Vega.